-

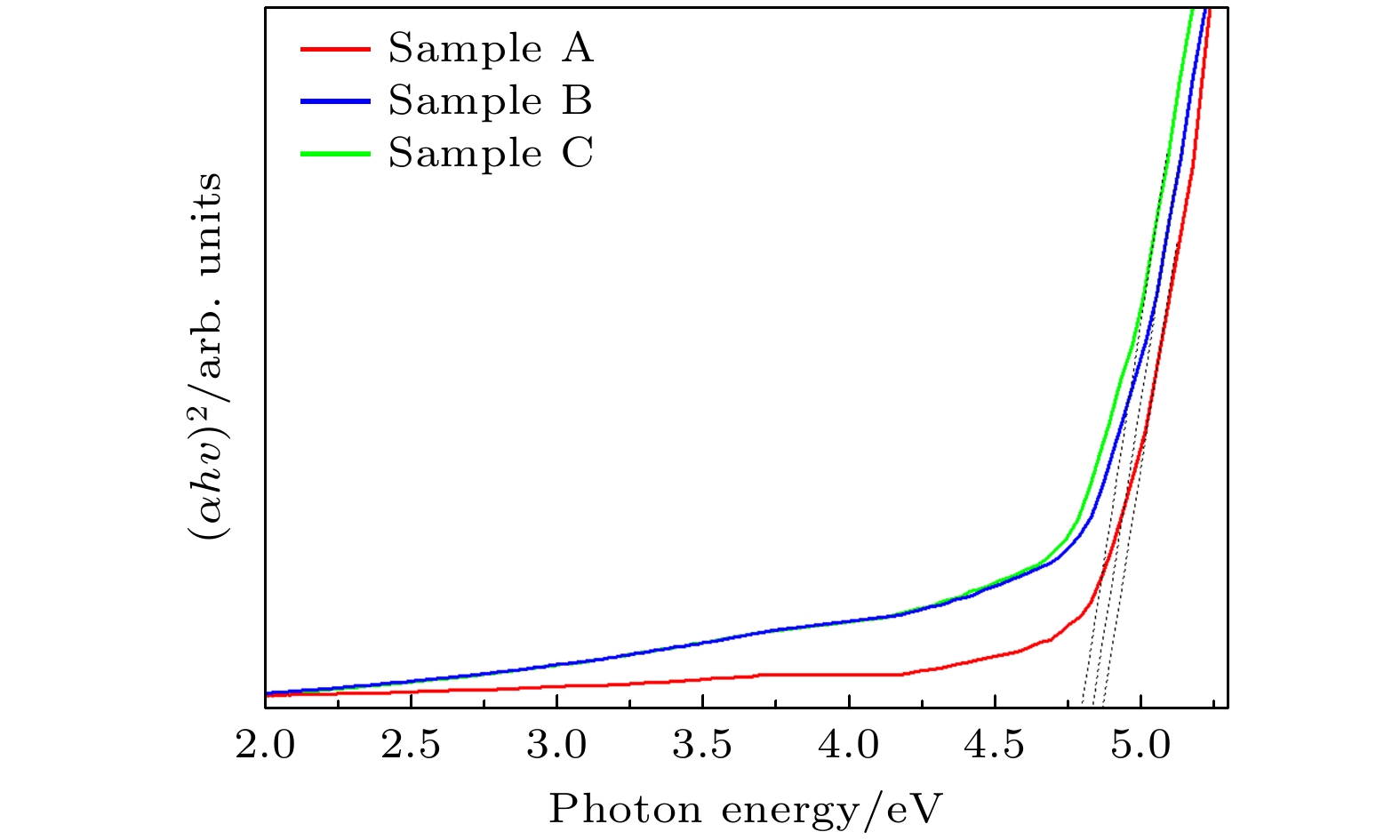

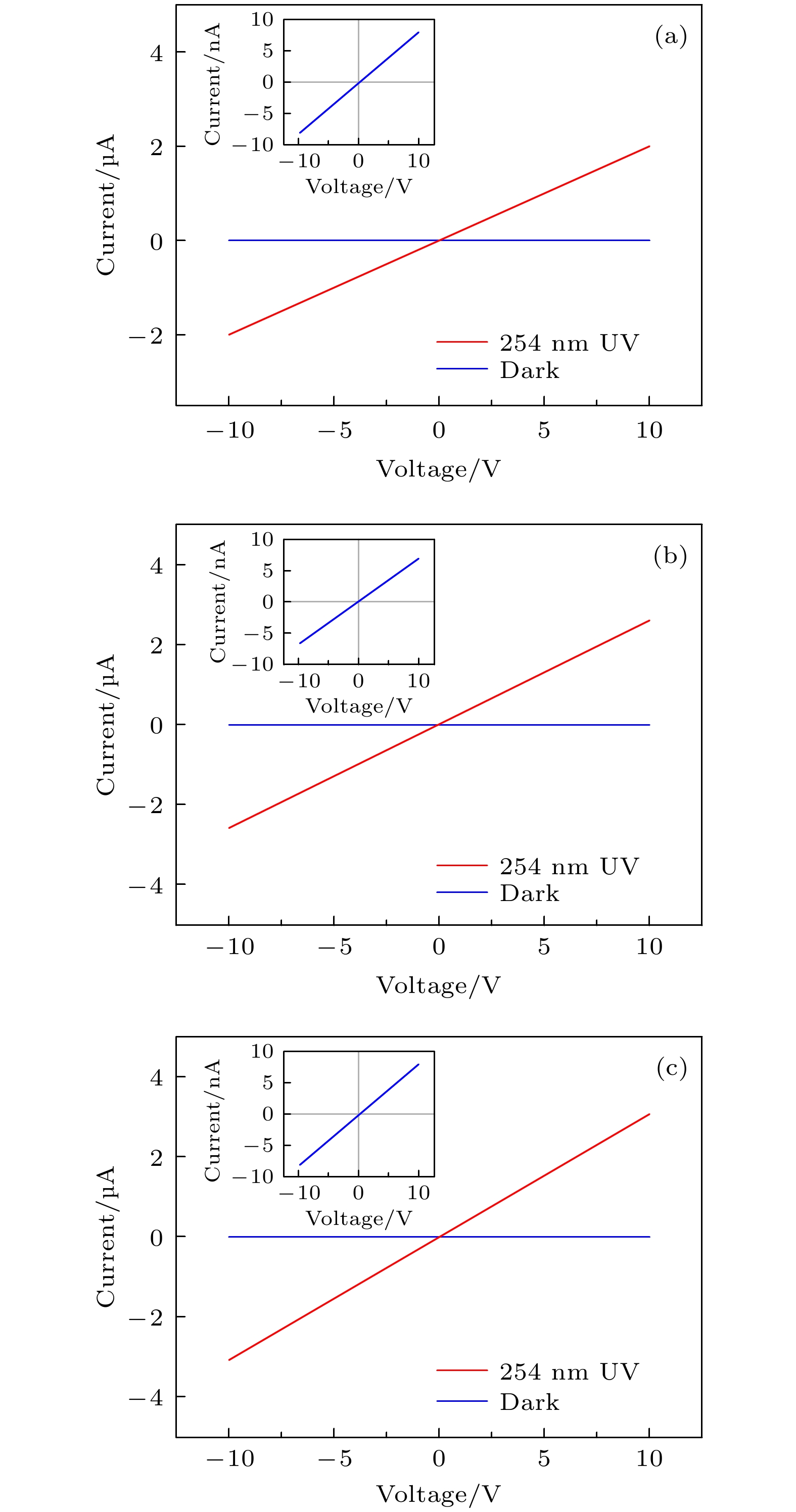

Solar-blind UV photodetectors (SBPs) have attracted great attention because they are widely used in missile tracking, fire detection, biochemical analysis, astronomical observations, space-to-space communications, etc. At present, it is found that wide bandgap semiconductor materials such as AlxGa1-xN, Mg1Zn1-xO, diamond and β-Ga2O3 are ideal semiconductor materials for developing high-performance SBPs. The ultra-wide band gap semiconductor material, β-Ga2O3, has a large band gap width of 4.9 eV, strong breakdown electric field, absorption edge located in the solar blind ultraviolet band (200–280 nm), and it also has high transmittance in the near ultraviolet and the whole visible band. Therefore, β-Ga2O3 is a very suitable material for making solar blind UV photodetectors. However, the p-type β-Ga2O3 is difficult to dope, which limits the further development of β-Ga2O3 devices. In this work, the β-Ga2O3 thin films with different Cu doping content are grown on sapphire substrates by chemical vapor deposition method, and the morphology, crystal structure and optical properties of β-Ga2O3 films are measured. The test results show that the surfaces of β-Ga2O3 films with different Cu content are relatively smooth, and the (

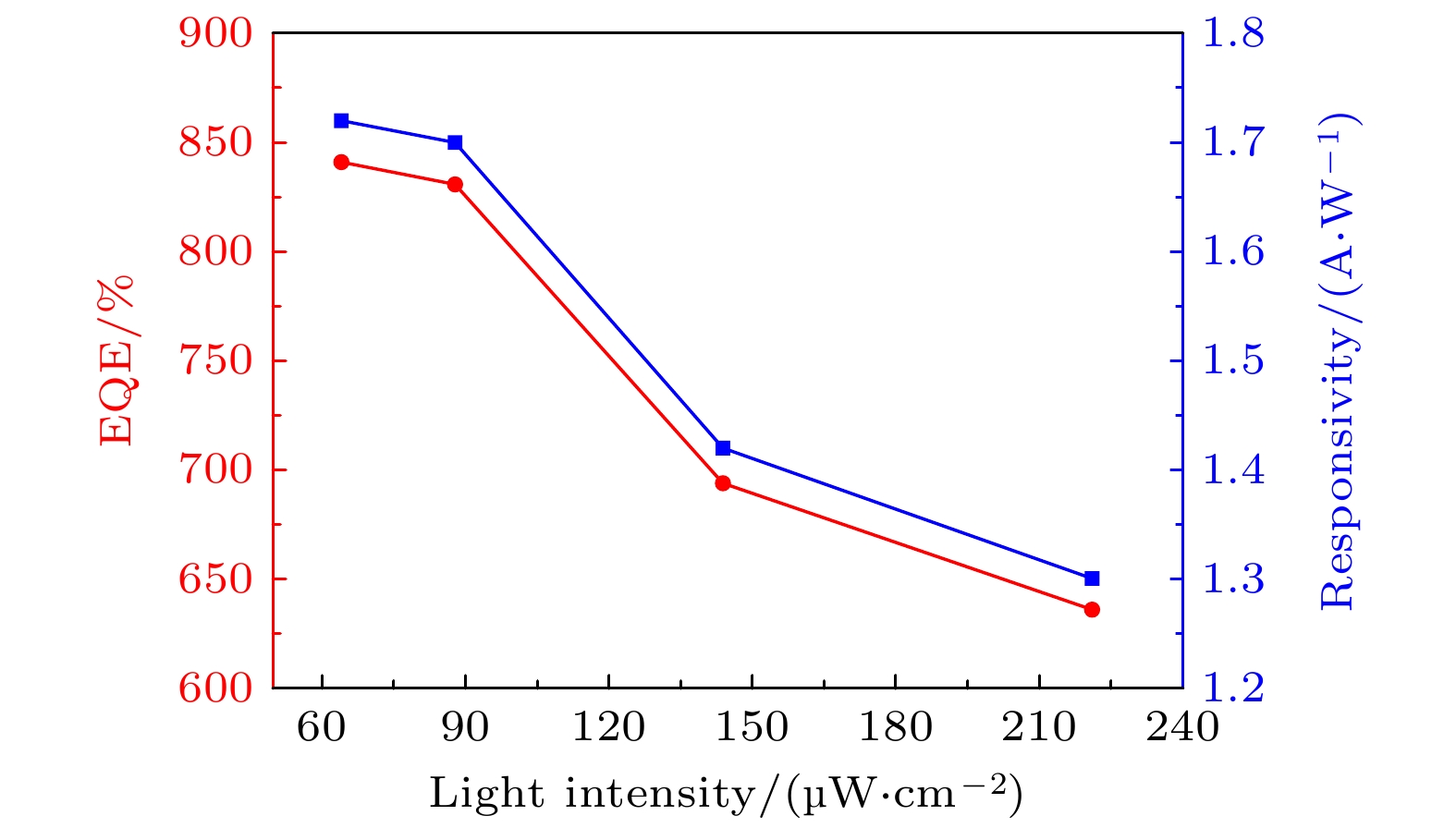

$ \bar 201 $ ) diffraction peak positions shift toward the lower degree side with the increase of Cu content, which indicates that Cu2+ replaces Ga3+ and enters into the β-Ga2O3 lattice. The optical absorption spectrum measurement indicates that the energy gaps of samples are evidently narrowed with the increase of Cu doping concentration. Hall measurements indicate that the Cu doped β-Ga2O3 thin films have a p-type conductivity with a hole concentration of 7.36 × 1014, 4.83 × 1015 and 1.69 × 1016 cm–3, respectively. In addition, a photoconductive UV detector with metal-semiconductor-metal structure is prepared by evaporating Au on a Cu-doped β-Ga2O3 thin film, and its UV detection performance is studied. The results show that the photocurrent value of the device increases with Cu content increasing. The photo-to-dark current ratio (Il/Id) is about 3.8×102 of 2.4% Cu content device under 254 nm-wavelength light at 10 V. The rise time and decay time are 0.11 s and 0.13 s, respectively. Furthermore, the responsivity and external quantum efficiency can reach 1.72 A/W and 841% under 254 nm-wavelength light with a light intensity of 64 μW/cm2.-

Keywords:

- chemical vapor deposition /

- p-type β-Ga2O3 /

- Cu doping /

- UV photodetector

[1] 谢自力, 张荣, 修向前, 韩平, 刘斌, 陈琳, 俞慧强, 江若琏, 施毅, 郑有炓 2007 56 6717

Google Scholar

Google Scholar

Xie Z L, Zhang R, Xiu X Q, Han P, Liu B, Chen L, Yu H Q, Jiang R L, Shi Y, Zheng Y D 2007 Acta Phys. Sin. 56 6717

Google Scholar

Google Scholar

[2] Zhang C X, Xu C B, Wen G J, Lian Y F 2018 Opt. Eng. 57 053109

[3] Alaie Z, Nejad S M, Yousefi M H 2014 J. Mater. Sci. Mater. Electron. 25 852

Google Scholar

Google Scholar

[4] Ouyang W, Teng F, Jiang M M, Fang X S 2017 Small 13 1702177

Google Scholar

Google Scholar

[5] Fan M M, Liu K W, Zhang Z Z, Li B H, Chen X, Zhao D X, Shan C X, Shen D Z 2014 Appl. Phys. Lett. 105 011117

Google Scholar

Google Scholar

[6] Cicek E, McClintock R, Cho C Y, Rahnema B, Razeghi M 2013 Appl. Phys. Lett. 103 191108

Google Scholar

Google Scholar

[7] Pearton S J, Yang J C, IV P H C, Ren F, Kim J, Tadjer M J, Mastro M A 2018 Appl. Phys. Rev. 5 011301

Google Scholar

Google Scholar

[8] Jubu P R, Yam F K 2020 Sens. Actuators A 312 112141

Google Scholar

Google Scholar

[9] Jin C, Park S, Kim H, Lee C 2012 Sens. Actuators B 161 223

Google Scholar

Google Scholar

[10] Qian Y P, Guo D Y, Chu X L, Shi H Z, Zhu W K, Wang K, Huang X K, Wang H, Wang S L, Li P G, Zhang X H, Tang W H 2017 Mater. Lett. 209 558

Google Scholar

Google Scholar

[11] Wang D, Ge K, Meng D, Chen Z 2023 Mater. Lett. 330 133251

Google Scholar

Google Scholar

[12] Zhang C, Li Z, Wang W 2021 Materials 14 5161

Google Scholar

Google Scholar

[13] 冯秋菊, 李芳, 李彤彤, 李昀铮, 石博, 李梦轲, 梁红伟 2018 67 218101

Google Scholar

Google Scholar

Feng Q J, Li F, Li T T, Li Y Z, Shi B, Li M K, Liang H W 2018 Acta Phys. Sin. 67 218101

Google Scholar

Google Scholar

[14] Feng Q J, Dong Z J, Liu W, Liang S, Yi Z Q, Yu C, Xie J Z, Song Z 2022 Micro Nanostruct. 167 207255

Google Scholar

Google Scholar

[15] Xu C, Shen L, Liu H, Pan X, Ye Z 2021 J. Electron. Mater. 50 2043

Google Scholar

Google Scholar

[16] Liu Z, Wang X, Liu Y, Guo D, Li S, Yan Z, Tan C K, Li W, Li P, Tang W 2019 J. Mater. Chem. C 7 13920

Google Scholar

Google Scholar

[17] Guo X C, Hao N H, Guo D Y, Wu Z P, An Y H, Chu X L, Li L H, Li P G, Lei M, Tang W H 2016 J. Alloy. Comp. 660 136

Google Scholar

Google Scholar

[18] Lin R C, Zheng W, Zhang D, Zhang Z J, Liao Q X, Yang L, Huang F 2018 ACS Appl. Mater. Interfaces 10 22419

Google Scholar

Google Scholar

[19] Dong L P, Pang T Q, Yu J G, Wang Y C, Zhu W G, Zheng H D, Yu J H, Jia R X, Zhe C 2019 J. Mater. Chem. C 7 14205

Google Scholar

Google Scholar

[20] Chu S Y, Yeh T H, Lee C T, Lee H Y 2022 Mater. Sci. Semicond. Process. 142 106471

Google Scholar

Google Scholar

[21] 落巨鑫, 高红丽, 邓金祥, 任家辉, 张庆, 李瑞东, 孟雪 2023 72 028502

Google Scholar

Google Scholar

Luo J X, Gao H L, Deng J X, Ren J H, Zhang Q, Li R D, Meng X 2023 Acta Phys. Sin. 72 028502

Google Scholar

Google Scholar

-

表 1 不同Cu掺杂量β-Ga2O3的实验参数

Table 1. Experimental parameters of β-Ga2O3 with different Cu contents.

样品 Ga2O3/CuO

质量比生长温度

/℃反应时间

/minAr流量

/(mL⋅min–1)O2流量

/(mL⋅min–1)A 25∶1 1000 30 200 50 B 25∶2 1000 30 200 50 C 25∶3 1000 30 200 50 表 2 样品A, B, C的电学性质

Table 2. Electrical properties of sample A, B, C.

样品 导电类型 载流子浓度/cm–3 霍尔迁移率/

(cm2⋅(V⋅s)–1)A p 7.36×1014 11.64 B p 4.83×1015 7.38 C p 1.69×1016 4.52 -

[1] 谢自力, 张荣, 修向前, 韩平, 刘斌, 陈琳, 俞慧强, 江若琏, 施毅, 郑有炓 2007 56 6717

Google Scholar

Google Scholar

Xie Z L, Zhang R, Xiu X Q, Han P, Liu B, Chen L, Yu H Q, Jiang R L, Shi Y, Zheng Y D 2007 Acta Phys. Sin. 56 6717

Google Scholar

Google Scholar

[2] Zhang C X, Xu C B, Wen G J, Lian Y F 2018 Opt. Eng. 57 053109

[3] Alaie Z, Nejad S M, Yousefi M H 2014 J. Mater. Sci. Mater. Electron. 25 852

Google Scholar

Google Scholar

[4] Ouyang W, Teng F, Jiang M M, Fang X S 2017 Small 13 1702177

Google Scholar

Google Scholar

[5] Fan M M, Liu K W, Zhang Z Z, Li B H, Chen X, Zhao D X, Shan C X, Shen D Z 2014 Appl. Phys. Lett. 105 011117

Google Scholar

Google Scholar

[6] Cicek E, McClintock R, Cho C Y, Rahnema B, Razeghi M 2013 Appl. Phys. Lett. 103 191108

Google Scholar

Google Scholar

[7] Pearton S J, Yang J C, IV P H C, Ren F, Kim J, Tadjer M J, Mastro M A 2018 Appl. Phys. Rev. 5 011301

Google Scholar

Google Scholar

[8] Jubu P R, Yam F K 2020 Sens. Actuators A 312 112141

Google Scholar

Google Scholar

[9] Jin C, Park S, Kim H, Lee C 2012 Sens. Actuators B 161 223

Google Scholar

Google Scholar

[10] Qian Y P, Guo D Y, Chu X L, Shi H Z, Zhu W K, Wang K, Huang X K, Wang H, Wang S L, Li P G, Zhang X H, Tang W H 2017 Mater. Lett. 209 558

Google Scholar

Google Scholar

[11] Wang D, Ge K, Meng D, Chen Z 2023 Mater. Lett. 330 133251

Google Scholar

Google Scholar

[12] Zhang C, Li Z, Wang W 2021 Materials 14 5161

Google Scholar

Google Scholar

[13] 冯秋菊, 李芳, 李彤彤, 李昀铮, 石博, 李梦轲, 梁红伟 2018 67 218101

Google Scholar

Google Scholar

Feng Q J, Li F, Li T T, Li Y Z, Shi B, Li M K, Liang H W 2018 Acta Phys. Sin. 67 218101

Google Scholar

Google Scholar

[14] Feng Q J, Dong Z J, Liu W, Liang S, Yi Z Q, Yu C, Xie J Z, Song Z 2022 Micro Nanostruct. 167 207255

Google Scholar

Google Scholar

[15] Xu C, Shen L, Liu H, Pan X, Ye Z 2021 J. Electron. Mater. 50 2043

Google Scholar

Google Scholar

[16] Liu Z, Wang X, Liu Y, Guo D, Li S, Yan Z, Tan C K, Li W, Li P, Tang W 2019 J. Mater. Chem. C 7 13920

Google Scholar

Google Scholar

[17] Guo X C, Hao N H, Guo D Y, Wu Z P, An Y H, Chu X L, Li L H, Li P G, Lei M, Tang W H 2016 J. Alloy. Comp. 660 136

Google Scholar

Google Scholar

[18] Lin R C, Zheng W, Zhang D, Zhang Z J, Liao Q X, Yang L, Huang F 2018 ACS Appl. Mater. Interfaces 10 22419

Google Scholar

Google Scholar

[19] Dong L P, Pang T Q, Yu J G, Wang Y C, Zhu W G, Zheng H D, Yu J H, Jia R X, Zhe C 2019 J. Mater. Chem. C 7 14205

Google Scholar

Google Scholar

[20] Chu S Y, Yeh T H, Lee C T, Lee H Y 2022 Mater. Sci. Semicond. Process. 142 106471

Google Scholar

Google Scholar

[21] 落巨鑫, 高红丽, 邓金祥, 任家辉, 张庆, 李瑞东, 孟雪 2023 72 028502

Google Scholar

Google Scholar

Luo J X, Gao H L, Deng J X, Ren J H, Zhang Q, Li R D, Meng X 2023 Acta Phys. Sin. 72 028502

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6282

- PDF Downloads: 130

- Cited By: 0

DownLoad:

DownLoad: