-

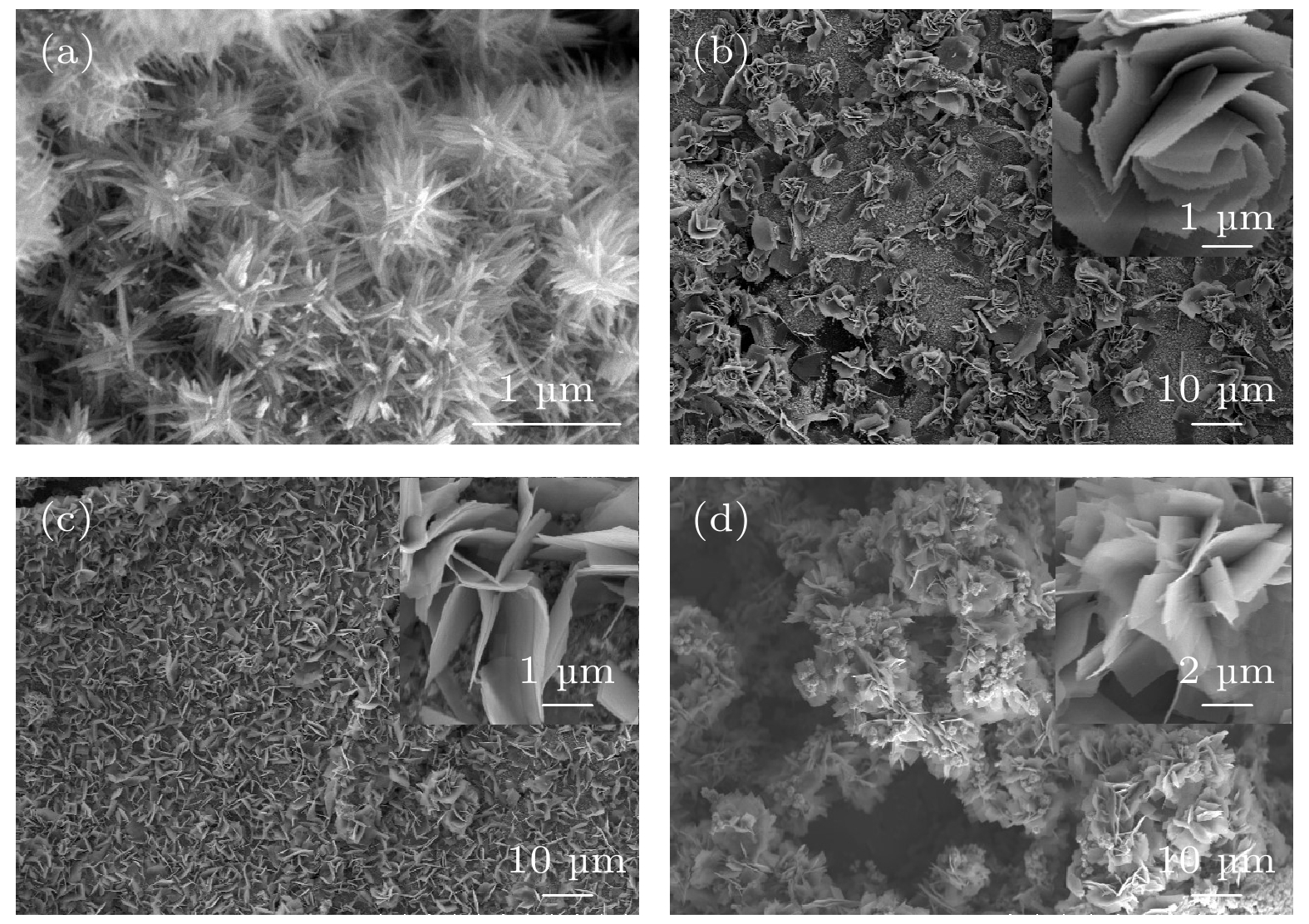

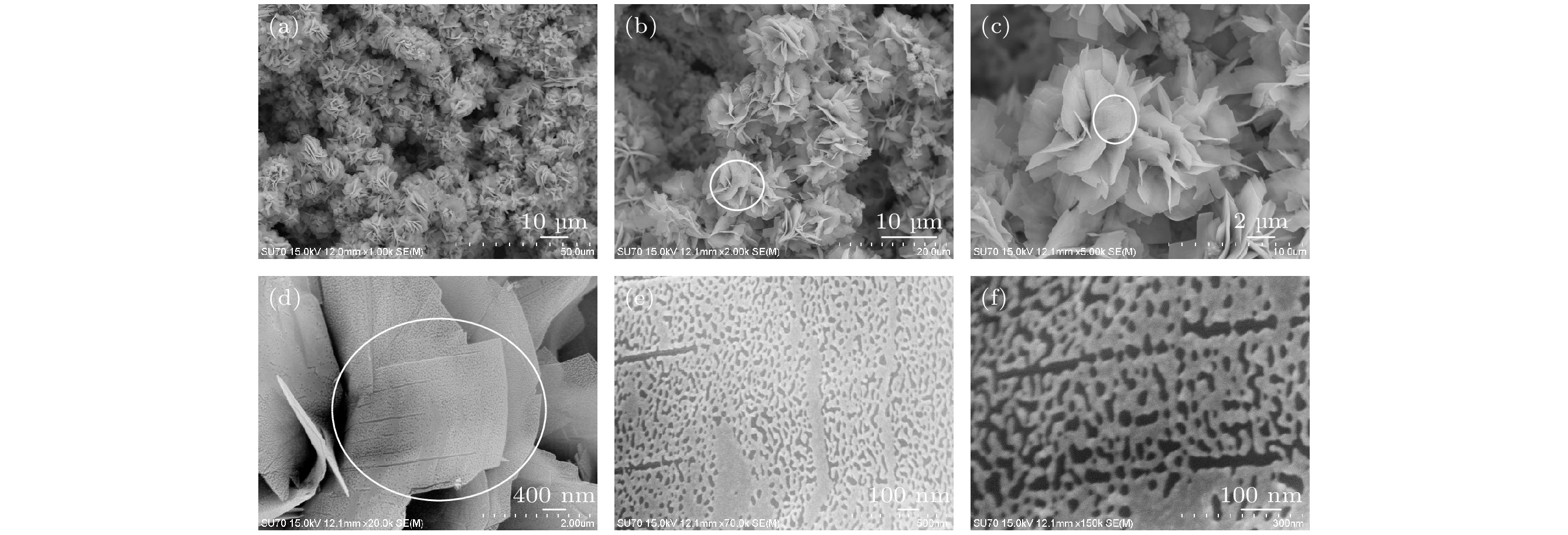

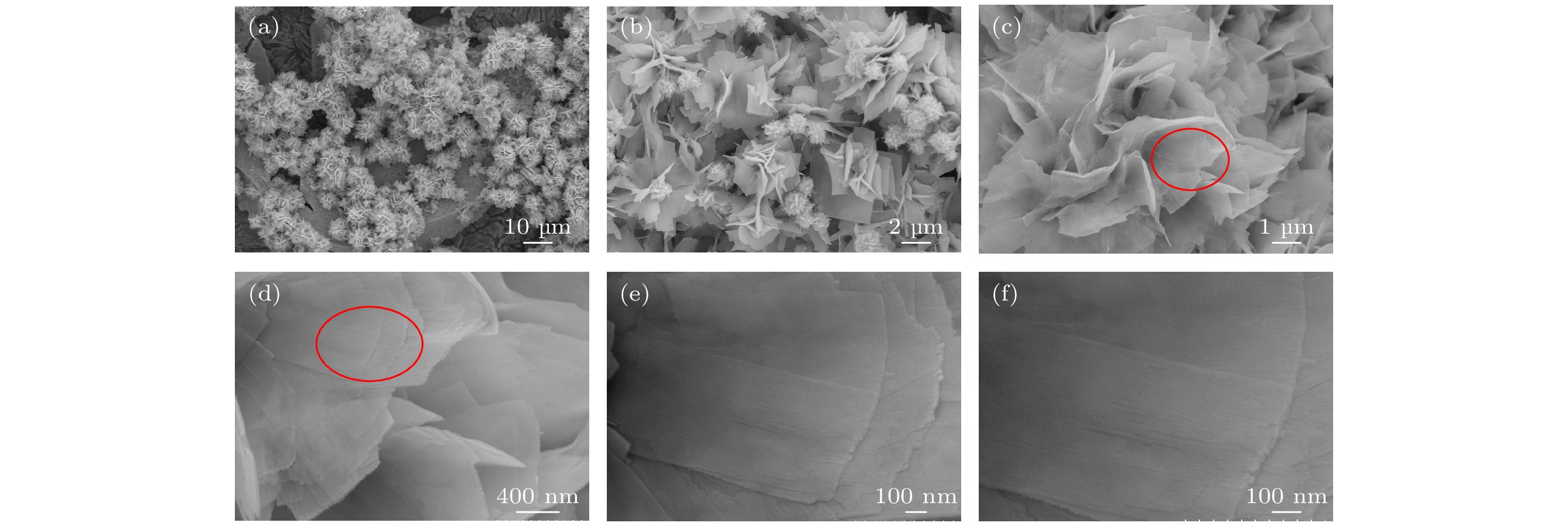

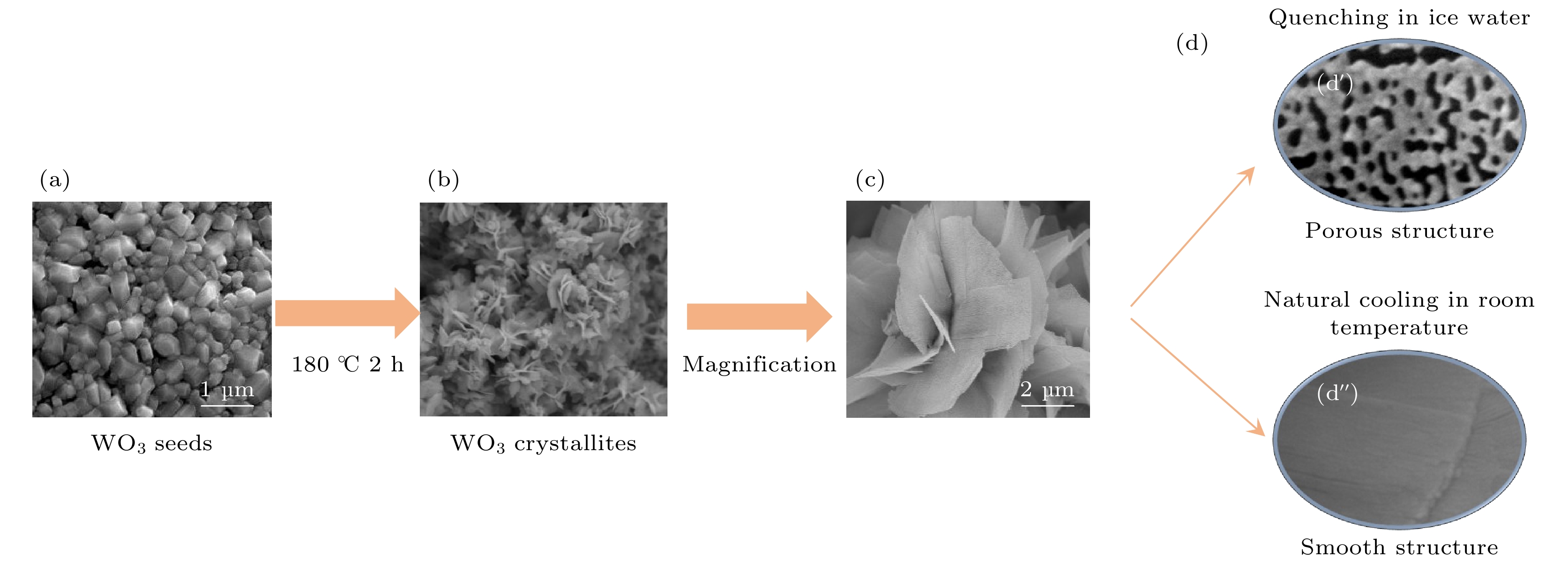

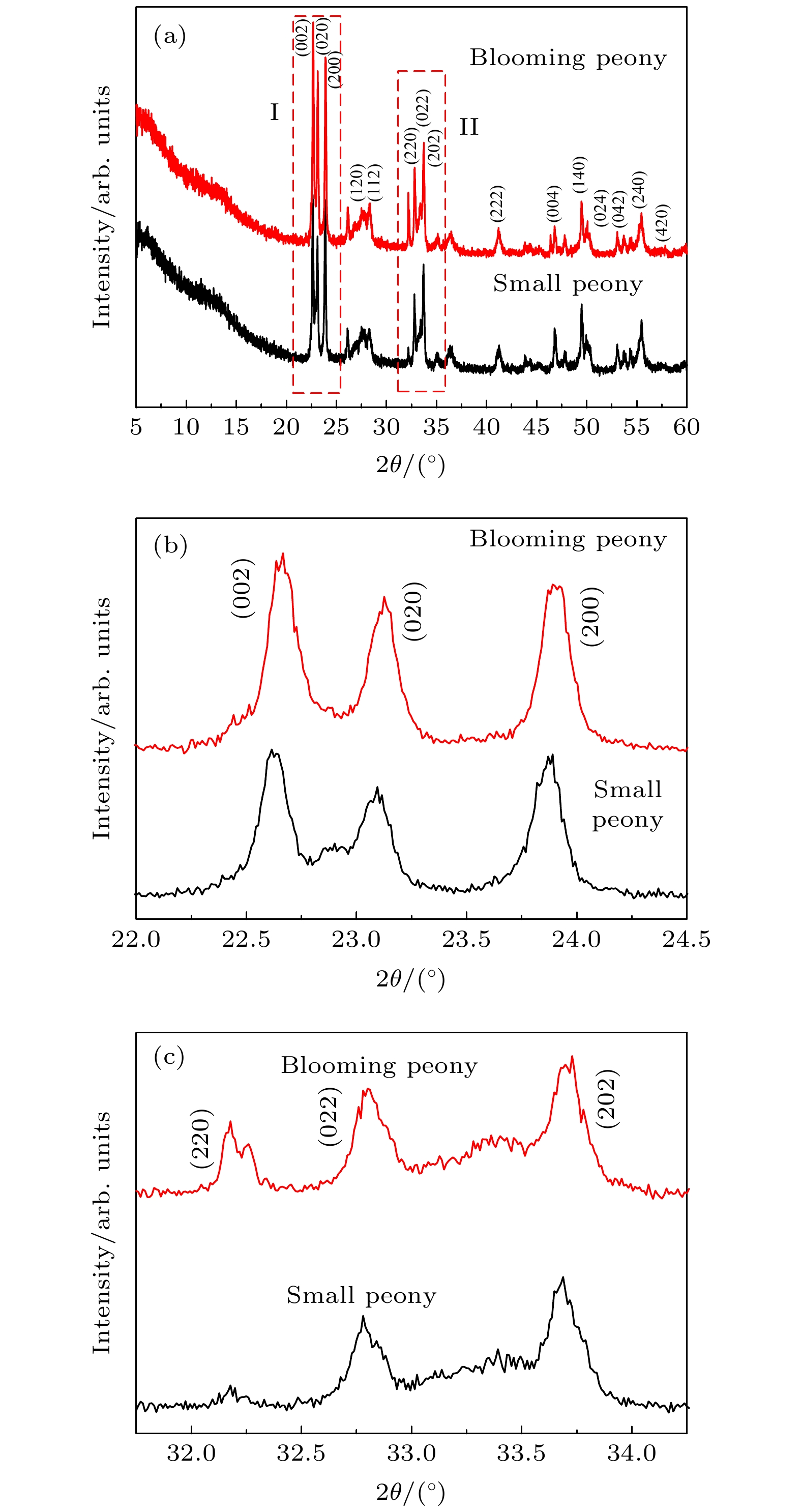

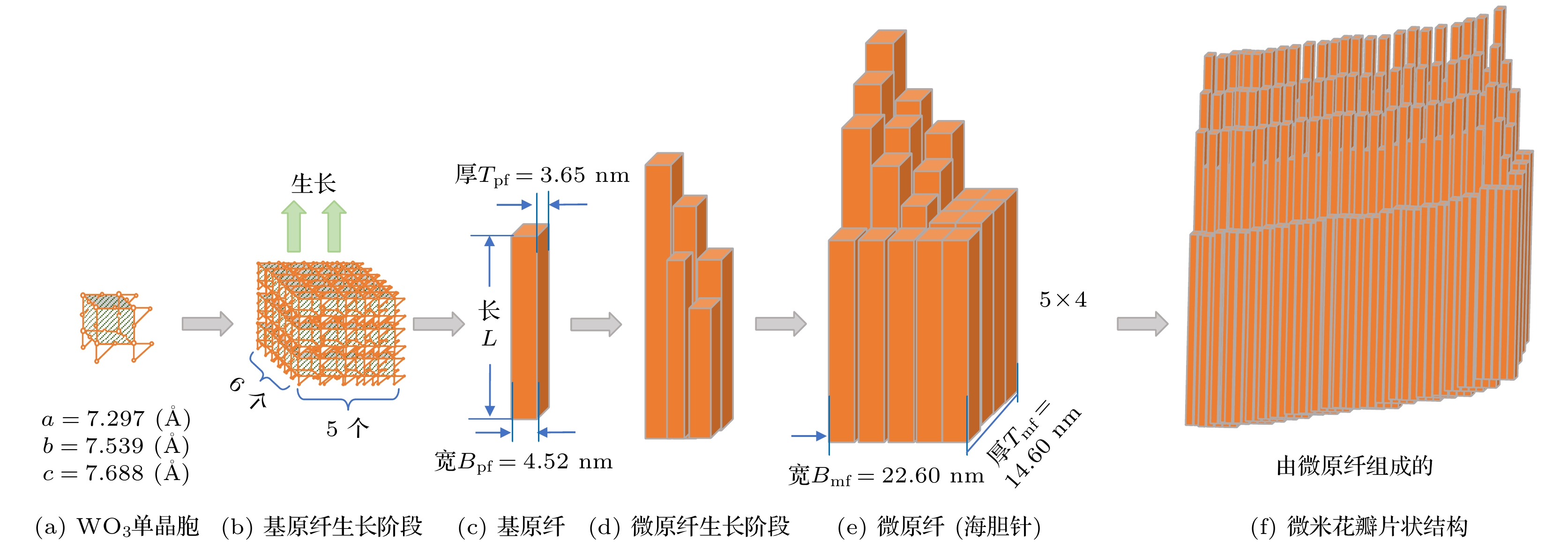

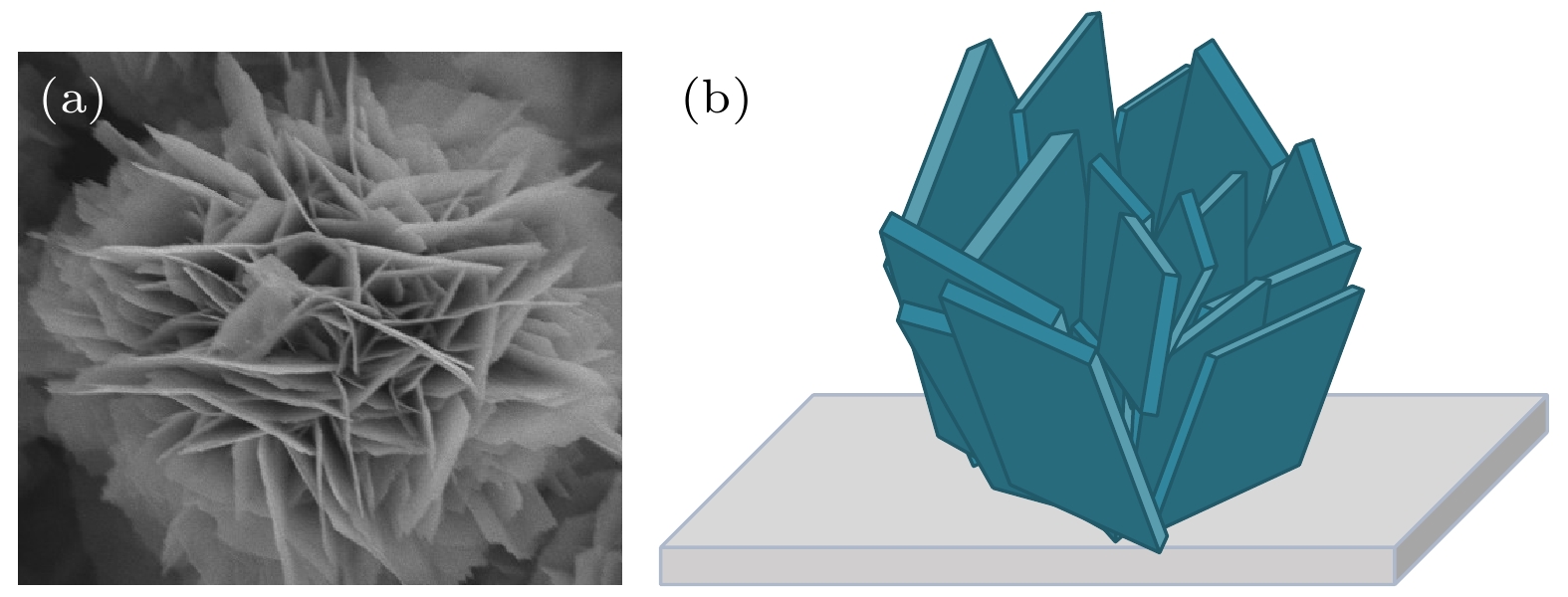

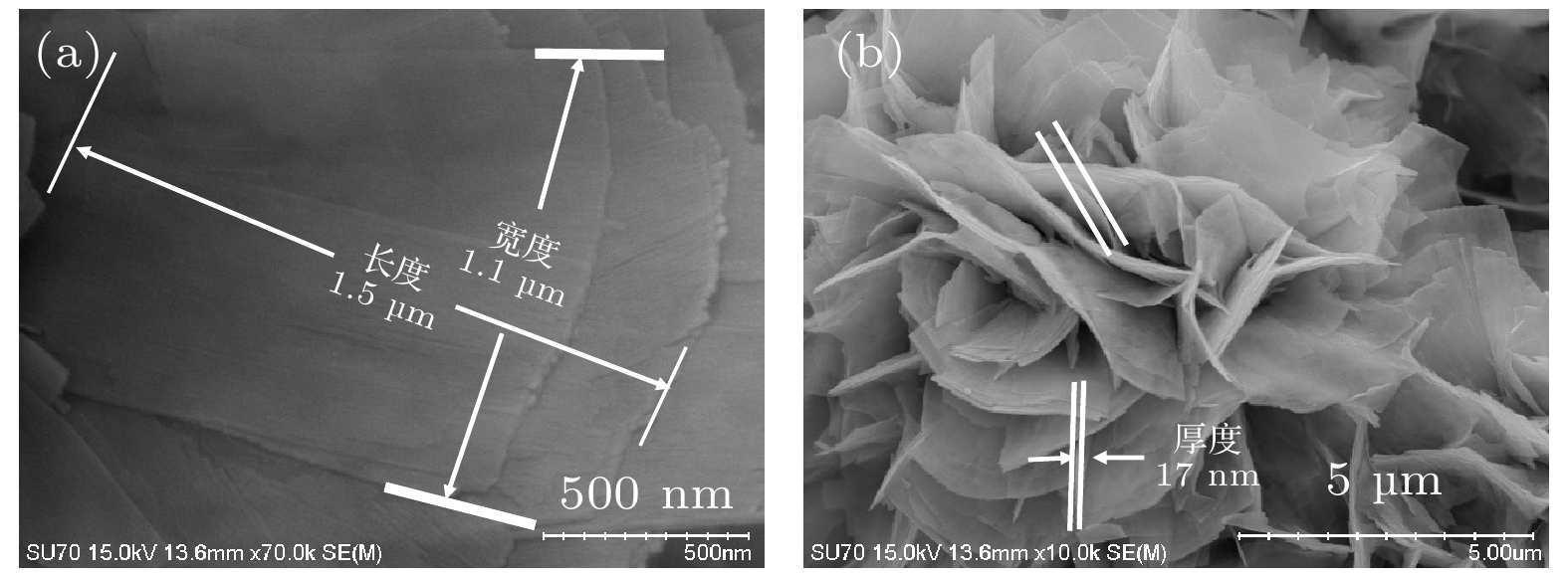

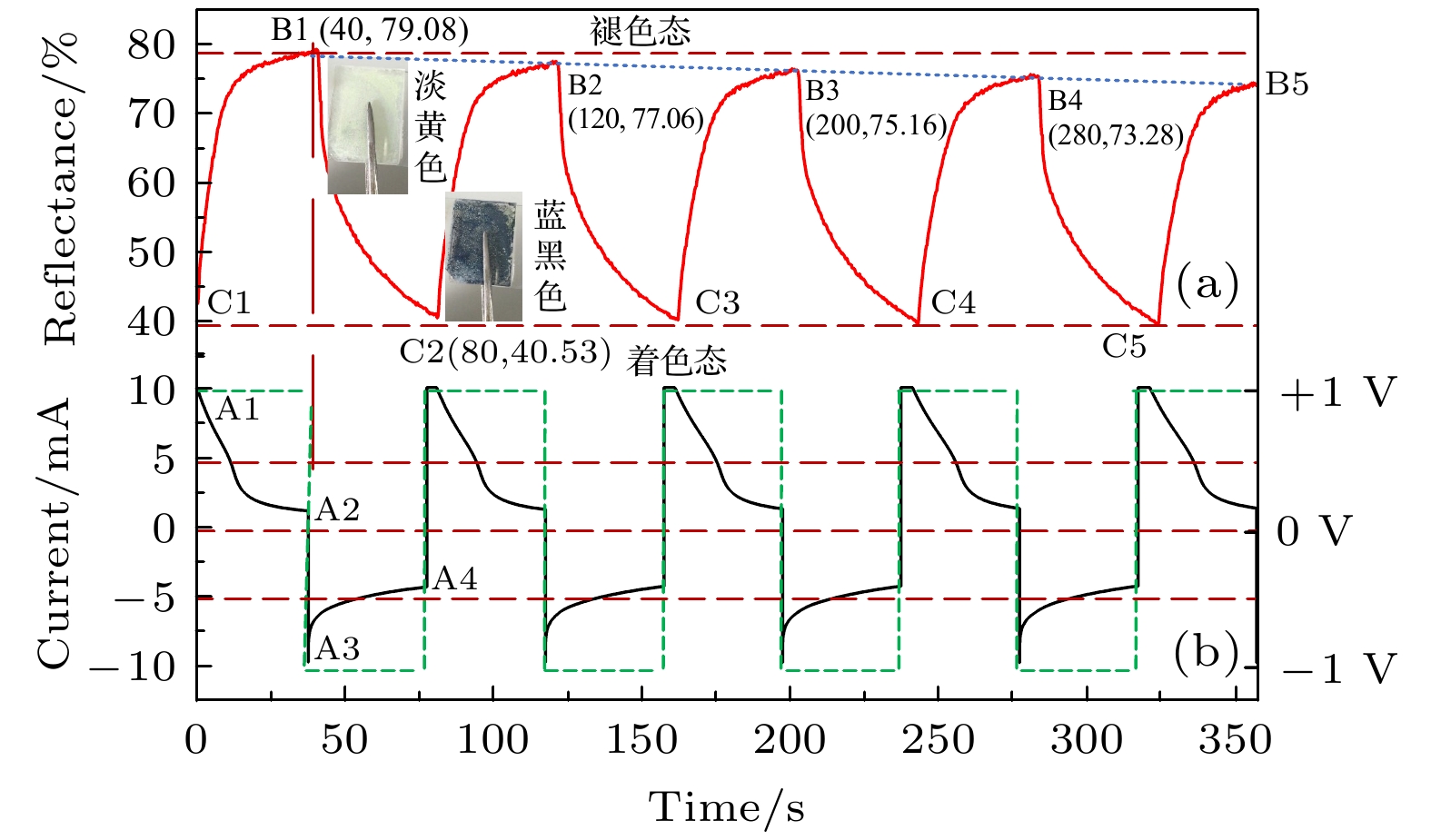

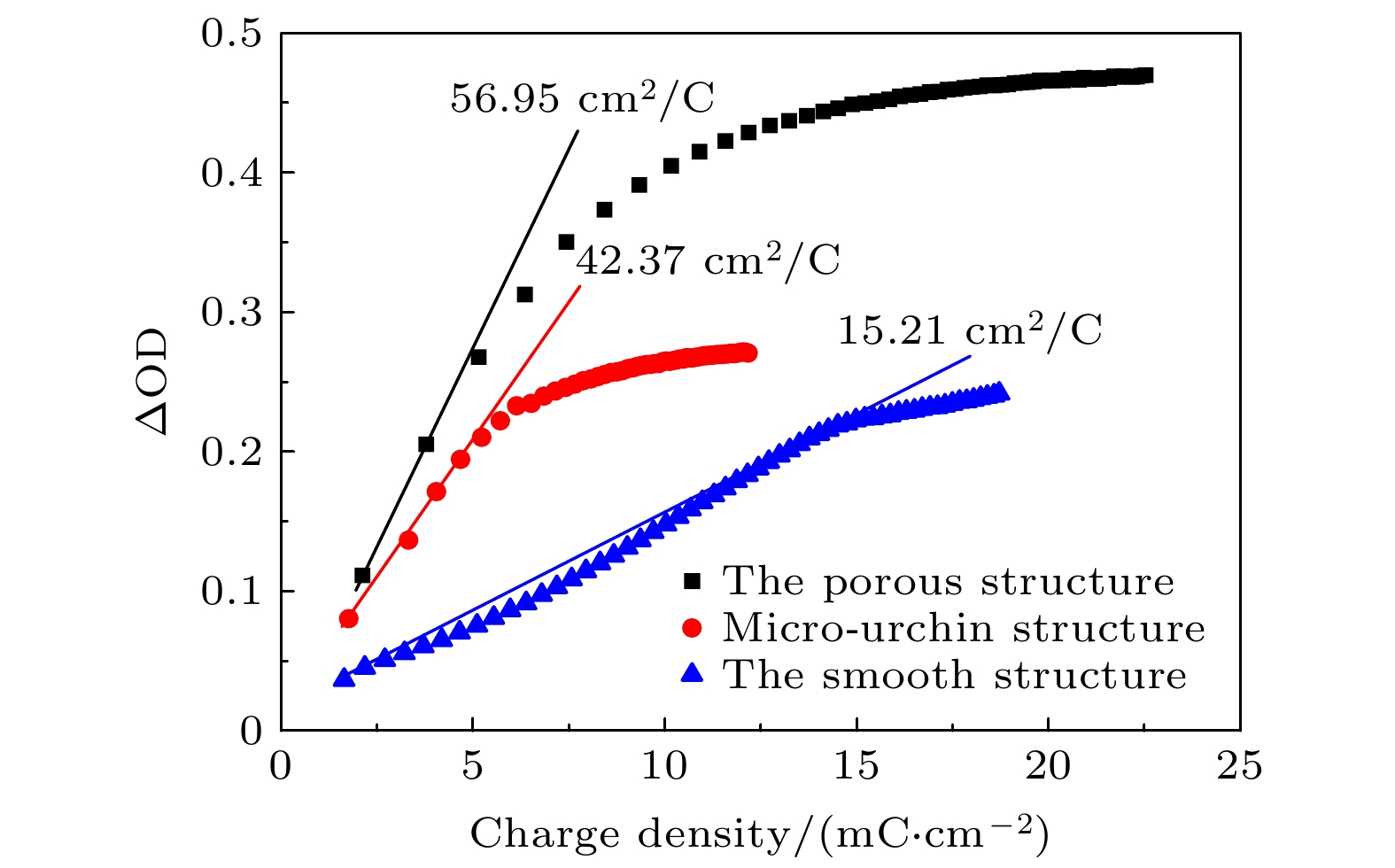

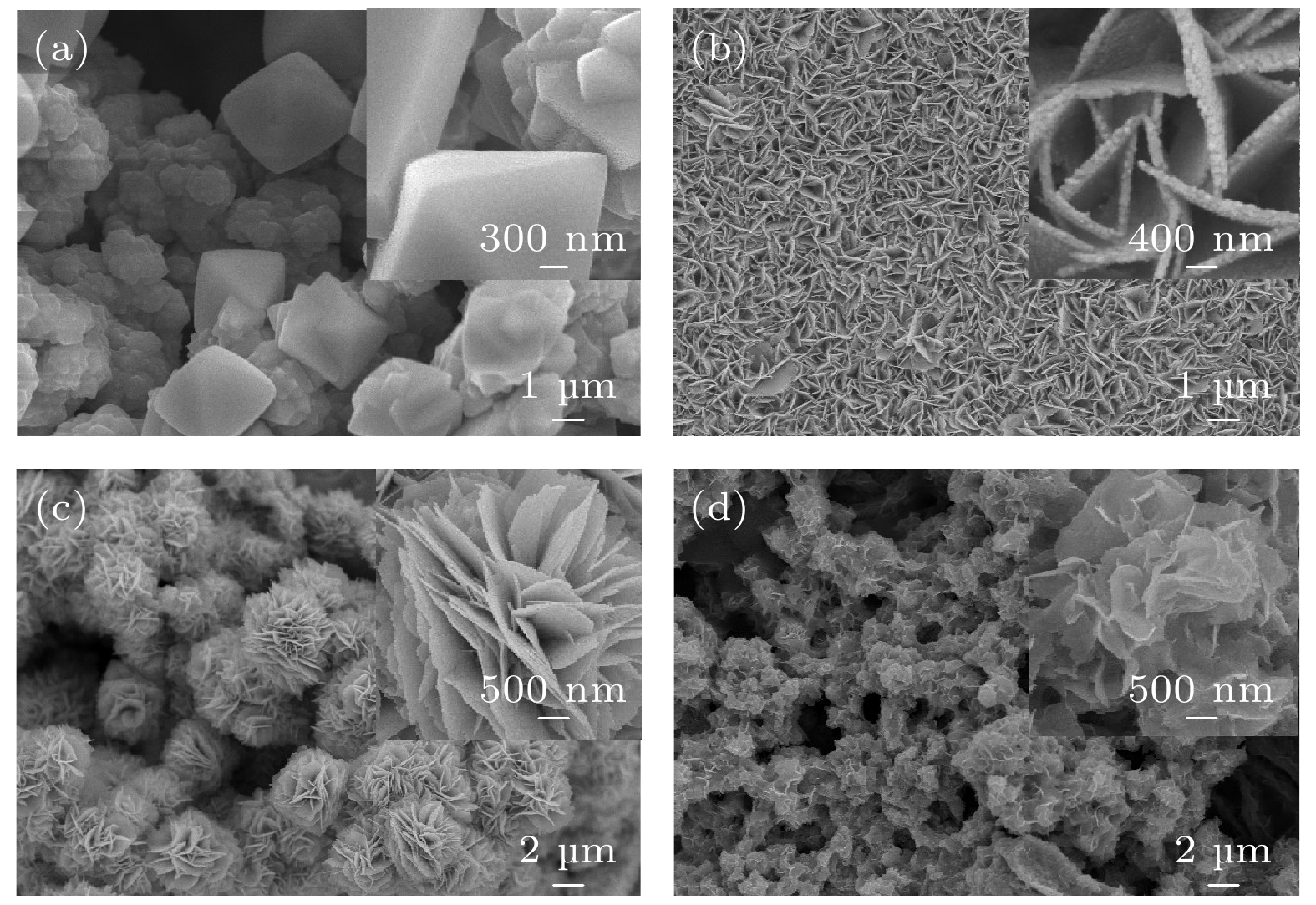

In this work, WO3 crystal structure films are deposited on conductive glass substrates by seed layer assisted hydrothermal reaction method. Through controlling the concentration of hydrochloric acid, oxalic acid, and the hydrothermal postprocessing temperature, the micro-peony, micro urchin-like, and porous petal-like WO3 crystal structures are obtained respectively. Scanning electron microscopy (SEM), X-ray diffraction (XRD), transmission electron microscopy (TEM) and electrochemical characterization are used to study the formation mechanism of different structures and their effects on the electrochromic properties of WO3 films. The Cl– in HCl has a strong promoting role towards the c axis in WO3 crystal growth and oxalic acid has a promoting effect towards an a axis. In terms of color efficiency, the CE value of micro-urchin is 42.37 cm2/C, far greater than those of two other WO3 structures, 15.21 cm2/C and 12.71 cm2/C. Owing to the cold-water quenching treatment, the CE value of WO3 micro-peony with porous surface structure is 56.95 cm2/C, quadruple CE value of the smooth surface structure, slightly better than that of the micro-urchin structure.

[1] Sarwar S, Park S, Dao T T, Hong S, Han C-H 2021 Sol. Energy Mat. Sol. C 224 110990

Google Scholar

Google Scholar

[2] He J, Zhao H, Wu H, Yang Y, Wang Z, He Z, Jiang G 2021 Phys. Chem. Chem. Phys.

Google Scholar

Google Scholar

[3] 汪鑫, 胡文杰, 徐耀 2021 光子学报 50 0731001

Wang X, Hu W J, Xu Y 2021 Acta Photon. Sin. 50 0731001

[4] Zhang L, Zhu T, Xia F, Cui Y, Xia H, Yang G, Gao Y 2021 Ceram. Int. 47 25854

Google Scholar

Google Scholar

[5] 史继超, 吴广明, 陈世文, 沈军, 周斌, 倪星元 2007 高等学校化学学报 28 1356

Google Scholar

Google Scholar

Shi J C, Wu G M, Chen S W, Shen J, Zhou B, Ni X Y 2007 Chem. J. Chin. Uni. 28 1356

Google Scholar

Google Scholar

[6] Yao M, Li T, Long Y, Shen P, Wang G, Li C, Liu J, Guo W, Wang Y, Shen L, Zhan X 2020 Sci. Bull. 65 217

Google Scholar

Google Scholar

[7] 刘畅, 孙依, 王晶, 唐莹, 马雪娇, 赵春山 2020 化学与黏合 42 181

Liu C, Sun Y, Wang J, Tang Y, Ma X J, Zhao C S 2020 Chem. Adhesion 42 181

[8] Karaca G Y, Eren E, Cogal G C, Uygun E, Oksuz L, Uygun Oksuz A 2019 Opt. Mater. 88 472

Google Scholar

Google Scholar

[9] Yao Y, Zhao Q, Wei W, Chen Z, Zhu Y, Zhang P, Zhang Z, Gao Y 2020 Nano Energy 68 104350

Google Scholar

Google Scholar

[10] Uchiyama H, Nakamura Y, Igarashi S 2021 RSC Adv. 11 7442

Google Scholar

Google Scholar

[11] Li Y, Zhao J, Chen X, Wang L, Li W, Zhang X 2021 J. Inorg. Mater. 36 451

Google Scholar

Google Scholar

[12] Gu H, Guo C, Zhang S, Bi L, Li T, Sun T, Liu S 2018 ACS Nano 12 559

Google Scholar

Google Scholar

[13] Fang H, Zheng P, Ma R, Xu C, Yang G, Wang Q, Wang H 2018 Mater. Horiz. 5 1000

Google Scholar

Google Scholar

[14] Zheng R, Wang Y, Pan J, Malik H A, Zhang H, Jia C, Weng X, Xie J, Deng L 2020 ACS Appl. Mater. Inter. 12 27526

Google Scholar

Google Scholar

[15] 方成, 汪洪, 施思奇 2016 65 168201

Google Scholar

Google Scholar

Fang C, Wang H, Shi S Q 2016 Acta Phys. Sin. 65 168201

Google Scholar

Google Scholar

[16] Wang J L, Lu Y R, Li H H, Liu J W, Yu S H 2017 J. Am. Chem. Soc. 139 9921

Google Scholar

Google Scholar

[17] 贾汉祥, 曹逊, 金平实 2020 无机材料学报 35 511

Google Scholar

Google Scholar

Jia H X, Cao X, Jin P S 2020 J. Inorg. Mater. 35 511

Google Scholar

Google Scholar

[18] Li J L, Liu X Y 2013 Soft Fibrillar Materials: Fabrication and Applications (Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA) pp163−182

[19] Albert R, Barabasi A L 2002 Rev. Mod. Phys. 74 47

Google Scholar

Google Scholar

[20] Lin N, Liu X Y 2015 Chem. Soc. Rev. 44 7881

Google Scholar

Google Scholar

[21] Yang B, Barnes P R F, Zhang Y, Luca V 2007 Catal. Lett. 118 280

Google Scholar

Google Scholar

[22] Miyauchi M, Shibuya M, Zhao Z G, Liu Z 2009 J. Phys. Chem. C 113 10642

Google Scholar

Google Scholar

[23] Zheng H, Ou J Z, Strano M S, Kaner R B, Mitchell A, Kalantar-zadeh K 2011 Adv. Funct. Mater. 21 2175

Google Scholar

Google Scholar

[24] Shibuya M, Miyauchi M 2009 Chem. Phys. Lett. 473 126

Google Scholar

Google Scholar

[25] Wang J, Khoo E, Lee P S, Ma J 2009 J. Phys. Chem. C 113 9655

Google Scholar

Google Scholar

[26] Adhikari S, Sarkar D 2014 RSC Adv. 4 20145

Google Scholar

Google Scholar

[27] Wu Y, Hu M, Tian Y 2017 Chin. Phys. B 26 020701

Google Scholar

Google Scholar

[28] Ma D, Wang H, Zhang Q, Li Y 2012 J. Mater. Chem. 22 16633

Google Scholar

Google Scholar

[29] Gu Z, Ma Y, Yang W, Zhang G, Yao J 2005 Chem. Commun. (Camb) 3597

[30] Liu Z, Miyauchi M, Yamazaki T, Shen Y 2009 Sensor. Actuat. B:Chem. 140 514

Google Scholar

Google Scholar

[31] Ko R M, Wang S J, Tsai W C, Liou B W, Lin Y R 2009 CrystEngComm 11 1529

Google Scholar

Google Scholar

[32] Su J, Feng X, Sloppy J D, Guo L, Grimes C A 2011 Nano Lett. 11 203

[33] Song Y, Zhang Z, Yan L, Zhang L, Liu S, Xie S, Xu L, Du J 2019 Nanomaterials (Basel) 9 1795

-

-

[1] Sarwar S, Park S, Dao T T, Hong S, Han C-H 2021 Sol. Energy Mat. Sol. C 224 110990

Google Scholar

Google Scholar

[2] He J, Zhao H, Wu H, Yang Y, Wang Z, He Z, Jiang G 2021 Phys. Chem. Chem. Phys.

Google Scholar

Google Scholar

[3] 汪鑫, 胡文杰, 徐耀 2021 光子学报 50 0731001

Wang X, Hu W J, Xu Y 2021 Acta Photon. Sin. 50 0731001

[4] Zhang L, Zhu T, Xia F, Cui Y, Xia H, Yang G, Gao Y 2021 Ceram. Int. 47 25854

Google Scholar

Google Scholar

[5] 史继超, 吴广明, 陈世文, 沈军, 周斌, 倪星元 2007 高等学校化学学报 28 1356

Google Scholar

Google Scholar

Shi J C, Wu G M, Chen S W, Shen J, Zhou B, Ni X Y 2007 Chem. J. Chin. Uni. 28 1356

Google Scholar

Google Scholar

[6] Yao M, Li T, Long Y, Shen P, Wang G, Li C, Liu J, Guo W, Wang Y, Shen L, Zhan X 2020 Sci. Bull. 65 217

Google Scholar

Google Scholar

[7] 刘畅, 孙依, 王晶, 唐莹, 马雪娇, 赵春山 2020 化学与黏合 42 181

Liu C, Sun Y, Wang J, Tang Y, Ma X J, Zhao C S 2020 Chem. Adhesion 42 181

[8] Karaca G Y, Eren E, Cogal G C, Uygun E, Oksuz L, Uygun Oksuz A 2019 Opt. Mater. 88 472

Google Scholar

Google Scholar

[9] Yao Y, Zhao Q, Wei W, Chen Z, Zhu Y, Zhang P, Zhang Z, Gao Y 2020 Nano Energy 68 104350

Google Scholar

Google Scholar

[10] Uchiyama H, Nakamura Y, Igarashi S 2021 RSC Adv. 11 7442

Google Scholar

Google Scholar

[11] Li Y, Zhao J, Chen X, Wang L, Li W, Zhang X 2021 J. Inorg. Mater. 36 451

Google Scholar

Google Scholar

[12] Gu H, Guo C, Zhang S, Bi L, Li T, Sun T, Liu S 2018 ACS Nano 12 559

Google Scholar

Google Scholar

[13] Fang H, Zheng P, Ma R, Xu C, Yang G, Wang Q, Wang H 2018 Mater. Horiz. 5 1000

Google Scholar

Google Scholar

[14] Zheng R, Wang Y, Pan J, Malik H A, Zhang H, Jia C, Weng X, Xie J, Deng L 2020 ACS Appl. Mater. Inter. 12 27526

Google Scholar

Google Scholar

[15] 方成, 汪洪, 施思奇 2016 65 168201

Google Scholar

Google Scholar

Fang C, Wang H, Shi S Q 2016 Acta Phys. Sin. 65 168201

Google Scholar

Google Scholar

[16] Wang J L, Lu Y R, Li H H, Liu J W, Yu S H 2017 J. Am. Chem. Soc. 139 9921

Google Scholar

Google Scholar

[17] 贾汉祥, 曹逊, 金平实 2020 无机材料学报 35 511

Google Scholar

Google Scholar

Jia H X, Cao X, Jin P S 2020 J. Inorg. Mater. 35 511

Google Scholar

Google Scholar

[18] Li J L, Liu X Y 2013 Soft Fibrillar Materials: Fabrication and Applications (Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA) pp163−182

[19] Albert R, Barabasi A L 2002 Rev. Mod. Phys. 74 47

Google Scholar

Google Scholar

[20] Lin N, Liu X Y 2015 Chem. Soc. Rev. 44 7881

Google Scholar

Google Scholar

[21] Yang B, Barnes P R F, Zhang Y, Luca V 2007 Catal. Lett. 118 280

Google Scholar

Google Scholar

[22] Miyauchi M, Shibuya M, Zhao Z G, Liu Z 2009 J. Phys. Chem. C 113 10642

Google Scholar

Google Scholar

[23] Zheng H, Ou J Z, Strano M S, Kaner R B, Mitchell A, Kalantar-zadeh K 2011 Adv. Funct. Mater. 21 2175

Google Scholar

Google Scholar

[24] Shibuya M, Miyauchi M 2009 Chem. Phys. Lett. 473 126

Google Scholar

Google Scholar

[25] Wang J, Khoo E, Lee P S, Ma J 2009 J. Phys. Chem. C 113 9655

Google Scholar

Google Scholar

[26] Adhikari S, Sarkar D 2014 RSC Adv. 4 20145

Google Scholar

Google Scholar

[27] Wu Y, Hu M, Tian Y 2017 Chin. Phys. B 26 020701

Google Scholar

Google Scholar

[28] Ma D, Wang H, Zhang Q, Li Y 2012 J. Mater. Chem. 22 16633

Google Scholar

Google Scholar

[29] Gu Z, Ma Y, Yang W, Zhang G, Yao J 2005 Chem. Commun. (Camb) 3597

[30] Liu Z, Miyauchi M, Yamazaki T, Shen Y 2009 Sensor. Actuat. B:Chem. 140 514

Google Scholar

Google Scholar

[31] Ko R M, Wang S J, Tsai W C, Liou B W, Lin Y R 2009 CrystEngComm 11 1529

Google Scholar

Google Scholar

[32] Su J, Feng X, Sloppy J D, Guo L, Grimes C A 2011 Nano Lett. 11 203

[33] Song Y, Zhang Z, Yan L, Zhang L, Liu S, Xie S, Xu L, Du J 2019 Nanomaterials (Basel) 9 1795

Catalog

Metrics

- Abstract views: 10028

- PDF Downloads: 169

- Cited By: 0

DownLoad:

DownLoad: