-

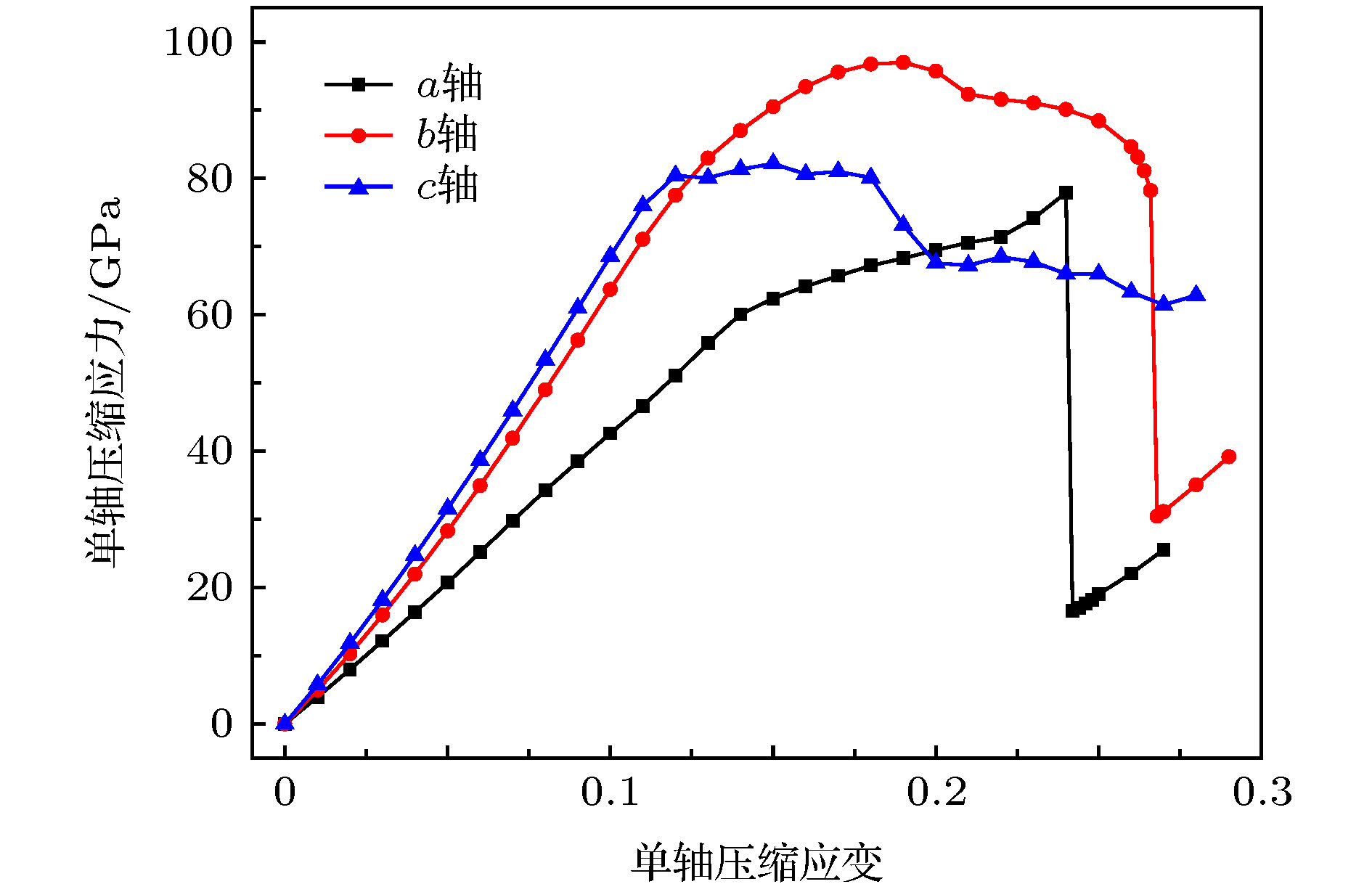

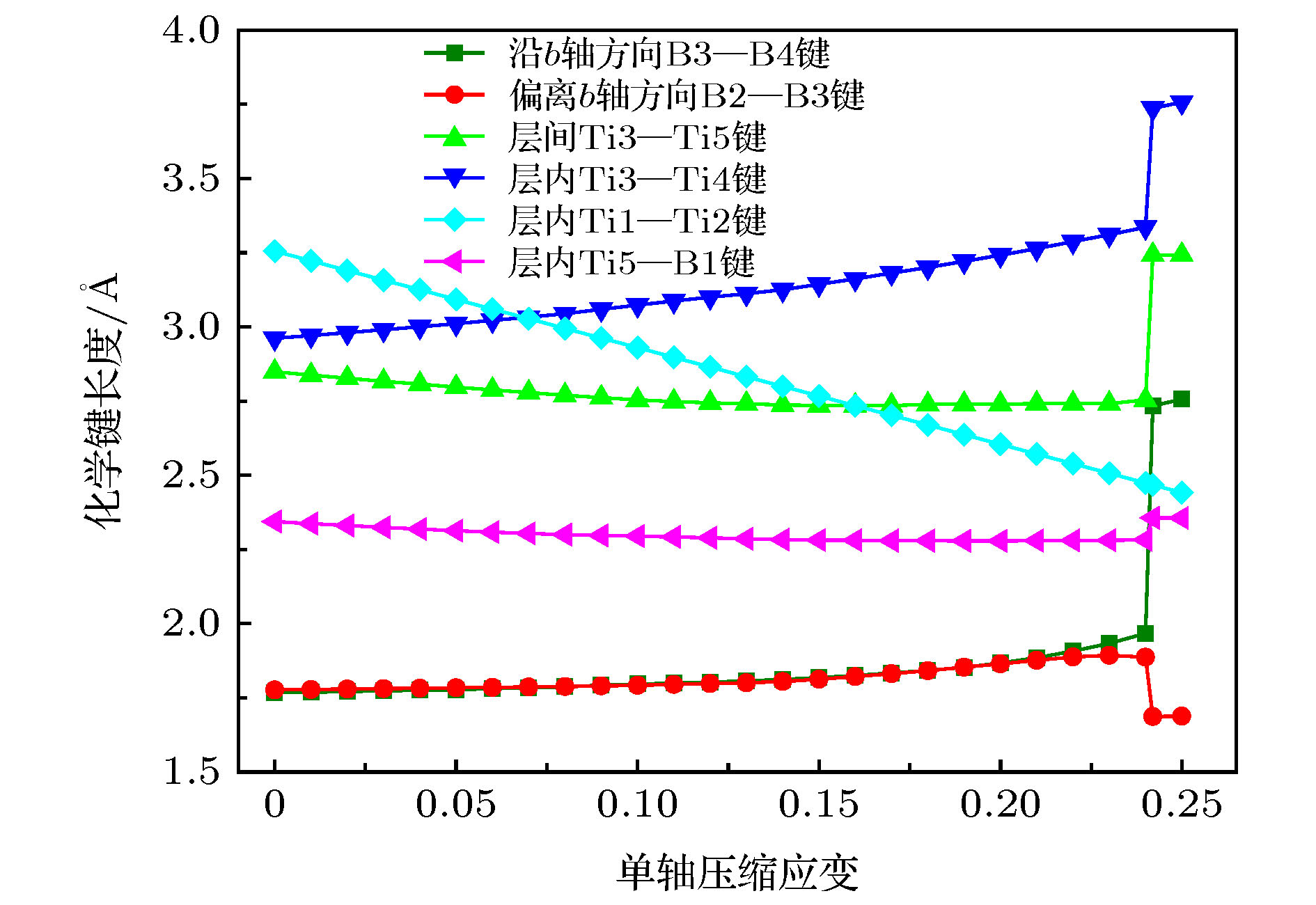

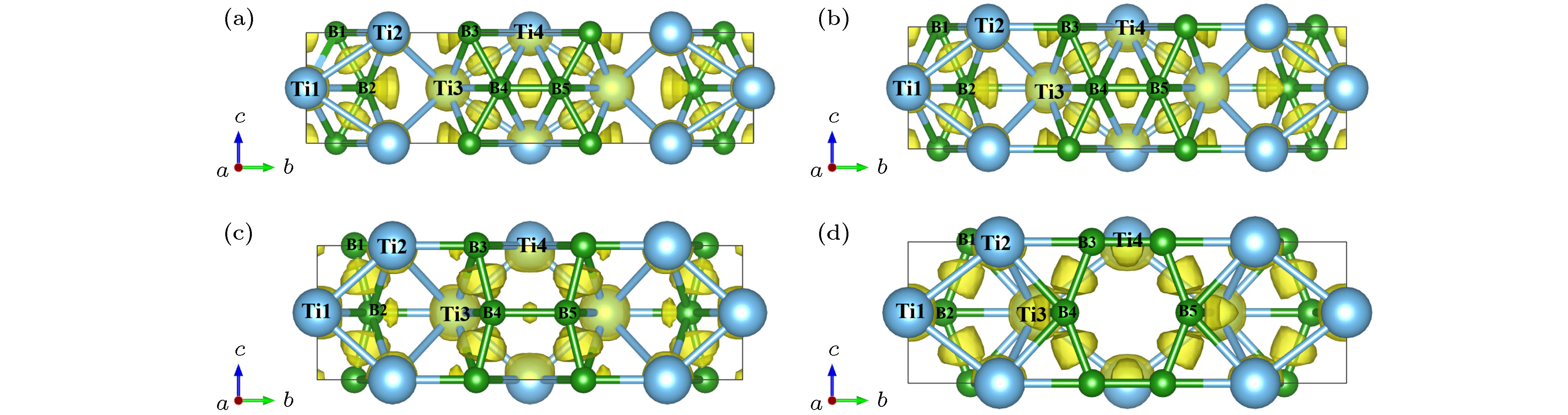

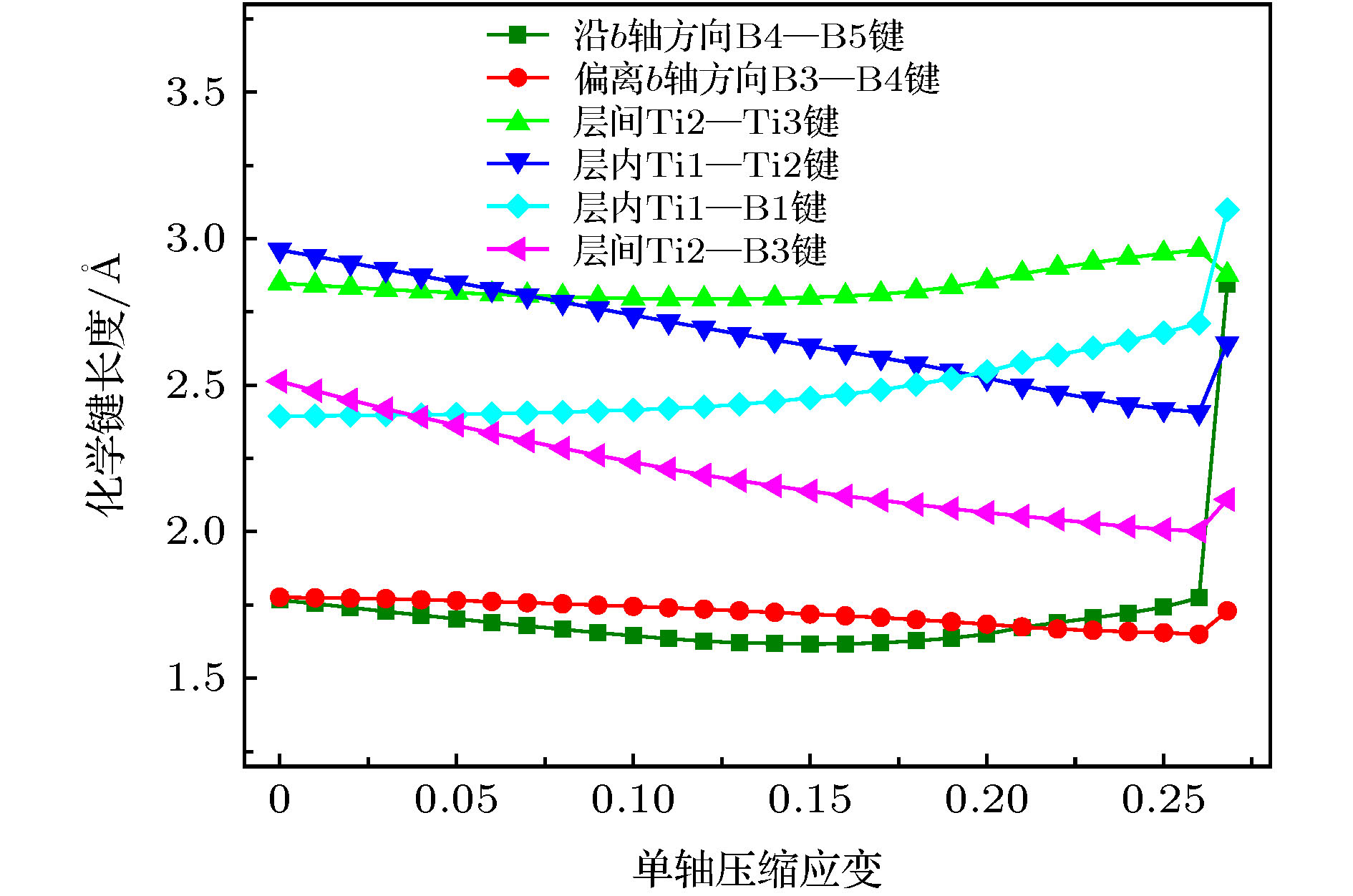

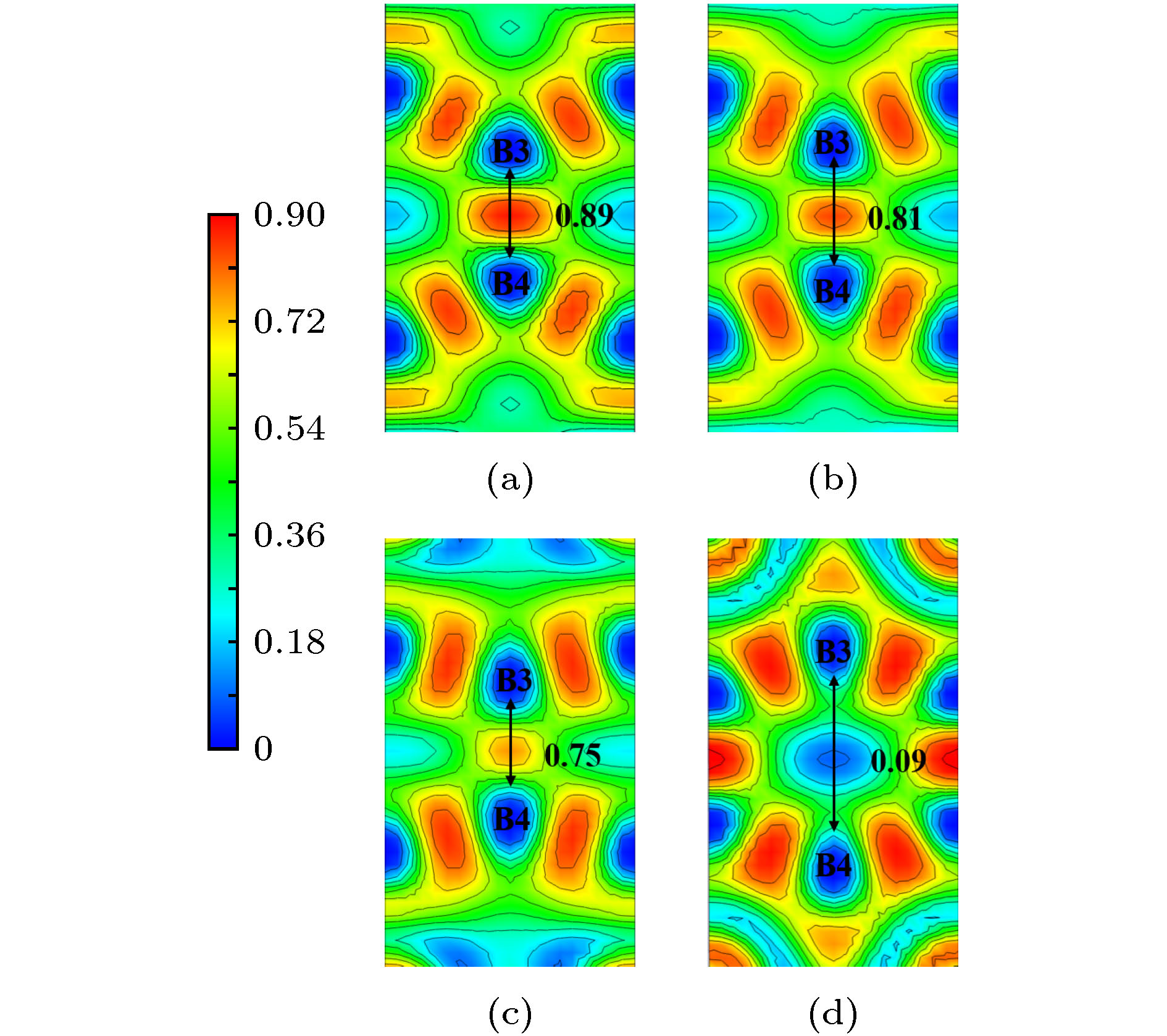

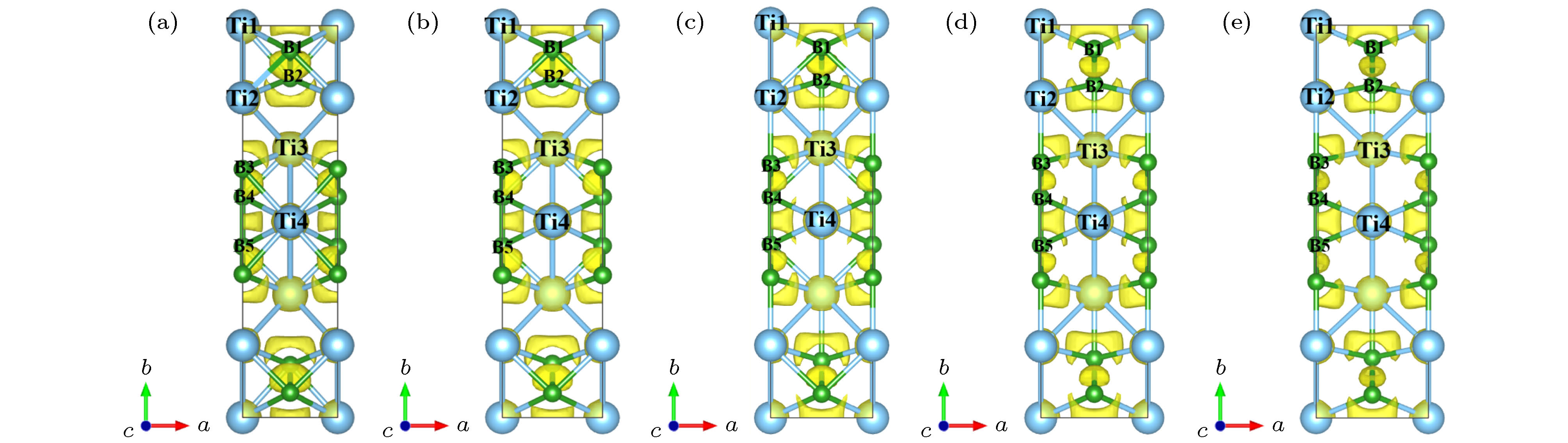

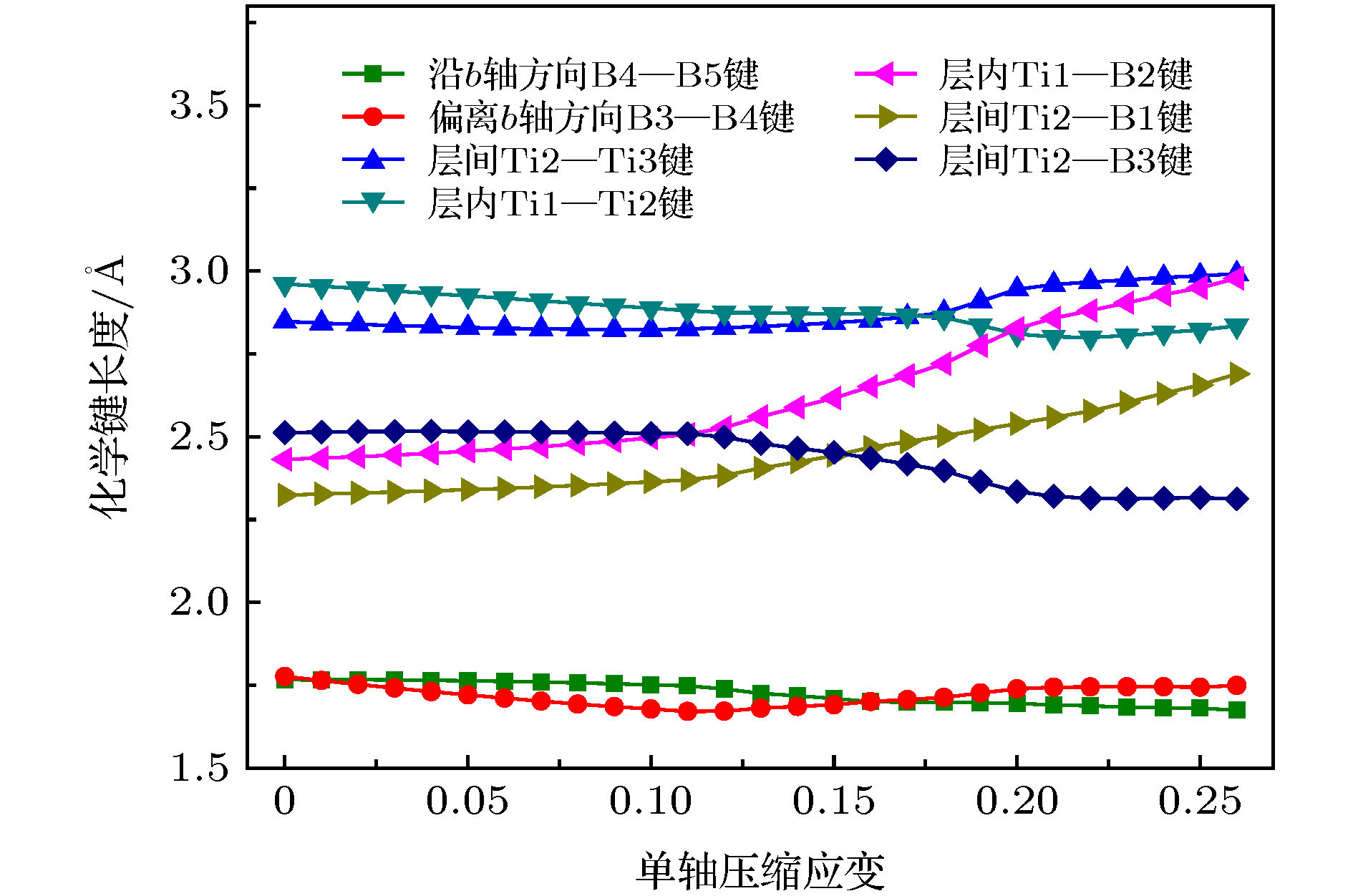

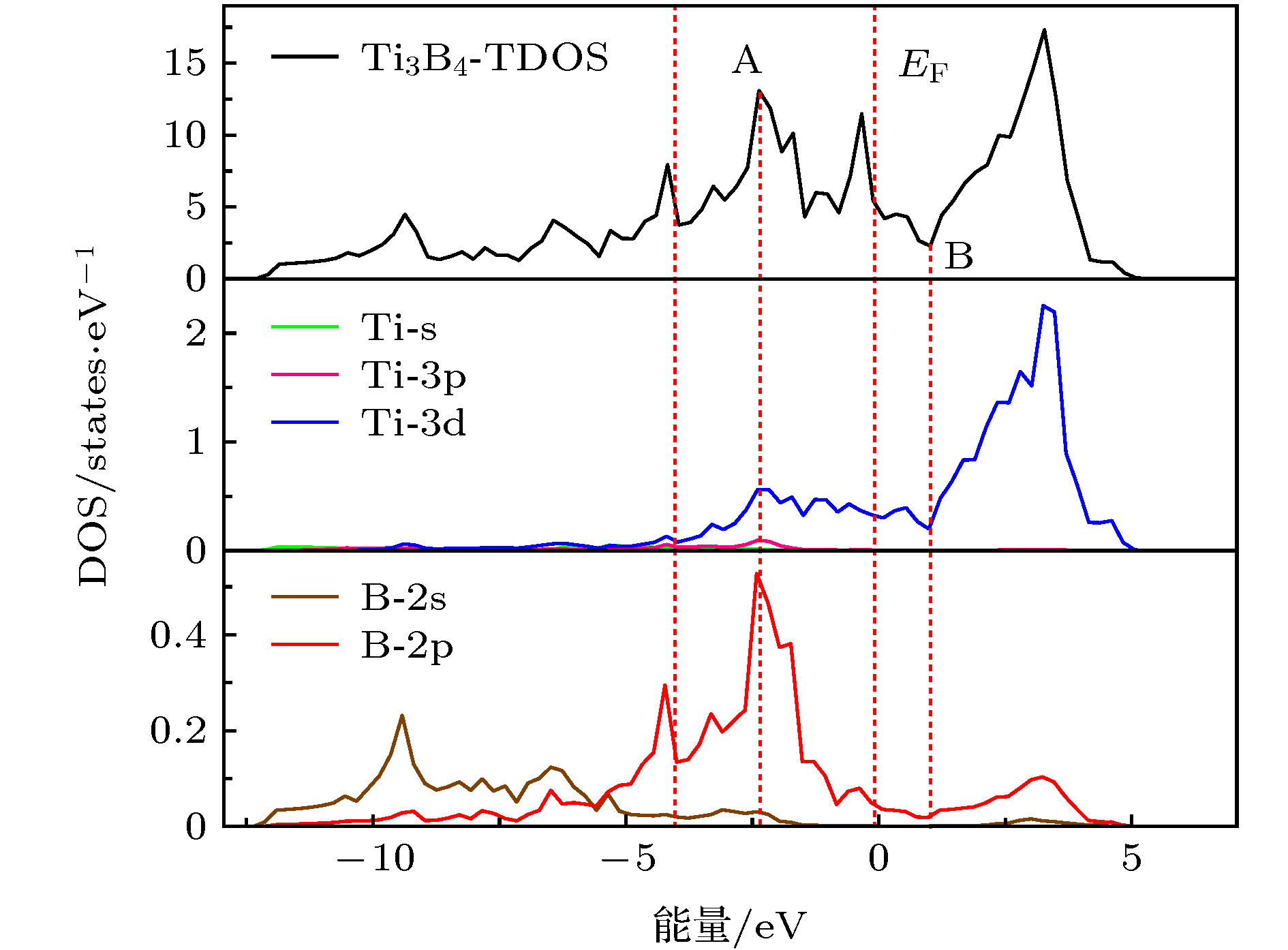

Ti3B4作为一种重要的钛硼化合物, 被广泛应用于工业生产和国防军事中. 但是有关Ti3B4在外载荷下的变形行为却鲜有报道, 这在很大程度上限制了它的应用. 本文采用基于密度泛函理论的第一性原理方法研究了Ti3B4在不同方向单轴压缩下的力学行为、电子结构以及变形机制. 结果表明, 在不同方向单轴压缩下, Ti3B4的变形行为表现出很强的各向异性. a轴压缩下, 层内Ti- Ti键减弱使Ti3B4承载能力降低, 最终层间Ti-Ti键和沿b轴B-B键断裂造成压缩应力突降; b轴压缩下, 层内Ti-B键减弱和层间Ti-B键增强导致Ti3B4承载能力逐渐降低, B-B键断裂导致结构破坏; c轴压缩下, 层内Ti-B键断裂和层间Ti-B键形成使结构稳定性降低. 由态密度分布可知, 在单轴压缩下, 变形后的Ti3B4仍然呈现金属性, 但是其共价性能降低. 通过讨论Ti3B4在不同方向单轴压缩下的力学行为与微观变形机制可以为改善其宏观性能提供一定的理论指导.As an important Ti-B component, Ti3B4 has been widely used in industry and military applications. However, its deformation behaviors are not clear, which greatly limits its applications. First-principles methods based on density function theory were employed to investigate the mechanical, electronic properties and deformation mechanisms of Ti3B4 under uniaxial compressions along different axis. The results show that the structure underwent a massive change under different axial compressions. Strong anisotropic of deformation behaviors in Ti3B4 was observed. The compressive strength along b-axis is the highest in Ti3B4 structure. Under a-axis compression, the interaction between intralayer Ti—Ti bonds becomes weaker as the compressive strain increases, causing the partly damage of Ti3B4. However, in this process, the structure is not destroyed and can sustain the stress continuously. After that, the interlayer Ti—Ti bonds and the intralyer B—B bonds which are along b-axis, are broken and then it causes the sudden drop in stress, implying that the Ti3B4 structure is fully destroyed. Under b-axis compression, the changes of Ti—B bonds in Ti3B4 structure lead to the decrease of stress. Similarly, the structure can sustain the stress continuously in the process. Then, the B—B bonds which are along b-axis are broken, resulting in the sudden drop in stress. Under c-axis compression, the formation of interlayer Ti—B bonds and the breakage of intralayer Ti—B bonds result in structural instability of Ti3B4. Meanwhile, the deformed Ti3B4 still exhibits a metallic feature in the crystalline state after uniaxial compressions. However, there is no noticeable pseudogap in DOS spectra for a-axis and b-axis compressions. While for c-axis compression, there still exists a pseudogap around the Fermi energy, but it moves to the lower energy. And the pseudogap becomes narrower than that of the initial structure, which means that the covalent properties of Ti3B4 are reduced after deformations. The present work provides necessary insights in understanding the mechanical behaviors and deformation mechanisms of Ti3B4, which is the basis for improving the mechanical performance of Ti3B4 at macroscale.

-

Keywords:

- Ti3B4 /

- First-principles methods /

- mechanical properties /

- deformation mechanisms

[1] Li P F, Zhou R L, Zeng X C 2015 ACS Appl. Mater. Interfaces 7 15607

Google Scholar

Google Scholar

[2] Munro R G 2000 J. Res. Nat. Inst. Stand. Technol. 105 709

Google Scholar

Google Scholar

[3] 黎军军, 赵学坪, 陶强, 黄晓庆, 朱品文, 崔田, 王欣 2013 62 026202

Google Scholar

Google Scholar

Li J J, Zhao X P, Tao Q, Huang X Q, Zhu P W, Cui T, Wang X 2013 Acta Phys. Sin. 62 026202

Google Scholar

Google Scholar

[4] Murray J L, Liao P K, Spear K E 1986 Bull. Alloy Phase Diagrams 7 550

Google Scholar

Google Scholar

[5] Spear K E, Mcdowell P, Mcmahon F 1986 J. Am. Ceram. Soc. 69 C-4

Google Scholar

Google Scholar

[6] Huang F, Fu Z Y, Yan A H, Wang W M, Wang H, Zhang J Y, Zhang Q J 2010 Powder Technol. 197 83

Google Scholar

Google Scholar

[7] Panda K B, Ravi Chandran K S 2006 Comput. Mater. Sci. 35 134

Google Scholar

Google Scholar

[8] Ma X Y, Li C R, Du Z M, Zhang W J 2004 J. Alloys Compd. 370 149

Google Scholar

Google Scholar

[9] Yan H Y, Wei Q, Chang S M, Guo P 2011 Trans. Nonferrous Met. Soc. China (English Ed.) 21 1627

Google Scholar

Google Scholar

[10] Tian J Z, Zhao Y H, Wang B, Hou H, Zhang Y M 2018 Mater. Chem. Phys. 209 200

Google Scholar

Google Scholar

[11] Sun L, Gao Y M, Xiao B, Li Y F, Wang G L 2013 J. Alloys Compd. 579 457

Google Scholar

Google Scholar

[12] Zhang X H, Luo X G, Li J P, Hu P, Han J C 2010 Scr. Mater. 62 625

Google Scholar

Google Scholar

[13] Cheng T B, Li W G 2015 J. Am. Ceram. Soc. 98 190

Google Scholar

Google Scholar

[14] Sun M, Wang C Y, Liu J P 2018 Chin. Phys. B 27 077103

Google Scholar

Google Scholar

[15] Arpita Aparajita A N, Sanjay Kumar N R, Chandra Shekar N V, Kalavathi S 2017 Mater. Res. Express 4 096508

Google Scholar

Google Scholar

[16] Tian D C, Wang X B 1992 J. Phys. Condens. Matter 4 8765

Google Scholar

Google Scholar

[17] Mouffok B, Feraoun H, Aourag H 2006 Mater. Lett. 60 1433

Google Scholar

Google Scholar

[18] Vajeeston P, Ravindran P, Ravi C, Asokamani R 2001 Phys. Rev. B 63 045115

Google Scholar

Google Scholar

[19] Wang C L, Yu B H, Huo H L, Chen D, Sun H B 2009 Chin. Phys. B 18 1248

Google Scholar

Google Scholar

[20] Peng F, Fu H Z, Cheng X L 2007 Phys. B Condens. Matter 400 83

Google Scholar

Google Scholar

[21] Xiang H M, Feng Z H, Li Z P, Zhou Y C 2015 J. Appl. Phys. 117 225902

Google Scholar

Google Scholar

[22] Wang M L 2014 Phys. Scr. 89 115702

Google Scholar

Google Scholar

[23] Lu J Q, Qin J N, Chen Y F, Zhang Z W, Lu W J, Zhang D 2010 J. Alloys Compd. 490 118

Google Scholar

Google Scholar

[24] Zhang R, Wang D J, Yuan S J 2017 Mater. Des. 134 250

Google Scholar

Google Scholar

[25] Chen D, Chen Z, Wu Y, Wang M L, Ma N H, Wang H W 2014 Intermetallics 52 64

Google Scholar

Google Scholar

[26] Panda K B, Ravi Chandran K S 2006 Acta Mater. 54 1641

Google Scholar

Google Scholar

[27] Rou S, Ravi Chandran K S 2018 J. Am. Ceram. Soc. 101 4308

Google Scholar

Google Scholar

[28] Wang G L, Li Y F, Gao Y M, Cheng Y H, Ma S Q 2015 Comput. Mater. Sci. 104 29

Google Scholar

Google Scholar

[29] Li J, Liu L S, Xu S, Zhang J Y and She W C 2019 J. Appl. Phys. A 125 222

Google Scholar

Google Scholar

[30] 房玉真, 孔祥晋, 王东亭, 崔守鑫, 刘军海 2018 67 117101

Google Scholar

Google Scholar

Fang Y Z, Kong X J, Wang D T, Cui S X, Liu J H 2018 Acta Phys. Sin. 67 117101

Google Scholar

Google Scholar

[31] 丁超, 李卫, 刘菊燕, 王琳琳, 蔡云, 潘沛锋 2018 67 213102

Google Scholar

Google Scholar

Ding C, Li W, Liu J Y, Wang L L, Cai Y, Pan P F 2018 Acta Phys. Sin. 67 213102

Google Scholar

Google Scholar

[32] 刘琪, 管鹏飞 2018 67 178101

Google Scholar

Google Scholar

Liu Q, Guan P F 2018 Acta Phys. Sin. 67 178101

Google Scholar

Google Scholar

[33] He X, Li J B 2019 Chin. Phys. B 28 037301

Google Scholar

Google Scholar

[34] 吕常伟, 王臣菊, 顾建兵 2019 68 077102

Google Scholar

Google Scholar

Lv C W, Wang C J, Gu J P 2019 Acta Phys. Sin. 68 077102

Google Scholar

Google Scholar

[35] Lu B K, Wang C Y 2018 Chin. Phys. B 27 077104

Google Scholar

Google Scholar

[36] Kresse G 1999 Phys. Rev. B 59 1758

Google Scholar

Google Scholar

[37] Kresse G, Furthmüller J 1996 Comput. Mater. Sci. 6 15

Google Scholar

Google Scholar

[38] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[39] Becke A D, Edgecombe K E 1990 J. Chem. Phys. 92 5397

Google Scholar

Google Scholar

[40] Momma K, Izumi F 2011 J. Appl. Crystallogr. (International Union Crystallogr.-IUCr) 44 1272

Google Scholar

Google Scholar

[41] Segall M, Shah R, Pickard C 1996 Phys. Rev. B 54 16317

Google Scholar

Google Scholar

[42] Gull E, Parcollet O, Millis A J 2013 Phys. Rev. Lett. 110 216405

Google Scholar

Google Scholar

[43] 王欣, 王发展, 雷哲锋, 王博, 马姗, 王哲, 吴振 2013 62 123101

Google Scholar

Google Scholar

Wang X, Wang F Z, Lei Z F, Wang B, Ma S, Wang Z, Wu Z 2013 Acta Phys. Sin. 62 123101

Google Scholar

Google Scholar

-

表 1 峰值A和谷值B处的Ti原子和B原子的PDOS和Ti3B4的TDOS (states/eV)

Table 1. The PDOS of a Ti and a B atom and TDOS of Ti3B4 at Peak A and Bottom B (states/eV).

D(Ti-s) D(Ti-3p) D(Ti-3d) D(B-2s) D(B-2p) D(Total) 峰值A 0.0137 0.0959 0.5610 0.0308 0.527 13.0945 谷值B 0.0001 0.0007 0.1996 0.0010 0.019 2.2669 -

[1] Li P F, Zhou R L, Zeng X C 2015 ACS Appl. Mater. Interfaces 7 15607

Google Scholar

Google Scholar

[2] Munro R G 2000 J. Res. Nat. Inst. Stand. Technol. 105 709

Google Scholar

Google Scholar

[3] 黎军军, 赵学坪, 陶强, 黄晓庆, 朱品文, 崔田, 王欣 2013 62 026202

Google Scholar

Google Scholar

Li J J, Zhao X P, Tao Q, Huang X Q, Zhu P W, Cui T, Wang X 2013 Acta Phys. Sin. 62 026202

Google Scholar

Google Scholar

[4] Murray J L, Liao P K, Spear K E 1986 Bull. Alloy Phase Diagrams 7 550

Google Scholar

Google Scholar

[5] Spear K E, Mcdowell P, Mcmahon F 1986 J. Am. Ceram. Soc. 69 C-4

Google Scholar

Google Scholar

[6] Huang F, Fu Z Y, Yan A H, Wang W M, Wang H, Zhang J Y, Zhang Q J 2010 Powder Technol. 197 83

Google Scholar

Google Scholar

[7] Panda K B, Ravi Chandran K S 2006 Comput. Mater. Sci. 35 134

Google Scholar

Google Scholar

[8] Ma X Y, Li C R, Du Z M, Zhang W J 2004 J. Alloys Compd. 370 149

Google Scholar

Google Scholar

[9] Yan H Y, Wei Q, Chang S M, Guo P 2011 Trans. Nonferrous Met. Soc. China (English Ed.) 21 1627

Google Scholar

Google Scholar

[10] Tian J Z, Zhao Y H, Wang B, Hou H, Zhang Y M 2018 Mater. Chem. Phys. 209 200

Google Scholar

Google Scholar

[11] Sun L, Gao Y M, Xiao B, Li Y F, Wang G L 2013 J. Alloys Compd. 579 457

Google Scholar

Google Scholar

[12] Zhang X H, Luo X G, Li J P, Hu P, Han J C 2010 Scr. Mater. 62 625

Google Scholar

Google Scholar

[13] Cheng T B, Li W G 2015 J. Am. Ceram. Soc. 98 190

Google Scholar

Google Scholar

[14] Sun M, Wang C Y, Liu J P 2018 Chin. Phys. B 27 077103

Google Scholar

Google Scholar

[15] Arpita Aparajita A N, Sanjay Kumar N R, Chandra Shekar N V, Kalavathi S 2017 Mater. Res. Express 4 096508

Google Scholar

Google Scholar

[16] Tian D C, Wang X B 1992 J. Phys. Condens. Matter 4 8765

Google Scholar

Google Scholar

[17] Mouffok B, Feraoun H, Aourag H 2006 Mater. Lett. 60 1433

Google Scholar

Google Scholar

[18] Vajeeston P, Ravindran P, Ravi C, Asokamani R 2001 Phys. Rev. B 63 045115

Google Scholar

Google Scholar

[19] Wang C L, Yu B H, Huo H L, Chen D, Sun H B 2009 Chin. Phys. B 18 1248

Google Scholar

Google Scholar

[20] Peng F, Fu H Z, Cheng X L 2007 Phys. B Condens. Matter 400 83

Google Scholar

Google Scholar

[21] Xiang H M, Feng Z H, Li Z P, Zhou Y C 2015 J. Appl. Phys. 117 225902

Google Scholar

Google Scholar

[22] Wang M L 2014 Phys. Scr. 89 115702

Google Scholar

Google Scholar

[23] Lu J Q, Qin J N, Chen Y F, Zhang Z W, Lu W J, Zhang D 2010 J. Alloys Compd. 490 118

Google Scholar

Google Scholar

[24] Zhang R, Wang D J, Yuan S J 2017 Mater. Des. 134 250

Google Scholar

Google Scholar

[25] Chen D, Chen Z, Wu Y, Wang M L, Ma N H, Wang H W 2014 Intermetallics 52 64

Google Scholar

Google Scholar

[26] Panda K B, Ravi Chandran K S 2006 Acta Mater. 54 1641

Google Scholar

Google Scholar

[27] Rou S, Ravi Chandran K S 2018 J. Am. Ceram. Soc. 101 4308

Google Scholar

Google Scholar

[28] Wang G L, Li Y F, Gao Y M, Cheng Y H, Ma S Q 2015 Comput. Mater. Sci. 104 29

Google Scholar

Google Scholar

[29] Li J, Liu L S, Xu S, Zhang J Y and She W C 2019 J. Appl. Phys. A 125 222

Google Scholar

Google Scholar

[30] 房玉真, 孔祥晋, 王东亭, 崔守鑫, 刘军海 2018 67 117101

Google Scholar

Google Scholar

Fang Y Z, Kong X J, Wang D T, Cui S X, Liu J H 2018 Acta Phys. Sin. 67 117101

Google Scholar

Google Scholar

[31] 丁超, 李卫, 刘菊燕, 王琳琳, 蔡云, 潘沛锋 2018 67 213102

Google Scholar

Google Scholar

Ding C, Li W, Liu J Y, Wang L L, Cai Y, Pan P F 2018 Acta Phys. Sin. 67 213102

Google Scholar

Google Scholar

[32] 刘琪, 管鹏飞 2018 67 178101

Google Scholar

Google Scholar

Liu Q, Guan P F 2018 Acta Phys. Sin. 67 178101

Google Scholar

Google Scholar

[33] He X, Li J B 2019 Chin. Phys. B 28 037301

Google Scholar

Google Scholar

[34] 吕常伟, 王臣菊, 顾建兵 2019 68 077102

Google Scholar

Google Scholar

Lv C W, Wang C J, Gu J P 2019 Acta Phys. Sin. 68 077102

Google Scholar

Google Scholar

[35] Lu B K, Wang C Y 2018 Chin. Phys. B 27 077104

Google Scholar

Google Scholar

[36] Kresse G 1999 Phys. Rev. B 59 1758

Google Scholar

Google Scholar

[37] Kresse G, Furthmüller J 1996 Comput. Mater. Sci. 6 15

Google Scholar

Google Scholar

[38] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[39] Becke A D, Edgecombe K E 1990 J. Chem. Phys. 92 5397

Google Scholar

Google Scholar

[40] Momma K, Izumi F 2011 J. Appl. Crystallogr. (International Union Crystallogr.-IUCr) 44 1272

Google Scholar

Google Scholar

[41] Segall M, Shah R, Pickard C 1996 Phys. Rev. B 54 16317

Google Scholar

Google Scholar

[42] Gull E, Parcollet O, Millis A J 2013 Phys. Rev. Lett. 110 216405

Google Scholar

Google Scholar

[43] 王欣, 王发展, 雷哲锋, 王博, 马姗, 王哲, 吴振 2013 62 123101

Google Scholar

Google Scholar

Wang X, Wang F Z, Lei Z F, Wang B, Ma S, Wang Z, Wu Z 2013 Acta Phys. Sin. 62 123101

Google Scholar

Google Scholar

计量

- 文章访问数: 8498

- PDF下载量: 119

- 被引次数: 0

下载:

下载: