-

In this study, we find new AgyIn3.33–y/3Se5 compounds in Ag-In-Se system by static diffusion method combined with common X-ray diffraction and backscattering electron analysis. The crystal structure belongs to the trilateral system with the P3m1 space group, which features a two-dimensional layered structure. The unit cell is composed of 9-atom quantum layers arranged in the sequence of Se1-In1-Se2-In2-Se3-Ag/In3-Se4-In4-Se5, and in-between these layers are bonded by the weak van der Waals force. The sintered bulk samples show highly anisotropic transport properties and have an ultra-low lattice thermal conductivity along the direction parallel to sintering pressure about 0.15 W·m–1·K–1 at 873 K. The intrinsically ultra-low lattice thermal conductivity mainly comes from low phonon velocity and the strong coupling between low frequency optical phonon and acoustic phonons. The AgyIn3.33–y/3Se5 compounds behave as an n-type conduction. The electrical conductivity is 4×104 S·m–1 and the Seebeck coefficient is –80 μV·K–1 at room temperature. Therefore, AgyIn3.33–y/3Se5 compounds show high electrical transport properties in a wide temperature range, and the power factor is around 5 μW·cm–1·K–2 in a range of 450–800 K. Owing to the ultra-low lattice thermal conductivity along the direction parallel to sintering pressure, Ag0.407In3.198Se5 reaches a maximum ZT of 1.01 at 873 K and an average ZT of 0.45 at 300–850 K. The discovery of AgyIn3.33–y/3Se5 expands the n-type copper based chalcogenide and lays an important foundation for the application of copper based chalcogenide.

-

Keywords:

- Ag-In-Se based compounds /

- two-dimensional layered structure /

- ultralow lattice thermal conductivity /

- thermoelectric properties

[1] Qin B, Wang D, Liu X, Qin Y, Dong J-F, Luo J, Li J-W, Liu W, Tan G, Tang X, Li J F, He J, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[2] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[3] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, Wang B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[4] Su X, Wei P, Li H, Liu W, Yan Y, Li P, Su C, Xie C, Zhao W, Zhai P, Zhang Q, Tang X, Uher C 2017 Adv. Mater. 29 23

Google Scholar

Google Scholar

[5] Deng R, Su X, Hao S, Zheng Z, Zhang M, Xie H, Liu W, Yan Y, Wolverton C, Uher C, Kanatzidis M G, Tang X 2018 Energy Environ. Sci. 11 1520

Google Scholar

Google Scholar

[6] Tao Q, Deng R, Li J, Yan Y, Su X, Poudeu P F P, Tang X 2020 ACS Appl. Mater. Interfaces 12 26330

Google Scholar

Google Scholar

[7] Tang X, Li Z, Liu W, Zhang Q, Uher C 2022 Interdiscip. Mater. 1 88

Google Scholar

Google Scholar

[8] Chen Z G, Shi X, Zhao L-D, Zou J 2018 Prog. Mater. Sci. 97 283

Google Scholar

Google Scholar

[9] Mangavati S, Pal A, Rao A, Jiang Z Z, Kuo Y K 2022 J. Phys. Chem. Solids. 160 110301

Google Scholar

Google Scholar

[10] Zhao X, Ning S, Qi N, Li Y, Dong Y, Zhang H, Liu J, Ye B, Chen Z 2021 ACS Appl. Mater. Interfaces 13 58936

Google Scholar

Google Scholar

[11] Zhang J, Zhu T, Zhang C, Yan Y, Tan G, Liu W, Su X, Tang X 2021 J. Alloy. Compd. 881 160639

Google Scholar

Google Scholar

[12] Zhang Q, Ti Z, Zhu Y, Zhang Y, Cao Y, Li S, Wang M, Li D, Zou B, Hou Y, Wang P, Tang G 2021 ACS Nano. 15 19345

Google Scholar

Google Scholar

[13] Zhang R, Pei J, Shan Z, Zhou W, Wu Y, Han Z, Zhao Y H, Li J F, Ge Z H, Zhang B P 2022 Chem. Eng. J. 429 132275

Google Scholar

Google Scholar

[14] 杨枭, 苏贤礼, 鄢永高, 唐新峰 2021 无机材料学报 36 75

Google Scholar

Google Scholar

Yang X, Su X L, Yan Y G, Tang X F 2021 J. Inorg. Mater. 36 75

Google Scholar

Google Scholar

[15] Cao Y, Bai H, Li Z, Zhang Z, Tang Y, Su X, Wu J, Tang X 2021 ACS Appl. Mater. Interfaces 13 43134

Google Scholar

Google Scholar

[16] Su X, Hao S, Bailey T P, Wang S, Hadar I, Tan G, Song T B, Zhang Q, Uher C, Wolverton C, Tang X, Kanatzidis M G 2018 Adv. Energy Mater. 8 1800659

Google Scholar

Google Scholar

[17] 杨东旺, 罗婷婷, 苏贤礼, 吴劲松, 唐新峰 2021 无机材料学报 36 991

Google Scholar

Google Scholar

Yang D W, Luo T T, Su X L, Wu J S, Tang X F 2021 J. Inorg. Mater. 36 991

Google Scholar

Google Scholar

[18] Cai S, Hao S, Luo Y, Su X, Luo Z-Z, Hu X, Wolverton C, Dravid V P, Kanatzidis M G 2020 Chem. Mater. 32 3561

Google Scholar

Google Scholar

[19] Ma N, Li F, Li J G, Liu X, Zhang D B, Li Y Y, Chen L, Wu L M 2021 J. Am. Chem. Soc. 143 18490

Google Scholar

Google Scholar

[20] Xia Y, Ozolins V, Wolverton C 2020 Phys. Rev. Lett. 125 085901

Google Scholar

Google Scholar

[21] Chen X, Carrete J, Sullivan S, van Roekeghem A, Li Z, Li X, Zhou J, Mingo N, Shi L 2019 Phys. Rev. Lett. 122 185901

Google Scholar

Google Scholar

[22] Zhang H, Liu H, Wei K, Kurakevych O O, Le Godec Y, Liu Z, Martin J, Guerrette M, Nolas G S, Strobel T A 2017 Phys. Rev. Lett. 118 146601

Google Scholar

Google Scholar

[23] Ren W, Geng H, Zhang Z, Zhang L 2017 Phys. Rev. Lett. 118 245901

Google Scholar

Google Scholar

[24] He J, Amsler M, Xia Y, Naghavi S S, Hegde V I, Hao S, Goedecker S, Ozolins V, Wolverton C 2016 Phys. Rev. Lett. 117 046602

Google Scholar

Google Scholar

[25] Cao Y, Su X, Meng F, Bailey T P, Zhao J, Xie H, He J, Uher C, Tang X 2020 Adv. Funct. Mater. 30 2005861

Google Scholar

Google Scholar

[26] Su X, Zhao N, Hao S, Stoumpos C C, Liu M, Chen H, Xie H, Zhang Q, Wolverton C, Tang X, Kanatzidis M G 2018 Adv. Funct. Mater. 29 1806534

Google Scholar

Google Scholar

[27] Shen X, Wang G, Li S, Yang C C, Tan H, Zhang Y, Lu X, He J, Wang G, Zhou X 2019 J. Alloy. Compd. 805 444

Google Scholar

Google Scholar

[28] Shen X, Shaheen N, Zhang A, Yang D, Yao W, Wang G, Lu X, Zhou X 2017 RSC Advances 7 12719

Google Scholar

Google Scholar

[29] Panda R, Naik R, Mishra N C 2019 J. Alloy. Compd. 778 819

Google Scholar

Google Scholar

[30] Shen X, Zhang B, Chen Q, Tan H, Zhang X, Wang G, Lu X, Zhou X 2019 Inorg. Chem. Front. 6 3545

Google Scholar

Google Scholar

[31] Ying P Z, Zhou H, Gao Y L, Li Y Y, Li Y P, Lian X L, Cui J L 2012 Key Eng. Mater. 519 188

Google Scholar

Google Scholar

[32] Xie H, Hao S, Cai S, Bailey T P, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2020 Energy Environ. Sci. 13 3693

Google Scholar

Google Scholar

[33] Xie H, Hao S, Bailey T P, Cai S, Zhang Y, Slade T J, Snyder G J, Dravid V P, Uher C, Wolverton C, Kanatzidis M G 2021 J. Am. Chem. Soc. 143 5978

Google Scholar

Google Scholar

[34] Zhu Y, Wei B, Liu J, Koocher N Z, Li Y, Hu L, He W, Deng G, Xu W, Wang X, Rondinelli J M, Zhao L-D, Snyder G J, Hong J 2021 Mater. Today Phys. 19 100428

Google Scholar

Google Scholar

[35] Qiu P, Qin Y, Zhang Q, Li R, Yang J, Song Q, Tang Y, Bai S, Shi X, Chen L 2018 Adv. Sci. 5 1700727

Google Scholar

Google Scholar

[36] 骆军, 何世洋, 李志立, 李永博, 王风, 张继业 2019 无机材料学报 34 247

Google Scholar

Google Scholar

Luo J, He S Y, Li Z L, Li Y B, Wang F, Zhang J Y 2019 J. Inorg. Mater. 34 247

Google Scholar

Google Scholar

[37] Deng T, Xing T, Brod M K, Sheng Y, Qiu P, Veremchuk I, Song Q, Wei T-R, Yang J, Snyder G J, Grin Y, Chen L, Shi X 2020 Energy Environ. Sci. 13 3041

Google Scholar

Google Scholar

[38] Aikebaier Y, Kurosaki K, Sugahara T, Ohishi Y, Muta H, Yamanaka S 2012 M. S. E.: B 177 999

[39] Yang N, Chen C, Pan L, Zhao Y, Wang Y 2020 J. Alloy. Compd. 847 156410

Google Scholar

Google Scholar

[40] Zhong Y, Luo Y, Li X, Cui J 2020 Appl. Energ. Mater. 3 12468

Google Scholar

Google Scholar

[41] Ying P, Li X, Wang Y, Yang J, Fu C, Zhang W, Zhao X, Zhu T 2017 Adv. Funct. Mater. 27 188

Google Scholar

Google Scholar

[42] Xie H, Su X, Zhang X, Hao S, Bailey T P, Stoumpos C C, Douvalis A P, Hu X, Wolverton C, Dravid V P, Uher C, Tang X, Kanatzidis M G 2019 J. Am. Chem. Soc. 141 10905

Google Scholar

Google Scholar

[43] Li Y, Li Z, Zhang C, Yang D, Liu T, Yan Y, Liu W, Tan G, Su X, Uher C, Tang X 2019 Mater. Today Phys. 9 10905

Google Scholar

Google Scholar

[44] Zhu Y, Liu Y, Wood M, Koocher N Z, Liu Y, Liu L, Hu T, Rondinelli J M, Hong J, Snyder G J, Xu W 2019 Chem. Mater. 31 8182

Google Scholar

Google Scholar

-

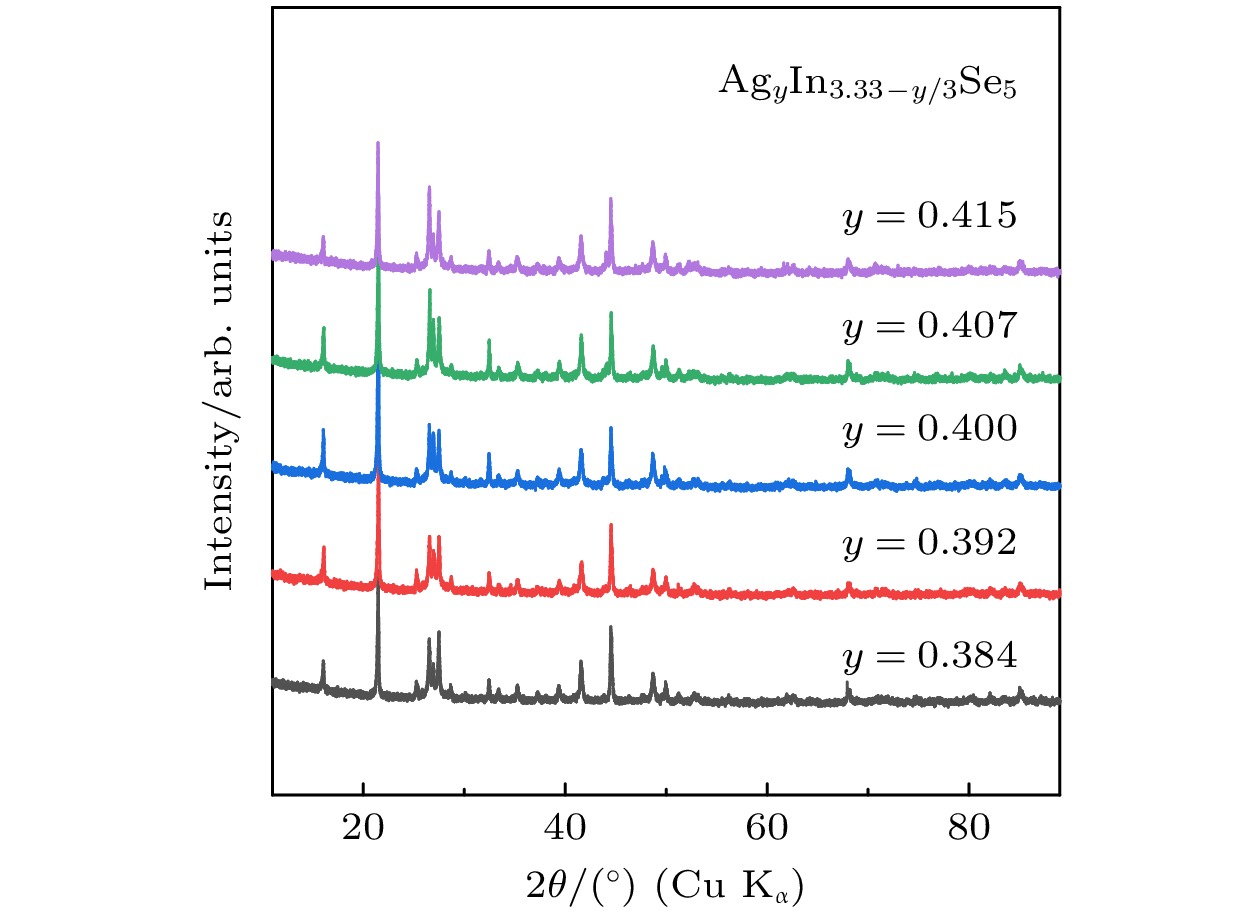

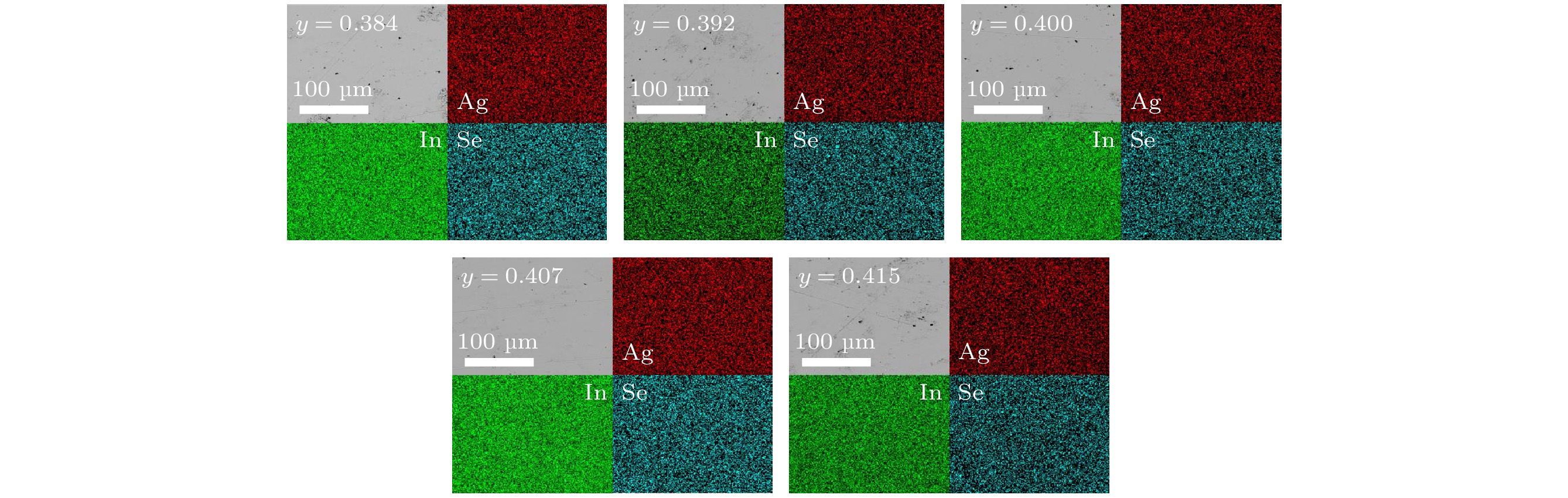

图 2 (a) (Ag2Se)x(In2Se3)100–x (x = 0—20)的粉末XRD图谱; (b) x = 0, 3.3, 5.3, 10.9, 13.6和16的背散射图片; (c) 所合成x = 0, 3.3, 5.3, 8.3, 10.9, 13.6和16的样品不同衬度区域电子能谱组成Ag/In比, 紫色虚线为合成样品名义组成线, 红色圆圈标出的为单相组成

Figure 2. (a) Powder XRD pattern of (Ag2Se)x(In2Se3)100–x (x = 0–20); (b) backscattering electron (BSE) image of the samples with x = 0, 3.3, 5.3, 10.9, 13.6 and 16; (c) the ratio of Ag/In in x = 0, 3.3, 5.3, 8.3, 10.9, 13.6 and 16, the purple dotted line is the nominal composition line, and the red circle is marked as single-phase composition.

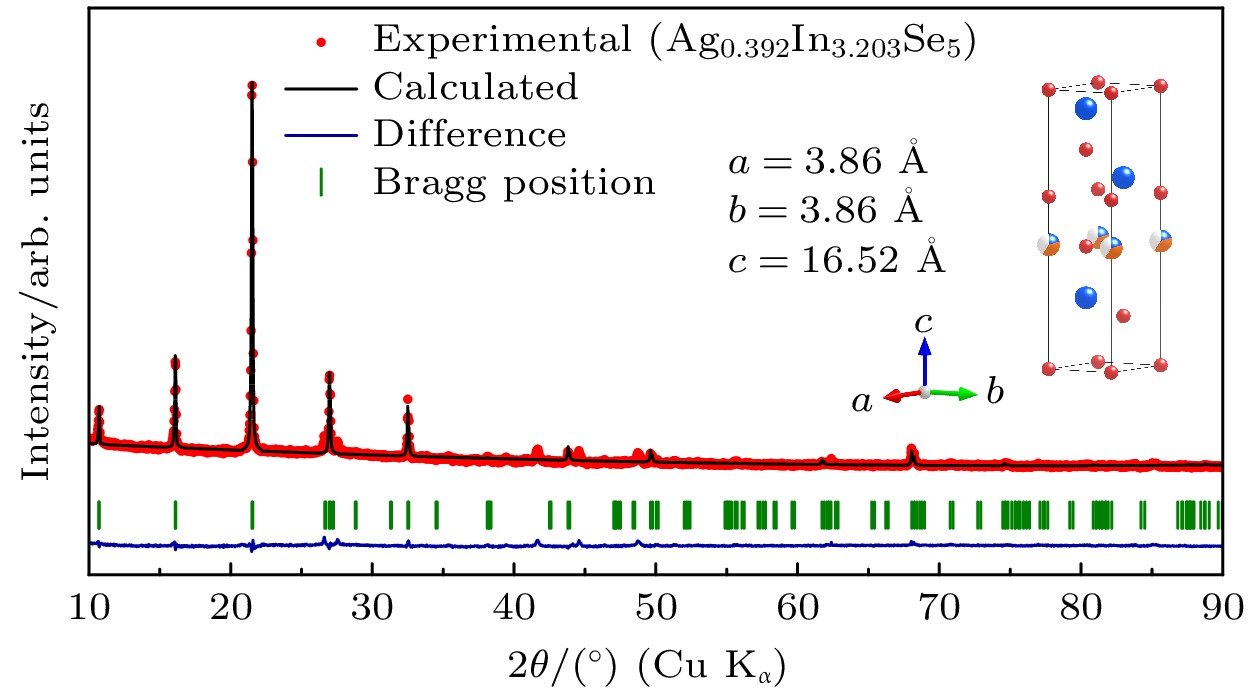

图 3 (Ag2Se)x(In2Se3)100–x (x = 10.9)样品的慢扫XRD(红色)(10°—90°), 精修得到的衍射峰(黑色), Bragg 峰位 (绿色), 衍射峰的差异(蓝色), Rp = 6.84%, Rwp = 9.31%.

Figure 3. Rietveld refinement of (Ag2Se)x(In2Se3)100–x (x = 10.9), experimental (red point), calculated (black), Bragg position (green), defference (blue) Rp = 6.84%, Rwp = 9.31%.

图 7 Ag0.392In3.203Se5 样品的微观图像 (a) [001]晶向的高倍高角度环形暗场像(HAADF-STEM); (b) 图(a)区域的选取电子衍射(SAED)和模拟的选取电子衍射(SAED); (c) [010] 晶向的高倍高角度环形暗场像(HAADF-STEM); (d) 图(c)区域的选取电子衍射(SAED)和模拟的选取电子衍射(SAED); (e), (f) 图(c)的染色放大图

Figure 7. Microstructure of Ag0.392In3.203Se5: (a) High-magnification HAADF-STEM image along the [001]; (b) SAED pattern and calculation of (a); (c) high-magnification HAADF-STEM image along the [010]; (d) SAED pattern and calculation of (c); (e), (f) enlarged image of Fig.7 (c).

图 8 AgyIn3.33–y/3Se5 (y = 0.384, 0.392, 0.400, 0.407, 0.415)电输运性能 (a) 电导率; (b) 赛贝克系数; (c) 功率因子; (d) 单抛带模型计算载流子有效质量

Figure 8. Temperature dependences of (a) the electrical conductivity, (b) Seebeck coefficient, and (c) power factor for the AgyIn3.33–y/3Se5 (y = 0.384, 0.392, 0.400, 0.407, 0.415) samples; (d) Seebeck coefficients as a function of the charge carrier concentration at 300 K, where the dashed lines are Pisarenko plots based on the SPB model.

图 9 AgyIn3.33–y/3Se5 (y = 0.384, 0.392, 0.400, 0.407, 0.415) 热输运性能和热电优值 (a) 热导率; (b) AgyIn3.33–y/3Se5 与AgInSe2[35], AgInTe2[38], AgIn5Se8[30]和CuInSe2[39]的晶格热导率; (c) AgyIn3.33–y/3Se5, AgInSe2[35], AgIn5Se8[30], Ag1.03In5Se8[30], Ag0.9Cd0.1InSe8[35], Ag1.02InSe2[35], Ag1.6InSe2.3[40]的ZT值, 300—873 K; (d) 300—850 K的平均ZTavg值

Figure 9. (a) The temperature-dependent of the total thermal conductivity for AgyIn3.33–y/3Se5; (b) the lattice thermal conductivity for AgyIn3.33–y/3Se5, AgInSe2[35], AgInTe2[38], AgIn5Se8[30] and CuInSe2[39]; (c) merit ZT for AgyIn3.33–y/3Se5, AgInSe2[35], AgIn5Se8[30], Ag1.03In5Se8[30], Ag0.9Cd0.1InSe8[35], Ag1.02InSe2[35], Ag1.6InSe2.3[40], at 300-873 K; (d) the average ZT at 300–850 K.

表 1 AgyIn3.33–y/3Se5样品的室温载流子浓度和迁移率

Table 1. The carrier concentration and Hall mobility of AgyIn3.33–y/3Se5 at room temperature.

Sample y = 0.384 y = 0.392 y = 0.400 y = 0.407 y = 0.415 μH / (cm2·V–1·s–1) 136.42 141.21 144.80 131.40 130.69 nH /(1019 cm–3) 1.88 1.70 1.68 1.93 1.85 表 2 Ag0.392In0.203Se5样品使用德拜-爱因斯坦模型拟合低温热容的参数

Table 2. Parameters obtained by fitting the experimental low-temperature heat capacity data to the Debye-Einstein model of Ag0.392In0.203Se5.

Sample γ/

(mJ·mol–1·K–2)b/

(mJ·mol–1·K–4)A1 θE1/K A2 θE1/K θD/K y = 0.392 0.02813 2.95 × 10–4 13.43 40.18 57.01 82.63 164 表 3 Ag0.392In0.203Se5, AgInSe2[44]和AgIn5Se8[30]的室温杨氏模量E、格林艾森常数常数γ对比

Table 3. Comparisons of Elastic properties and Grüneisen parameters at room temperature between Ag0.392In0.203Se5, AgInSe2[44], and AgIn5Se8[30].

Parameter Ag0.392In3.203Se5 AgInSe2 AgIn5Se8 vl/(m·s–1) 3058 3584 3778 vs/(m·s–1) 1527 1530 1803 va/(m·s–1) 1713 1729 2028 E /GPa 35.0 52.5 50.6 γ 2.00 2.87 2.20 -

[1] Qin B, Wang D, Liu X, Qin Y, Dong J-F, Luo J, Li J-W, Liu W, Tan G, Tang X, Li J F, He J, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[2] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[3] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, Wang B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[4] Su X, Wei P, Li H, Liu W, Yan Y, Li P, Su C, Xie C, Zhao W, Zhai P, Zhang Q, Tang X, Uher C 2017 Adv. Mater. 29 23

Google Scholar

Google Scholar

[5] Deng R, Su X, Hao S, Zheng Z, Zhang M, Xie H, Liu W, Yan Y, Wolverton C, Uher C, Kanatzidis M G, Tang X 2018 Energy Environ. Sci. 11 1520

Google Scholar

Google Scholar

[6] Tao Q, Deng R, Li J, Yan Y, Su X, Poudeu P F P, Tang X 2020 ACS Appl. Mater. Interfaces 12 26330

Google Scholar

Google Scholar

[7] Tang X, Li Z, Liu W, Zhang Q, Uher C 2022 Interdiscip. Mater. 1 88

Google Scholar

Google Scholar

[8] Chen Z G, Shi X, Zhao L-D, Zou J 2018 Prog. Mater. Sci. 97 283

Google Scholar

Google Scholar

[9] Mangavati S, Pal A, Rao A, Jiang Z Z, Kuo Y K 2022 J. Phys. Chem. Solids. 160 110301

Google Scholar

Google Scholar

[10] Zhao X, Ning S, Qi N, Li Y, Dong Y, Zhang H, Liu J, Ye B, Chen Z 2021 ACS Appl. Mater. Interfaces 13 58936

Google Scholar

Google Scholar

[11] Zhang J, Zhu T, Zhang C, Yan Y, Tan G, Liu W, Su X, Tang X 2021 J. Alloy. Compd. 881 160639

Google Scholar

Google Scholar

[12] Zhang Q, Ti Z, Zhu Y, Zhang Y, Cao Y, Li S, Wang M, Li D, Zou B, Hou Y, Wang P, Tang G 2021 ACS Nano. 15 19345

Google Scholar

Google Scholar

[13] Zhang R, Pei J, Shan Z, Zhou W, Wu Y, Han Z, Zhao Y H, Li J F, Ge Z H, Zhang B P 2022 Chem. Eng. J. 429 132275

Google Scholar

Google Scholar

[14] 杨枭, 苏贤礼, 鄢永高, 唐新峰 2021 无机材料学报 36 75

Google Scholar

Google Scholar

Yang X, Su X L, Yan Y G, Tang X F 2021 J. Inorg. Mater. 36 75

Google Scholar

Google Scholar

[15] Cao Y, Bai H, Li Z, Zhang Z, Tang Y, Su X, Wu J, Tang X 2021 ACS Appl. Mater. Interfaces 13 43134

Google Scholar

Google Scholar

[16] Su X, Hao S, Bailey T P, Wang S, Hadar I, Tan G, Song T B, Zhang Q, Uher C, Wolverton C, Tang X, Kanatzidis M G 2018 Adv. Energy Mater. 8 1800659

Google Scholar

Google Scholar

[17] 杨东旺, 罗婷婷, 苏贤礼, 吴劲松, 唐新峰 2021 无机材料学报 36 991

Google Scholar

Google Scholar

Yang D W, Luo T T, Su X L, Wu J S, Tang X F 2021 J. Inorg. Mater. 36 991

Google Scholar

Google Scholar

[18] Cai S, Hao S, Luo Y, Su X, Luo Z-Z, Hu X, Wolverton C, Dravid V P, Kanatzidis M G 2020 Chem. Mater. 32 3561

Google Scholar

Google Scholar

[19] Ma N, Li F, Li J G, Liu X, Zhang D B, Li Y Y, Chen L, Wu L M 2021 J. Am. Chem. Soc. 143 18490

Google Scholar

Google Scholar

[20] Xia Y, Ozolins V, Wolverton C 2020 Phys. Rev. Lett. 125 085901

Google Scholar

Google Scholar

[21] Chen X, Carrete J, Sullivan S, van Roekeghem A, Li Z, Li X, Zhou J, Mingo N, Shi L 2019 Phys. Rev. Lett. 122 185901

Google Scholar

Google Scholar

[22] Zhang H, Liu H, Wei K, Kurakevych O O, Le Godec Y, Liu Z, Martin J, Guerrette M, Nolas G S, Strobel T A 2017 Phys. Rev. Lett. 118 146601

Google Scholar

Google Scholar

[23] Ren W, Geng H, Zhang Z, Zhang L 2017 Phys. Rev. Lett. 118 245901

Google Scholar

Google Scholar

[24] He J, Amsler M, Xia Y, Naghavi S S, Hegde V I, Hao S, Goedecker S, Ozolins V, Wolverton C 2016 Phys. Rev. Lett. 117 046602

Google Scholar

Google Scholar

[25] Cao Y, Su X, Meng F, Bailey T P, Zhao J, Xie H, He J, Uher C, Tang X 2020 Adv. Funct. Mater. 30 2005861

Google Scholar

Google Scholar

[26] Su X, Zhao N, Hao S, Stoumpos C C, Liu M, Chen H, Xie H, Zhang Q, Wolverton C, Tang X, Kanatzidis M G 2018 Adv. Funct. Mater. 29 1806534

Google Scholar

Google Scholar

[27] Shen X, Wang G, Li S, Yang C C, Tan H, Zhang Y, Lu X, He J, Wang G, Zhou X 2019 J. Alloy. Compd. 805 444

Google Scholar

Google Scholar

[28] Shen X, Shaheen N, Zhang A, Yang D, Yao W, Wang G, Lu X, Zhou X 2017 RSC Advances 7 12719

Google Scholar

Google Scholar

[29] Panda R, Naik R, Mishra N C 2019 J. Alloy. Compd. 778 819

Google Scholar

Google Scholar

[30] Shen X, Zhang B, Chen Q, Tan H, Zhang X, Wang G, Lu X, Zhou X 2019 Inorg. Chem. Front. 6 3545

Google Scholar

Google Scholar

[31] Ying P Z, Zhou H, Gao Y L, Li Y Y, Li Y P, Lian X L, Cui J L 2012 Key Eng. Mater. 519 188

Google Scholar

Google Scholar

[32] Xie H, Hao S, Cai S, Bailey T P, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2020 Energy Environ. Sci. 13 3693

Google Scholar

Google Scholar

[33] Xie H, Hao S, Bailey T P, Cai S, Zhang Y, Slade T J, Snyder G J, Dravid V P, Uher C, Wolverton C, Kanatzidis M G 2021 J. Am. Chem. Soc. 143 5978

Google Scholar

Google Scholar

[34] Zhu Y, Wei B, Liu J, Koocher N Z, Li Y, Hu L, He W, Deng G, Xu W, Wang X, Rondinelli J M, Zhao L-D, Snyder G J, Hong J 2021 Mater. Today Phys. 19 100428

Google Scholar

Google Scholar

[35] Qiu P, Qin Y, Zhang Q, Li R, Yang J, Song Q, Tang Y, Bai S, Shi X, Chen L 2018 Adv. Sci. 5 1700727

Google Scholar

Google Scholar

[36] 骆军, 何世洋, 李志立, 李永博, 王风, 张继业 2019 无机材料学报 34 247

Google Scholar

Google Scholar

Luo J, He S Y, Li Z L, Li Y B, Wang F, Zhang J Y 2019 J. Inorg. Mater. 34 247

Google Scholar

Google Scholar

[37] Deng T, Xing T, Brod M K, Sheng Y, Qiu P, Veremchuk I, Song Q, Wei T-R, Yang J, Snyder G J, Grin Y, Chen L, Shi X 2020 Energy Environ. Sci. 13 3041

Google Scholar

Google Scholar

[38] Aikebaier Y, Kurosaki K, Sugahara T, Ohishi Y, Muta H, Yamanaka S 2012 M. S. E.: B 177 999

[39] Yang N, Chen C, Pan L, Zhao Y, Wang Y 2020 J. Alloy. Compd. 847 156410

Google Scholar

Google Scholar

[40] Zhong Y, Luo Y, Li X, Cui J 2020 Appl. Energ. Mater. 3 12468

Google Scholar

Google Scholar

[41] Ying P, Li X, Wang Y, Yang J, Fu C, Zhang W, Zhao X, Zhu T 2017 Adv. Funct. Mater. 27 188

Google Scholar

Google Scholar

[42] Xie H, Su X, Zhang X, Hao S, Bailey T P, Stoumpos C C, Douvalis A P, Hu X, Wolverton C, Dravid V P, Uher C, Tang X, Kanatzidis M G 2019 J. Am. Chem. Soc. 141 10905

Google Scholar

Google Scholar

[43] Li Y, Li Z, Zhang C, Yang D, Liu T, Yan Y, Liu W, Tan G, Su X, Uher C, Tang X 2019 Mater. Today Phys. 9 10905

Google Scholar

Google Scholar

[44] Zhu Y, Liu Y, Wood M, Koocher N Z, Liu Y, Liu L, Hu T, Rondinelli J M, Hong J, Snyder G J, Xu W 2019 Chem. Mater. 31 8182

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6832

- PDF Downloads: 105

- Cited By: 0

DownLoad:

DownLoad: