-

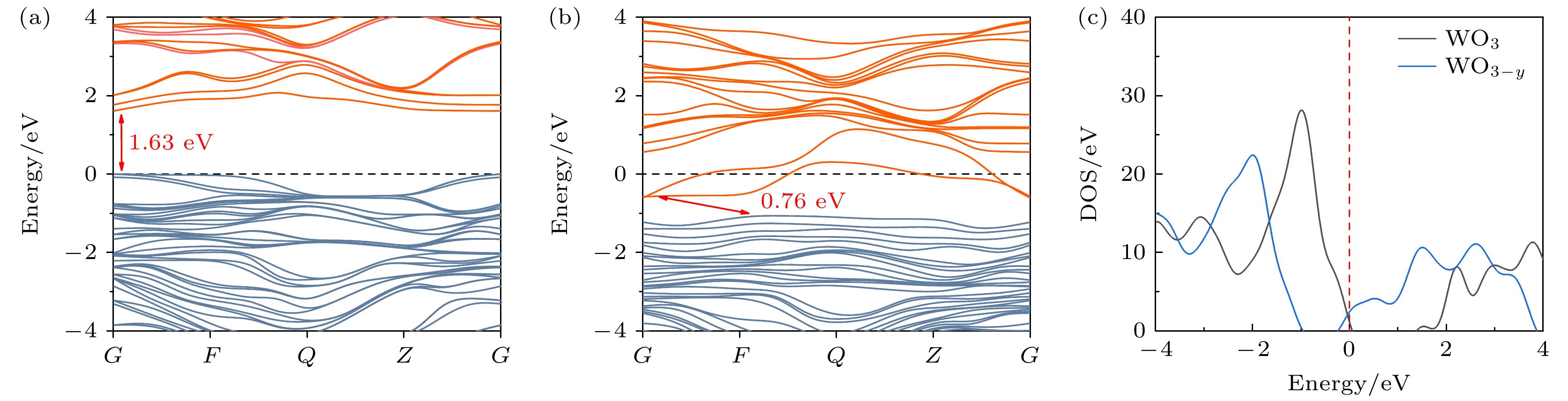

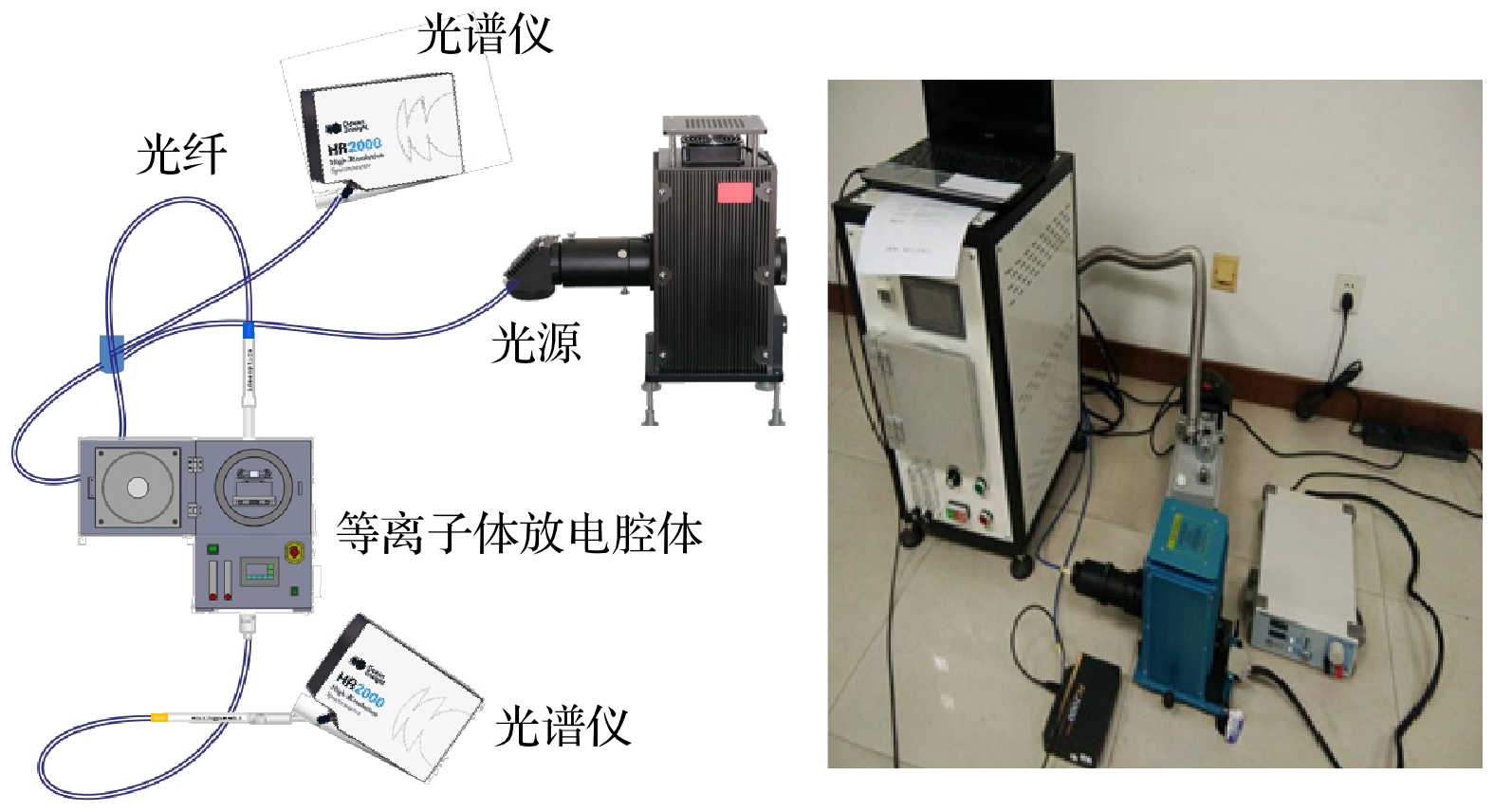

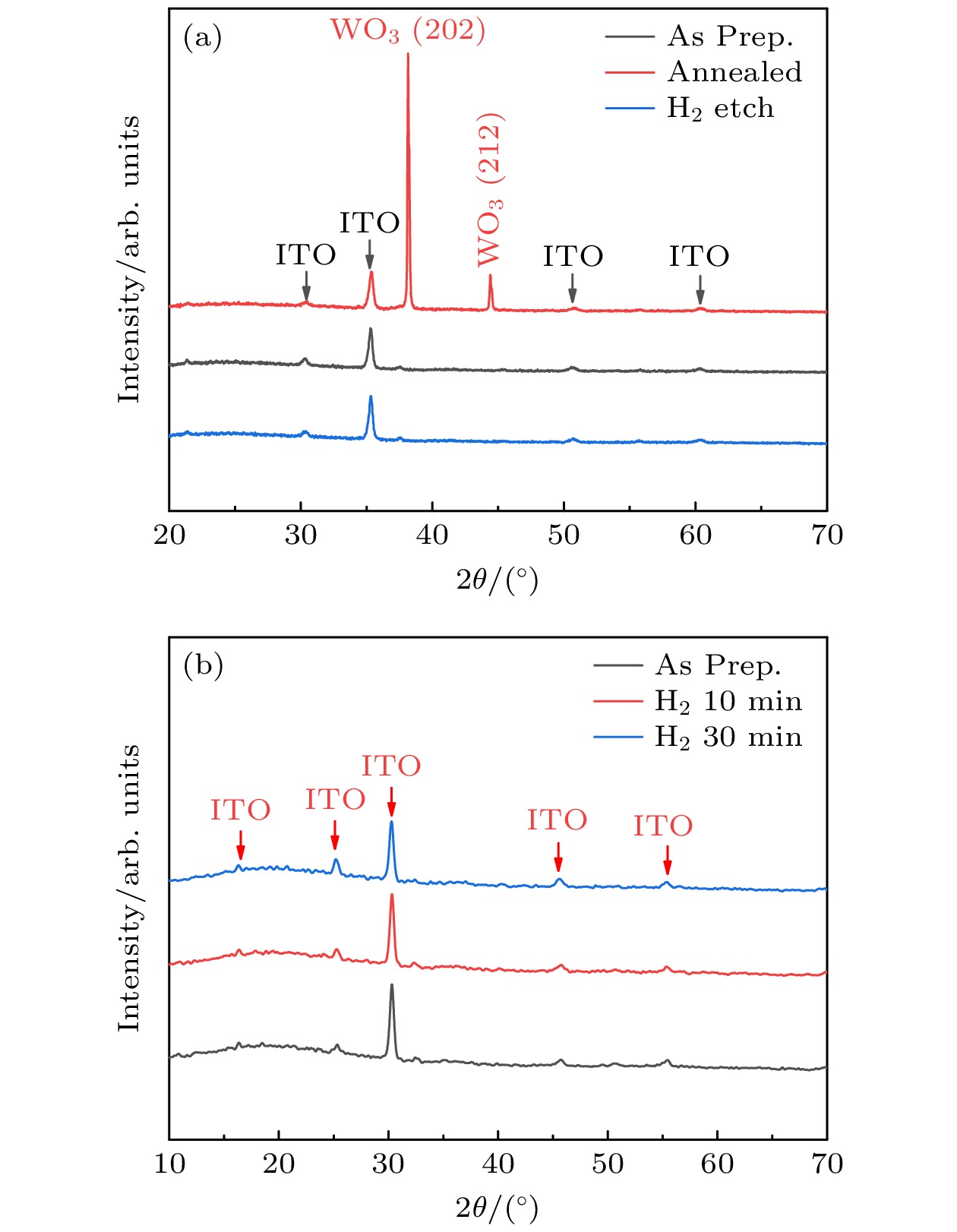

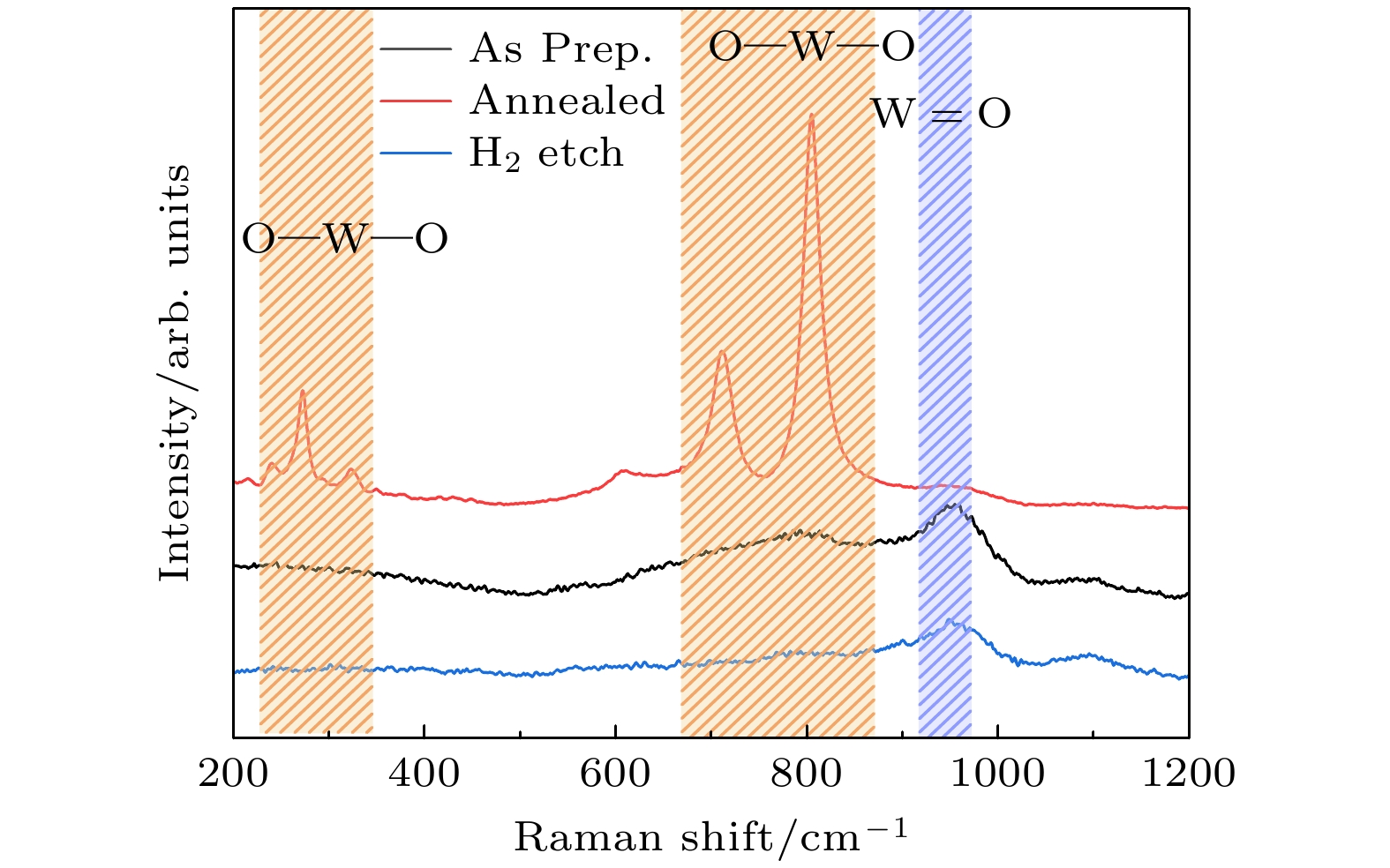

In recent years, electrochromic materials have been extensively utilized in smart windows, displays, and dimmable devices. WO3, as a typical electrochromic material has received significant attention. Existing researches indicate that the concentration and distribution of oxygen vacancies in WO3 are both important in determining electrochromic effect. However, it has been reported that traditional preparation methods such as annealing can significantly reduce the ability to modulate the crystallinity and optical performance. Hence, proposing a novel approach to enhance the electrochromic properties of WO3 films holds important research significance and application prospects. In this work, the electrochromic properties of WO3 thin films are enhanced by increasing the oxygen vacancy concentration and forming its gradient distribution on the surface through plasma treatment. Firstly, the oxygen vacancy concentration and distribution of the film are optimized by regulating the power and duration of the plasma treatment. Secondly, the structure and optical properties of the plasma treated WO3 films are analyzed using X-ray diffraction (XRD), scanning electron microscopy (SEM), and UV-Vis spectroscopy. Finally, the stability and response speed of each film during the electrochromic cycle are evaluated via electrochemical tests. Through plasma treatment, the concentrations of oxygen vacancies on the surfaces of WO3 films are all significantly increased, and a gradient distribution is formed, which is conducive to enhancing the ability to inject and extract electrons. The treated WO3 films demonstrate better electrochemical stability and chromic stability during the electrochromic cycle, and their transparencies and electrochromic response speeds are also significantly enhanced. Additionally, by increasing the concentration of oxygen vacancies through plasma treatment, the band gap of the film decreases and the electrical conductivity increases, which further validates the effectiveness of modulating concentration of oxygen vacancies on the electrical conductivity of WO3 film. Overall, these results indicate that plasma treatment is an emerging method of significantly improving the electrochromic properties of WO3 films.

-

Keywords:

- WO3 /

- oxygen vacancy /

- plasma /

- electrochromism

[1] Thai L H, Thanh N, Le T, Hiep N M, Khan D T, Dat T N, Truong S, Le V T, Truong T Q, Sinh L H 2024 Sol. Energy Mater Sol. Cells 278 113179

Google Scholar

Google Scholar

[2] Invernale M A, Ding Y J, Sotzing G A 2010 ACS Appl. Mater. Interfaces 2 296

Google Scholar

Google Scholar

[3] Liu L, Wang T, He Z B, Yi Y, Wang M Y, Luo Z H, Liu Q R, Huang J L, Zhong X L, Du K, Diao, X G 2021 Chem. Eng. J. 414 128892

Google Scholar

Google Scholar

[4] Zhang D S, Wang J X, Tong Z F, Ji H B , Qu H Y 2021 Adv. Funct. Mater. 31 2106577

Google Scholar

Google Scholar

[5] 邵光伟, 于瑞, 傅婷, 陈南梁, 刘向阳 2022 71 028201

Google Scholar

Google Scholar

Shao G W, Yu R, Fu T, Chen N L, Liu X Y 2022 Acta Phys. Sin. 71 028201

Google Scholar

Google Scholar

[6] 方成, 汪洪, 施思齐 2016 65 168201

Google Scholar

Google Scholar

Fang C, Wang H, Shi S Q 2016 Acta Phys. Sin. 65 168201

Google Scholar

Google Scholar

[7] Shi, Y D, Sun M J, Zhang Y, Cui J W, Shu X, Wang Y, Qin Y Q, Liu J Q, Tan H H , Wu Y C 2020 ACS Appl. Mater. Interfaces 12 32658

Google Scholar

Google Scholar

[8] Wang X Q, Yang Y, Jin Q Y, Lou Q C, Hu Q Z, Xie Z L, Song W J 2023 Adv. Funct. Mater. 33 2214417

Google Scholar

Google Scholar

[9] Zheng Y F, Fu K X, Yu Z H, Su Y, Han R, Liu Q L 2023 J. Mater. Chem. A 10 14171

Google Scholar

Google Scholar

[10] Shi Y D, Sun M J, Zhang Y, Cui J W, Wang Y, Shu X, Qin Y, Tan H H, Liu J Q, Wu Y C 2020 Sol. Energy Mater. Sol. Cells 212 110579

Google Scholar

Google Scholar

[11] Yu H, Guo J J, Wang C, Zhang J Y, Liu J, Dong G B, Zhong X L, Diao X G 2020 Electrochim. Acta 332 135504

Google Scholar

Google Scholar

[12] Li Z X, Liu Z F, Li J W, Yan W G 2022 Colloids Surf. , A 641 128615

Google Scholar

Google Scholar

[13] Qiao N, Wei P, Xing Y F, Qin X S, Wang X, Li X, Bu L J, Lu G H, Zhu Y W 2022 Adv. Mater. Interfaces 9 2200713

Google Scholar

Google Scholar

[14] Qiu Y M, Wei P, Wang Z H, Lu W L, Jiang Y H, Zhang C F, Qu Y Q, LuG H 2018 Phys. Status Solidi RRL 12 1800297

Google Scholar

Google Scholar

[15] Xing Y F, Qiao N, Yu J D, Zhang M, Dai J P, Niu T T, Wang Y H, Zhu Y W, Bu L J, LuG H 2022 Rev. Sci. Instrum. 93 073903

Google Scholar

Google Scholar

[16] 陈锦峰, 朱林繁 2024 73 095201

Google Scholar

Google Scholar

Chen J F, Zhu L F 2024 Acta Phys. Sin. 73 095201

Google Scholar

Google Scholar

[17] Shen Z C, Jiang Y H, Yu J D, Zhu Y W, Bu L J, LuG H 2020 Adv. Mater. Interfaces 8 2101476

Google Scholar

Google Scholar

[18] Huang Y J, Li M, Pan F, Zhu Z Y, Sun H M, Tang Y W, Fu G T 2023 Carbon Energy 5 e279

Google Scholar

Google Scholar

[19] Zhang G B, Xiong T F, Yan M Y, He L, Liao X B, He C Q, Yin C S, Zhang H N, Mai L Q 2018 Nano Energy 49 555

Google Scholar

Google Scholar

[20] 姜国平, 汪正兵, 闫永潘 2017 66 086801

Google Scholar

Google Scholar

Jiang P G, Wang Z B, Yan Y P 2017 Acta Phys. Sin. 66 086801

Google Scholar

Google Scholar

[21] Zhu Y W, Qiao N, Dong S Q, Qu G, Chen Y, Lu W L, Qin Z Z, Li D F, Wu K N, Nie Y J, Li S T, Lu G H 2022 Chem. Mater. 34 6505

Google Scholar

Google Scholar

[22] 杨光敏, 徐强, 李冰, 张汉壮, 贺小光 2015 64 127301

Google Scholar

Google Scholar

Yang G M, Xu Q, Li B, Zhang H Z, He X G 2015 Acta Phys. Sin. 64 127301

Google Scholar

Google Scholar

[23] 薛丽, 任一鸣 2016 65 156301

Google Scholar

Google Scholar

Xue L, Ren Y M 2016 Acta Phys. Sin. 65 156301

Google Scholar

Google Scholar

[24] Stampfl C, Van de Walle C 1999 Phys. Rev. B 59 5521

Google Scholar

Google Scholar

[25] Arvizu M A, Qu H Y, Cindemir U, Qiu Z, Rojas-González E A, Primetzhofer D, Granqvis, C G, Österlund L, Niklasson G A 2019 J. Mater. Chem. A 7 2908

Google Scholar

Google Scholar

[26] Khong Y J, Niang K M, Han S, Coburn N J, Wyatt-Moon G, Flewitt A J 2021 Adv. Mater. Interfaces 8 210049

Google Scholar

Google Scholar

[27] Lee S H, Cheong M H, Han S, Tracy C E, Mascarenhas A, Czanderna A W, Deb S K 1999 Appl. Phys. Lett. 75 1541

Google Scholar

Google Scholar

-

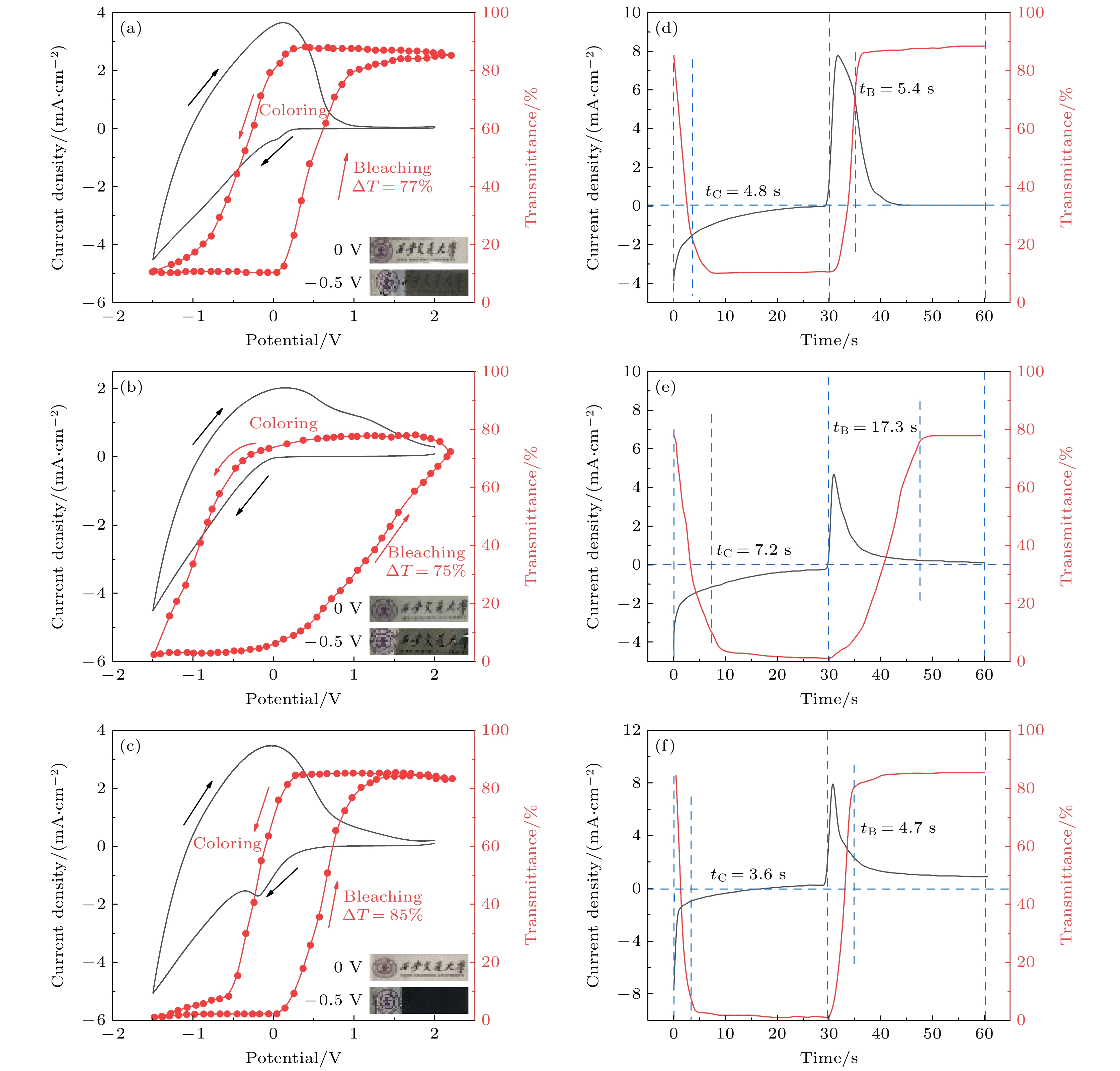

图 11 (a)原始状态、(b)退火处理后和(c)等离子体处理后WO3薄膜的CV测试和实时光谱透过率以及施加不同电压后的薄膜照片; (d)原始状态、(e)退火处理后和(f)等离子体处理后WO3薄膜在–1.0和+2.0 V电势下30s的电流密度变化(黑色曲线)、透光率变化(红色曲线)以及在有色和漂白状态之间的切换时间特性

Figure 11. CV test and real-time spectral transmittance of WO3 films at (a) initial preparation, (b) annealing and (c) plasma treatment, and photographs of films at different voltages; (d) changes in current density (black curve), transmittance (red curve) and switching time between colored and bleached WO3 films at –1.0 V and + 2.0 V potentials for 30s after initial preparation, (e) annealing and (f) plasma treatment.

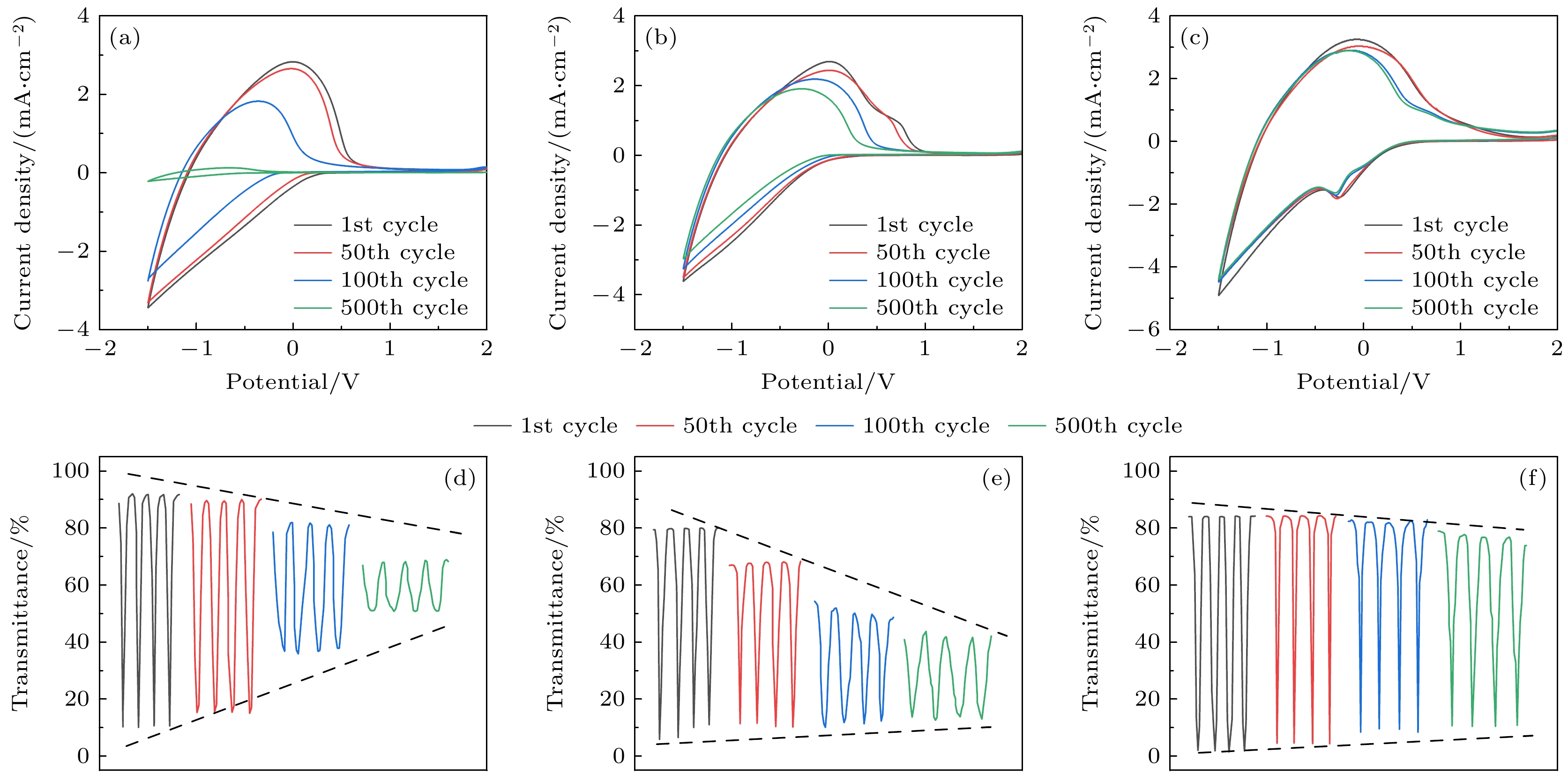

图 12 (a)原始状态、(b)退火处理后和(c)等离子体处理后WO3薄膜的长时CV测试; (d)原始状态、(e)退火处理后和(f)等离子体处理后WO3薄膜的长时透过率测试

Figure 12. Long-term CV tests of WO3 films (a) in their original state, (b) after annealing and (c) after plasma treatment; long term transmittance tests of WO3 films (d) in their original state, (e) after annealing, and (f) after plasma treatment.

表 1 不同处理工艺方案的四探针电导率测试结果

Table 1. Results of four-probe conductivity tests for various treatment schemes.

样品处理方式 电导率/(10–3 S·m–1) 原始状态 8.27 退火处理 25.30 等离子体处理 10.80 表 2 不同等离子体处理工艺方案设计及测试结果

Table 2. Design and test results of different plasma treatment processes.

等离子体放

电功率/W改性时间/min O/W原子比 光学

透过率/%5 10 2.86 84.5 10 20 2.75 81.1 20 30 2.58 74.2 5 20 2.83 82.8 10 30 2.71 78.4 20 10 2.68 79.7 5 30 2.80 80.6 10 10 2.79 83.2 20 20 2.63 76.3 -

[1] Thai L H, Thanh N, Le T, Hiep N M, Khan D T, Dat T N, Truong S, Le V T, Truong T Q, Sinh L H 2024 Sol. Energy Mater Sol. Cells 278 113179

Google Scholar

Google Scholar

[2] Invernale M A, Ding Y J, Sotzing G A 2010 ACS Appl. Mater. Interfaces 2 296

Google Scholar

Google Scholar

[3] Liu L, Wang T, He Z B, Yi Y, Wang M Y, Luo Z H, Liu Q R, Huang J L, Zhong X L, Du K, Diao, X G 2021 Chem. Eng. J. 414 128892

Google Scholar

Google Scholar

[4] Zhang D S, Wang J X, Tong Z F, Ji H B , Qu H Y 2021 Adv. Funct. Mater. 31 2106577

Google Scholar

Google Scholar

[5] 邵光伟, 于瑞, 傅婷, 陈南梁, 刘向阳 2022 71 028201

Google Scholar

Google Scholar

Shao G W, Yu R, Fu T, Chen N L, Liu X Y 2022 Acta Phys. Sin. 71 028201

Google Scholar

Google Scholar

[6] 方成, 汪洪, 施思齐 2016 65 168201

Google Scholar

Google Scholar

Fang C, Wang H, Shi S Q 2016 Acta Phys. Sin. 65 168201

Google Scholar

Google Scholar

[7] Shi, Y D, Sun M J, Zhang Y, Cui J W, Shu X, Wang Y, Qin Y Q, Liu J Q, Tan H H , Wu Y C 2020 ACS Appl. Mater. Interfaces 12 32658

Google Scholar

Google Scholar

[8] Wang X Q, Yang Y, Jin Q Y, Lou Q C, Hu Q Z, Xie Z L, Song W J 2023 Adv. Funct. Mater. 33 2214417

Google Scholar

Google Scholar

[9] Zheng Y F, Fu K X, Yu Z H, Su Y, Han R, Liu Q L 2023 J. Mater. Chem. A 10 14171

Google Scholar

Google Scholar

[10] Shi Y D, Sun M J, Zhang Y, Cui J W, Wang Y, Shu X, Qin Y, Tan H H, Liu J Q, Wu Y C 2020 Sol. Energy Mater. Sol. Cells 212 110579

Google Scholar

Google Scholar

[11] Yu H, Guo J J, Wang C, Zhang J Y, Liu J, Dong G B, Zhong X L, Diao X G 2020 Electrochim. Acta 332 135504

Google Scholar

Google Scholar

[12] Li Z X, Liu Z F, Li J W, Yan W G 2022 Colloids Surf. , A 641 128615

Google Scholar

Google Scholar

[13] Qiao N, Wei P, Xing Y F, Qin X S, Wang X, Li X, Bu L J, Lu G H, Zhu Y W 2022 Adv. Mater. Interfaces 9 2200713

Google Scholar

Google Scholar

[14] Qiu Y M, Wei P, Wang Z H, Lu W L, Jiang Y H, Zhang C F, Qu Y Q, LuG H 2018 Phys. Status Solidi RRL 12 1800297

Google Scholar

Google Scholar

[15] Xing Y F, Qiao N, Yu J D, Zhang M, Dai J P, Niu T T, Wang Y H, Zhu Y W, Bu L J, LuG H 2022 Rev. Sci. Instrum. 93 073903

Google Scholar

Google Scholar

[16] 陈锦峰, 朱林繁 2024 73 095201

Google Scholar

Google Scholar

Chen J F, Zhu L F 2024 Acta Phys. Sin. 73 095201

Google Scholar

Google Scholar

[17] Shen Z C, Jiang Y H, Yu J D, Zhu Y W, Bu L J, LuG H 2020 Adv. Mater. Interfaces 8 2101476

Google Scholar

Google Scholar

[18] Huang Y J, Li M, Pan F, Zhu Z Y, Sun H M, Tang Y W, Fu G T 2023 Carbon Energy 5 e279

Google Scholar

Google Scholar

[19] Zhang G B, Xiong T F, Yan M Y, He L, Liao X B, He C Q, Yin C S, Zhang H N, Mai L Q 2018 Nano Energy 49 555

Google Scholar

Google Scholar

[20] 姜国平, 汪正兵, 闫永潘 2017 66 086801

Google Scholar

Google Scholar

Jiang P G, Wang Z B, Yan Y P 2017 Acta Phys. Sin. 66 086801

Google Scholar

Google Scholar

[21] Zhu Y W, Qiao N, Dong S Q, Qu G, Chen Y, Lu W L, Qin Z Z, Li D F, Wu K N, Nie Y J, Li S T, Lu G H 2022 Chem. Mater. 34 6505

Google Scholar

Google Scholar

[22] 杨光敏, 徐强, 李冰, 张汉壮, 贺小光 2015 64 127301

Google Scholar

Google Scholar

Yang G M, Xu Q, Li B, Zhang H Z, He X G 2015 Acta Phys. Sin. 64 127301

Google Scholar

Google Scholar

[23] 薛丽, 任一鸣 2016 65 156301

Google Scholar

Google Scholar

Xue L, Ren Y M 2016 Acta Phys. Sin. 65 156301

Google Scholar

Google Scholar

[24] Stampfl C, Van de Walle C 1999 Phys. Rev. B 59 5521

Google Scholar

Google Scholar

[25] Arvizu M A, Qu H Y, Cindemir U, Qiu Z, Rojas-González E A, Primetzhofer D, Granqvis, C G, Österlund L, Niklasson G A 2019 J. Mater. Chem. A 7 2908

Google Scholar

Google Scholar

[26] Khong Y J, Niang K M, Han S, Coburn N J, Wyatt-Moon G, Flewitt A J 2021 Adv. Mater. Interfaces 8 210049

Google Scholar

Google Scholar

[27] Lee S H, Cheong M H, Han S, Tracy C E, Mascarenhas A, Czanderna A W, Deb S K 1999 Appl. Phys. Lett. 75 1541

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 1830

- PDF Downloads: 77

- Cited By: 0

DownLoad:

DownLoad: