-

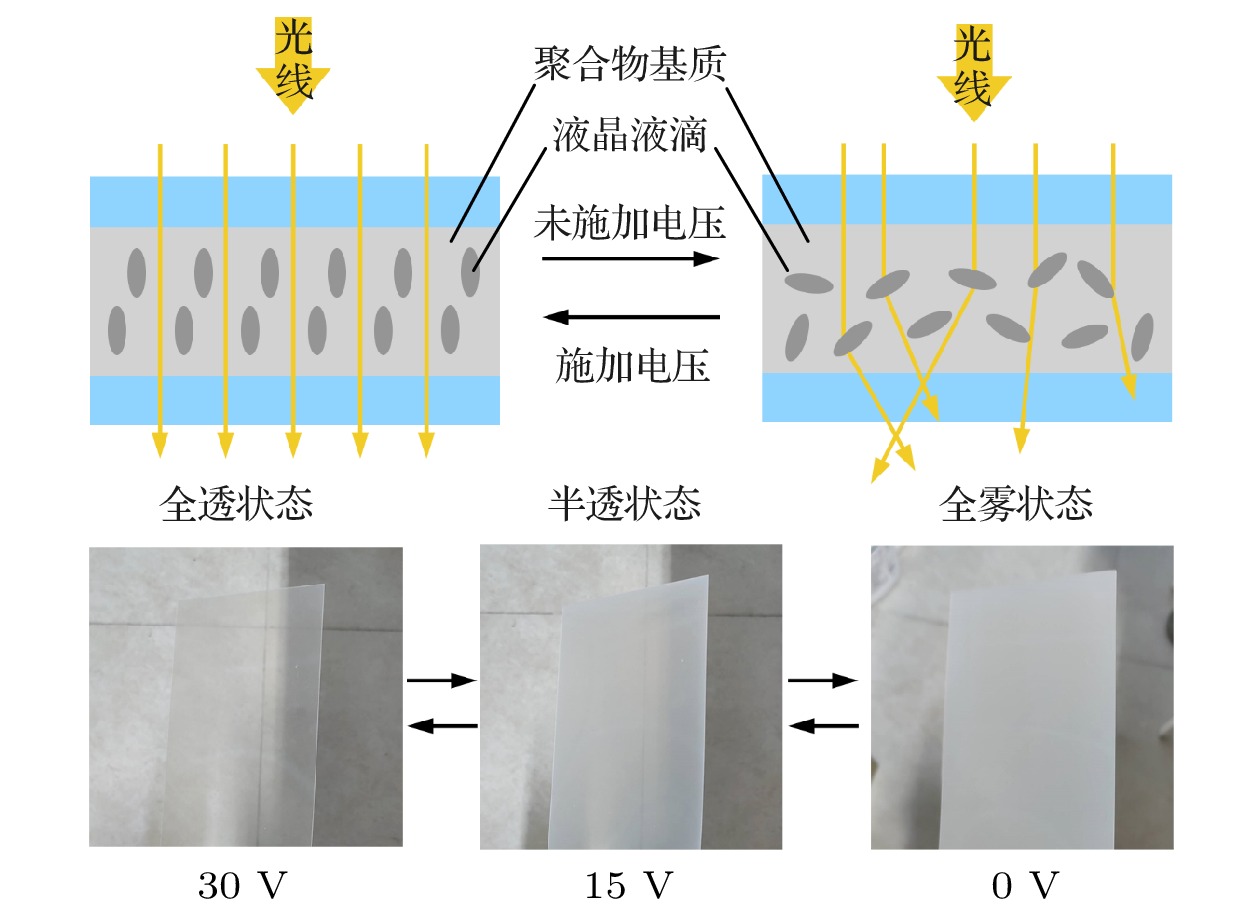

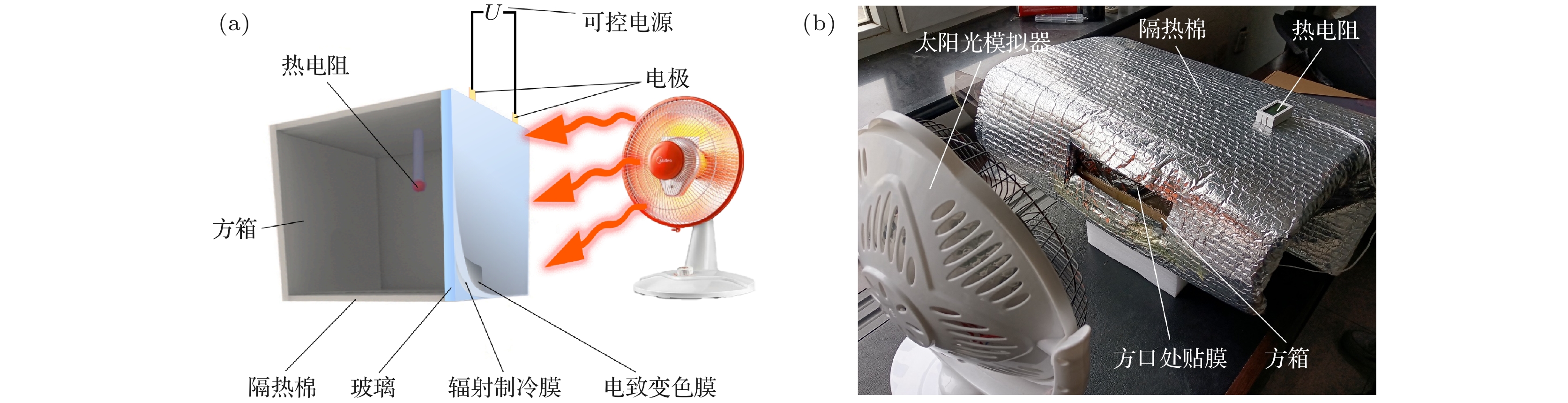

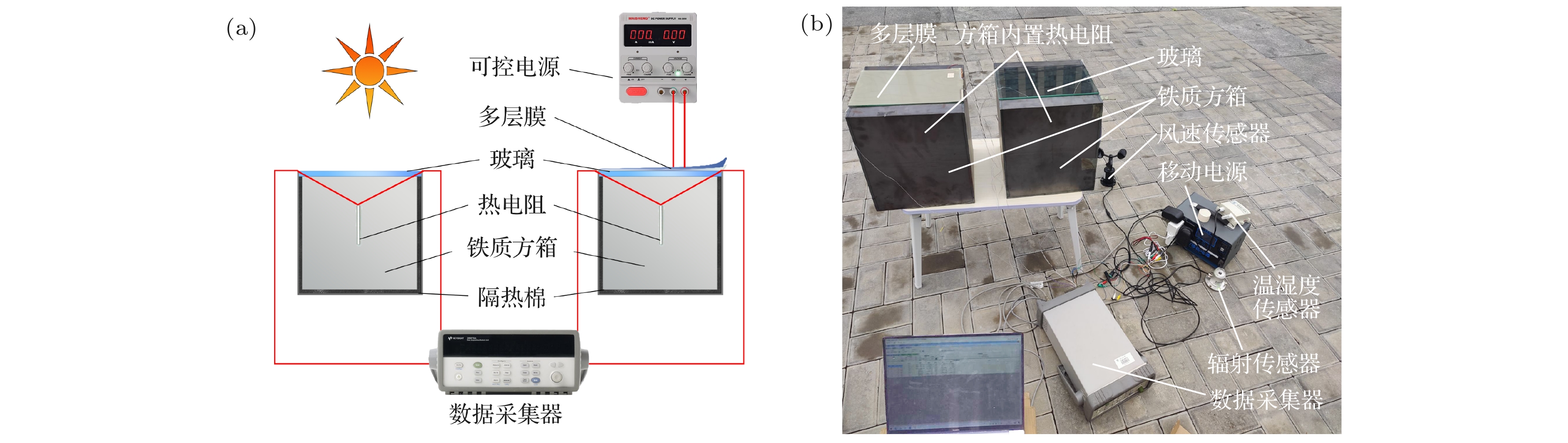

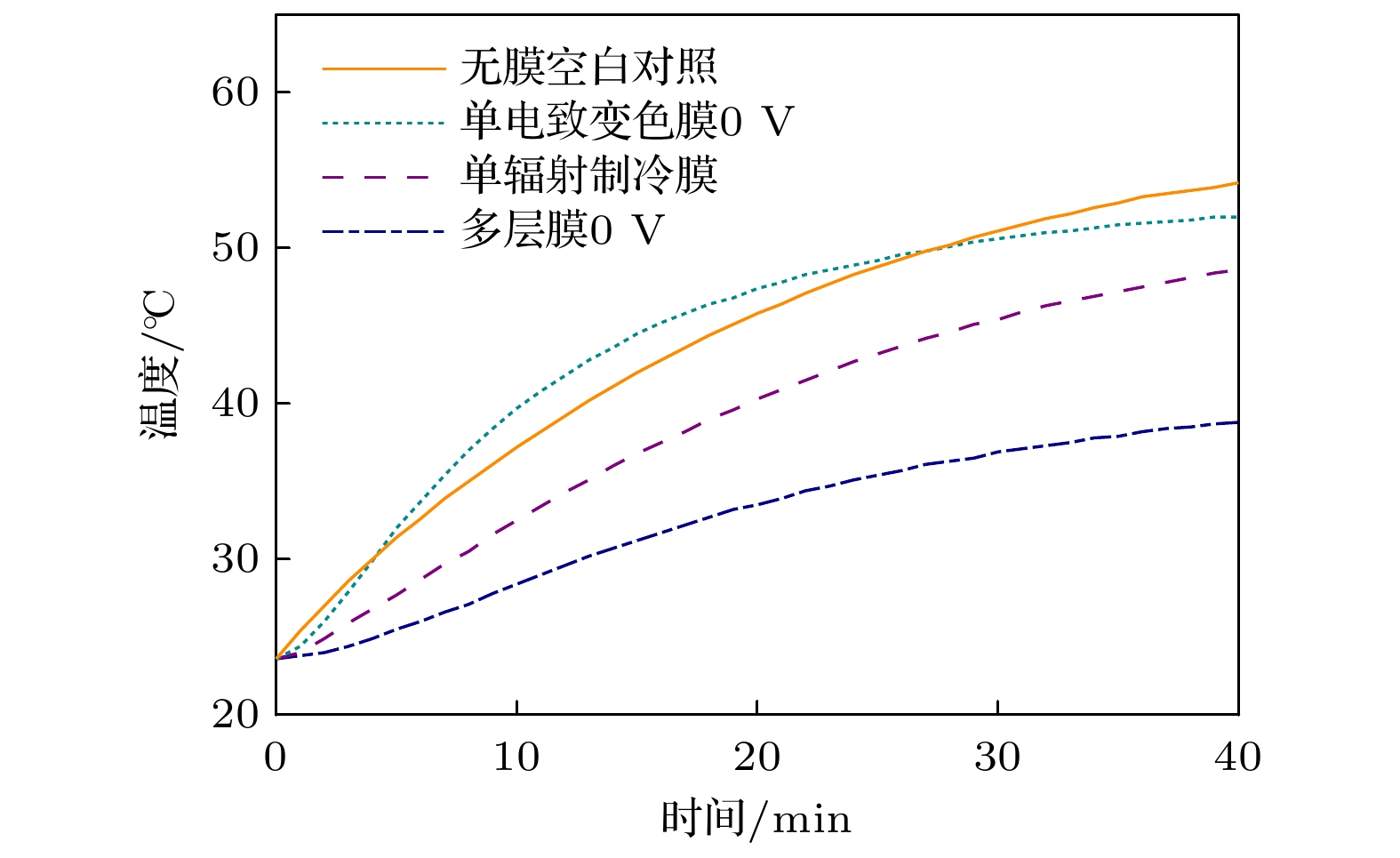

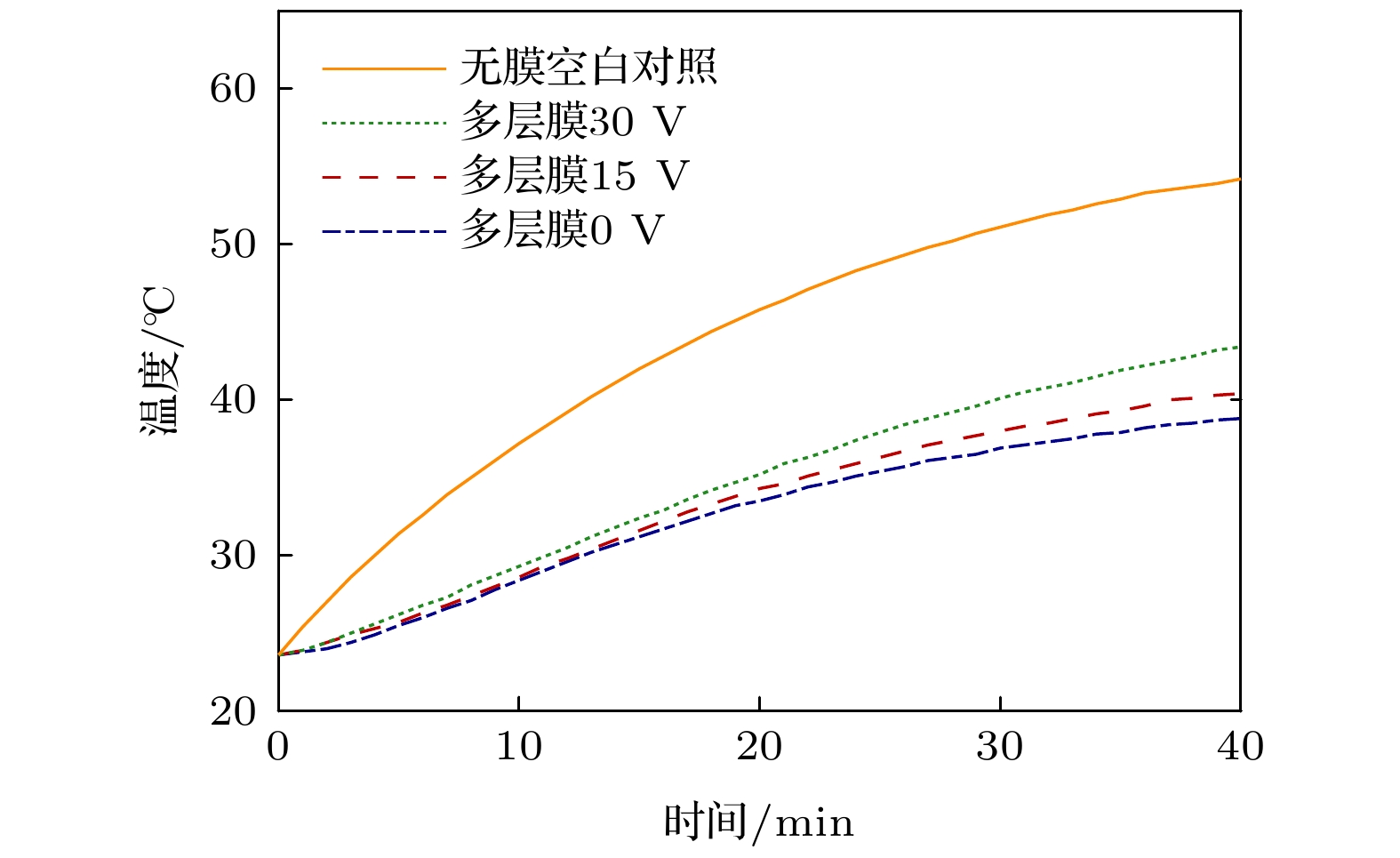

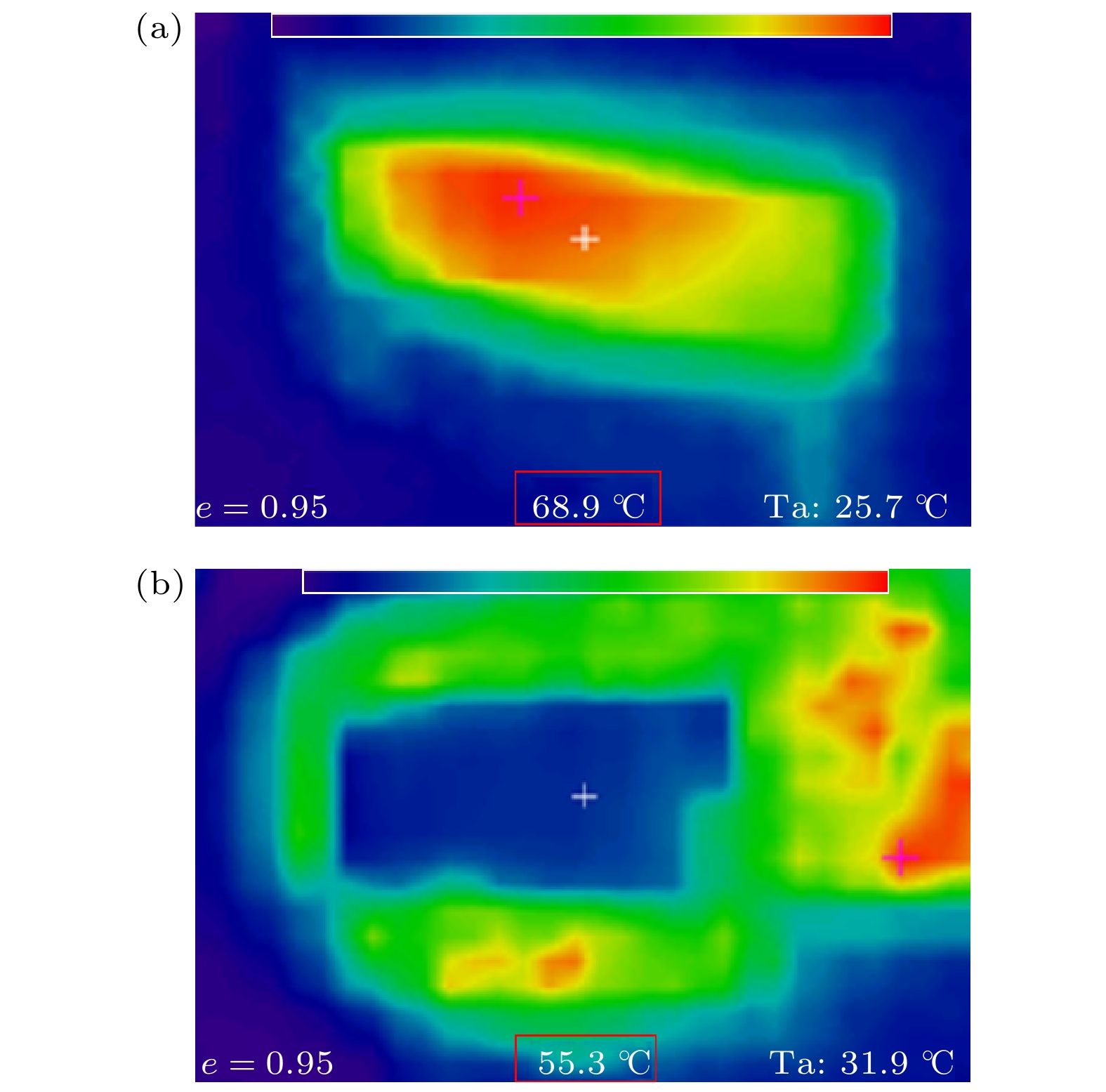

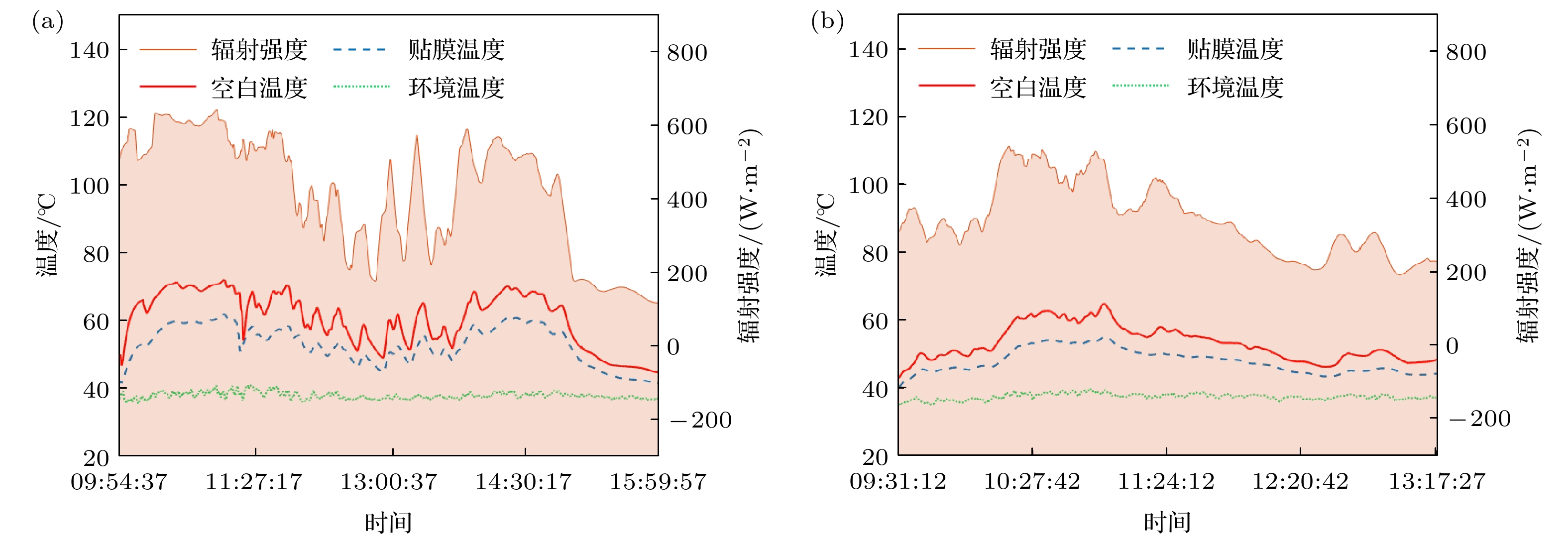

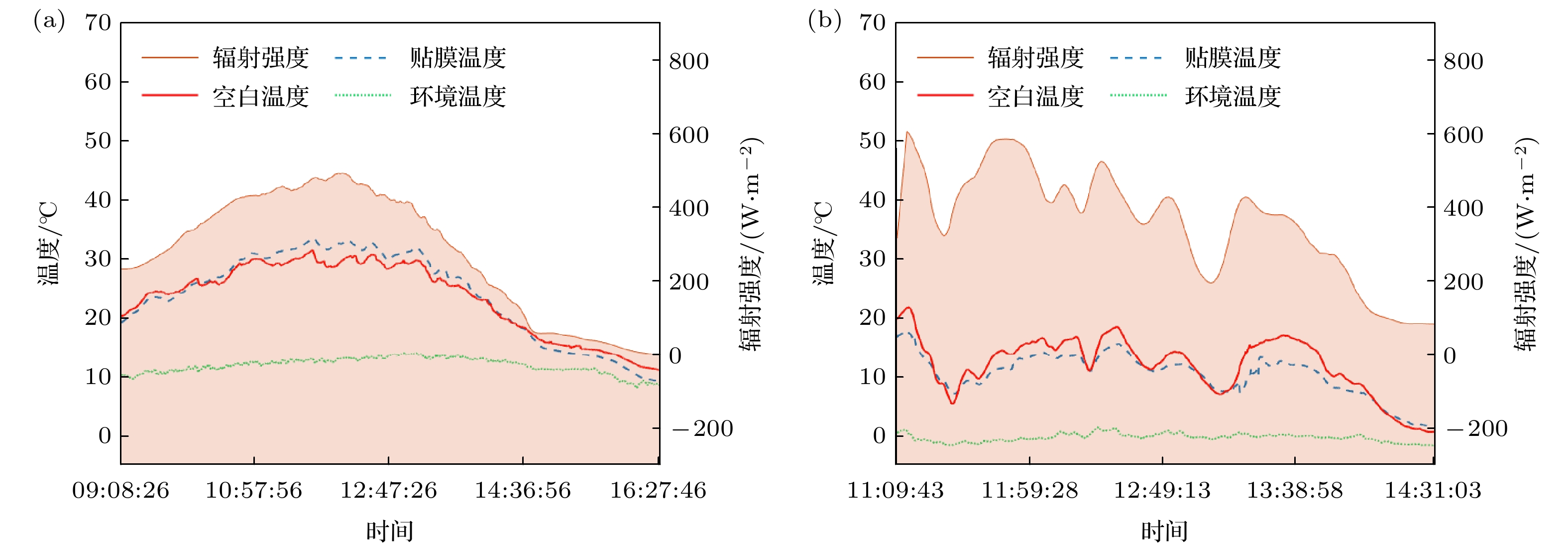

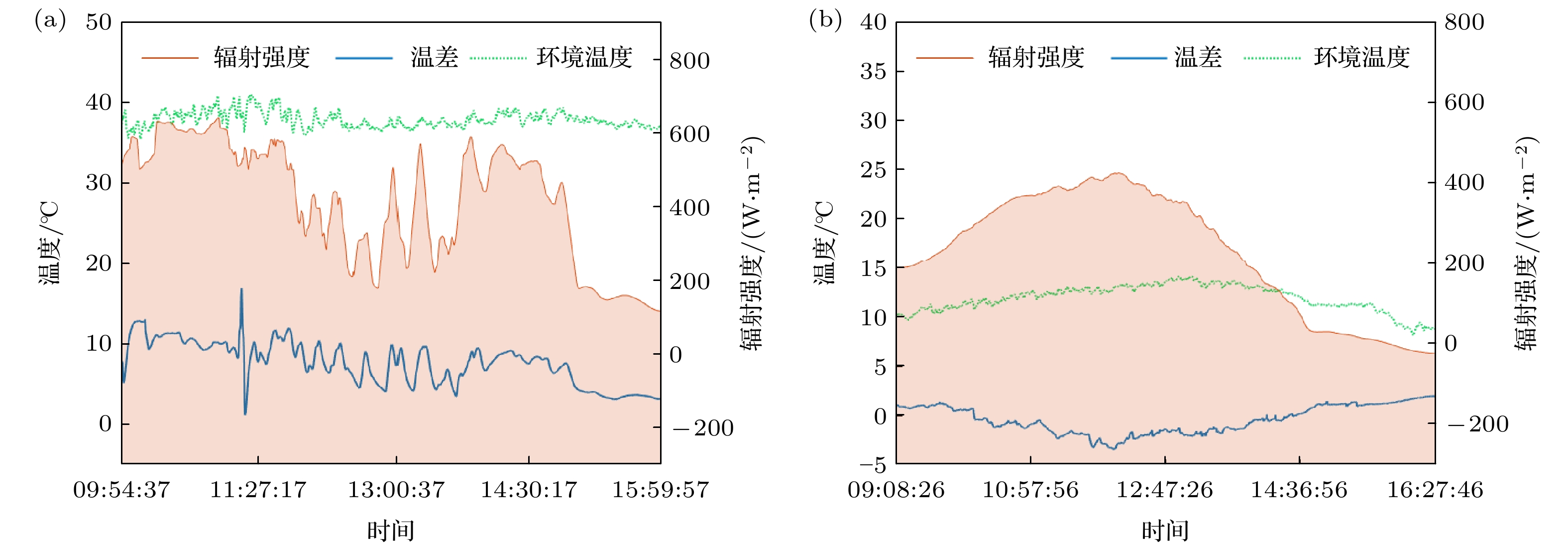

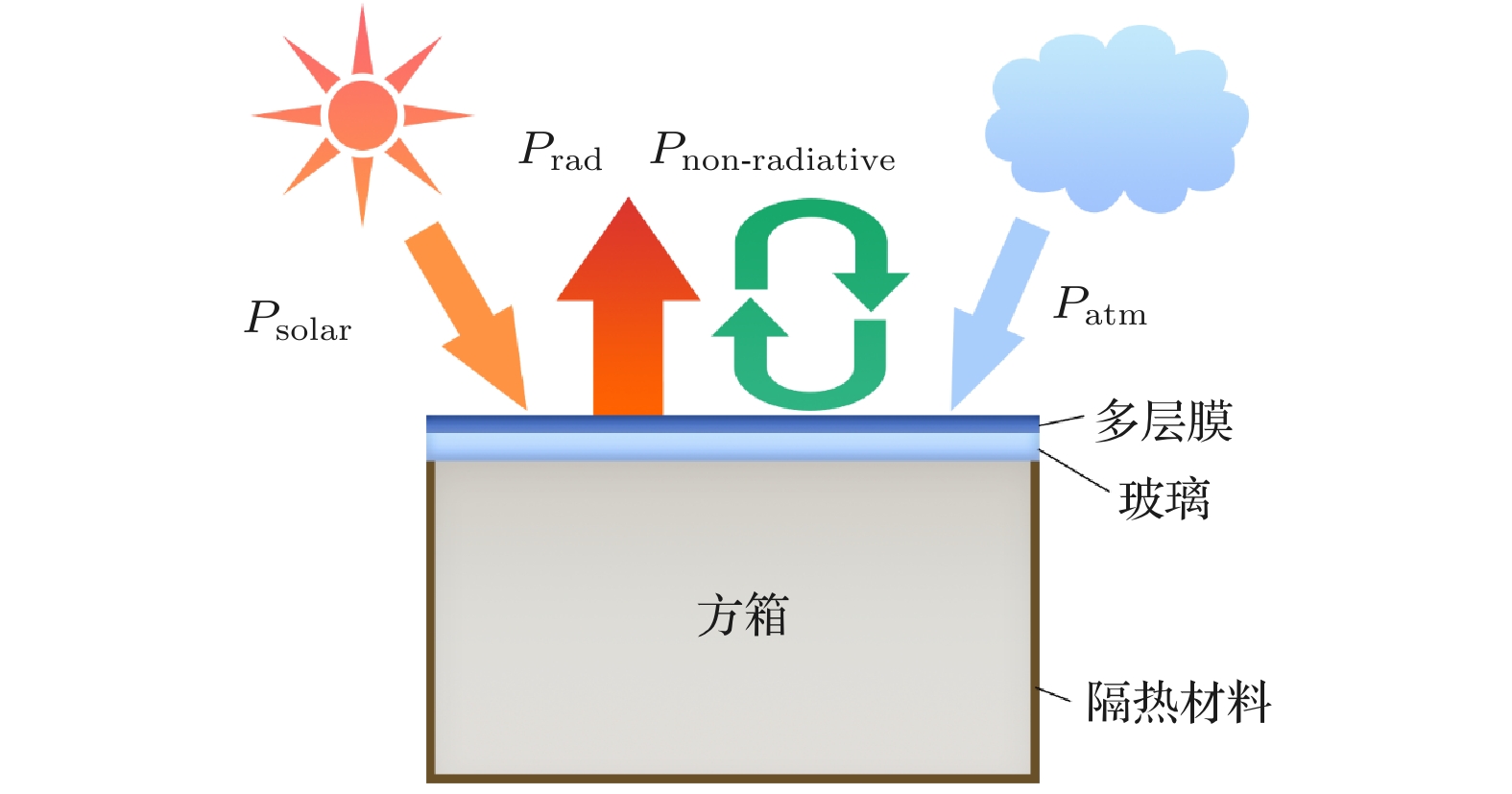

针对车用空调的高能耗问题, 设计了一种将辐射制冷膜和电致变色膜结合的可调节多层膜. 为研究多层膜的降温与温度调节性能, 搭建了贴膜方箱装置, 并在室内对贴膜装置进行太阳光模拟器照射实验, 结果表明, 多层膜相比单层辐射制冷膜最大箱内降温提升约9.8 ℃, 且能通过改变多层膜透过率实现约4.6 ℃的温度调节, 具有较强的降温与温度调节潜力. 为研究多层膜的环境适应性, 在夏季和冬季的室外对贴膜装置进行实际太阳照射实验, 结果表明: 夏季多层膜降温效果明显, 最大箱内降温高达12.9 ℃; 而冬季多层膜降温效果较弱, 最大箱内降温仅有1.9 ℃, 具有良好的环境适应性. 综上, 该多层膜可为降低汽车空调能耗提供一种新的解决方案.Energy and environmental challenges caused by the excessive consumption of fossil fuels are major concerns worldwide, and the use of automotive air conditioning can increase total fuel consumption by 10% to 30%, thereby exacerbating these problems. To reduce the energy consumption for automotive air conditioning, a multilayer-film design based on radiative cooling and electrochromic modulation is proposed for regulating the temperature inside vehicles. The designed multilayer-film not only passively realizes temperature drop but also actively regulates the entry of solar radiation, which can help the vehicle air conditioning system to adjust the interior temperature autonomously. To verify its effectiveness, a film-applied empty box device is designed for radiometric temperature measurement. Experimental results indicate that the maximum interior temperature drop of the multilayer film increases by approximately 9.8 ℃ compared with that of single-layer films in the sunlight irradiation, and dynamic temperature regulation of about 4.6 ℃ can be achieved by adjusting the transmittance of the multilayer film. To study the environmental adaptability of the multilayer film, experiments are conducted on an outdoor film-applied device during the summer and winter in Shenyang, China ($\rm 41^\circ44'N, 123^\circ39'E$), the place which is characterized by a typical temperate continental climate. Results indicate that under high temperature conditions of 30–40 ℃ in summer, the maximum internal temperature drop of the multilayer film reaches 12.9 ℃; while under low temperature conditions of 0–15 ℃ in autumn and winter, the maximum internal temperature drop is only 1.9 ℃, preventing the interior temperature from being too low. In addition, the maximum interior temperature drop increases with the solar radiation intensity and ambient temperature increasing. Therefore, the proposed multilayer-film design, with its potential for temperature self-regulation, provides a promising solution for reducing energy consumption and improving passenger comfort.

-

Keywords:

- radiative cooling /

- electrochromism /

- temperature regulation

[1] 国家统计局 2023 中国统计年鉴 42 284

National Bureau of Statistics 2023 China Stat. Yearbook 42 284

[2] Mogro A E, Huertas J I 2021 Int. J. Interact. Des. Manuf. 15 271

Google Scholar

Google Scholar

[3] Tuchinda C, Srivannaboon S, Lim H W 2006 J. Am. Acad. Dermatol. 54 845

Google Scholar

Google Scholar

[4] Mousavi N S S, Azzopardi B 2023 Energies 16 5256

Google Scholar

Google Scholar

[5] Catalanotti S, Cuomo V, Piro G, Ruggi D, Silvestrini V, Troise G 1975 Sol. Energy 17 83

Google Scholar

Google Scholar

[6] Lin K T, Han J H, Li K, Guo C S, Lin H, Jia B H 2021 Nano Energy 80 105517

Google Scholar

Google Scholar

[7] Li Z Z, Chen Q Y, Song Y, Zhu B, Zhu J 2020 Adv. Mater. Technol. 5 1901007

Google Scholar

Google Scholar

[8] 刘扬, 潘登, 陈文, 王文强, 沈昊, 徐红星 2020 69 036501

Google Scholar

Google Scholar

Liu Y, Pan D, Chen W, Wang W Q, Shen H, Xu H X 2020 Acta Phys. Sin. 69 036501

Google Scholar

Google Scholar

[9] 刘士彦, 姚博, 谭永胜, 徐海涛, 冀婷, 方泽波 2017 66 248801

Google Scholar

Google Scholar

Liu S Y, Yao B, Tan Y S, Xu H T, Ji T, Fang Z B 2017 Acta Phys. Sin. 66 248801

Google Scholar

Google Scholar

[10] 于海童, 刘东, 杨震, 段远源 2018 67 024209

Google Scholar

Google Scholar

Yu H T, Liu D, Yang Z, Duan Y Y 2018 Acta Phys. Sin. 67 024209

Google Scholar

Google Scholar

[11] Cannavale A, Ayr U, Martellotta F 2018 Energy Procedia 148 900

Google Scholar

Google Scholar

[12] Hemaida A, Ghosh A, Sundaram S, Mallick T K 2020 Sol. Energy 195 185

Google Scholar

Google Scholar

[13] Jaksic N I, Salahifar C 2003 Sol. Energy Mater. Sol. Cells 79 409

Google Scholar

Google Scholar

[14] Sun J W, Chen Y N, Liang Z Q 2016 Adv. Funct. Mater. 26 2783

Google Scholar

Google Scholar

[15] Wu Z X, Zhao Q, Luo X Y, Ma H D, Zheng W Q, Yu J W, Zhang Z L, Zhang K Y, Qu K, Yang R P, Jian N N, Hou J, Liu X M, Xu J K, Lu B Y 2022 Chem. Mater. 34 9923

Google Scholar

Google Scholar

[16] Ling H, Wu J C, Su F Y, Tian Y Q, Liu Y J 2021 Nat. Commun. 12 1010

Google Scholar

Google Scholar

[17] Zhang H M, Miao Z C, Shen W B 2022 Composites Part A 163 107234

Google Scholar

Google Scholar

[18] Lee S J, Song S Y 2023 Energy Build. 298 113514

Google Scholar

Google Scholar

[19] Casini M 2018 Renewable Energy 119 923

Google Scholar

Google Scholar

[20] Hakemi H 2017 Liq. Cryst. Today 26 70

Google Scholar

Google Scholar

-

表 1 辐射制冷膜主要参数

Table 1. Main parameters of radiation cooling film.

参数 百分数/% 参数 百分数/% 反射率 8 光太阳能

增益系数1.24 穿透率 66 太阳能总隔断率 47 紫外线阻隔率 99.9 热增益减少率 28.67 太阳能辐射

吸收系数0.53 炫光减少率 26 表 2 电致变色膜主要参数

Table 2. Main parameters of electrochromic film.

参数 数值 参数 数值 穿透率(30 V)% 73.5 功耗/(W·m–²) 6 穿透率(15 V)/% 65.5 使用寿命/h >50000 穿透率(0 V)/% 10.4 工作温度/℃ –20—70 紫外线隔断率/% 98 可视角度/(°) 120 工作电压/V 0—30 基材厚度/μm 600±50 -

[1] 国家统计局 2023 中国统计年鉴 42 284

National Bureau of Statistics 2023 China Stat. Yearbook 42 284

[2] Mogro A E, Huertas J I 2021 Int. J. Interact. Des. Manuf. 15 271

Google Scholar

Google Scholar

[3] Tuchinda C, Srivannaboon S, Lim H W 2006 J. Am. Acad. Dermatol. 54 845

Google Scholar

Google Scholar

[4] Mousavi N S S, Azzopardi B 2023 Energies 16 5256

Google Scholar

Google Scholar

[5] Catalanotti S, Cuomo V, Piro G, Ruggi D, Silvestrini V, Troise G 1975 Sol. Energy 17 83

Google Scholar

Google Scholar

[6] Lin K T, Han J H, Li K, Guo C S, Lin H, Jia B H 2021 Nano Energy 80 105517

Google Scholar

Google Scholar

[7] Li Z Z, Chen Q Y, Song Y, Zhu B, Zhu J 2020 Adv. Mater. Technol. 5 1901007

Google Scholar

Google Scholar

[8] 刘扬, 潘登, 陈文, 王文强, 沈昊, 徐红星 2020 69 036501

Google Scholar

Google Scholar

Liu Y, Pan D, Chen W, Wang W Q, Shen H, Xu H X 2020 Acta Phys. Sin. 69 036501

Google Scholar

Google Scholar

[9] 刘士彦, 姚博, 谭永胜, 徐海涛, 冀婷, 方泽波 2017 66 248801

Google Scholar

Google Scholar

Liu S Y, Yao B, Tan Y S, Xu H T, Ji T, Fang Z B 2017 Acta Phys. Sin. 66 248801

Google Scholar

Google Scholar

[10] 于海童, 刘东, 杨震, 段远源 2018 67 024209

Google Scholar

Google Scholar

Yu H T, Liu D, Yang Z, Duan Y Y 2018 Acta Phys. Sin. 67 024209

Google Scholar

Google Scholar

[11] Cannavale A, Ayr U, Martellotta F 2018 Energy Procedia 148 900

Google Scholar

Google Scholar

[12] Hemaida A, Ghosh A, Sundaram S, Mallick T K 2020 Sol. Energy 195 185

Google Scholar

Google Scholar

[13] Jaksic N I, Salahifar C 2003 Sol. Energy Mater. Sol. Cells 79 409

Google Scholar

Google Scholar

[14] Sun J W, Chen Y N, Liang Z Q 2016 Adv. Funct. Mater. 26 2783

Google Scholar

Google Scholar

[15] Wu Z X, Zhao Q, Luo X Y, Ma H D, Zheng W Q, Yu J W, Zhang Z L, Zhang K Y, Qu K, Yang R P, Jian N N, Hou J, Liu X M, Xu J K, Lu B Y 2022 Chem. Mater. 34 9923

Google Scholar

Google Scholar

[16] Ling H, Wu J C, Su F Y, Tian Y Q, Liu Y J 2021 Nat. Commun. 12 1010

Google Scholar

Google Scholar

[17] Zhang H M, Miao Z C, Shen W B 2022 Composites Part A 163 107234

Google Scholar

Google Scholar

[18] Lee S J, Song S Y 2023 Energy Build. 298 113514

Google Scholar

Google Scholar

[19] Casini M 2018 Renewable Energy 119 923

Google Scholar

Google Scholar

[20] Hakemi H 2017 Liq. Cryst. Today 26 70

Google Scholar

Google Scholar

计量

- 文章访问数: 4654

- PDF下载量: 136

- 被引次数: 0

下载:

下载: