-

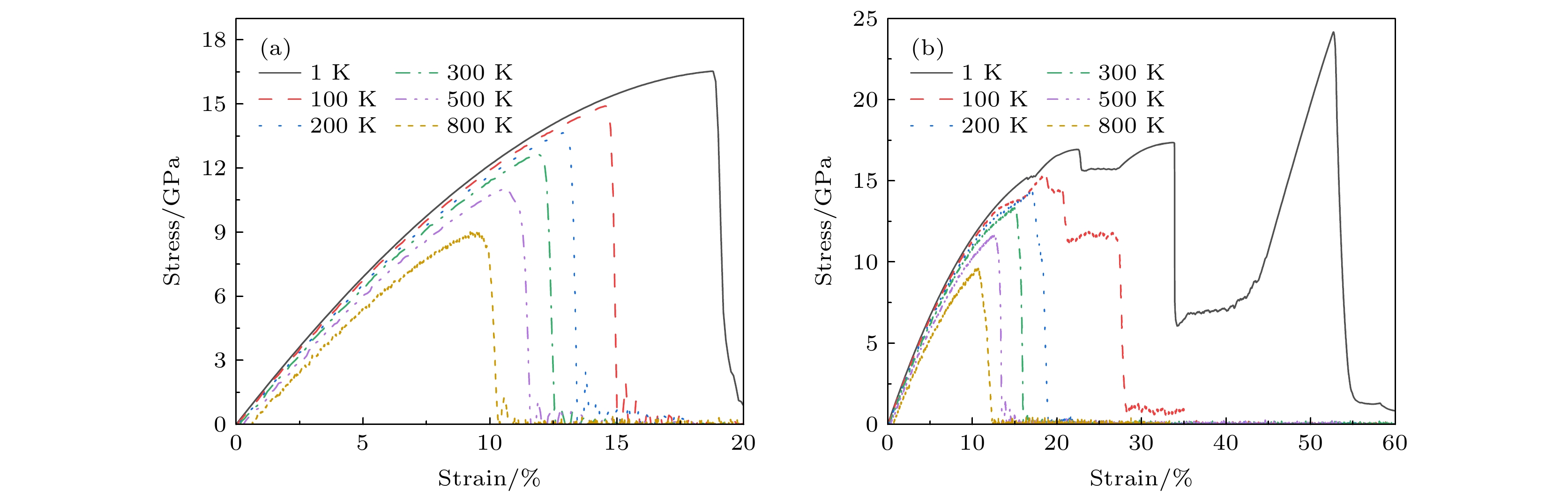

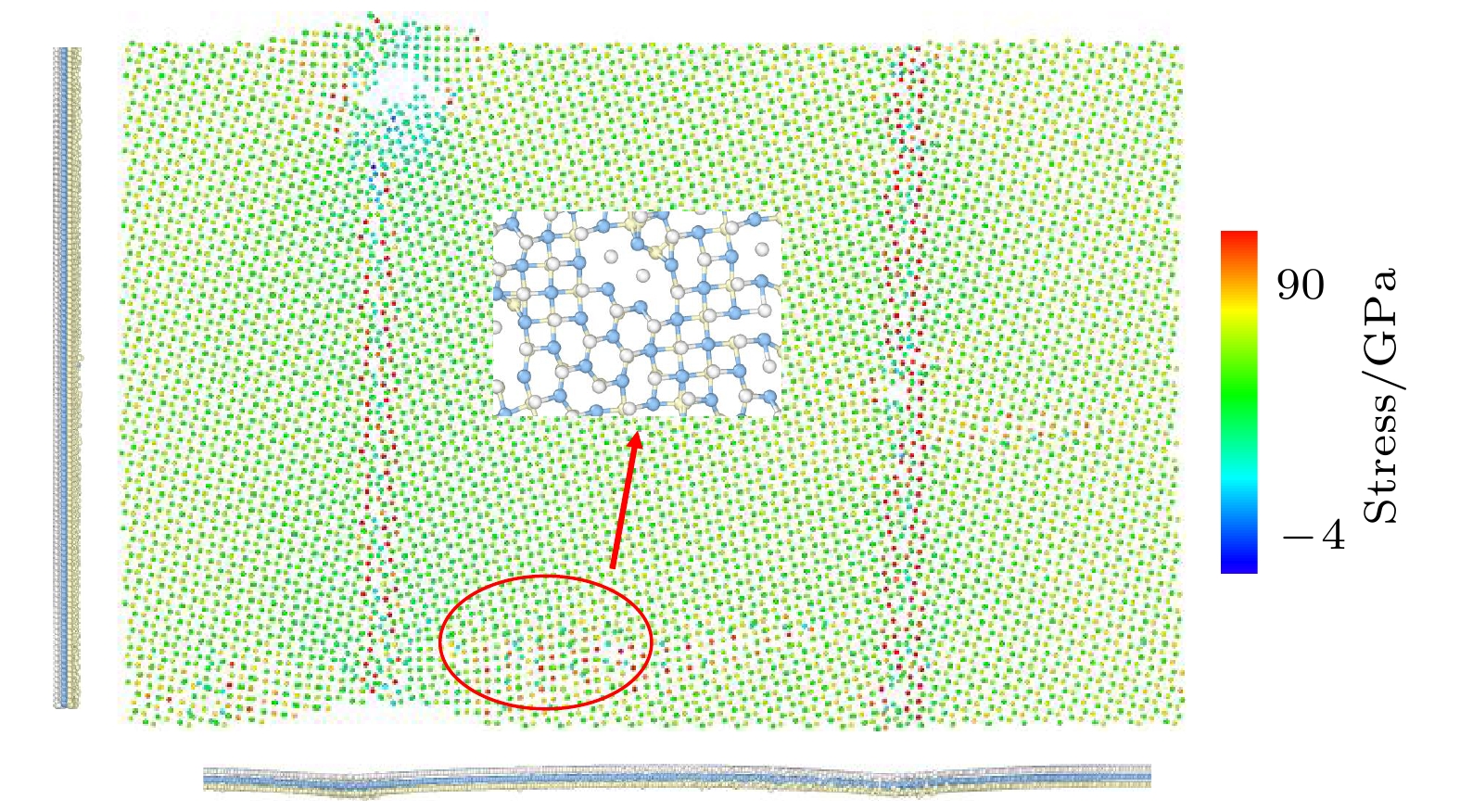

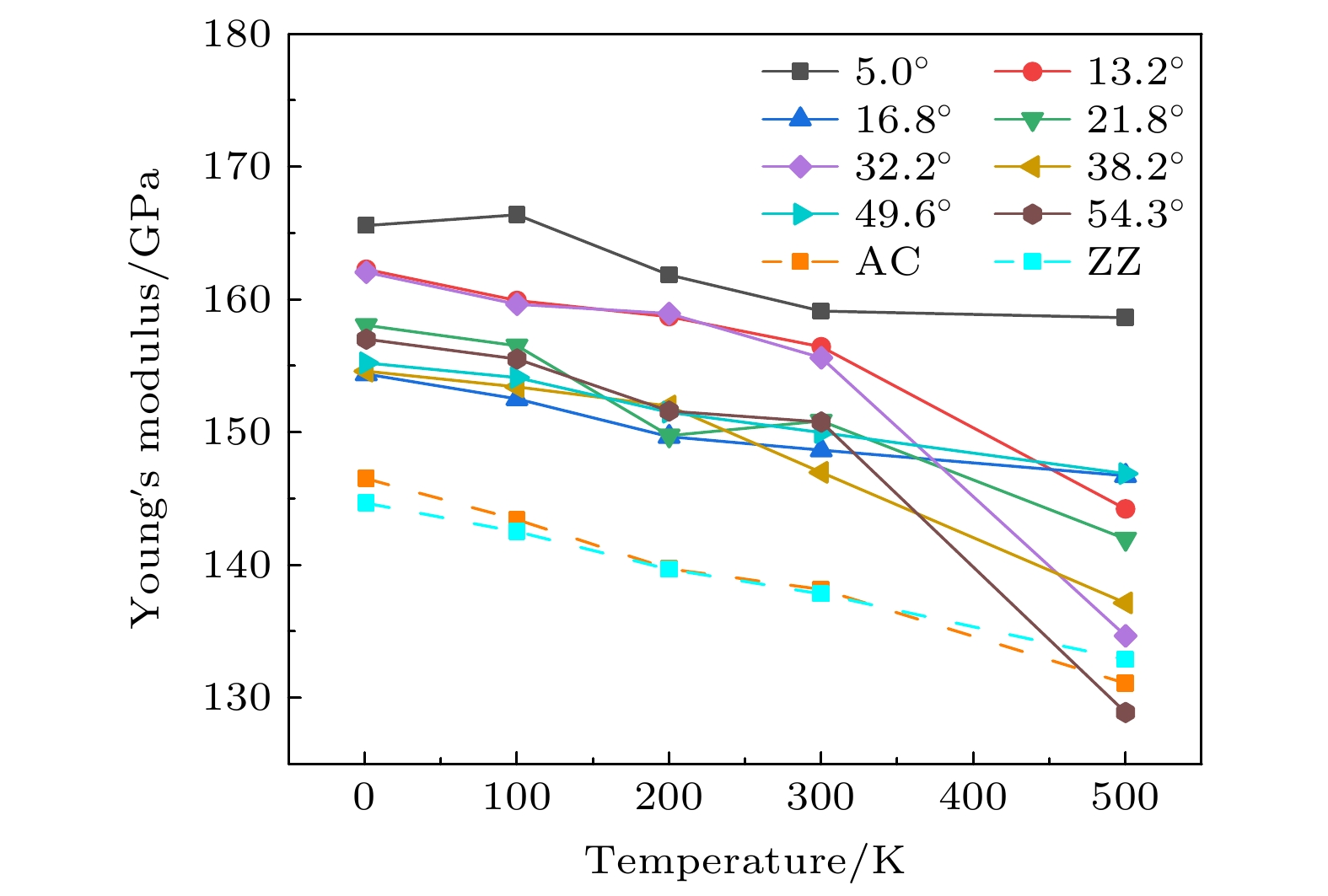

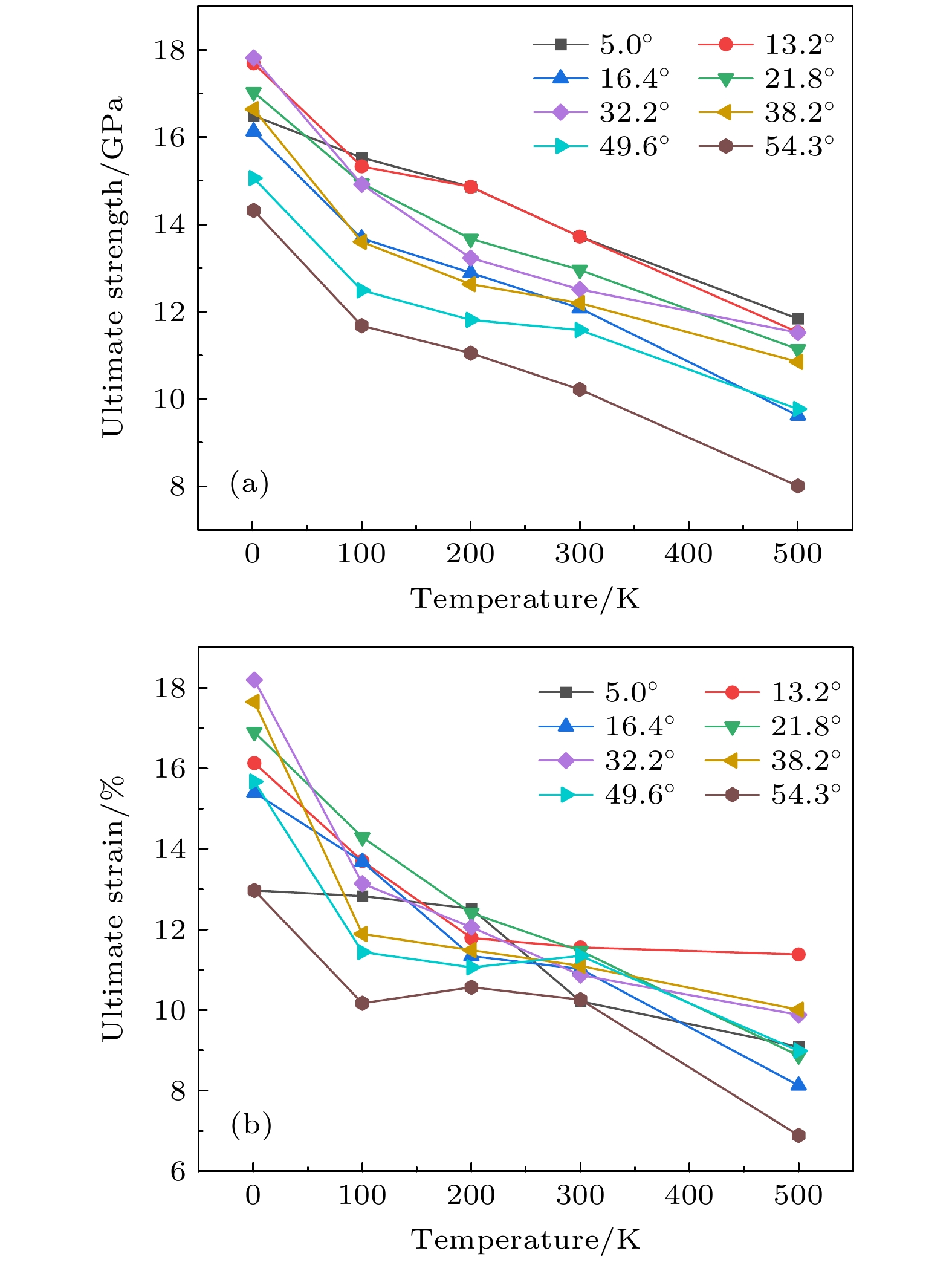

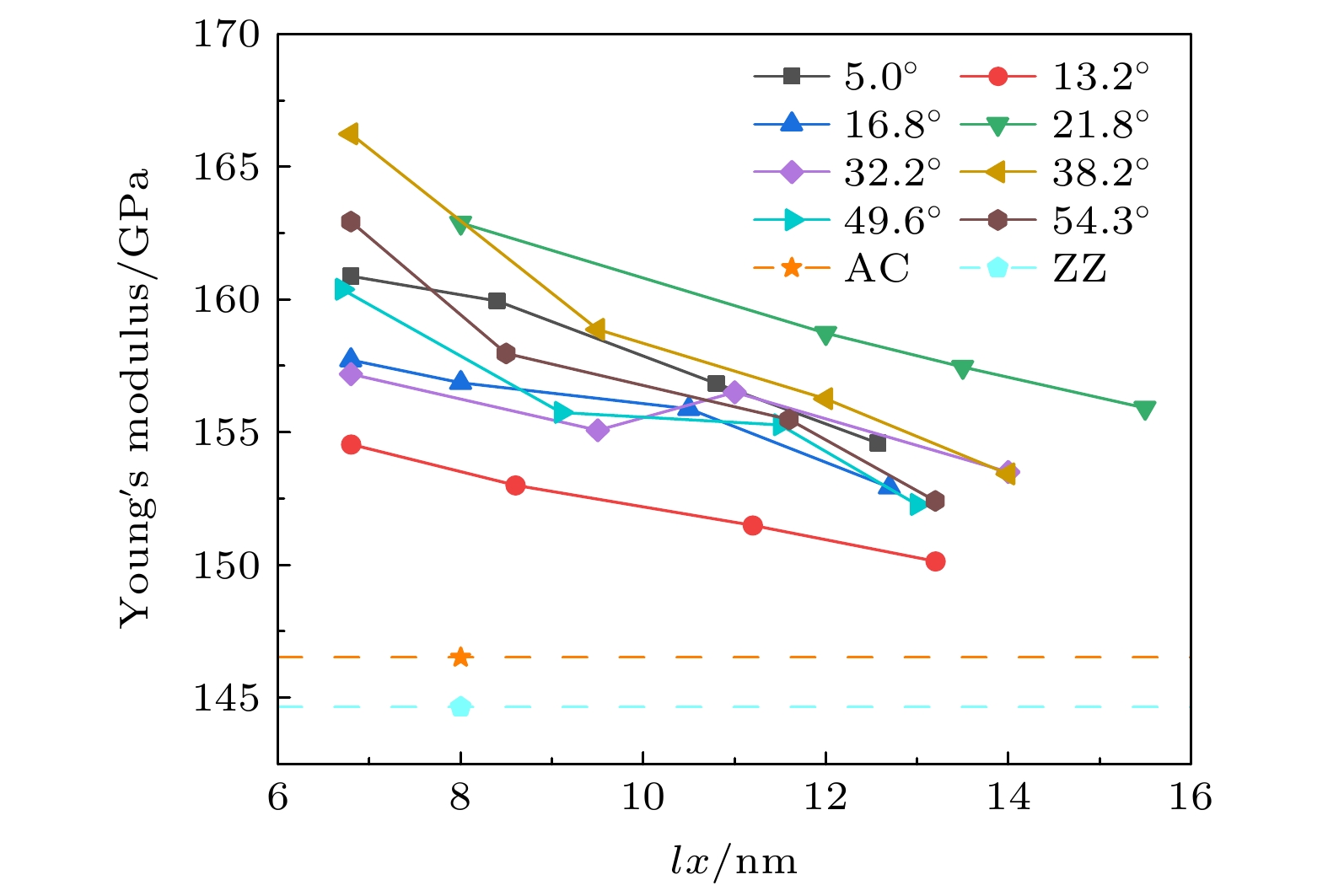

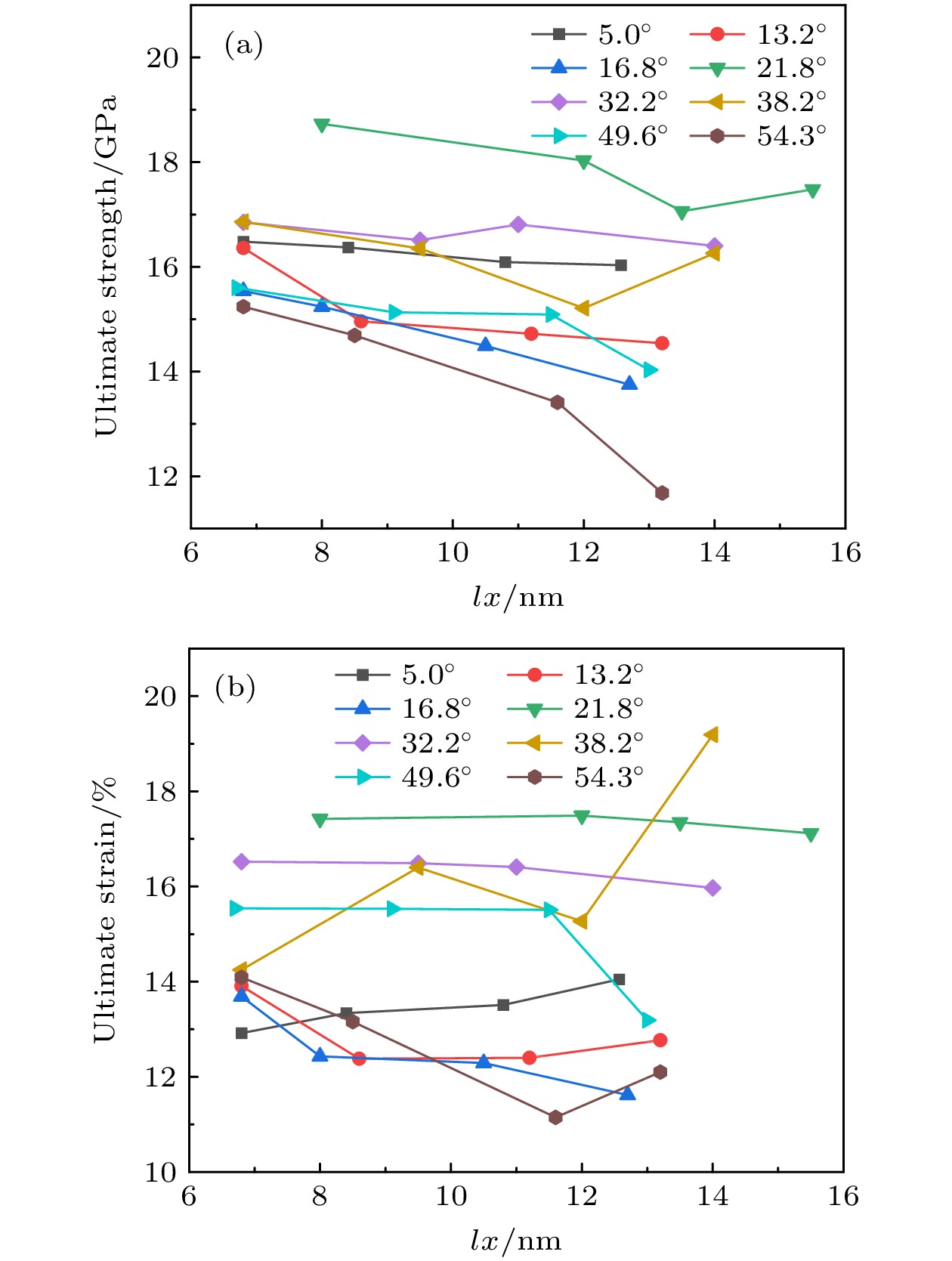

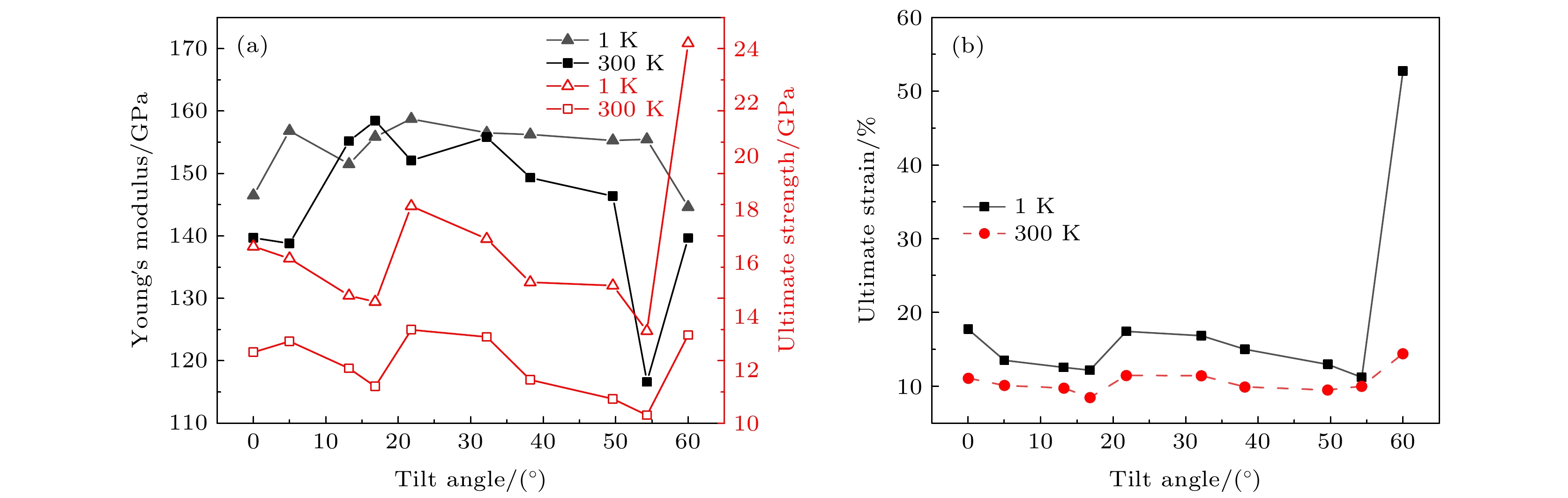

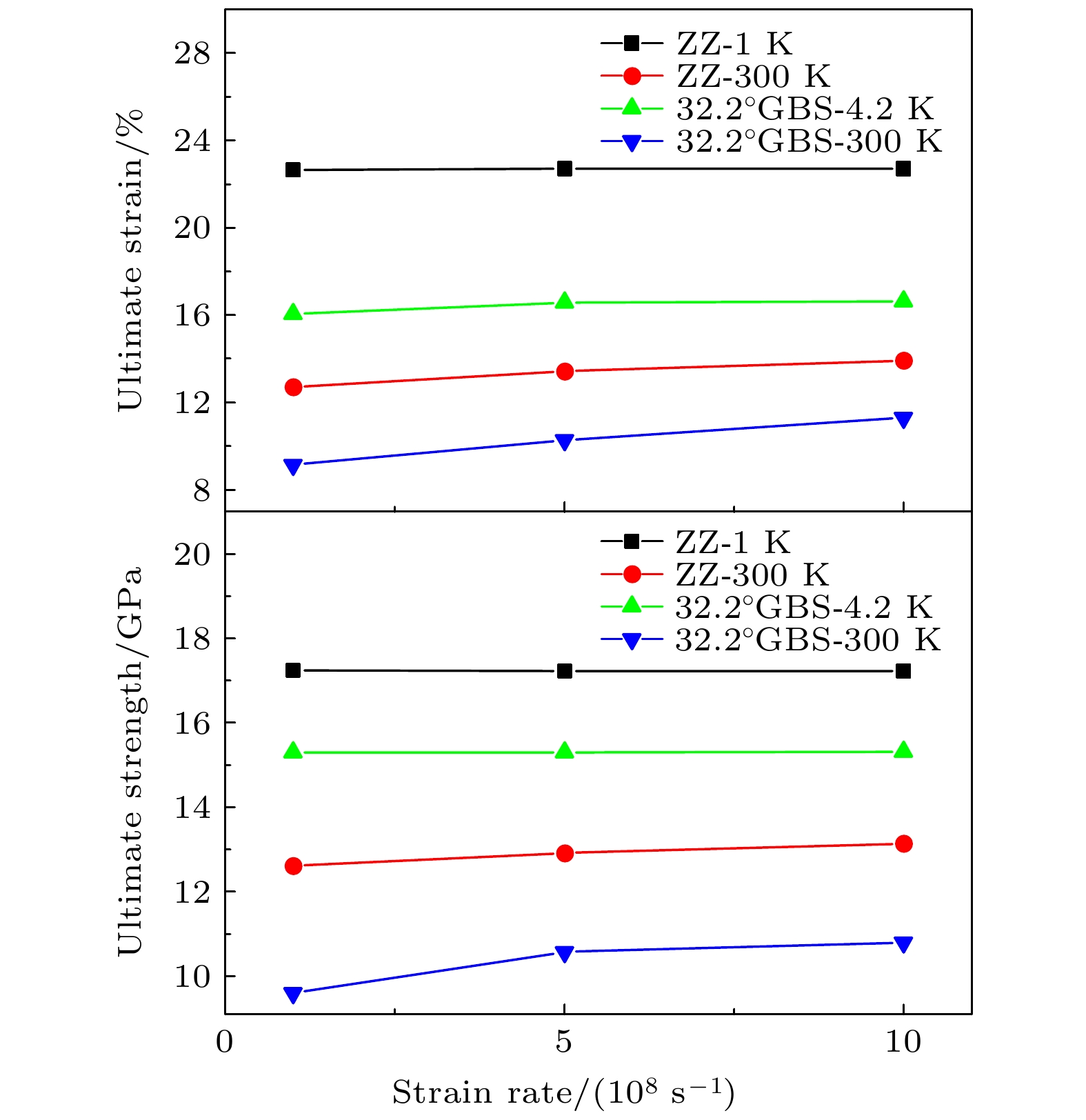

This work systematically studies the mechanical responses of a novel semiconducting Janus MoSSe monolayer subjected to uniaxial tensile loadings by molecular dynamics simulations. It is found that the Janus MoSSe monolayer shows clearly anisotropic responses along armchair direction and the zigzag direction. The phase transition behavior is observed when the Janus MoSSe monolayer is under the action of tension along the zigzag direction at temperatures below 100 K, while it does not exist in any other conditions. The Young’s modulus, ultimate strength and ultimate strain decrease with temperature increasing. Particularly, the ductile-to-brittle fracture behavior is observed when uniaxial tension is applied along the zigzag direction depending on temperatures. The underline fracture mechanism is analyzed. Moreover, mechanical properties of Janus MoSSe monolayer with various grain boundaries are also carefully explored. It is found that the ultimate strength and ultimate strain depend more sensitively on narrow grains than on those wider ones. The crack is initialized near the grain boundaries and propagates along the direction almost perpendicular to the grain boundaries. The findings of this work may shed light on design and optimization of nanoscale electronic devices based on the Janus MoSSe monolayers.

-

Keywords:

- Janus MoSSe monolayer /

- mechanical properties /

- grain boundaries /

- molecular dynamics simulations

[1] Castro Neto A H, Guinea F, Peres N M R, Novoselov K S, Geim A K 2009 Rev. Mod. Phys. 81 109

Google Scholar

Google Scholar

[2] Geim A K 2009 Science 324 1530

Google Scholar

Google Scholar

[3] Avouris P, Dimitrakopoulos C 2012 Mater. Today 15 86

Google Scholar

Google Scholar

[4] Akinwande D, Brennan C J, Bunch J S, Egberts P, Felts J R, Gao H J, Huang R, Kim J S, Li T, Li Y, Liechti K M, Lu N S, Park H S, Reed E J, Wang P, Yakobson B I, Zhang T, Zhang Y W, Zhou Y, Zhu Y 2017 Extreme Mech. Lett. 13 42

Google Scholar

Google Scholar

[5] Molle A, Grazianetti C, Tao L, Taneja D, Alam M H, Akinwande D 2018 Chem. Soc. Rev. 47 6370

Google Scholar

Google Scholar

[6] Liu H, Neal A T, Zhu Z, Luo Z, Xu X F, Tomanek D, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[7] Zhang K L, Feng Y L, Wang F, Yang Z C, Wang J 2017 J. Mater. Chem. C 5 11992

Google Scholar

Google Scholar

[8] Wyatt B C, Rosenkranz A, Anasori B 2021 Adv. Mater. 33 2007973

Google Scholar

Google Scholar

[9] Manzeli S, Ovchinnikov D, Pasquier D, Yazyev O V, Kis A 2017 Nature Rev. Mater. 2 17033

Google Scholar

Google Scholar

[10] Wang H T, Yuan H T, Hong S S, Li Y B, Cui Y 2015 Chem. Soc. Rev. 44 2664

Google Scholar

Google Scholar

[11] Huang H H, Fan X F, Singh D J, Zheng W T 2020 Nanoscale 12 1247

Google Scholar

Google Scholar

[12] Chen H J, Chen C Z, Li Y, Fang X W 2016 J. Semicond. 37 114004

Google Scholar

Google Scholar

[13] Shen Y, Tian H, Ren T L 2022 J. Semicond. 43 082002

Google Scholar

Google Scholar

[14] Lu A Y, Zhu H Y, Xiao J, Chuu C P, Han Y M, Chiu M H, Cheng C C, Yang C W, Wei K H, Yang Y M, Wang Y, Sokaras D, Nordlund D, Yang P D, Muller D A, Chou M Y, Zhang X, Li L J 2017 Nat. Nanotech. 12 744

Google Scholar

Google Scholar

[15] Zhang J, Jia S, Kholmanov I, Dong L, Er D Q, Chen W B, Guo H, Jin Z H, Shenoy V B, Shi L, Lou J 2017 ACS Nano 11 8192

Google Scholar

Google Scholar

[16] Hu T, Jia F H, Zhao G D, Wu J Y, Stroppa A, Ren W 2018 Phys. Rev. B 97 235404

Google Scholar

Google Scholar

[17] Zhang L, Xia Y, Li X D, Li L Y, Fu X, Cheng J J, Pan R K 2022 J. Appl. Phys. 131 230902

Google Scholar

Google Scholar

[18] 王盼, 宗易昕, 文宏玉, 夏建白, 魏钟鸣 2021 70 026801

Google Scholar

Google Scholar

Wang P, Zong Y X, Wen H Y, Xia J B, Wei Z M 2021 Acta Phys. Sin. 70 026801

Google Scholar

Google Scholar

[19] Cheng Y C, Zhu Z Y, Tahir M, Schwingenschlogl U 2013 Europhys. Lett. 102 57001

Google Scholar

Google Scholar

[20] Xia C X, Xiong W Q, Du J, Wang T X, Peng Y T, Li J B 2018 Phys. Rev. B 98 165424

Google Scholar

Google Scholar

[21] Shi W W, Li G Q, Wang Z G 2019 J. Phys. Chem. C. 123 12261

Google Scholar

Google Scholar

[22] Guan S S, Ke S S, Yu F F, Deng H X, Guo Y, Lu H F 2019 Appl. Sur. Sci. 496 143692

Google Scholar

Google Scholar

[23] Dong L, Lou J, Shenoy V B 2017 ACS Nano 11 8242

Google Scholar

Google Scholar

[24] Javvaji B, He B, Zhuang X Y, Park S H 2019 Phys. Rev. Mater. 3 125402

Google Scholar

Google Scholar

[25] Li R P, Cheng Y C, Huang W 2018 Small 14 1802091

Google Scholar

Google Scholar

[26] Ji Y J, Yang M Y, Lin H P, Hou T J, Wang L, Li Y Y, Lee S T 2018 J. Phys. Chem. C 122 3123

Google Scholar

Google Scholar

[27] Cai H F, Gao Y F, Gao H J, Guo W L 2019 Nano Energy 56 33

Google Scholar

Google Scholar

[28] Thanh V V, Van N D, Truong D V, Saito R, Hung N T 2020 Appl. Surf. Sci. 526 146730

Google Scholar

Google Scholar

[29] 韩同伟, 贺鹏飞 2010 59 3408

Google Scholar

Google Scholar

Han T W, He P F 2010 Acta Phys. Sin. 59 3408

Google Scholar

Google Scholar

[30] 王卫东, 郝跃, 纪翔, 易成龙, 牛翔宇 2012 61 200207

Google Scholar

Google Scholar

Wang W D, Hao Y, Ji X, Yi C L Niu X Y 2012 Acta Phys. Sin. 61 200207

Google Scholar

Google Scholar

[31] Zhao J H, Kou L Z, Jiang J W, Rabczuk T 2014 Nanotechnology 25 295701

Google Scholar

Google Scholar

[32] 李明林, 万亚玲, 胡建玥, 王卫东 2016 65 176201

Google Scholar

Google Scholar

Li M L, Wan Y L, Hu J Y, Wang W D 2016 Acta Phys. Sin. 65 176201

Google Scholar

Google Scholar

[33] Xiong Q L, Zhou J L, Zhang J, Kitamura T, Li Z H 2018 Phys. Chem. Chem. Phys. 20 20988

Google Scholar

Google Scholar

[34] Yang F, Shang J, Kou L Z, Li C, Deng Z C 2022 Nanomaterials 12 1910

Google Scholar

Google Scholar

[35] Fox A, Ray U, Li T 2019 Carbon 142 388

Google Scholar

Google Scholar

[36] Gibb A L, Alem N, Chen J H, Erickson K J, Ciston J, Gautam A, Linck M, Zettl A 2013 J. Am. Chem. Soc. 135 6758

Google Scholar

Google Scholar

[37] Zou X L, Liu Y Y, Yakobson B I 2013 Nano Lett. 13 253

Google Scholar

Google Scholar

[38] Liang Q J, Zhang Q, Zhao X X, Liu M Z, Wee A T S 2021 ACS Nano 15 2165

Google Scholar

Google Scholar

[39] 邵宇飞, 孟凡顺, 李久会, 赵星 2019 68 8

Google Scholar

Google Scholar

Shao Y F, Meng F S, Li J H, Zhao X 2019 Acta Phys. Sin. 68 8

Google Scholar

Google Scholar

[40] Hao W J, Wu Z G, Li X B, Pu Y X 2021 J. Appl. Phys. 129 185101

Google Scholar

Google Scholar

[41] Khossossi N, Singh D, Ainane A, Ahuja R 2020 Chem. Asian J. 15 3390

Google Scholar

Google Scholar

[42] Barik G, Pal S 2019 J. Phys. Chem. C 123 21852

Google Scholar

Google Scholar

[43] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[44] Stukowski A 2010 Model. Simul. Mater. Sc. 18 015012

Google Scholar

Google Scholar

[45] Jiang J W, Park H S, Rabczuk T 2013 J. Appl. Phys. 114 064307

Google Scholar

Google Scholar

[46] Jiang J W, Zhou Y P 2017 arXiv: 1704.03147 [cond-mat. mtrl-sci]

[47] Han Y K, Chen P J, Zhang C, Dong J W, Liu H 2021 Comput. Mater. Sci. 188 110188

Google Scholar

Google Scholar

[48] Giannozzi P, Baroni S, Bonini N, Calandra M, Car R, Cavazzoni C, Ceresoli D, Chiarotti G L, Cococcioni M, Dabo I, Dal Corso A, De Gironcoli S, Fabris S, Fratesi G, Gebauer R, Gerstmann U, Gougoussis C, Kokalj A, Lazzeri M, Martin-Samos L, Marzari N, Mauri F, Mazzarello R, Paolini S, Pasquarello A, Paulatto L, Sbraccia C, Scandolo S, Sclauzero G, Seitsonen A P, Smogunov A, Umari P, Wentzcovitch R M 2009 J. Phys. Condens. Matter. 21 395502

Google Scholar

Google Scholar

[49] Lukyanov S I, Bandura A V, Evarestov R A 2016 RSC Adv. 6 16037

Google Scholar

Google Scholar

[50] 谭一云, 于虹, 黄庆安, 刘同庆 2007 电子器件 30 755

Tan Y Y, Yu H, Huang Q A, Liu T Q 2007 Chin. J. Electron. 30 755

[51] Yang L, Liu J J, Lin Y W, Xu K, Cao X Z, Zhang Z S, Wu J Y 2021 Chem. Mater. 33 8758

Google Scholar

Google Scholar

-

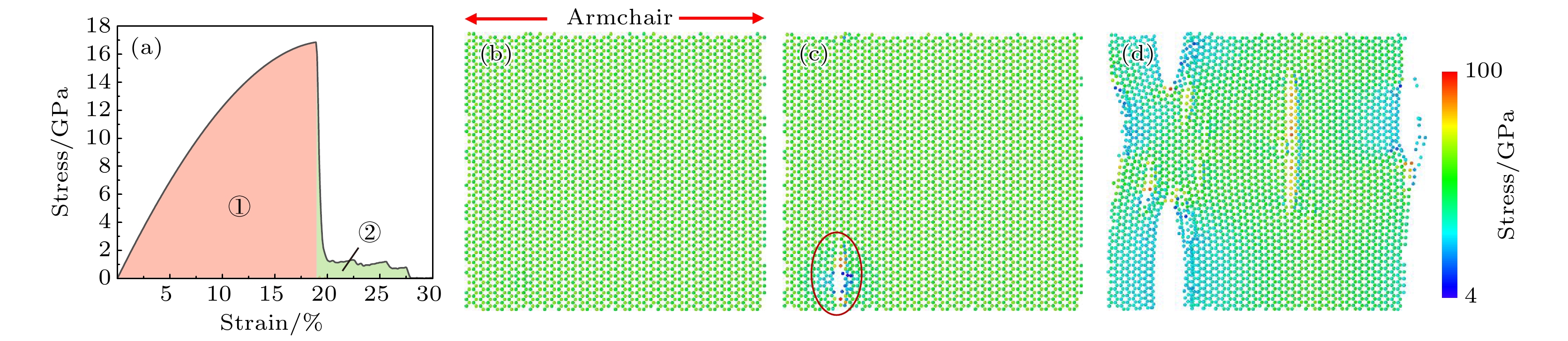

图 4 (a) 完美单层MoSSe在1 K温度下沿AC向受拉的应力-应变曲线, 以及(b) 18.96%, (c) 18.97% 和(d) 19.16%应变状态下的原子结构演变与应力分布图

Figure 4. (a) Stress-strain curve for perfect Janus MoSSe monolayer under tension along AC direction at 1 K; atomic snapshot and associated stress distribution under each strain state of (b) 18.96%, (c) 18.97%, and (d) 19.16%.

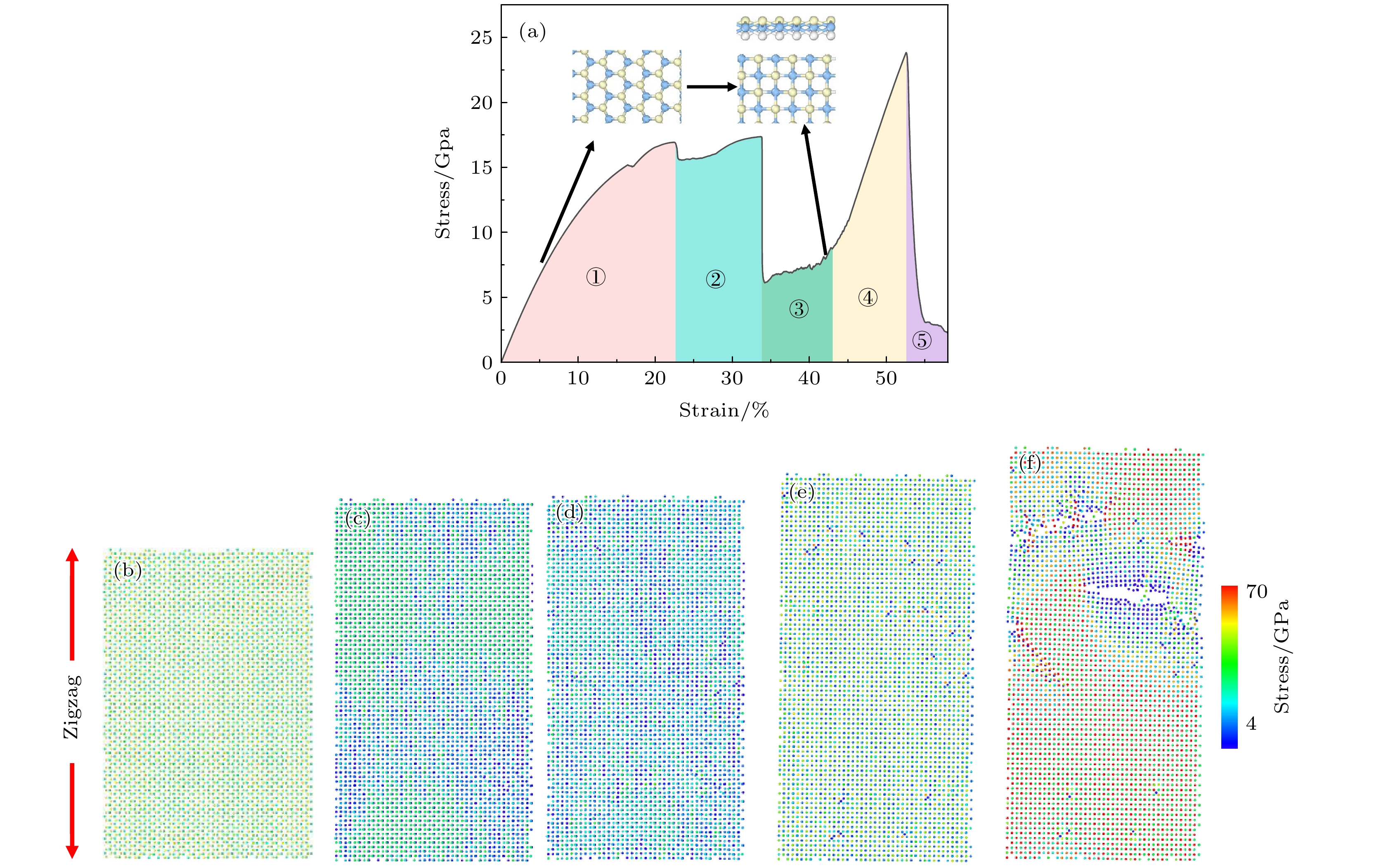

图 5 单层MoSSe在1 K温度下沿ZZ向受拉伸作用应力-应变曲线(a), 以及(b) 22.4%, (c) 33.9%, (d) 35.0%, (e) 44.0% 和 (f) 53.0%应变状态下的原子结构与相应的应力分布图

Figure 5. (a) Stress-strain curve for perfect Janus MoSSe monolayer under tension along ZZ direction at 1 K; atomic snapshot and associated stress distribution under strain states of (b) 22.4%; (c) 33.9%; (d) 35.0%; (e) 44.0% and (f) 53.0%.

图 6 (a) 沿锯齿形向受单轴拉伸作用下对应的最优结构; 此处仅展示相变前后几种应变状态所对应的结构(b) 沿扶手椅向受单轴拉伸作用下对应的最优结构

Figure 6. Taking a few snapshots of MoSSe monolayer under uniaxial strain states as examples: (a) Relaxed structures under uniaxial strain along zigzag direction before and after phase transtion; (b) relaxed structures under uniaxial strain along armchair direction.

图 9 1 K温度下 (a) 完美单层MoSSe结构, (b) 10% 的Se原子被去除, (c) 20%的Se原子被去除, (d) 50%的Se原子被替换为S原子和 (e) 全部Se原子被S原子替换即本征对称MoS2, 经过400 ps的弛豫平衡后原子形貌

Figure 9. Atomic snapshots of (a) perfect MoSSe monolayer, (b) 10% Se atoms removed, (c) 20% Se atoms removed, (d) 50% Se atoms replaced by S atoms and (e) 100% Se atoms replaced by S atoms, i.e. MoS2 monolayer, after 400 ps equilibrium simulation time at 1 K

图 11 (a) 扶手椅形方向(0°)、锯齿形方向(60°)和晶界倾斜角度定义示意图; 3种含镜像对称晶界的单层MoSSe结构 (b) 晶界倾斜角为13.2°; (c) 晶界倾斜角为16.4°; (d) 晶界倾斜角21.8°; 两种非镜像对称晶界的MoSSe (e) 晶界倾斜角为32.2°; (f) 晶界倾斜角为38.2°

Figure 11. (a) Definition diagram of armchair (0°), zigzag (60°) directions and other tilt angles; grain boundary structures with tilt angles (b) 13.2°, (c) 16.4°, (d) 21.8°, (e) 32.2° and (f) 38.2°.

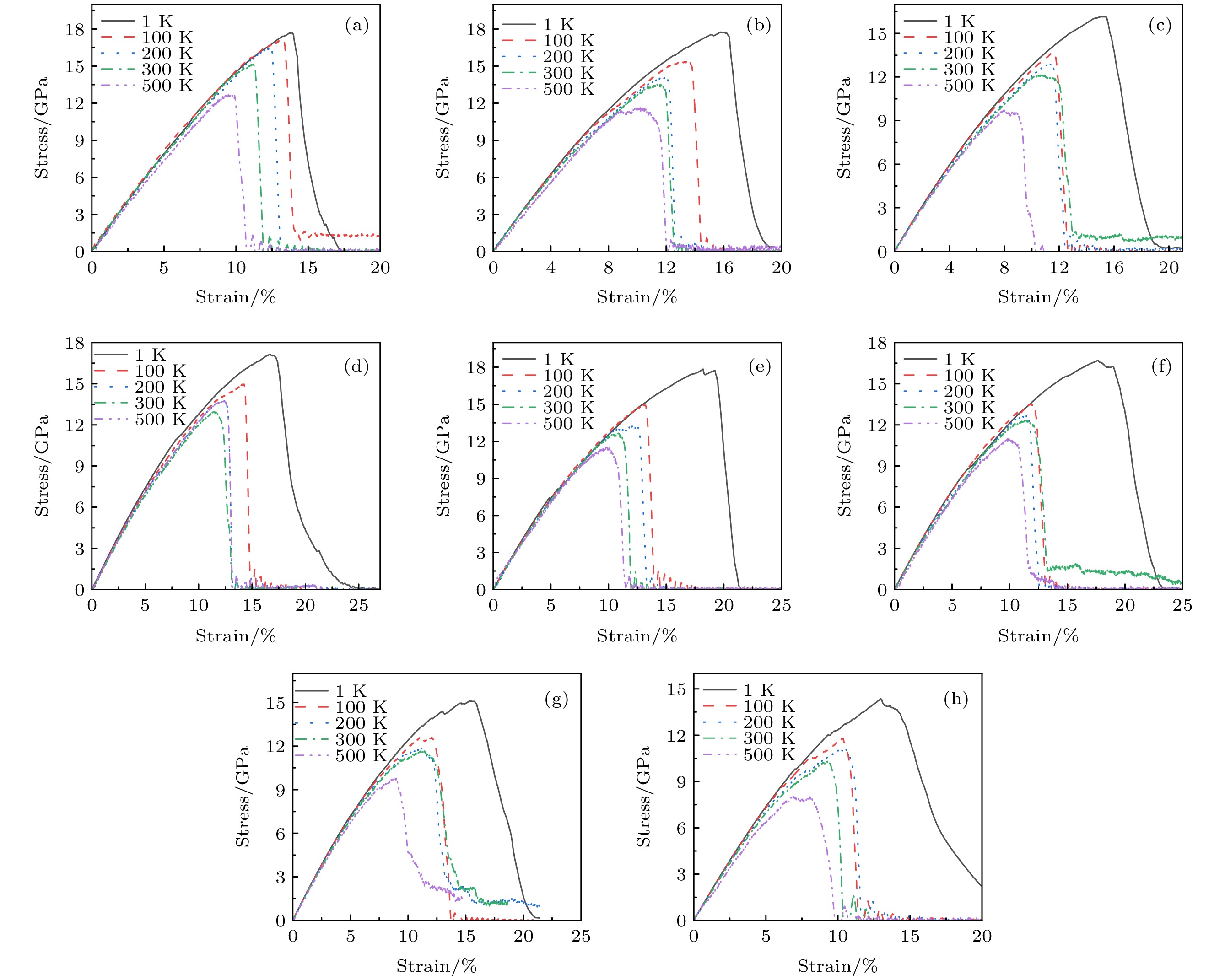

图 12 不同温度下4种镜像对称晶界MoSSe (a) 倾斜角为5.0°, (b) 倾斜角为13.2°, (c) 倾斜角为16.8°和(d) 倾斜角为21.8°; 4种镜像非对称晶界MoSSe (e) 倾斜角为32.2°, (f) 倾斜角为38.2°, (g) 倾斜角为49.6°和(h) 倾斜角为54.3°的应力-应变曲线

Figure 12. Stress-strain curves for Janus MoSSe monolayer with four kinds of symmetric grain boundaries with tilt angles of (a) 5.0°, (b) 13.2°, (c) 16.8° and (d) 21.8°, and four kinds of asymmetric grain boundaries with tilt angles of (e) 32.2°, (f) 38.2°, (g) 49.6° and (h) 54.3° at various temperatures.

-

[1] Castro Neto A H, Guinea F, Peres N M R, Novoselov K S, Geim A K 2009 Rev. Mod. Phys. 81 109

Google Scholar

Google Scholar

[2] Geim A K 2009 Science 324 1530

Google Scholar

Google Scholar

[3] Avouris P, Dimitrakopoulos C 2012 Mater. Today 15 86

Google Scholar

Google Scholar

[4] Akinwande D, Brennan C J, Bunch J S, Egberts P, Felts J R, Gao H J, Huang R, Kim J S, Li T, Li Y, Liechti K M, Lu N S, Park H S, Reed E J, Wang P, Yakobson B I, Zhang T, Zhang Y W, Zhou Y, Zhu Y 2017 Extreme Mech. Lett. 13 42

Google Scholar

Google Scholar

[5] Molle A, Grazianetti C, Tao L, Taneja D, Alam M H, Akinwande D 2018 Chem. Soc. Rev. 47 6370

Google Scholar

Google Scholar

[6] Liu H, Neal A T, Zhu Z, Luo Z, Xu X F, Tomanek D, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[7] Zhang K L, Feng Y L, Wang F, Yang Z C, Wang J 2017 J. Mater. Chem. C 5 11992

Google Scholar

Google Scholar

[8] Wyatt B C, Rosenkranz A, Anasori B 2021 Adv. Mater. 33 2007973

Google Scholar

Google Scholar

[9] Manzeli S, Ovchinnikov D, Pasquier D, Yazyev O V, Kis A 2017 Nature Rev. Mater. 2 17033

Google Scholar

Google Scholar

[10] Wang H T, Yuan H T, Hong S S, Li Y B, Cui Y 2015 Chem. Soc. Rev. 44 2664

Google Scholar

Google Scholar

[11] Huang H H, Fan X F, Singh D J, Zheng W T 2020 Nanoscale 12 1247

Google Scholar

Google Scholar

[12] Chen H J, Chen C Z, Li Y, Fang X W 2016 J. Semicond. 37 114004

Google Scholar

Google Scholar

[13] Shen Y, Tian H, Ren T L 2022 J. Semicond. 43 082002

Google Scholar

Google Scholar

[14] Lu A Y, Zhu H Y, Xiao J, Chuu C P, Han Y M, Chiu M H, Cheng C C, Yang C W, Wei K H, Yang Y M, Wang Y, Sokaras D, Nordlund D, Yang P D, Muller D A, Chou M Y, Zhang X, Li L J 2017 Nat. Nanotech. 12 744

Google Scholar

Google Scholar

[15] Zhang J, Jia S, Kholmanov I, Dong L, Er D Q, Chen W B, Guo H, Jin Z H, Shenoy V B, Shi L, Lou J 2017 ACS Nano 11 8192

Google Scholar

Google Scholar

[16] Hu T, Jia F H, Zhao G D, Wu J Y, Stroppa A, Ren W 2018 Phys. Rev. B 97 235404

Google Scholar

Google Scholar

[17] Zhang L, Xia Y, Li X D, Li L Y, Fu X, Cheng J J, Pan R K 2022 J. Appl. Phys. 131 230902

Google Scholar

Google Scholar

[18] 王盼, 宗易昕, 文宏玉, 夏建白, 魏钟鸣 2021 70 026801

Google Scholar

Google Scholar

Wang P, Zong Y X, Wen H Y, Xia J B, Wei Z M 2021 Acta Phys. Sin. 70 026801

Google Scholar

Google Scholar

[19] Cheng Y C, Zhu Z Y, Tahir M, Schwingenschlogl U 2013 Europhys. Lett. 102 57001

Google Scholar

Google Scholar

[20] Xia C X, Xiong W Q, Du J, Wang T X, Peng Y T, Li J B 2018 Phys. Rev. B 98 165424

Google Scholar

Google Scholar

[21] Shi W W, Li G Q, Wang Z G 2019 J. Phys. Chem. C. 123 12261

Google Scholar

Google Scholar

[22] Guan S S, Ke S S, Yu F F, Deng H X, Guo Y, Lu H F 2019 Appl. Sur. Sci. 496 143692

Google Scholar

Google Scholar

[23] Dong L, Lou J, Shenoy V B 2017 ACS Nano 11 8242

Google Scholar

Google Scholar

[24] Javvaji B, He B, Zhuang X Y, Park S H 2019 Phys. Rev. Mater. 3 125402

Google Scholar

Google Scholar

[25] Li R P, Cheng Y C, Huang W 2018 Small 14 1802091

Google Scholar

Google Scholar

[26] Ji Y J, Yang M Y, Lin H P, Hou T J, Wang L, Li Y Y, Lee S T 2018 J. Phys. Chem. C 122 3123

Google Scholar

Google Scholar

[27] Cai H F, Gao Y F, Gao H J, Guo W L 2019 Nano Energy 56 33

Google Scholar

Google Scholar

[28] Thanh V V, Van N D, Truong D V, Saito R, Hung N T 2020 Appl. Surf. Sci. 526 146730

Google Scholar

Google Scholar

[29] 韩同伟, 贺鹏飞 2010 59 3408

Google Scholar

Google Scholar

Han T W, He P F 2010 Acta Phys. Sin. 59 3408

Google Scholar

Google Scholar

[30] 王卫东, 郝跃, 纪翔, 易成龙, 牛翔宇 2012 61 200207

Google Scholar

Google Scholar

Wang W D, Hao Y, Ji X, Yi C L Niu X Y 2012 Acta Phys. Sin. 61 200207

Google Scholar

Google Scholar

[31] Zhao J H, Kou L Z, Jiang J W, Rabczuk T 2014 Nanotechnology 25 295701

Google Scholar

Google Scholar

[32] 李明林, 万亚玲, 胡建玥, 王卫东 2016 65 176201

Google Scholar

Google Scholar

Li M L, Wan Y L, Hu J Y, Wang W D 2016 Acta Phys. Sin. 65 176201

Google Scholar

Google Scholar

[33] Xiong Q L, Zhou J L, Zhang J, Kitamura T, Li Z H 2018 Phys. Chem. Chem. Phys. 20 20988

Google Scholar

Google Scholar

[34] Yang F, Shang J, Kou L Z, Li C, Deng Z C 2022 Nanomaterials 12 1910

Google Scholar

Google Scholar

[35] Fox A, Ray U, Li T 2019 Carbon 142 388

Google Scholar

Google Scholar

[36] Gibb A L, Alem N, Chen J H, Erickson K J, Ciston J, Gautam A, Linck M, Zettl A 2013 J. Am. Chem. Soc. 135 6758

Google Scholar

Google Scholar

[37] Zou X L, Liu Y Y, Yakobson B I 2013 Nano Lett. 13 253

Google Scholar

Google Scholar

[38] Liang Q J, Zhang Q, Zhao X X, Liu M Z, Wee A T S 2021 ACS Nano 15 2165

Google Scholar

Google Scholar

[39] 邵宇飞, 孟凡顺, 李久会, 赵星 2019 68 8

Google Scholar

Google Scholar

Shao Y F, Meng F S, Li J H, Zhao X 2019 Acta Phys. Sin. 68 8

Google Scholar

Google Scholar

[40] Hao W J, Wu Z G, Li X B, Pu Y X 2021 J. Appl. Phys. 129 185101

Google Scholar

Google Scholar

[41] Khossossi N, Singh D, Ainane A, Ahuja R 2020 Chem. Asian J. 15 3390

Google Scholar

Google Scholar

[42] Barik G, Pal S 2019 J. Phys. Chem. C 123 21852

Google Scholar

Google Scholar

[43] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[44] Stukowski A 2010 Model. Simul. Mater. Sc. 18 015012

Google Scholar

Google Scholar

[45] Jiang J W, Park H S, Rabczuk T 2013 J. Appl. Phys. 114 064307

Google Scholar

Google Scholar

[46] Jiang J W, Zhou Y P 2017 arXiv: 1704.03147 [cond-mat. mtrl-sci]

[47] Han Y K, Chen P J, Zhang C, Dong J W, Liu H 2021 Comput. Mater. Sci. 188 110188

Google Scholar

Google Scholar

[48] Giannozzi P, Baroni S, Bonini N, Calandra M, Car R, Cavazzoni C, Ceresoli D, Chiarotti G L, Cococcioni M, Dabo I, Dal Corso A, De Gironcoli S, Fabris S, Fratesi G, Gebauer R, Gerstmann U, Gougoussis C, Kokalj A, Lazzeri M, Martin-Samos L, Marzari N, Mauri F, Mazzarello R, Paolini S, Pasquarello A, Paulatto L, Sbraccia C, Scandolo S, Sclauzero G, Seitsonen A P, Smogunov A, Umari P, Wentzcovitch R M 2009 J. Phys. Condens. Matter. 21 395502

Google Scholar

Google Scholar

[49] Lukyanov S I, Bandura A V, Evarestov R A 2016 RSC Adv. 6 16037

Google Scholar

Google Scholar

[50] 谭一云, 于虹, 黄庆安, 刘同庆 2007 电子器件 30 755

Tan Y Y, Yu H, Huang Q A, Liu T Q 2007 Chin. J. Electron. 30 755

[51] Yang L, Liu J J, Lin Y W, Xu K, Cao X Z, Zhang Z S, Wu J Y 2021 Chem. Mater. 33 8758

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7771

- PDF Downloads: 193

- Cited By: 0

DownLoad:

DownLoad: