-

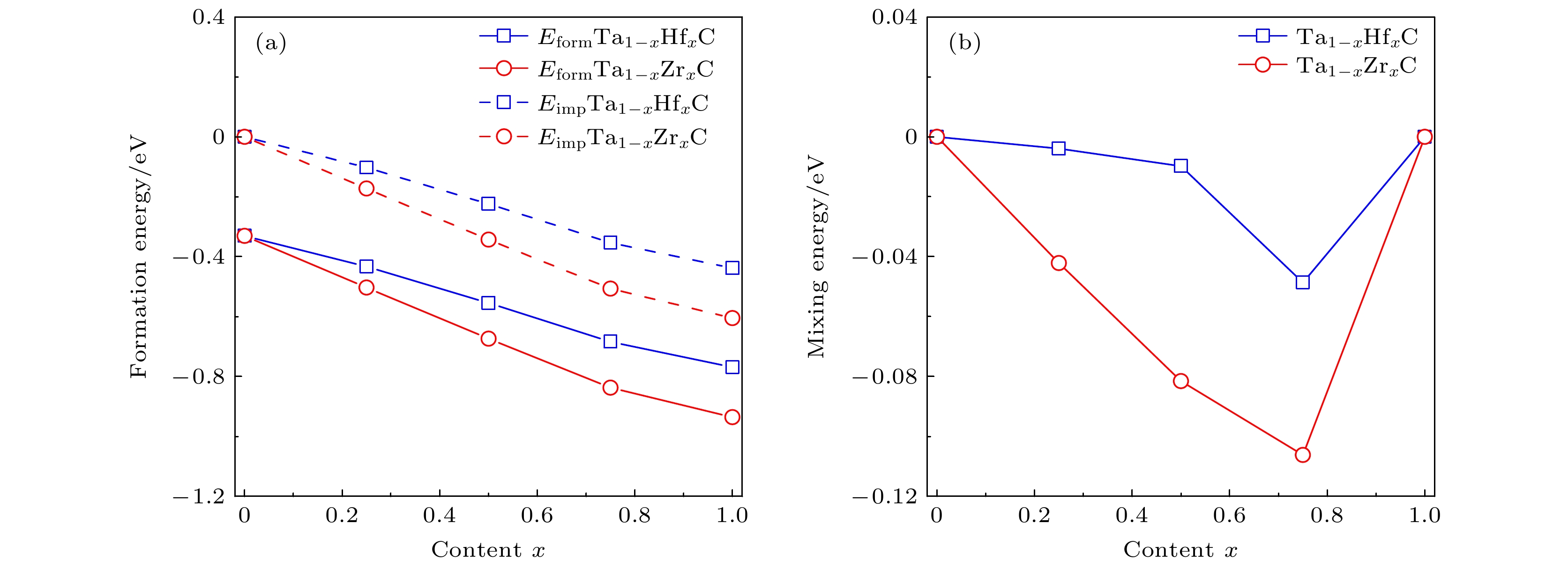

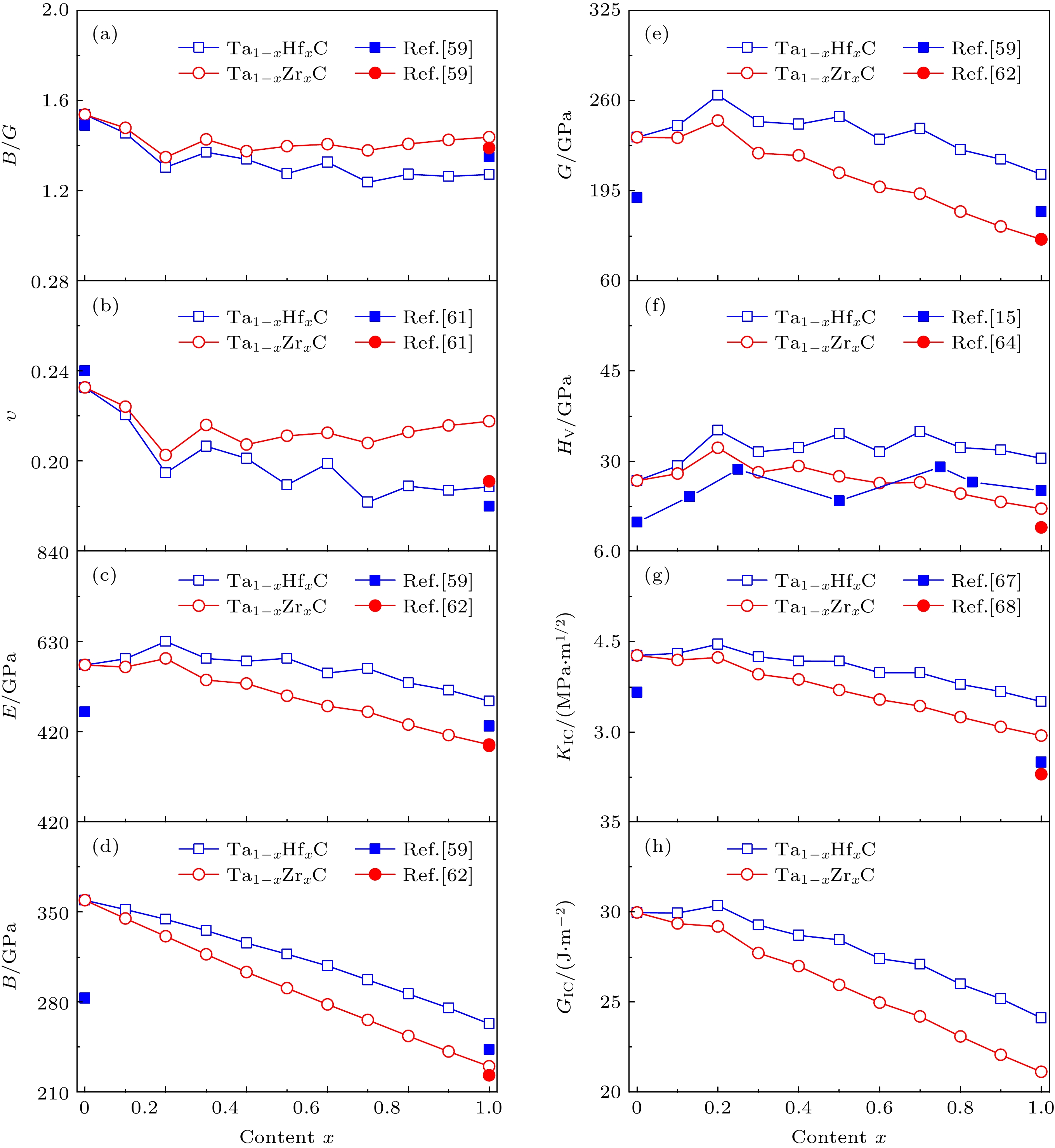

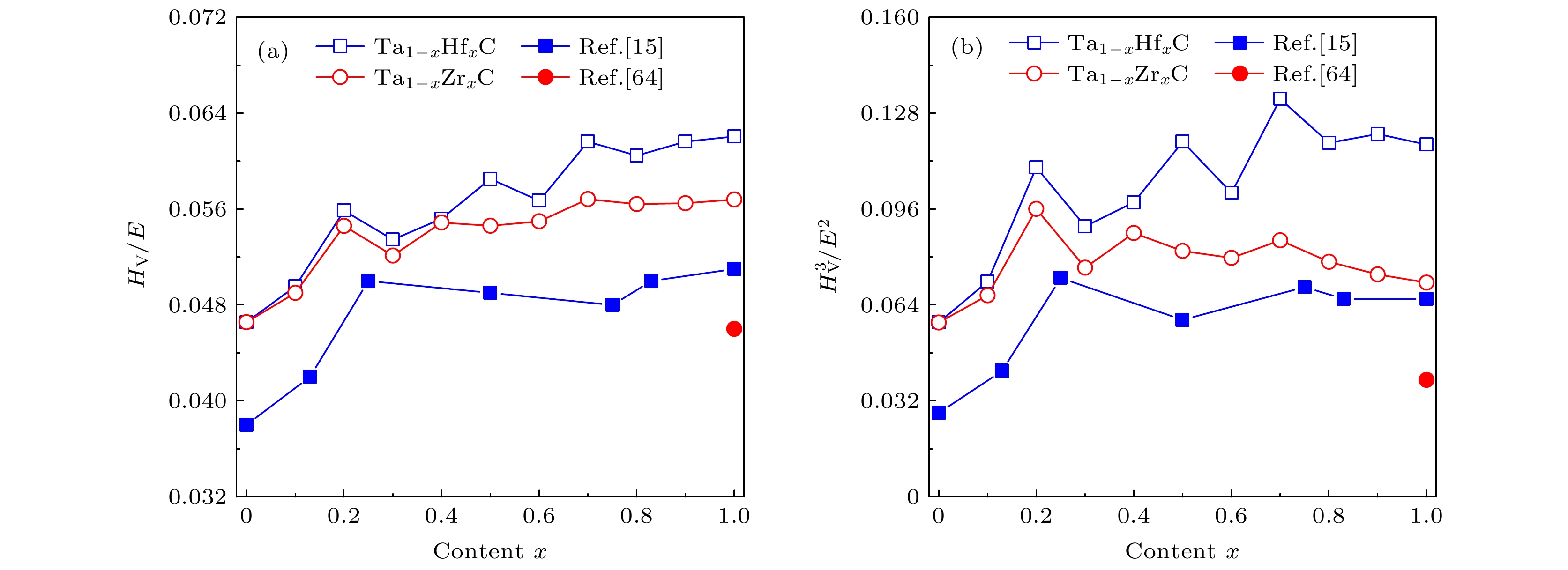

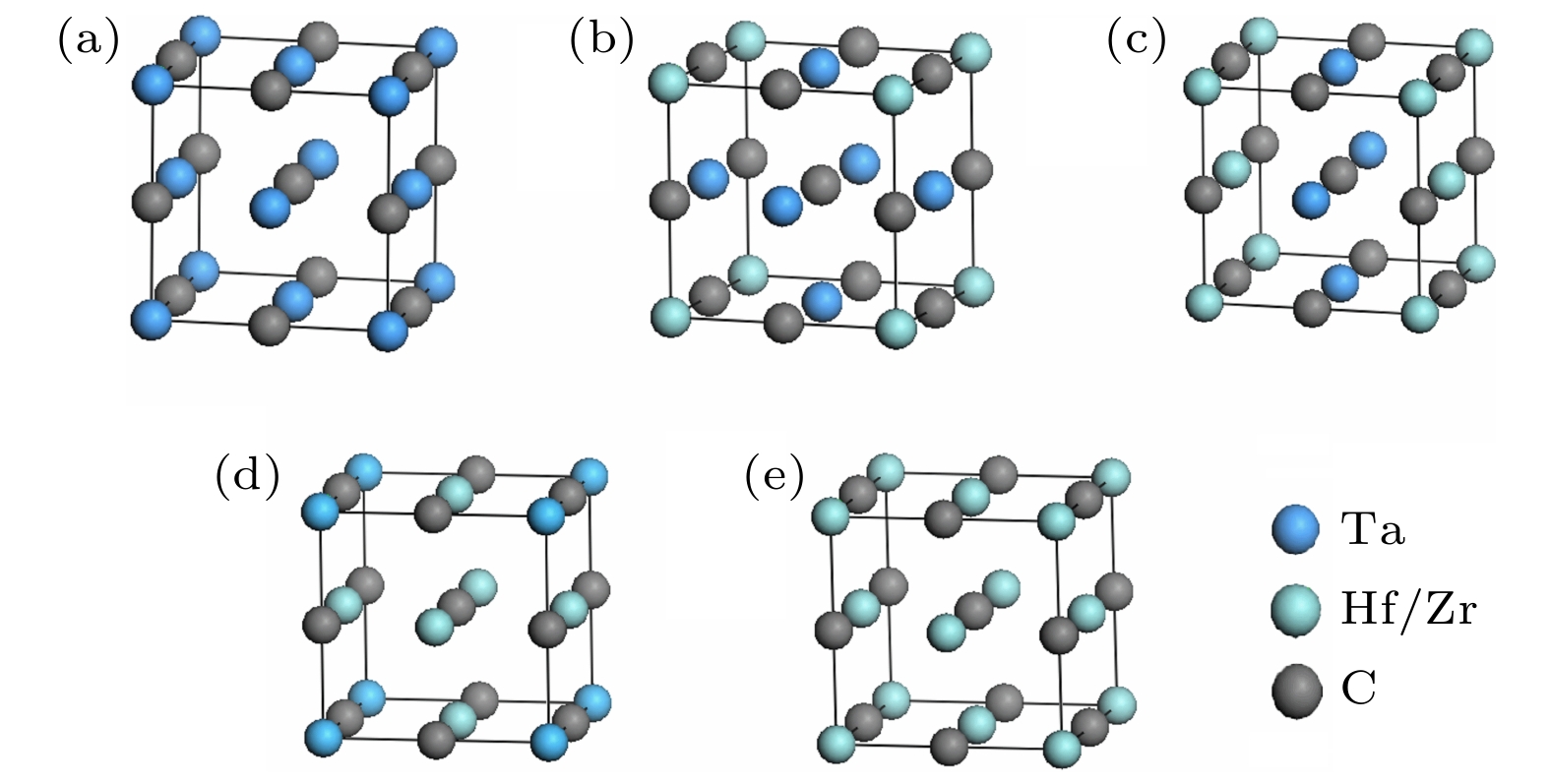

With the rapid development of the aerospace field, the harsh environment requires ultra-high temperature ceramic materials with better mechanical properties and ultra-high melting points. At present, the ultra-high temperature ceramic materials of single metal carbides are required more and more urgently. In order to solve the problem about the insufficient performance of transition metal single carbides, we systematically study the various physical properties of Ta1–xHfxC and Ta1–xZrxC solid solutions in an entire content range (0 ≤ x ≤ 1) based on density functional theory, including the formation energy, impurity formation energy, mixing energy, lattice parameters, elastic constants, elastic modulus, Vickers hardness, fracture toughness, wear resistance, melting point and electronic density of states. The results of formation energy show that with the increase of Hf and Zr doping concentration, the structural stability of Ta1–xHfxC and Ta1–xZrxC solid solutions gradually increase. And the structure of Ta1–xZrxC solid solution is more stable than that of Ta1–xHfxC solid solution when the doping content of Hf and Zr are the same. The results of mixing energy indicate that the formation of binary metal carbides from single metal carbides is an exothermic process. Furthermore, we also find that with the increase of Hf and Zr doping content, the lattice constant and volume of Ta1–xHfxC and Ta1–xZrxC solid solutions can expand, which is mainly attributed to the atomic radii of Hf and Zr being larger than the radius of Ta. The results of mechanical properties show that the Ta1–xHfxC and Ta1–xZrxC solid solution are brittle materials in the entire Hf/Zr content range and have mechanical stability. The bulk modulus of Ta1–xHfxC and Ta1–xZrxC solid solutions decrease with the increase of Hf and Zr content, while the melting point, Young's modulus, shear modulus, Vickers hardness and fracture toughness of Ta1–xHfxC and Ta1–xZrxC solid solutions have peaks with the doping content x = 0.2. Moreover, the addition of Hf/Zr can enhance the wear resistance of TaC. The results of the electronic density of states show that as the doping content increases, the density of states at the Fermi level of Ta1–xHfxC and Ta1–xZrxC solid solutions decrease, which also indicates that the solid solution structure becomes more and more stable.

-

Keywords:

- metal carbides /

- first-principles /

- mechanical properties /

- electronic structure

[1] Kurbatkina V V, Patsrea E I, Vorotilo S A, Levashov E A, Timofeev A N 2016 Ceram. Int. 42 16491

Google Scholar

Google Scholar

[2] Liu J X, Huang X, Zhang G J 2013 J. Am. Ceram. Soc. 96 1751

Google Scholar

Google Scholar

[3] Patsrea E I, Levashov E A, Kurbatkina V V, Kovalev D Y 2015 Ceram. Int. 41 8885

Google Scholar

Google Scholar

[4] Ghaffari S A, Faghihi-Sani M A, Golestani-Fard F, Mandal H 2013 J. Eur. Ceram. Soc. 33 1479

Google Scholar

Google Scholar

[5] Hao W, Ni N, Guo F W, Cao F C, Jiang J, Zhao X F, Xiao P 2019 J. Am. Ceram. Soc. 102 997

Google Scholar

Google Scholar

[6] Oyama S T 1996 The Chemistry of Transition Metal Carbides and Nitrides (Glasgow: Blackie Academic and Professional) pp1−27

[7] Pierson H O 1996 Handbook of Refractory Carbides and Nitrides (New Jersey: Noyes Publications) pp5−16

[8] Sciti D, Silvestroni L, Guicciardi S, Fabbriche D D, Bellosi A 2009 J. Mater. Res. 24 2056

Google Scholar

Google Scholar

[9] Jiang D Y, Wang Q L, Hu W, Wei Z Q, Tong J B, Wan H Q 2016 J. Mater. Res. 31 3401

Google Scholar

Google Scholar

[10] Adjaoud O, Steinle-Neumann G, Burton B P, Walle A 2009 Phys. Rev. B 80 134112

Google Scholar

Google Scholar

[11] Wang X G, Liu J X, Kan Y M, Zhang G J 2012 J. Eur. Ceram. Soc. 32 1795

Google Scholar

Google Scholar

[12] Simonenko E P, Ignatov N A, Simonenko N P, Ezhov Y S, Sevastyanov V G, Kuznetsov N T 2011 Russ. J. Inorg. Chem. 56 1681

Google Scholar

Google Scholar

[13] Agte C, Alterthum H 1930 Z. Tech. Physik 11 182

[14] Barraza O C, Grasso S, Nasiri N A, Jayaseelan D D, Reece M J, Lee W E 2016 J. Eur. Ceram. Soc. 36 1539

Google Scholar

Google Scholar

[15] Smith C J, Yu X, Guo Q, Weinberger C R 2018 Acta. Mater. 145 142

Google Scholar

Google Scholar

[16] Gladyshevsky E I, Fedorov T F, Gorshkova L V 1964 Russ. J. Inorg. Chem. 9 639

[17] Avgustinik A I, Ordan’yan S S 1966 Zh. Prikl. Kim. 39 318

[18] Rudy E 1969 Techn. Rep. AFML-TR 65 334

[19] Yate L, Coy L E, Aperador W 2017 Sci. Rep. 7 3080

Google Scholar

Google Scholar

[20] Segall M D, Lindan P L D, Probert M J, Pickard C J, Hasnip P J, Clark S J 2002 J. Phys. Condens. Matter 14 2717

Google Scholar

Google Scholar

[21] Milman V, Winkler B, White J A, Pickard C J, Payne M C, Akhmatskaya E V, Nobes R H 2000 Int. J. Quantum Chem. 77 895

Google Scholar

Google Scholar

[22] Li X, Chen X, Han L, Ruan C, Lu P, Guan P 2016 J. Mater. Res. 31 2956

Google Scholar

Google Scholar

[23] Sun S, Fu H, Lin J, Guo G, Lei Y, Wang R 2018 J. Mater. Res. 33 495

Google Scholar

Google Scholar

[24] Sun X W, Zhang X Y, Zhu Y Z, Zhang S H, Qin J Q, Ma M Z, Liu R P 2013 J. Mater. Sci. 48 7743

Google Scholar

Google Scholar

[25] Hamann D R 1989 Phys. Rev. B 40 2980

Google Scholar

Google Scholar

[26] Liu S Y, Liu S, Li D, Shen Y, Dang H, Liu Y, Xue W, Wang S 2014 J. Am. Ceram. Soc. 97 4019

Google Scholar

Google Scholar

[27] Liu S Y, Zhang E, Liu S, Li D J, Li Y, Liu Y, Shen Y, Wang S 2016 J. Am. Ceram. Soc. 99 3336

Google Scholar

Google Scholar

[28] Liu S Y, Meng Y, Liu S, Li D J, Li Y, Liu Y, Shen Y, Wang S 2017 J. Am. Ceram. Soc. 100 1221

Google Scholar

Google Scholar

[29] Liu S Y, Meng Y, Liu S, Li D J, Li Y, Liu Y, Shen Y, Wang S 2017 Phys. Chem. Chem. Phys. 19 22190

Google Scholar

Google Scholar

[30] Liu S Y, Chen Q Y, Liu S, Li D J, Li Y, Liu Y, Wang S 2018 J. Alloys Compd. 764 869

Google Scholar

Google Scholar

[31] Liu S Y, Yu D S, Lv Y K, Li D J, Li Y, Cao M S 2013 Chin. Phys. B 22 017702

Google Scholar

Google Scholar

[32] 邵庆生, 刘士余, 赵辉, 余大书, 曹茂盛 2012 61 047103

Google Scholar

Google Scholar

Shao Q S, Liu S Y, Zhao H, Yu D S, Cao M S 2012 Acta Phys. Sin. 61 047103

Google Scholar

Google Scholar

[33] 刘士余, 余大书, 吕跃凯, 李德军, 曹茂盛 2013 62 177102

Google Scholar

Google Scholar

Liu S Y, Yu D S, Lv Y K, Li D J, Cao M S 2013 Acta Phys. Sin. 62 177102

Google Scholar

Google Scholar

[34] Liu S Y, Shang J X, Wang F H, Zhang Y 2009 J. Phys. Condens. Matter. 21 225005

Google Scholar

Google Scholar

[35] 尚家香, 喻显扬 2008 57 2380

Google Scholar

Google Scholar

Shang J X, Yu X Y 2008 Acta Phys. Sin. 57 2380

Google Scholar

Google Scholar

[36] 尚家香, 于潭波 2009 58 1179

Google Scholar

Google Scholar

Shang J X, Yu X Y 2009 Acta Phys. Sin. 58 1179

Google Scholar

Google Scholar

[37] Voigt W 1928 Lehrbuch der Kristallophysik Teuber-Leipzig (New York: Macmillan Publishers)

[38] Reuss A 1929 Z. Angew. Math. Mech. 9 49

Google Scholar

Google Scholar

[39] Hill R 1952 Proc. Phys. Soc. A 65 349

Google Scholar

Google Scholar

[40] Yang J, Gao F M 2012 Physica B: Condens. Matter 407 3527

Google Scholar

Google Scholar

[41] Tian Y J, Xu B, Zhao Z H 2012 Int. J. Refract. Met. Hard. Mater 33 93

Google Scholar

Google Scholar

[42] Niu H Y, Niu S W, Oganov A R 2019 J. Appl. Phys. 125 065105

Google Scholar

Google Scholar

[43] Broek D 1982 Elementary Engineering Fracture Mechanics (3rd Ed.) (Netherlands: Martinus Nijhoff Publishers)

[44] Yan X L, Constantin L, Lu Y F, Silvain J F, Nastasi M, Cui B 2018 J. Am. Ceram. Soc. 101 4486

Google Scholar

Google Scholar

[45] Yu X X, Thompson G B, Weinberger C R 2015 J. Eur. Ceram. Soc. 35 95

Google Scholar

Google Scholar

[46] Wehr M R, Richards J A, Adair T W 1978 Physics of the Atom (Boston: Addison-Wesley Publishing Company)

[47] Ha D G, Kim J, Han J S, Kang S 2018 Ceram. Int. 44 19247

Google Scholar

Google Scholar

[48] Vorotilo S, Sidnov K, Mosyagin I Y, Khvan A V, Levashov E A, Patsera E I, Abrikosov I A 2019 J. Alloys Compd. 778 480

Google Scholar

Google Scholar

[49] Huang B, Duan Y H, Sun Y, Peng M J, Chen S 2015 J. Alloys Compd. 635 213

Google Scholar

Google Scholar

[50] Weber W 1973 Phys. Rev. B 8 5082

Google Scholar

Google Scholar

[51] Li H, Zhang L T, Zeng Q F, Guan K, Li K Y, Ren H T, Liu S H, Cheng L F 2011 Solid State Commun. 151 602

Google Scholar

Google Scholar

[52] Gautam G S, Hari Kumar K C 2014 J. Alloys. Compd. 587 380

Google Scholar

Google Scholar

[53] Fine M E, Brown L D, Marcus H L 1984 Scr. Metall. 18 951

Google Scholar

Google Scholar

[54] Huang H M, Jiang Z Y and Luo S J 2017 Chin. Phys. B 26 096301

Google Scholar

Google Scholar

[55] Fahrenholtz W G, Hilmas G E, Talmy I G, Zaykoski J A 2007 J. Am. Ceram. Soc. 90 1347

Google Scholar

Google Scholar

[56] Ionescu E I, Bernard S, Lucas R, Kroll P, Ushakov S, Navrotsky A, Riedel R 2019 Adv. Eng. Mater. 21 1900269

Google Scholar

Google Scholar

[57] Pugh S F 1954 Phiosl. Mag.J. Sci. 45 823

Google Scholar

Google Scholar

[58] Liu Y Z, Jiang Y H, Zhou R, Feng J 2014 J. Alloys Compd. 582 500

Google Scholar

Google Scholar

[59] Jiang X, Zhao J J, Jiang X 2011 Comput. Mater Sci. 50 2287

Google Scholar

Google Scholar

[60] Frantsevich I N, Voronov F F, Bokuta S A 1983 Elastic Constants and Elastic Moduli of Metals and Insulators (Kiev: Naukova Dumka) pp60−180

[61] Yadav D S, Verma J, Singh D P 2016 J. Pure Appl. Ind. Phys. 6 212

[62] Brown H L, Kempter C P 1966 Phys. Stat. Sol. 18 K21

Google Scholar

Google Scholar

[63] Zhang J, McMahon J M 2021 J. Mater Sci. 56 4266

Google Scholar

Google Scholar

[64] Feng L, Fahrenholtz W G, Hilmas G E, Watts J, Zhou Y 2019 J. Am. Ceram. Soc. 102 5786

Google Scholar

Google Scholar

[65] Valenccia D P, Yate L, Aperador W, Li Y G, Coy E 2018 J. Phys. Chem. C 122 25433

Google Scholar

Google Scholar

[66] Silvestroni L, Pienti L, Guicciardi S, Sciti D 2015 Compos. Part B Eng. 72 10

Google Scholar

Google Scholar

[67] He L F, Bao Y W, Wang J Y, Li M S, Zhou Y C 2009 Acta. Mater. 57 2765

Google Scholar

Google Scholar

[68] Leyland A, Matthews A 2000 Wear 246 1

Google Scholar

Google Scholar

[69] Carlsson A E 1990 Advances in Research and Applications (New York: Academic Press)

[70] Zhou J, Fu C L, Yoo M H, 1995 Phil. Mag. Lett. 71 45

Google Scholar

Google Scholar

[71] 李荣, 罗小玲, 梁国明, 付文升 2011 60 117105

Google Scholar

Google Scholar

Li R, Luo X L, Liang G M, Fu W S 2011 Acta Phys. Sin. 60 117105

Google Scholar

Google Scholar

[72] Laverntyev A A, Gabrelian B V, Vorzhev V B, Nikiforov I Y, Khyzhun O Y, Rehr J J 2008 J. Alloys Compd. 462 4

Google Scholar

Google Scholar

-

图 5 Ta1–xHfxC和Ta1–xZrxC固溶体的力学性质随Hf或Zr含量x的变化 (a) B/G比; (b)泊松比; (c) 杨氏模量; (d) 体积模量; (e) 剪切模量; (f) 维氏硬度; (g) 断裂韧性; (h) 临界能量释放率

Figure 5. The mechanical properties of Ta1–xHfxC and Ta1–xZrxC solid solutions as a function of the Hf/Zr content: (a) B/G ratio; (b) Poisson’s ratio; (c) Young’s modulus; (d) bulk modulus; (e) shear modulus; (f) Vickers hardness; (g) fracture toughness; (h) critical energy release rate.

-

[1] Kurbatkina V V, Patsrea E I, Vorotilo S A, Levashov E A, Timofeev A N 2016 Ceram. Int. 42 16491

Google Scholar

Google Scholar

[2] Liu J X, Huang X, Zhang G J 2013 J. Am. Ceram. Soc. 96 1751

Google Scholar

Google Scholar

[3] Patsrea E I, Levashov E A, Kurbatkina V V, Kovalev D Y 2015 Ceram. Int. 41 8885

Google Scholar

Google Scholar

[4] Ghaffari S A, Faghihi-Sani M A, Golestani-Fard F, Mandal H 2013 J. Eur. Ceram. Soc. 33 1479

Google Scholar

Google Scholar

[5] Hao W, Ni N, Guo F W, Cao F C, Jiang J, Zhao X F, Xiao P 2019 J. Am. Ceram. Soc. 102 997

Google Scholar

Google Scholar

[6] Oyama S T 1996 The Chemistry of Transition Metal Carbides and Nitrides (Glasgow: Blackie Academic and Professional) pp1−27

[7] Pierson H O 1996 Handbook of Refractory Carbides and Nitrides (New Jersey: Noyes Publications) pp5−16

[8] Sciti D, Silvestroni L, Guicciardi S, Fabbriche D D, Bellosi A 2009 J. Mater. Res. 24 2056

Google Scholar

Google Scholar

[9] Jiang D Y, Wang Q L, Hu W, Wei Z Q, Tong J B, Wan H Q 2016 J. Mater. Res. 31 3401

Google Scholar

Google Scholar

[10] Adjaoud O, Steinle-Neumann G, Burton B P, Walle A 2009 Phys. Rev. B 80 134112

Google Scholar

Google Scholar

[11] Wang X G, Liu J X, Kan Y M, Zhang G J 2012 J. Eur. Ceram. Soc. 32 1795

Google Scholar

Google Scholar

[12] Simonenko E P, Ignatov N A, Simonenko N P, Ezhov Y S, Sevastyanov V G, Kuznetsov N T 2011 Russ. J. Inorg. Chem. 56 1681

Google Scholar

Google Scholar

[13] Agte C, Alterthum H 1930 Z. Tech. Physik 11 182

[14] Barraza O C, Grasso S, Nasiri N A, Jayaseelan D D, Reece M J, Lee W E 2016 J. Eur. Ceram. Soc. 36 1539

Google Scholar

Google Scholar

[15] Smith C J, Yu X, Guo Q, Weinberger C R 2018 Acta. Mater. 145 142

Google Scholar

Google Scholar

[16] Gladyshevsky E I, Fedorov T F, Gorshkova L V 1964 Russ. J. Inorg. Chem. 9 639

[17] Avgustinik A I, Ordan’yan S S 1966 Zh. Prikl. Kim. 39 318

[18] Rudy E 1969 Techn. Rep. AFML-TR 65 334

[19] Yate L, Coy L E, Aperador W 2017 Sci. Rep. 7 3080

Google Scholar

Google Scholar

[20] Segall M D, Lindan P L D, Probert M J, Pickard C J, Hasnip P J, Clark S J 2002 J. Phys. Condens. Matter 14 2717

Google Scholar

Google Scholar

[21] Milman V, Winkler B, White J A, Pickard C J, Payne M C, Akhmatskaya E V, Nobes R H 2000 Int. J. Quantum Chem. 77 895

Google Scholar

Google Scholar

[22] Li X, Chen X, Han L, Ruan C, Lu P, Guan P 2016 J. Mater. Res. 31 2956

Google Scholar

Google Scholar

[23] Sun S, Fu H, Lin J, Guo G, Lei Y, Wang R 2018 J. Mater. Res. 33 495

Google Scholar

Google Scholar

[24] Sun X W, Zhang X Y, Zhu Y Z, Zhang S H, Qin J Q, Ma M Z, Liu R P 2013 J. Mater. Sci. 48 7743

Google Scholar

Google Scholar

[25] Hamann D R 1989 Phys. Rev. B 40 2980

Google Scholar

Google Scholar

[26] Liu S Y, Liu S, Li D, Shen Y, Dang H, Liu Y, Xue W, Wang S 2014 J. Am. Ceram. Soc. 97 4019

Google Scholar

Google Scholar

[27] Liu S Y, Zhang E, Liu S, Li D J, Li Y, Liu Y, Shen Y, Wang S 2016 J. Am. Ceram. Soc. 99 3336

Google Scholar

Google Scholar

[28] Liu S Y, Meng Y, Liu S, Li D J, Li Y, Liu Y, Shen Y, Wang S 2017 J. Am. Ceram. Soc. 100 1221

Google Scholar

Google Scholar

[29] Liu S Y, Meng Y, Liu S, Li D J, Li Y, Liu Y, Shen Y, Wang S 2017 Phys. Chem. Chem. Phys. 19 22190

Google Scholar

Google Scholar

[30] Liu S Y, Chen Q Y, Liu S, Li D J, Li Y, Liu Y, Wang S 2018 J. Alloys Compd. 764 869

Google Scholar

Google Scholar

[31] Liu S Y, Yu D S, Lv Y K, Li D J, Li Y, Cao M S 2013 Chin. Phys. B 22 017702

Google Scholar

Google Scholar

[32] 邵庆生, 刘士余, 赵辉, 余大书, 曹茂盛 2012 61 047103

Google Scholar

Google Scholar

Shao Q S, Liu S Y, Zhao H, Yu D S, Cao M S 2012 Acta Phys. Sin. 61 047103

Google Scholar

Google Scholar

[33] 刘士余, 余大书, 吕跃凯, 李德军, 曹茂盛 2013 62 177102

Google Scholar

Google Scholar

Liu S Y, Yu D S, Lv Y K, Li D J, Cao M S 2013 Acta Phys. Sin. 62 177102

Google Scholar

Google Scholar

[34] Liu S Y, Shang J X, Wang F H, Zhang Y 2009 J. Phys. Condens. Matter. 21 225005

Google Scholar

Google Scholar

[35] 尚家香, 喻显扬 2008 57 2380

Google Scholar

Google Scholar

Shang J X, Yu X Y 2008 Acta Phys. Sin. 57 2380

Google Scholar

Google Scholar

[36] 尚家香, 于潭波 2009 58 1179

Google Scholar

Google Scholar

Shang J X, Yu X Y 2009 Acta Phys. Sin. 58 1179

Google Scholar

Google Scholar

[37] Voigt W 1928 Lehrbuch der Kristallophysik Teuber-Leipzig (New York: Macmillan Publishers)

[38] Reuss A 1929 Z. Angew. Math. Mech. 9 49

Google Scholar

Google Scholar

[39] Hill R 1952 Proc. Phys. Soc. A 65 349

Google Scholar

Google Scholar

[40] Yang J, Gao F M 2012 Physica B: Condens. Matter 407 3527

Google Scholar

Google Scholar

[41] Tian Y J, Xu B, Zhao Z H 2012 Int. J. Refract. Met. Hard. Mater 33 93

Google Scholar

Google Scholar

[42] Niu H Y, Niu S W, Oganov A R 2019 J. Appl. Phys. 125 065105

Google Scholar

Google Scholar

[43] Broek D 1982 Elementary Engineering Fracture Mechanics (3rd Ed.) (Netherlands: Martinus Nijhoff Publishers)

[44] Yan X L, Constantin L, Lu Y F, Silvain J F, Nastasi M, Cui B 2018 J. Am. Ceram. Soc. 101 4486

Google Scholar

Google Scholar

[45] Yu X X, Thompson G B, Weinberger C R 2015 J. Eur. Ceram. Soc. 35 95

Google Scholar

Google Scholar

[46] Wehr M R, Richards J A, Adair T W 1978 Physics of the Atom (Boston: Addison-Wesley Publishing Company)

[47] Ha D G, Kim J, Han J S, Kang S 2018 Ceram. Int. 44 19247

Google Scholar

Google Scholar

[48] Vorotilo S, Sidnov K, Mosyagin I Y, Khvan A V, Levashov E A, Patsera E I, Abrikosov I A 2019 J. Alloys Compd. 778 480

Google Scholar

Google Scholar

[49] Huang B, Duan Y H, Sun Y, Peng M J, Chen S 2015 J. Alloys Compd. 635 213

Google Scholar

Google Scholar

[50] Weber W 1973 Phys. Rev. B 8 5082

Google Scholar

Google Scholar

[51] Li H, Zhang L T, Zeng Q F, Guan K, Li K Y, Ren H T, Liu S H, Cheng L F 2011 Solid State Commun. 151 602

Google Scholar

Google Scholar

[52] Gautam G S, Hari Kumar K C 2014 J. Alloys. Compd. 587 380

Google Scholar

Google Scholar

[53] Fine M E, Brown L D, Marcus H L 1984 Scr. Metall. 18 951

Google Scholar

Google Scholar

[54] Huang H M, Jiang Z Y and Luo S J 2017 Chin. Phys. B 26 096301

Google Scholar

Google Scholar

[55] Fahrenholtz W G, Hilmas G E, Talmy I G, Zaykoski J A 2007 J. Am. Ceram. Soc. 90 1347

Google Scholar

Google Scholar

[56] Ionescu E I, Bernard S, Lucas R, Kroll P, Ushakov S, Navrotsky A, Riedel R 2019 Adv. Eng. Mater. 21 1900269

Google Scholar

Google Scholar

[57] Pugh S F 1954 Phiosl. Mag.J. Sci. 45 823

Google Scholar

Google Scholar

[58] Liu Y Z, Jiang Y H, Zhou R, Feng J 2014 J. Alloys Compd. 582 500

Google Scholar

Google Scholar

[59] Jiang X, Zhao J J, Jiang X 2011 Comput. Mater Sci. 50 2287

Google Scholar

Google Scholar

[60] Frantsevich I N, Voronov F F, Bokuta S A 1983 Elastic Constants and Elastic Moduli of Metals and Insulators (Kiev: Naukova Dumka) pp60−180

[61] Yadav D S, Verma J, Singh D P 2016 J. Pure Appl. Ind. Phys. 6 212

[62] Brown H L, Kempter C P 1966 Phys. Stat. Sol. 18 K21

Google Scholar

Google Scholar

[63] Zhang J, McMahon J M 2021 J. Mater Sci. 56 4266

Google Scholar

Google Scholar

[64] Feng L, Fahrenholtz W G, Hilmas G E, Watts J, Zhou Y 2019 J. Am. Ceram. Soc. 102 5786

Google Scholar

Google Scholar

[65] Valenccia D P, Yate L, Aperador W, Li Y G, Coy E 2018 J. Phys. Chem. C 122 25433

Google Scholar

Google Scholar

[66] Silvestroni L, Pienti L, Guicciardi S, Sciti D 2015 Compos. Part B Eng. 72 10

Google Scholar

Google Scholar

[67] He L F, Bao Y W, Wang J Y, Li M S, Zhou Y C 2009 Acta. Mater. 57 2765

Google Scholar

Google Scholar

[68] Leyland A, Matthews A 2000 Wear 246 1

Google Scholar

Google Scholar

[69] Carlsson A E 1990 Advances in Research and Applications (New York: Academic Press)

[70] Zhou J, Fu C L, Yoo M H, 1995 Phil. Mag. Lett. 71 45

Google Scholar

Google Scholar

[71] 李荣, 罗小玲, 梁国明, 付文升 2011 60 117105

Google Scholar

Google Scholar

Li R, Luo X L, Liang G M, Fu W S 2011 Acta Phys. Sin. 60 117105

Google Scholar

Google Scholar

[72] Laverntyev A A, Gabrelian B V, Vorzhev V B, Nikiforov I Y, Khyzhun O Y, Rehr J J 2008 J. Alloys Compd. 462 4

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 9015

- PDF Downloads: 167

- Cited By: 0

DownLoad:

DownLoad: