-

Bi2O2Se is a new type of semiconductor material, which has the advantages of high carrier mobility, air stability, strong spin-orbit coupling, etc. It has a variety of synthesis methods and a wide range of applications. In the past few years, many explorations have been made in the synthesis, large-size growth, and applications of Bi2O2Se. It has been applied to field effect transistors, infrared photodetectors, semiconductor devices, heterojunctions, spin electronics, etc. Since nanowire has a larger surface area-to-volume ratio than nano-film, nanowire may have greater advantages in gate regulation and strong spin-orbit coupling, and these properties can play a crucial role in certain fields. However, most of the studies focused on its two-dimensional films, and there are less researches of its one-dimensional counterpart. In this work, a method of growing Bi2O2Se one-dimensional nanowires by chemical vapor deposition in a three-temperature-zone tubular furnace is introduced. High-quality suspended Bi2O2Se nanowires are obtained. In addition, the effects on the Bi2O2Se nanowire growth of the position of the mica substrates, i.e, different horizontal positions and vertical heights in the quartz boat, are studied, and the optimal conditions for the growth are summarized. The nanowires are characterized by atomic force microscope and energy dispersive spectrometer to show the information about the size and component. Then, superconducting quantum interference device based on the Bi2O2Se nanowires is constructed, and the superconducting quantum interference in a magnetic field is observed, which provides a way to broaden the application of Bi2O2Se nanowires.

-

Keywords:

- Bi2O2Se nanowires /

- chemical vapor deposition /

- superconducting quantum interference devices

[1] Wu J X, Yuan H T, Meng M M, Chen C, Sun Y, Chen Z Y, Dang W H, Tan C W, Liu Y J, Yin J B, Zhou Y B, Huang S Y, Xu H Q, Cui Y, Hwang H Y, Liu Z F, Chen Y L, Yan B H, Peng H L 2017 Nat. Nanotechnol. 12 530

Google Scholar

Google Scholar

[2] Wu J, Tan C, Tan Z, Liu Y, Yin J, Dang W, Wang M, Peng H 2017 Nano Lett. 17 3021

Google Scholar

Google Scholar

[3] Zhao K, Liu H, Tan C, Xiao J, Shen J, Liu G, Peng H, Lu L, Qu F 2022 Appl. Phys. Lett. 121 212104

Google Scholar

Google Scholar

[4] Wu J X, Liu Y J, Tan Z, Tan C, Yin J B, Li T, Tu T, Peng H 2017 Adv. Mater. 29 1704060

Google Scholar

Google Scholar

[5] Meng M M, Huang S Y, Tan C, Wu J X, Jing Y, Peng H, Xu H Q 2018 Nanoscale 10 2704

Google Scholar

Google Scholar

[6] Meng M M, Huang S Y, Tan C, Wu J X, Li X, Peng H, Xu H Q 2019 Nanoscale 11 10622

Google Scholar

Google Scholar

[7] Li J, Wang Z, Wen Y, Chu J, Yin L, Cheng R, Lei L, He P, Jiang C, Feng L, He J 2018 Adv. Funct. Mater. 28 1706437

Google Scholar

Google Scholar

[8] Xu S, Fu H, Tian Y, Deng T, Cai J, Wu J, Tu T, Li T, Tan C, Liang Y, Zhang C, Liu Z, Liu Z, Chen Y, Jiang Y, Yan B, Peng H 2020 Angew. Chem. Int. Ed. 59 17938

Google Scholar

Google Scholar

[9] Hong C Y, Tao Y, Nie A M, Zhang M H, Wang N, Li R P, Huang J Q, Huang Y Q, Ren X M, Cheng Y C, Liu X L 2020 ACS Nano 14 16803

Google Scholar

Google Scholar

[10] Song Y, Li Z, Li H, Tang S, Mu G, Xu L, Peng W, Shen D, Chen Y, Xie X, Jiang M 2020 Nanotechnology 31 165704

Google Scholar

Google Scholar

[11] Ghosh T, Samanta M, Vasdev A, Dolui K, Ghatak J, Das T, Sheet G, Biswas K 2019 Nano Lett. 19 5703

Google Scholar

Google Scholar

[12] Khan U, Luo Y, Tang L, Teng C, Liu J, Liu B, Cheng H M 2019 Adv. Funct. Mater. 29 1807979

Google Scholar

Google Scholar

[13] Wu Z, Liu G L, Wang Y X, Yang X, Wei T Q, Wang Q J, Liang J, Xu N, Li Z Z, Zhu B, Qi H S, Deng Y, Zhu J 2019 Adv. Funct. Mater. 29 1906639

Google Scholar

Google Scholar

[14] Liu S, Tan C, He D, Wang Y, Peng H, Zhao H 2020 Adv. Optical Mater. 8 1901567

Google Scholar

Google Scholar

[15] Zou X, Sun Y, Wang C 2022 Small Methods 6 2200347

Google Scholar

Google Scholar

[16] Khan U, Nairan A, Khan K, Li S, Liu B, Gao J 2022 Small 19 2206648

Google Scholar

Google Scholar

[17] Khan U, Tang L, Ding B, Yuting L, Feng S, Chen W, Khan M J, Liu B, Cheng H M 2021 Adv. Funct. Mater. 31 2101170

Google Scholar

Google Scholar

[18] Yu J, Sun Q 2018 Appl. Phys. Lett. 112 053901

Google Scholar

Google Scholar

[19] Mao Q, Geng X, Yang J, Zhang J, Zhu S, Yu Q, Wang Y, Li H, Li R, Hao H 2018 J. Cryst. Growth. 498 244

Google Scholar

Google Scholar

[20] Kim M, Park D, Kim J 2021 J. Alloy. Compd. 851 156905

Google Scholar

Google Scholar

[21] Li J, Wang Z, Chu J, Cheng Z, He P, Wang J, Yin L, Cheng R, Li N, Wen Y, He J 2019 Appl. Phys. Lett. 114 151104

Google Scholar

Google Scholar

[22] Bluhm H, Foletti S, Neder I, Rudner M, Mahalu D, Umansky V, Yacoby A 2010 Nat. Phys. 7 109

Google Scholar

Google Scholar

[23] Quhe R, Liu J, Wu J, Yang J, Wang Y, Li Q, Li T, Guo Y, Yang J, Peng H, Lei M, Lu J 2019 Nanoscale 11 532

Google Scholar

Google Scholar

[24] Yin J, Tan Z, Hong H, Wu J, Yuan H, Liu Y, Chen C, Tan C, Yao F, Li T, Chen Y, Liu Z, Liu K, Peng H 2018 Nat. Commun. 9 3311

Google Scholar

Google Scholar

[25] Fan C, Dai B, Liang H, Xu X, Qi Z, Jiang H, Duan H, Zhang Q 2021 Adv. Funct. Mater. 31 2010263

Google Scholar

Google Scholar

[26] Jiang K, Hu J 2022 Nat. Phys. 18 1145

Google Scholar

Google Scholar

[27] Mayer W, Dartiailh M C, Yuan J, Wickramasinghe K S, Rossi E, Shabani J 2020 Nat. Commun. 11 212

Google Scholar

Google Scholar

[28] Fukaya Y, Tanaka Y, Gentile P, Yada K, Cuoco M 2022 npj Quantum Mater. 7 99

Google Scholar

Google Scholar

[29] Jiang D, Yu D Y, Zheng Z, Cao X C, Lin Q, Liu W M 2022 Acta Phys. Sin. 71 160302

Google Scholar

Google Scholar

[30] Frolov S M, Manfra M J, Sau J D 2020 Nat. Phys. 16 718

Google Scholar

Google Scholar

[31] Breunig O, Ando Y 2021 Nat. Rev. Phys. 4 184

Google Scholar

Google Scholar

[32] Matsuo S, Imoto T, Yokoyama T, Sato Y, Lindemann T, Gronin S, Gardner G C, Manfra M J, Tarucha S 2023 Nat. Phys. 19 1636

Google Scholar

Google Scholar

[33] Mourik V, Zuo K, Frolov S M, Plissard S R, Bakkers E P A M, Kouwenhoven L P 2012 Science 336 1003

Google Scholar

Google Scholar

[34] Dvir T, Wang G, van Loo N, Liu C X, Mazur G P, Bordin A, ten Haaf S L D, Wang J Y, van Driel D, Zatelli F, Li X, Malinowski F K, Gazibegovic S, Badawy G, Bakkers E P A M, Wimmer M, Kouwenhoven L P 2023 Nature 614 445

Google Scholar

Google Scholar

[35] Deng M T, Vaitiekėnas S, Hansen E B, Danon J, Leijnse M, Flensberg K, Nygård J, Krogstrup P, Marcus C M 2016 Science 354 1557

Google Scholar

Google Scholar

[36] Pal B, Chakraborty A, Sivakumar P K, Davydova M, Gopi A K, Pandeya A K, Krieger J A, Zhang Y, Date M, Ju S, Yuan N, Schröter N B M, Fu L, Parkin S S P 2022 Nat. Phys. 18 1228

Google Scholar

Google Scholar

[37] Chen A Q, Park M J, Gill S T, Xiao Y R, Reigi-Plessis D, MacDougall G J, Gilbert M J, Mason N 2018 Nat. Commun. 9 3478

Google Scholar

Google Scholar

-

图 1 (a)三温区管式炉的示意图, Bi2Se3粉末放置在温区A的中央, Bi2O3粉末放置在温区C的中央, 带有云母衬底的石英舟放置在管式炉的右边缘. (b), (c)带有云母衬底的石英舟的示意图和光学照片

Figure 1. (a) Schematic diagram of the three-temperature-zone tubular furnace, with Bi2Se3 powder placed at the center of zone A and Bi2O3 powder at the center of zone C, a quartz boat with mica substrates is placed at the right edge of the quartz tube. (b), (c) Schematic diagram and optical photograph of a quartz boat with mica substrates, respectively.

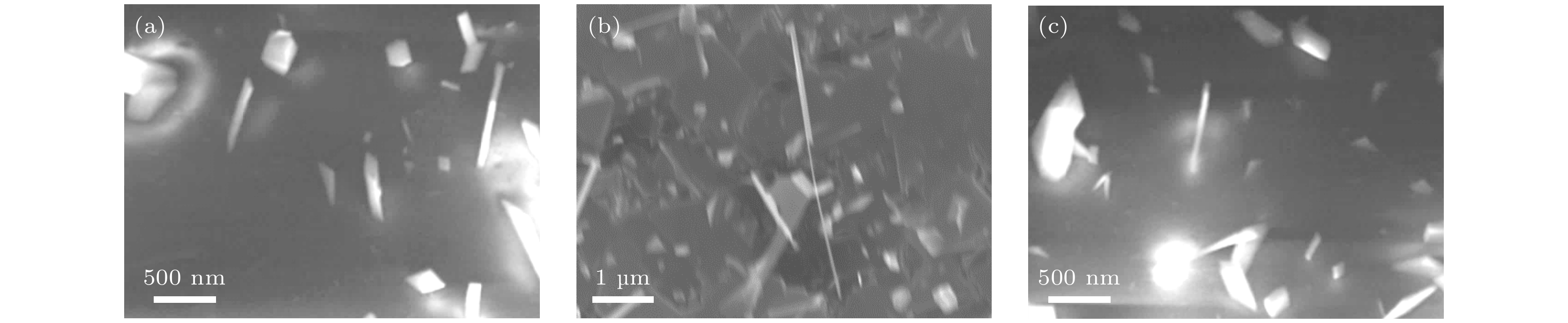

图 2 不同水平位置的云母衬底生长的Bi2O2Se光学显微镜照片和SEM照片 (a), (c), (e)对应2号、4号和5号云母衬底生长Bi2O2Se后的光学显微镜照片; (b), (d), (f)对应2号、4号和5号云母衬底生长Bi2O2Se后的SEM照片

Figure 2. Optical microscope photos and SEM photos of Bi2O2Se grown on mica substrates at different horizontal positions: (a), (c), (e) Optical microscope photos of Bi2O2Se grown on mica substrates at positions No.2, No.4 and No.5, respectively; (b), (d), (f) SEM photos of Bi2O2Se grown on mica substrates at positions No.2, No.4 and No.5, respectively.

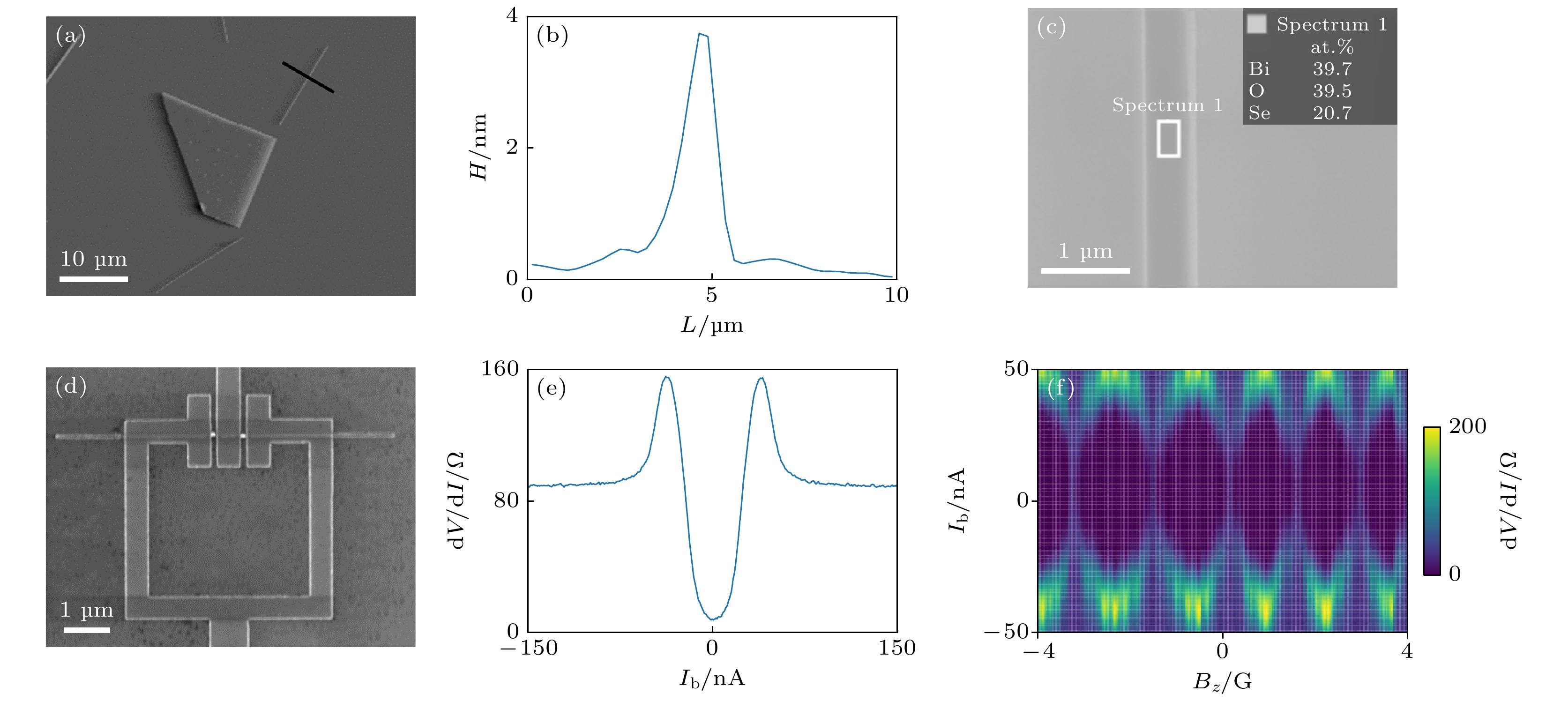

图 4 (a), (b) Bi2O2Se纳米线的AFM表征; (c) Bi2O2Se纳米线的EDS能谱; (d)使用Bi2O2Se纳米线制备的SQUID的SEM照片; (e) SQUID的dV/dI-Ib曲线; (d) SQUID干涉图案

Figure 4. (a), (b) AFM characterization of Bi2O2Se nanowire; (c) EDS spectra of Bi2O2Se nanowire; (d) SEM images of SQUID device; (e) dV/dI-Ib curve of SQUID; (f) SQUID interference pattern.

表 1 Bi2O2Se纳米线的生长步骤

Table 1. Growth steps of Bi2O2Se nanowires.

步骤 第1步 第2步 第3步 第4步 温区A

(Bi2Se3)温度/℃ 室温—100 100—580 580 580—室温 时间/min 5 25 30 — 温区B 温度/℃ 室温—100 100—610 610 610—室温 时间/min 5 30 25 — 温区C

(Bi2O3)温度/℃ 室温—100 100—630 630 630—室温 时间/min 5 30 25 — -

[1] Wu J X, Yuan H T, Meng M M, Chen C, Sun Y, Chen Z Y, Dang W H, Tan C W, Liu Y J, Yin J B, Zhou Y B, Huang S Y, Xu H Q, Cui Y, Hwang H Y, Liu Z F, Chen Y L, Yan B H, Peng H L 2017 Nat. Nanotechnol. 12 530

Google Scholar

Google Scholar

[2] Wu J, Tan C, Tan Z, Liu Y, Yin J, Dang W, Wang M, Peng H 2017 Nano Lett. 17 3021

Google Scholar

Google Scholar

[3] Zhao K, Liu H, Tan C, Xiao J, Shen J, Liu G, Peng H, Lu L, Qu F 2022 Appl. Phys. Lett. 121 212104

Google Scholar

Google Scholar

[4] Wu J X, Liu Y J, Tan Z, Tan C, Yin J B, Li T, Tu T, Peng H 2017 Adv. Mater. 29 1704060

Google Scholar

Google Scholar

[5] Meng M M, Huang S Y, Tan C, Wu J X, Jing Y, Peng H, Xu H Q 2018 Nanoscale 10 2704

Google Scholar

Google Scholar

[6] Meng M M, Huang S Y, Tan C, Wu J X, Li X, Peng H, Xu H Q 2019 Nanoscale 11 10622

Google Scholar

Google Scholar

[7] Li J, Wang Z, Wen Y, Chu J, Yin L, Cheng R, Lei L, He P, Jiang C, Feng L, He J 2018 Adv. Funct. Mater. 28 1706437

Google Scholar

Google Scholar

[8] Xu S, Fu H, Tian Y, Deng T, Cai J, Wu J, Tu T, Li T, Tan C, Liang Y, Zhang C, Liu Z, Liu Z, Chen Y, Jiang Y, Yan B, Peng H 2020 Angew. Chem. Int. Ed. 59 17938

Google Scholar

Google Scholar

[9] Hong C Y, Tao Y, Nie A M, Zhang M H, Wang N, Li R P, Huang J Q, Huang Y Q, Ren X M, Cheng Y C, Liu X L 2020 ACS Nano 14 16803

Google Scholar

Google Scholar

[10] Song Y, Li Z, Li H, Tang S, Mu G, Xu L, Peng W, Shen D, Chen Y, Xie X, Jiang M 2020 Nanotechnology 31 165704

Google Scholar

Google Scholar

[11] Ghosh T, Samanta M, Vasdev A, Dolui K, Ghatak J, Das T, Sheet G, Biswas K 2019 Nano Lett. 19 5703

Google Scholar

Google Scholar

[12] Khan U, Luo Y, Tang L, Teng C, Liu J, Liu B, Cheng H M 2019 Adv. Funct. Mater. 29 1807979

Google Scholar

Google Scholar

[13] Wu Z, Liu G L, Wang Y X, Yang X, Wei T Q, Wang Q J, Liang J, Xu N, Li Z Z, Zhu B, Qi H S, Deng Y, Zhu J 2019 Adv. Funct. Mater. 29 1906639

Google Scholar

Google Scholar

[14] Liu S, Tan C, He D, Wang Y, Peng H, Zhao H 2020 Adv. Optical Mater. 8 1901567

Google Scholar

Google Scholar

[15] Zou X, Sun Y, Wang C 2022 Small Methods 6 2200347

Google Scholar

Google Scholar

[16] Khan U, Nairan A, Khan K, Li S, Liu B, Gao J 2022 Small 19 2206648

Google Scholar

Google Scholar

[17] Khan U, Tang L, Ding B, Yuting L, Feng S, Chen W, Khan M J, Liu B, Cheng H M 2021 Adv. Funct. Mater. 31 2101170

Google Scholar

Google Scholar

[18] Yu J, Sun Q 2018 Appl. Phys. Lett. 112 053901

Google Scholar

Google Scholar

[19] Mao Q, Geng X, Yang J, Zhang J, Zhu S, Yu Q, Wang Y, Li H, Li R, Hao H 2018 J. Cryst. Growth. 498 244

Google Scholar

Google Scholar

[20] Kim M, Park D, Kim J 2021 J. Alloy. Compd. 851 156905

Google Scholar

Google Scholar

[21] Li J, Wang Z, Chu J, Cheng Z, He P, Wang J, Yin L, Cheng R, Li N, Wen Y, He J 2019 Appl. Phys. Lett. 114 151104

Google Scholar

Google Scholar

[22] Bluhm H, Foletti S, Neder I, Rudner M, Mahalu D, Umansky V, Yacoby A 2010 Nat. Phys. 7 109

Google Scholar

Google Scholar

[23] Quhe R, Liu J, Wu J, Yang J, Wang Y, Li Q, Li T, Guo Y, Yang J, Peng H, Lei M, Lu J 2019 Nanoscale 11 532

Google Scholar

Google Scholar

[24] Yin J, Tan Z, Hong H, Wu J, Yuan H, Liu Y, Chen C, Tan C, Yao F, Li T, Chen Y, Liu Z, Liu K, Peng H 2018 Nat. Commun. 9 3311

Google Scholar

Google Scholar

[25] Fan C, Dai B, Liang H, Xu X, Qi Z, Jiang H, Duan H, Zhang Q 2021 Adv. Funct. Mater. 31 2010263

Google Scholar

Google Scholar

[26] Jiang K, Hu J 2022 Nat. Phys. 18 1145

Google Scholar

Google Scholar

[27] Mayer W, Dartiailh M C, Yuan J, Wickramasinghe K S, Rossi E, Shabani J 2020 Nat. Commun. 11 212

Google Scholar

Google Scholar

[28] Fukaya Y, Tanaka Y, Gentile P, Yada K, Cuoco M 2022 npj Quantum Mater. 7 99

Google Scholar

Google Scholar

[29] Jiang D, Yu D Y, Zheng Z, Cao X C, Lin Q, Liu W M 2022 Acta Phys. Sin. 71 160302

Google Scholar

Google Scholar

[30] Frolov S M, Manfra M J, Sau J D 2020 Nat. Phys. 16 718

Google Scholar

Google Scholar

[31] Breunig O, Ando Y 2021 Nat. Rev. Phys. 4 184

Google Scholar

Google Scholar

[32] Matsuo S, Imoto T, Yokoyama T, Sato Y, Lindemann T, Gronin S, Gardner G C, Manfra M J, Tarucha S 2023 Nat. Phys. 19 1636

Google Scholar

Google Scholar

[33] Mourik V, Zuo K, Frolov S M, Plissard S R, Bakkers E P A M, Kouwenhoven L P 2012 Science 336 1003

Google Scholar

Google Scholar

[34] Dvir T, Wang G, van Loo N, Liu C X, Mazur G P, Bordin A, ten Haaf S L D, Wang J Y, van Driel D, Zatelli F, Li X, Malinowski F K, Gazibegovic S, Badawy G, Bakkers E P A M, Wimmer M, Kouwenhoven L P 2023 Nature 614 445

Google Scholar

Google Scholar

[35] Deng M T, Vaitiekėnas S, Hansen E B, Danon J, Leijnse M, Flensberg K, Nygård J, Krogstrup P, Marcus C M 2016 Science 354 1557

Google Scholar

Google Scholar

[36] Pal B, Chakraborty A, Sivakumar P K, Davydova M, Gopi A K, Pandeya A K, Krieger J A, Zhang Y, Date M, Ju S, Yuan N, Schröter N B M, Fu L, Parkin S S P 2022 Nat. Phys. 18 1228

Google Scholar

Google Scholar

[37] Chen A Q, Park M J, Gill S T, Xiao Y R, Reigi-Plessis D, MacDougall G J, Gilbert M J, Mason N 2018 Nat. Commun. 9 3478

Google Scholar

Google Scholar

-

4-20231600Suppl.pdf

4-20231600Suppl.pdf

Catalog

Metrics

- Abstract views: 4411

- PDF Downloads: 178

- Cited By: 0

DownLoad:

DownLoad: