-

Transparent conductive films (TCFs) play an indispensable role in optoelectronic devices because of their high conductivity and high optical transmittance. In order to obtain indium-free transparent conductive films with better performance, we need to improve the conductivity, while not damaging the transmittance. Metal mesh is highly conductive but prone to oxidation and abrasion, while transparent conductive oxide (TCO) is stable but less conductive. Thus, we composite the metal mesh with the stable TCO to achieve complementary advantages. In this work, we fabricate a hexagonal Cu mesh and then cover the Cu mesh with Al-doped ZnO (AZO) film by using lithography and magnetron sputtering. The line width and length of mesh are 15 µm and 150 µm, respectively, which are not visible to the naked eye. The effect of AZO growth temperature on the properties of such AZO/Cu mesh composite film is studied and the optimal temperature is 300 ℃. By designing the mesh and optimizing the process, the transmittance (400–800 nm), sheet resistance and FoM of AZO/ Cu mesh composite film reach 86.4%, 4.9 Ω/sq and 4.73 × 10–2 Ω–1, respectively, thus possessing both transparent and conductive property. Because of its low cost, competitive optoelectronic performance and stability, the potential applications of AZO/Cu mesh composite film in transparent electronics are fantastic. When used as a transparent conductor to connect LED to 3 V DC power, the luminance of LED in series with AZO/Cu mesh composite film is lighter than that of AZO film and Cu mesh. According to the Ohmic heating effect of electric current passing through a conductor, AZO/Cu mesh composite film can be designed as electric heating film. At low voltage safe for human body, AZO/Cu mesh composite film can implement fast, uniform and stabile heat. In the cyclic electric heating test, the AZO/Cu mesh composite film can be heated rapidly to 175 ℃ all the time, showing a fast temperature response and stable cyclic performance. More importantly, the AZO is itself transparent and conductive and prevents the metal from oxidizing effectively, thus ensuring the overall performance and maintaining the electric heating response. The experimental result and simulation application show that the AZO/Cu mesh composite film has a great potential application in transparent and heating film for defogging and defrosting glass.

-

Keywords:

- ZnO /

- metal mesh /

- transparent conductive film /

- electric heating film

[1] 刘宏燕, 颜悦, 望咏林, 伍建华, 张官理, 厉蕾 2015 航空材料学报 35 63

Google Scholar

Google Scholar

Liu H Y, Yan Y, Wang Y L, Wu J H, Zhang G L, Li L 2015 J. Aeronautical Mater. 35 63

Google Scholar

Google Scholar

[2] 刘世丽, 辛智青, 李修, 方一, 李亚玲, 莫黎昕, 李路海 2015 功能材料与器件学报 21 13

Liu S L, Xin Z Q, Li X, Fang Y, Li Y L, Mo L X, Li L H 2015 J. Functional Mater. Dev. 21 13

[3] 杨桢林, 费纯纯, 成程, 张宏梅 2019 发光学报 40 238

Google Scholar

Google Scholar

Yang Z L, Fei C C, Cheng C, Zhang H M 2019 Chin. J. Luminescence 40 238

Google Scholar

Google Scholar

[4] Hautcoeur J, Colombel F, Himdi M, Castel X, Cruz E M 2013 IEEE Antennas Wirel. Propag. Lett. 12 933

Google Scholar

Google Scholar

[5] Zhao Z Y, Xia K Q, Hou Y, Zhang Q H, Ye Z Z, Lu J G 2021 Chem. Soc. Rev. 50 12702

Google Scholar

Google Scholar

[6] Bel Hadj Tahar R, Ban T, Ohya Y, Takahashi Y 1998 J. Appl. Phys. 83 2631

Google Scholar

Google Scholar

[7] 廖亚琴, 李愿杰, 黄添懋 2014 东方电气评论 28 13

Google Scholar

Google Scholar

Liao Y Q, Li Y J, Huang T M 2014 Dongfang Electric. Review 28 13

Google Scholar

Google Scholar

[8] Lu J G, Fujita S, Kawaharamura T, Nishinaka H, Kamada Y, Ohshima T, Ye Z Z, Zeng Y J, Zhang Y Z, Zhu L P, He H P, Zhao B H 2007 J. Appl. Phys. 101 083705

Google Scholar

Google Scholar

[9] Lu J G, Ye Z Z, Zeng Y J, Zhu L P, Wang L, Yuan J, Zhao B H, Liang Q L 2006 J. Appl. Phys. 100 073714

Google Scholar

Google Scholar

[10] 李佳, 杨晔, 朱科, 魏铁锋, 王木钦, 朱超挺, 宋伟杰 2015 中国科学: 技术科学 45 941

Google Scholar

Google Scholar

Li J, Yang Y, Zhu K, Wei T F, Wang M Q, Zhu C T, Song W J 2015 Sci. Sin. Technol. 45 941

Google Scholar

Google Scholar

[11] Jiang Q J, Lu J G, Yuan Y L, Cai H, Zhang J, Deng N, Ye Z Z 2014 Mater. Lett. 123 14

Google Scholar

Google Scholar

[12] Gong L, Lu J, Ye Z 2011 Thin Solid Films 519 3870

Google Scholar

Google Scholar

[13] Wang Y P, Lu J G, Bie X, Ye Z Z, Li X, Song D, Zhao X Y, Ye W Y 2011 Appl. Surf. Sci. 257 5966

Google Scholar

Google Scholar

[14] Qin L H, Yan Y Q, Yu G, Zhang Z Y, Zhama T, Sun H 2021 Materials (Basel) 14 4097

Google Scholar

Google Scholar

[15] Catrysse P B, Fan S 2010 Nano Lett. 10 2944

Google Scholar

Google Scholar

[16] Afshinmanesh F, Curto A G, Milaninia K M, van Hulst N F, Brongersma M L 2014 Nano Lett. 14 5068

Google Scholar

Google Scholar

[17] Jang C, Jiang Q J, Lu J G, Ye Z Z 2015 J. Mater. Sci. Technol. 31 1108

Google Scholar

Google Scholar

[18] Khan A, Lee S, Jang T, Xiong Z, Zhang C, Tang J, Guo L J, Li W D 2016 Small 12 3021

Google Scholar

Google Scholar

[19] Liu W, Fang Y, Xu Y F, Li X, Li L H 2014 Sci. China Tech. Sci. 57 2536

Google Scholar

Google Scholar

[20] Choi K H, Kim J Y, Lee Y S, Kim H J 1999 Thin Solid Films 341 152

Google Scholar

Google Scholar

[21] 杨田林, 张之圣, 宋淑梅, 李延辉, 吕茂水, 韩圣浩, 庞智勇 2009 太阳能学报 30 1209

Google Scholar

Google Scholar

Yang T L, Zhang Z S, Song S M, Li Y H, Lv M S, Han S H, Pang Z Y 2009 Acta Energiae Solaris Sinica 30 1209

Google Scholar

Google Scholar

[22] Wang Y P, Lu J G, Bie X, Gong L, Li X, Song D, Zhao X Y, Ye W Y, Ye Z Z 2011 J. Vac. Sci. Technol. A 29 031505

Google Scholar

Google Scholar

[23] Sahu D R, Huang J L 2007 Microelectron. J. 38 299

Google Scholar

Google Scholar

[24] Chen Z, Li W, Li R, Zhang Y, Xu G, Cheng H 2013 Langmuir 29 13836

Google Scholar

Google Scholar

[25] Tran N H, Duong T H, Kim H C 2017 Sci. Rep. 7 15093

Google Scholar

Google Scholar

[26] Jiu J, Nogi M, Sugahara T, Tokuno T, Araki T, Komoda N, Suganuma K, Uchida H, Shinozaki K 2012 J. Mater. Chem. 22 23561

Google Scholar

Google Scholar

[27] Li L, Fan Q, Xue H, Zhang S, Wu S, He Z, Wang J 2020 Rsc Adv. 10 9894

Google Scholar

Google Scholar

[28] Zhu C, Tan R, Song W, Ouyang B, Cai M, Zhou S, Lu Y, Li N 2018 Mater. Res. Express. 5 066427

Google Scholar

Google Scholar

[29] Zhou W X, Chen J, Li Y, Wang D B, Chen J Y, Feng X M, Huang Z D, Liu R Q, Lin X J, Zhang H M, Mi B X, Ma Y W 2016 ACS Appl. Mater. Interfaces 8 11122

Google Scholar

Google Scholar

[30] Kang J, Kim H, Kim K S, Lee S K, Bae S, Ahn J H, Kim Y J, Choi J B, Hong B H 2011 Nano Lett. 11 5154

Google Scholar

Google Scholar

[31] Kim Y, Lee H R, Saito T, Nishi Y 2017 Appl. Phys. Lett. 110 153301

Google Scholar

Google Scholar

[32] Vosgueritchian M, Lipomi D J, Bao Z 2012 Adv. Funct. Mater. 22 421

Google Scholar

Google Scholar

[33] Kim Y H, Sachse C, Machala M L, May C, Müller-Meskamp L, Leo K 2011 Adv. Funct. Mater. 21 1076

Google Scholar

Google Scholar

[34] Li H, Liu Y, Su A, Wang J, Duan Y 2019 Sci. Rep. 9 17998

Google Scholar

Google Scholar

[35] Kim T H, Choi B H, Park J S, Lee S M, Lee Y S, Park L S 2010 Mol. Cryst. Liq. Cryst. 520 485

Google Scholar

Google Scholar

[36] Acosta M, Mendez-Gamboa J, Riech I, Acosta C, Zambrano M 2019 Superlattices Microstruct. 127 49

Google Scholar

Google Scholar

-

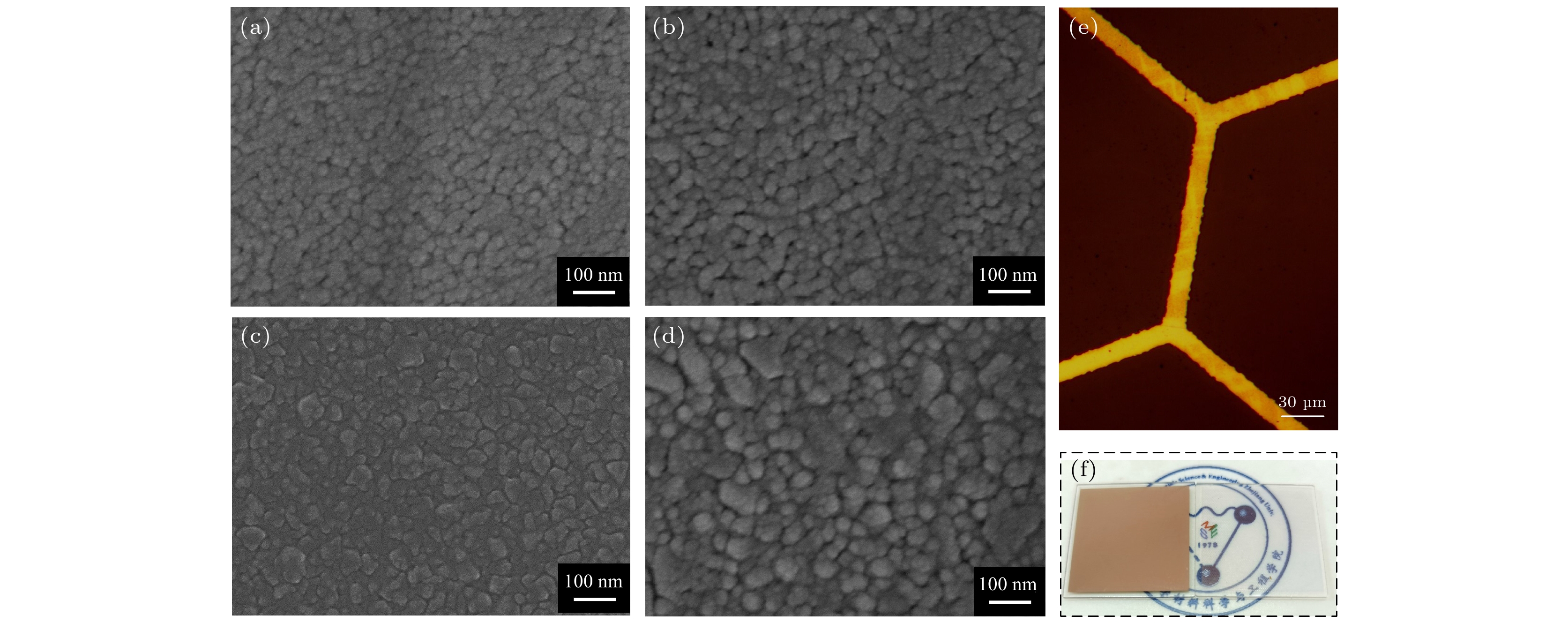

图 3 在(a) 100 ℃, (b) 200 ℃, (c) 300 ℃, (d) 400 ℃生长AZO后制备的AZO/Cu网格复合膜的SEM图; 300 ℃生长AZO后制备的AZO/Cu网格复合膜的(e)光学显微镜图和(f)照片

Figure 3. SEM images of AZO/Cu mesh composite films deposited at different AZO growth temperatures of (a) 100 ℃, (b) 200 ℃, (c) 300 ℃, (d) 400 ℃; (e) microscope image and (f) photo of AZO/Cu mesh composite film when AZO is grown at 300 ℃.

图 4 (a) AZO/Cu网格复合膜的电阻率、霍尔迁移率、载流子浓度与AZO生长温度的关系; (b) AZO/Cu网格复合膜的透射光谱 (AZO生长温度为300 ℃); (c) AZO/Cu网格复合膜的平均透过率(400—800 nm)、品质因数与AZO生长温度的关系; (d) 现有TCFs的性能对比

Figure 4. (a) Resistivity, Hall mobility and carrier concentrations of AZO/Cu mesh composite films as a function of AZO growth temperatures; (b) transmission spectrum of AZO/Cu mesh composite film (AZO is grown at 300 ℃); (c) average transmittance (400–800 nm) and FoM of AZO/Cu mesh composite film as a function of AZO growth temperatures; (d) performance comparison of TCFs.

图 6 红外相机拍摄AZO/Cu网格复合膜表面温度分布的(a)装置图及所得到的(b)红外热分布图; AZO/Cu网格复合膜与单层Cu网格、单层AZO膜在5 V下的(c)温度响应和(d)循环性能

Figure 6. (a) Measurement setup and (b) the thermal radiation of AZO/Cu mesh composite film measured with an infrared camera; (c) temperature response and (d) cyclic performance of AZO/Cu mesh composite film, Cu mesh and AZO film at 5 V.

-

[1] 刘宏燕, 颜悦, 望咏林, 伍建华, 张官理, 厉蕾 2015 航空材料学报 35 63

Google Scholar

Google Scholar

Liu H Y, Yan Y, Wang Y L, Wu J H, Zhang G L, Li L 2015 J. Aeronautical Mater. 35 63

Google Scholar

Google Scholar

[2] 刘世丽, 辛智青, 李修, 方一, 李亚玲, 莫黎昕, 李路海 2015 功能材料与器件学报 21 13

Liu S L, Xin Z Q, Li X, Fang Y, Li Y L, Mo L X, Li L H 2015 J. Functional Mater. Dev. 21 13

[3] 杨桢林, 费纯纯, 成程, 张宏梅 2019 发光学报 40 238

Google Scholar

Google Scholar

Yang Z L, Fei C C, Cheng C, Zhang H M 2019 Chin. J. Luminescence 40 238

Google Scholar

Google Scholar

[4] Hautcoeur J, Colombel F, Himdi M, Castel X, Cruz E M 2013 IEEE Antennas Wirel. Propag. Lett. 12 933

Google Scholar

Google Scholar

[5] Zhao Z Y, Xia K Q, Hou Y, Zhang Q H, Ye Z Z, Lu J G 2021 Chem. Soc. Rev. 50 12702

Google Scholar

Google Scholar

[6] Bel Hadj Tahar R, Ban T, Ohya Y, Takahashi Y 1998 J. Appl. Phys. 83 2631

Google Scholar

Google Scholar

[7] 廖亚琴, 李愿杰, 黄添懋 2014 东方电气评论 28 13

Google Scholar

Google Scholar

Liao Y Q, Li Y J, Huang T M 2014 Dongfang Electric. Review 28 13

Google Scholar

Google Scholar

[8] Lu J G, Fujita S, Kawaharamura T, Nishinaka H, Kamada Y, Ohshima T, Ye Z Z, Zeng Y J, Zhang Y Z, Zhu L P, He H P, Zhao B H 2007 J. Appl. Phys. 101 083705

Google Scholar

Google Scholar

[9] Lu J G, Ye Z Z, Zeng Y J, Zhu L P, Wang L, Yuan J, Zhao B H, Liang Q L 2006 J. Appl. Phys. 100 073714

Google Scholar

Google Scholar

[10] 李佳, 杨晔, 朱科, 魏铁锋, 王木钦, 朱超挺, 宋伟杰 2015 中国科学: 技术科学 45 941

Google Scholar

Google Scholar

Li J, Yang Y, Zhu K, Wei T F, Wang M Q, Zhu C T, Song W J 2015 Sci. Sin. Technol. 45 941

Google Scholar

Google Scholar

[11] Jiang Q J, Lu J G, Yuan Y L, Cai H, Zhang J, Deng N, Ye Z Z 2014 Mater. Lett. 123 14

Google Scholar

Google Scholar

[12] Gong L, Lu J, Ye Z 2011 Thin Solid Films 519 3870

Google Scholar

Google Scholar

[13] Wang Y P, Lu J G, Bie X, Ye Z Z, Li X, Song D, Zhao X Y, Ye W Y 2011 Appl. Surf. Sci. 257 5966

Google Scholar

Google Scholar

[14] Qin L H, Yan Y Q, Yu G, Zhang Z Y, Zhama T, Sun H 2021 Materials (Basel) 14 4097

Google Scholar

Google Scholar

[15] Catrysse P B, Fan S 2010 Nano Lett. 10 2944

Google Scholar

Google Scholar

[16] Afshinmanesh F, Curto A G, Milaninia K M, van Hulst N F, Brongersma M L 2014 Nano Lett. 14 5068

Google Scholar

Google Scholar

[17] Jang C, Jiang Q J, Lu J G, Ye Z Z 2015 J. Mater. Sci. Technol. 31 1108

Google Scholar

Google Scholar

[18] Khan A, Lee S, Jang T, Xiong Z, Zhang C, Tang J, Guo L J, Li W D 2016 Small 12 3021

Google Scholar

Google Scholar

[19] Liu W, Fang Y, Xu Y F, Li X, Li L H 2014 Sci. China Tech. Sci. 57 2536

Google Scholar

Google Scholar

[20] Choi K H, Kim J Y, Lee Y S, Kim H J 1999 Thin Solid Films 341 152

Google Scholar

Google Scholar

[21] 杨田林, 张之圣, 宋淑梅, 李延辉, 吕茂水, 韩圣浩, 庞智勇 2009 太阳能学报 30 1209

Google Scholar

Google Scholar

Yang T L, Zhang Z S, Song S M, Li Y H, Lv M S, Han S H, Pang Z Y 2009 Acta Energiae Solaris Sinica 30 1209

Google Scholar

Google Scholar

[22] Wang Y P, Lu J G, Bie X, Gong L, Li X, Song D, Zhao X Y, Ye W Y, Ye Z Z 2011 J. Vac. Sci. Technol. A 29 031505

Google Scholar

Google Scholar

[23] Sahu D R, Huang J L 2007 Microelectron. J. 38 299

Google Scholar

Google Scholar

[24] Chen Z, Li W, Li R, Zhang Y, Xu G, Cheng H 2013 Langmuir 29 13836

Google Scholar

Google Scholar

[25] Tran N H, Duong T H, Kim H C 2017 Sci. Rep. 7 15093

Google Scholar

Google Scholar

[26] Jiu J, Nogi M, Sugahara T, Tokuno T, Araki T, Komoda N, Suganuma K, Uchida H, Shinozaki K 2012 J. Mater. Chem. 22 23561

Google Scholar

Google Scholar

[27] Li L, Fan Q, Xue H, Zhang S, Wu S, He Z, Wang J 2020 Rsc Adv. 10 9894

Google Scholar

Google Scholar

[28] Zhu C, Tan R, Song W, Ouyang B, Cai M, Zhou S, Lu Y, Li N 2018 Mater. Res. Express. 5 066427

Google Scholar

Google Scholar

[29] Zhou W X, Chen J, Li Y, Wang D B, Chen J Y, Feng X M, Huang Z D, Liu R Q, Lin X J, Zhang H M, Mi B X, Ma Y W 2016 ACS Appl. Mater. Interfaces 8 11122

Google Scholar

Google Scholar

[30] Kang J, Kim H, Kim K S, Lee S K, Bae S, Ahn J H, Kim Y J, Choi J B, Hong B H 2011 Nano Lett. 11 5154

Google Scholar

Google Scholar

[31] Kim Y, Lee H R, Saito T, Nishi Y 2017 Appl. Phys. Lett. 110 153301

Google Scholar

Google Scholar

[32] Vosgueritchian M, Lipomi D J, Bao Z 2012 Adv. Funct. Mater. 22 421

Google Scholar

Google Scholar

[33] Kim Y H, Sachse C, Machala M L, May C, Müller-Meskamp L, Leo K 2011 Adv. Funct. Mater. 21 1076

Google Scholar

Google Scholar

[34] Li H, Liu Y, Su A, Wang J, Duan Y 2019 Sci. Rep. 9 17998

Google Scholar

Google Scholar

[35] Kim T H, Choi B H, Park J S, Lee S M, Lee Y S, Park L S 2010 Mol. Cryst. Liq. Cryst. 520 485

Google Scholar

Google Scholar

[36] Acosta M, Mendez-Gamboa J, Riech I, Acosta C, Zambrano M 2019 Superlattices Microstruct. 127 49

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7242

- PDF Downloads: 141

- Cited By: 0

DownLoad:

DownLoad: