-

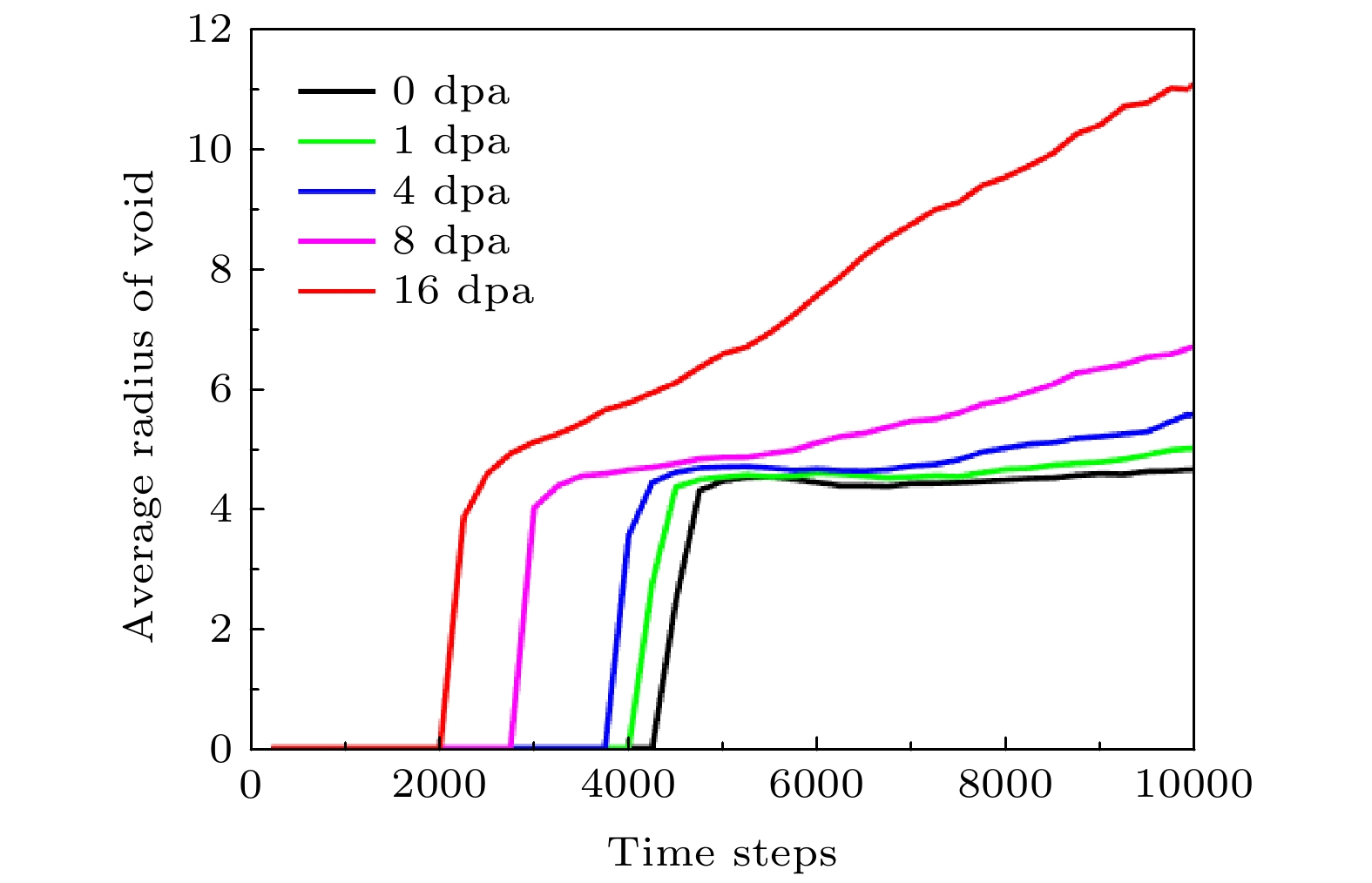

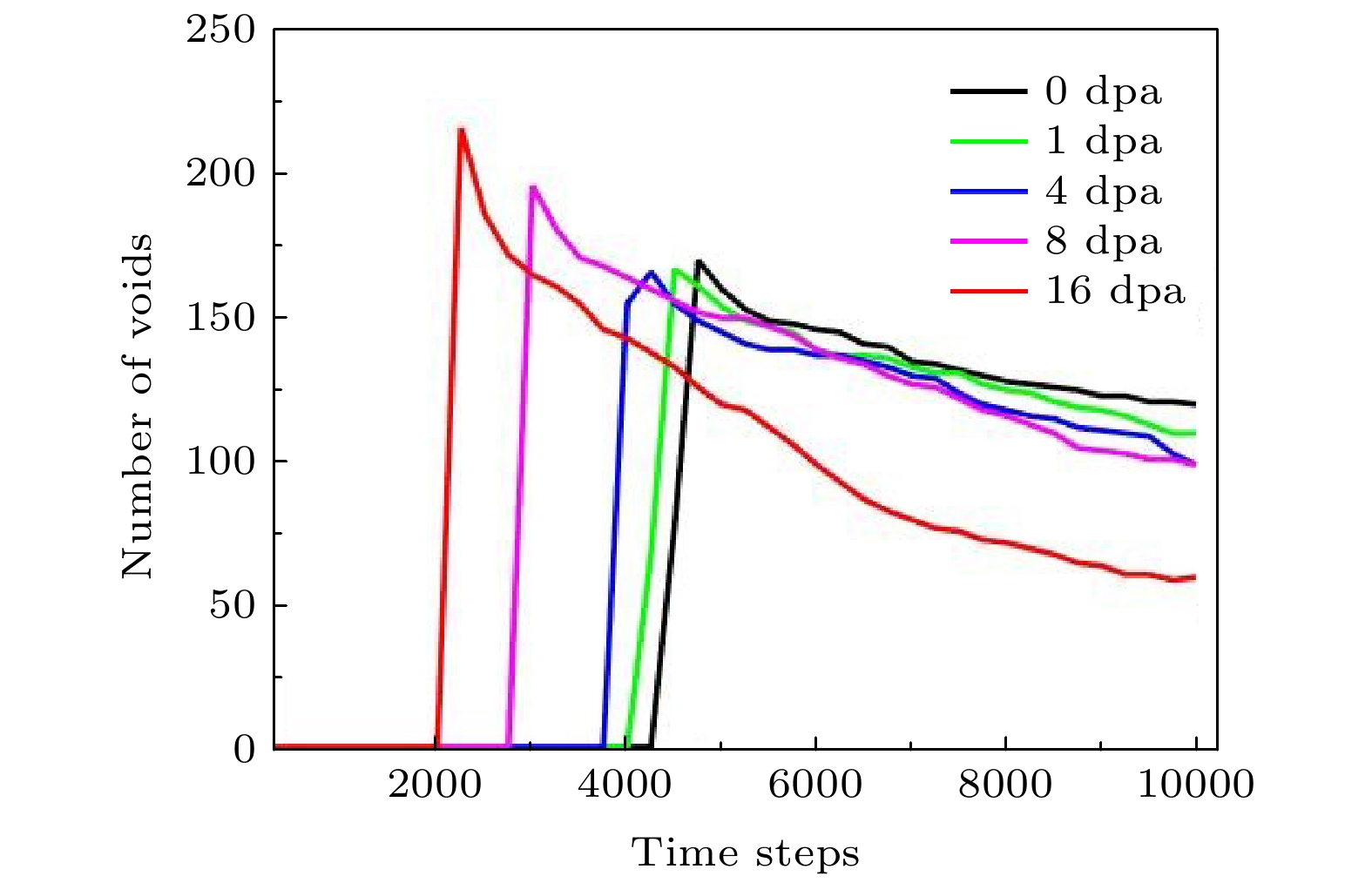

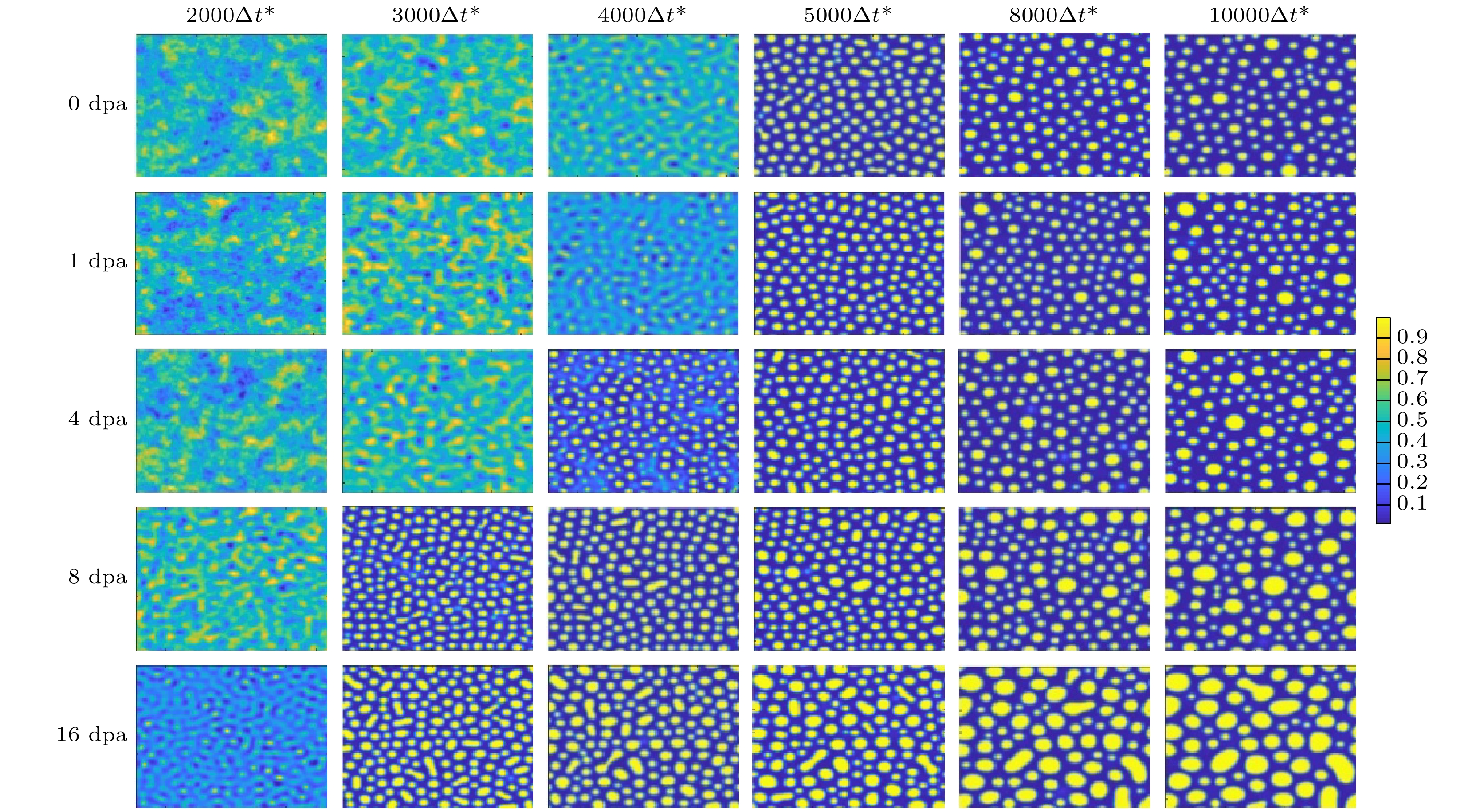

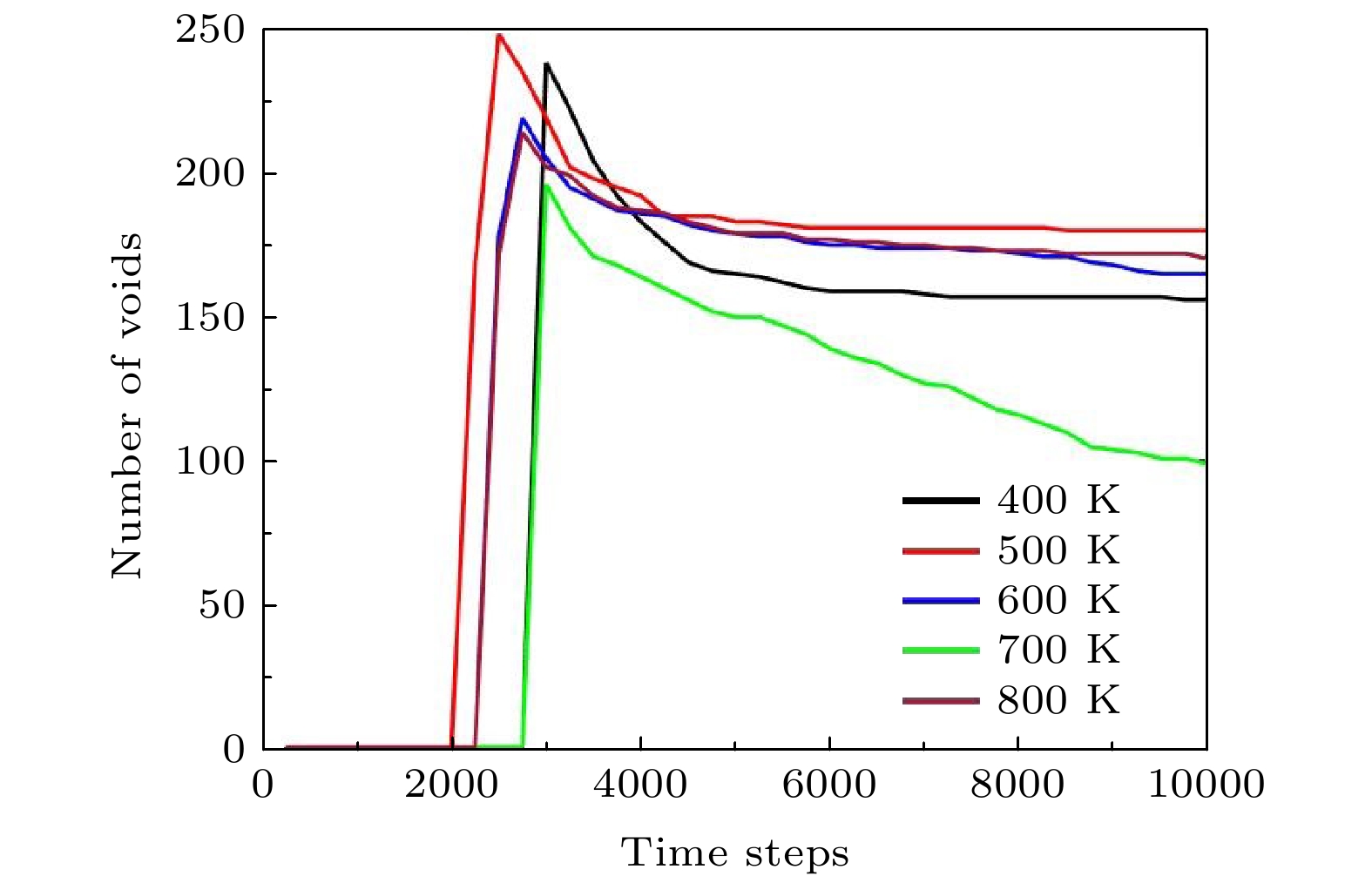

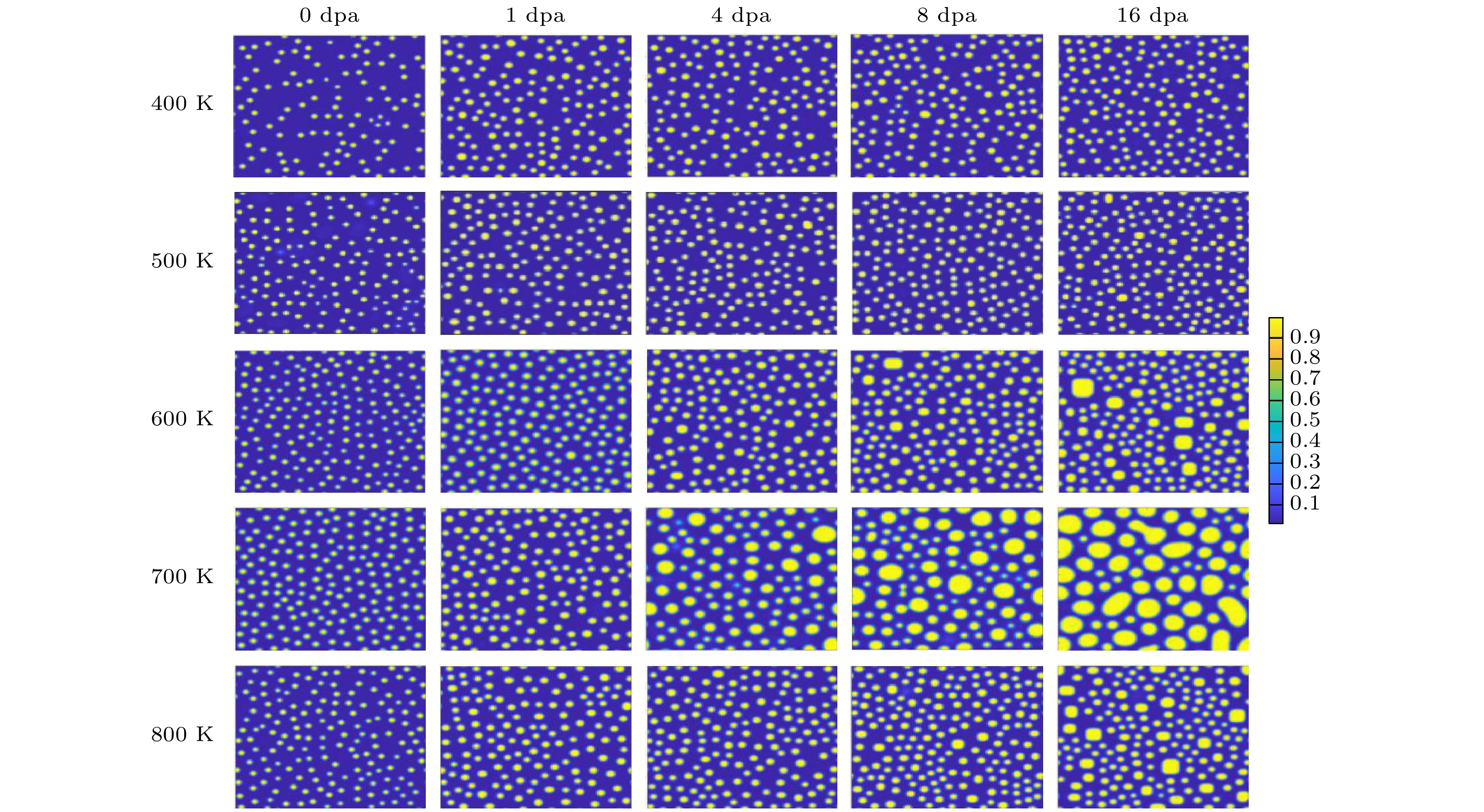

Fe-Cr合金作为包壳材料在高温高辐照强度等极端环境下服役, 产生空位和间隙原子等辐照缺陷, 辐照缺陷簇聚诱发空洞、位错环等缺陷团簇, 引起辐照肿胀、晶格畸变, 导致辐照硬化或软化致使材料失效. 理解辐照缺陷簇聚和长大过程的组织演化, 能更有效调控组织获得稳定服役性能. 本文采用相场法研究Fe-Cr合金中空洞的演化, 模型考虑了温度效应对点缺陷的影响以及空位和间隙的产生和复合. 选择400—800 K温度区间、0—16 dpa辐照剂量范围的Fe-Cr体系为对象, 研究在不同服役温度和辐照剂量下的空位扩散、复合和簇聚形成空洞的过程. 在400—800 K温度区间, 随着温度的升高, Fe-Cr合金空洞团簇形核率呈现出先升高后下降的趋势. 考虑空位与间隙的重新组合受温度的影响可以很好地解释空洞率随温度变化时出现先升高后降低的现象. 由于温度的变化将影响Fe-Cr合金中原子离位阀能, 从而影响产生空位和间隙原子. 同一温度下, 空洞半径和空洞的体积分数随辐照剂量的增大而增大. 辐照剂量的增大, 级联碰撞反应加强, 空位与间隙原子大量产生, 高温下空位迅速的扩散聚集在Fe-Cr合金中将形成更多数量以及更大尺寸的空洞.As cladding materials, Fe-Cr alloys are used in the extreme environments of high temperature, high pressure, and energetic particle radiation, thus generating irradiation defects such as vacancies and interstitials. The clustering of irradiation defects leads the voids or dislocation loops to form, resulting in irradiation swelling and lattice distortion, and further radiation hardening or softening, finally, material failure. It is beneficial to tailor desired microstructures and obtain stable service performances by understanding defects cluster and voids formation process. In this paper, the phase-field method is employed to study the evolution of voids of Fe-Cr alloy. In the model the temperature effects on point defects and generation/recombination of vacancies and interstitials are taken into consideration. The 400–800 K temperature range and 0–16 dpa radiation dose range are selected, in which the voids’ formation process including generation and recombination, as well as vacancy clustering caused by vacancy diffusion, is studied for Fe-Cr alloy. The nucleation rate of the void cluster shows a trend of first increasing and then decreasing with temperature increasing from 400 to 800 K. This phenomenon is related to complex interactions among defects concentration, atomic diffusion, recombination, nucleation, and growth conditions. At a given temperature, the average radius and the volume fraction of the voids grow bigger as the radiation dose increases. With the increase of irradiation dose, the cascade collision reaction is strengthened, and the number of Frenkel defect pairs is also increases. A large number of vacancies and interstitial atoms are generated, and the rapid diffusion and accumulation of vacancies in the Fe-Cr alloy at high temperature form a larger number and larger size of voids. The incubation period of vacancy clusters and voids are quite different due to the influence of irradiation temperature and dose. The higher the irradiation dose, the shorter the incubation period is. The relationship between the incubation period and temperature is more complicated. When the temperature is relatively low, the incubation period is shortened as the temperature increases, and as the temperature continues to increase to a higher temperature, the incubation period is extended. This relates to the increase in the concentration of vacancies, the recombination of vacancies and interstitials, and the increase of the critical nucleus radius for the growth of voids when the temperature increases.

-

Keywords:

- phase-field method /

- void evolution /

- irradiation dose /

- cascade collision

[1] Klueh R L, Nelson A T 2007 J. Nucl. Mater. 371 37

Google Scholar

Google Scholar

[2] Buongiorno J, Swindeman R, Corwin W, Rowchitte A, McDonald P, Was G, Mansur L, Wikon D, Nanstad R, Wright I 2003 Supercritical Water Reactor (SCWR) : Survey of Materials Experience and R&D Needs to Assess Viability, Idaho National EngineeringLaboratory Report INEEL/EXT-03-00693 (Rev. 1) Idaho September 2003

[3] Sass S L, Eyre B L 1973 Philos. Mag. 27 1447

Google Scholar

Google Scholar

[4] Une K, Nogita K, Kashibe S, Imamura M 1992 J. Nucl. Mater. 188 65

Google Scholar

Google Scholar

[5] Nogita K, Une K 1993 J. Nucl. Mater. 91 301

[6] Zacharie I, Lansiart S, Combette P, Trotabas M, Coster M, Groos M 1998 J. Nucl. Mater. 255 92

Google Scholar

Google Scholar

[7] Katsuyama K, Nagamine T, Matsumoto S, Ito M 2002 J. Nucl. Sci. Technol. 39 804

Google Scholar

Google Scholar

[8] 张娜, 刘波, 林黎蔚 2020 69 016101

Google Scholar

Google Scholar

Zhang N, Liu B, Lin L W 2020 Acta Phys. Sin. 69 016101

Google Scholar

Google Scholar

[9] 高云亮, 朱芫江, 李进平 2017 66 057104

Google Scholar

Google Scholar

Gao Y L, Zhu Y J, Li J P 2017 Acta Phys. Sin. 66 057104

Google Scholar

Google Scholar

[10] Lindhard J, Nielsen V, Scharff M, Thomsen P V 1963 Mat. Fys. Medd. Dan. Vid. Selsk. 33 706

[11] 郁金南 2007 核材料科学与工程——材料辐照效应 (北京: 化学工业出版社) 第198—203页

Yu J N 2007 Nuclear Materials Science and Engineering Radiation Effects of Materials (Beijing: Chemical Industry Press) pp198–203 (in Chinese)

[12] Becker C H 1972 US Patent 3 657 707 [1972-4-18]

[13] 黄鹤飞, 李健健, 刘仁多, 陈怀灿, 闫隆 2014 金属学报 50 1189

Google Scholar

Google Scholar

Huang H F, Li J J, Liu R D, Chen H C, Yan L 2014 J. Acta Metall. Sin. 50 1189

Google Scholar

Google Scholar

[14] 丁兆楠, 杨义涛, 宋银, 张丽卿, 缑洁, 张崇宏, 罗广南 2017 66 112501

Google Scholar

Google Scholar

Ding Z N, Yang Y T, Song Y, Zhang L Q, Gou J, Zhang C H, Luo G N 2017 Acta Phys. Sin. 66 112501

Google Scholar

Google Scholar

[15] Lambrecht M, Malerba L 2011 Acta Mater. 59 6547

Google Scholar

Google Scholar

[16] Reese E R, Almirall N, Yamamoto T 2018 Scr. Mater. 146 213

Google Scholar

Google Scholar

[17] Liu Y L, Zhang Y, Zhou H B 2009 Phys. Rev. B 79 172103

Google Scholar

Google Scholar

[18] Zhou H B, Liu Y L, Jin S 2010 Nucl. Fusi. 50 115010

Google Scholar

Google Scholar

[19] Alkhamees A, Liu Y L, Zhou H B 2009 J. Nucl. Mater. 393 508

Google Scholar

Google Scholar

[20] 梁晋洁, 高宁, 李玉红 2020 69 116102

Google Scholar

Google Scholar

Liang J J, Gao N, Li Y H 2020 Acta Phys. Sin. 69 116102

Google Scholar

Google Scholar

[21] 朱琪, 王升涛, 赵福祺, 潘昊 2020 69 036201

Google Scholar

Google Scholar

Zhu Q, Wang S T, Zhao F Q, Pan H 2020 Acta Phys. Sin. 69 036201

Google Scholar

Google Scholar

[22] 梁晋洁, 高宁, 李玉红 2020 69 036101

Google Scholar

Google Scholar

Liang J J, Gao N, Li Y H 2020 Acta Phys. Sin. 69 036101

Google Scholar

Google Scholar

[23] 梁林云, 吕广宏 2013 62 182801

Google Scholar

Google Scholar

Liang L Y, Lü G H 2013 Acta Phys. Sin. 62 182801

Google Scholar

Google Scholar

[24] 李然然, 张一帆, 耿殿程, 张高伟, 渡边英雄, 韩文妥, 万发荣 2019 68 216101

Google Scholar

Google Scholar

Li R R, Zhang Y F, Geng D C, Zhang G W, Watanabe Hideo, Han W T, Wan F R 2019 Acta Phys. Sin. 68 216101

Google Scholar

Google Scholar

[25] Hu S Y, Henager C H, Heinisch H L 2009 J. Nucl. Mater. 392 292

Google Scholar

Google Scholar

[26] Rokkam S, El-Azab A, Millett P 2009 Model Simul. Mater.Sci. Eng. 17 064002

Google Scholar

Google Scholar

[27] Millett P C, Rokkam S, El-Azab A 2009 Model Simul. Mater. Sci. Eng. 17 064003

Google Scholar

Google Scholar

[28] Zhao B J, Zhao Y H, Sun Y Y, Yang W K, Hou H 2019 Acta Metall. Sin. 55 593

[29] Yan Z W, Shi S J, Li Y S, Chen J, Maqbool S 2020 Phys. Chem. Chem. Phys. 22 3611

Google Scholar

Google Scholar

[30] Provatas N, Elder K 2010 Phase-field Methods in Materials Science and Engineering (Germany: Weinheim Wiley-VCH) pp2−5

[31] Hu S Y, Henager C H 2010 Acta Mater. 58 3230

Google Scholar

Google Scholar

[32] Li Y, Hu S, Sun X 2010 J. Nucl. Mater. 407 119

Google Scholar

Google Scholar

[33] Simeone D, Ribis J, Luneville L 2018 J. Mater. Res. 33 440

Google Scholar

Google Scholar

[34] Ortiz C J, Caturla M J 2007 Phys. Rev. B 75 184101

Google Scholar

Google Scholar

[35] Bacon D J, Gao F, Osetsky Y N 2000 J. Nucl. Mater. 276 1

Google Scholar

Google Scholar

[36] Souidi A, Becquart C S, Domain C 2006 J. Nucl. Mater. 355 89

Google Scholar

Google Scholar

[37] Boisse J, Domain C, Becquart C S 2014 J. Nucl. Mater. 455 10

Google Scholar

Google Scholar

[38] 徐恒均 2009 材料科学基础(第一版)(北京: 北京工业大学出版社) 第205−214页

Xu H J 2009 Foundations of Materials Science (Vol.1) (Beijjing: Beijing University of Technology Press) pp205−214 (in Chinese)

[39] Wong K L, Lee H J, Shim J H, Sadigh B, Wirth B D 2009 J. Nucl. Mater 386 227

[40] Norris, D I R 1972 Radiation Effects 14 1

Google Scholar

Google Scholar

[41] Getto E, Jiao Z, Monterrosa A M 2015 J. Nucl.Mater. 462 458

Google Scholar

Google Scholar

[42] Toloczko M B, Garner F A, Voyevodin V N 2014 J. Nucl.Mater. 453 323

Google Scholar

Google Scholar

[43] Brailsford A D, Bullough R, Hayns M R 1978 J. Nucl. Mater. 60 246

-

-

[1] Klueh R L, Nelson A T 2007 J. Nucl. Mater. 371 37

Google Scholar

Google Scholar

[2] Buongiorno J, Swindeman R, Corwin W, Rowchitte A, McDonald P, Was G, Mansur L, Wikon D, Nanstad R, Wright I 2003 Supercritical Water Reactor (SCWR) : Survey of Materials Experience and R&D Needs to Assess Viability, Idaho National EngineeringLaboratory Report INEEL/EXT-03-00693 (Rev. 1) Idaho September 2003

[3] Sass S L, Eyre B L 1973 Philos. Mag. 27 1447

Google Scholar

Google Scholar

[4] Une K, Nogita K, Kashibe S, Imamura M 1992 J. Nucl. Mater. 188 65

Google Scholar

Google Scholar

[5] Nogita K, Une K 1993 J. Nucl. Mater. 91 301

[6] Zacharie I, Lansiart S, Combette P, Trotabas M, Coster M, Groos M 1998 J. Nucl. Mater. 255 92

Google Scholar

Google Scholar

[7] Katsuyama K, Nagamine T, Matsumoto S, Ito M 2002 J. Nucl. Sci. Technol. 39 804

Google Scholar

Google Scholar

[8] 张娜, 刘波, 林黎蔚 2020 69 016101

Google Scholar

Google Scholar

Zhang N, Liu B, Lin L W 2020 Acta Phys. Sin. 69 016101

Google Scholar

Google Scholar

[9] 高云亮, 朱芫江, 李进平 2017 66 057104

Google Scholar

Google Scholar

Gao Y L, Zhu Y J, Li J P 2017 Acta Phys. Sin. 66 057104

Google Scholar

Google Scholar

[10] Lindhard J, Nielsen V, Scharff M, Thomsen P V 1963 Mat. Fys. Medd. Dan. Vid. Selsk. 33 706

[11] 郁金南 2007 核材料科学与工程——材料辐照效应 (北京: 化学工业出版社) 第198—203页

Yu J N 2007 Nuclear Materials Science and Engineering Radiation Effects of Materials (Beijing: Chemical Industry Press) pp198–203 (in Chinese)

[12] Becker C H 1972 US Patent 3 657 707 [1972-4-18]

[13] 黄鹤飞, 李健健, 刘仁多, 陈怀灿, 闫隆 2014 金属学报 50 1189

Google Scholar

Google Scholar

Huang H F, Li J J, Liu R D, Chen H C, Yan L 2014 J. Acta Metall. Sin. 50 1189

Google Scholar

Google Scholar

[14] 丁兆楠, 杨义涛, 宋银, 张丽卿, 缑洁, 张崇宏, 罗广南 2017 66 112501

Google Scholar

Google Scholar

Ding Z N, Yang Y T, Song Y, Zhang L Q, Gou J, Zhang C H, Luo G N 2017 Acta Phys. Sin. 66 112501

Google Scholar

Google Scholar

[15] Lambrecht M, Malerba L 2011 Acta Mater. 59 6547

Google Scholar

Google Scholar

[16] Reese E R, Almirall N, Yamamoto T 2018 Scr. Mater. 146 213

Google Scholar

Google Scholar

[17] Liu Y L, Zhang Y, Zhou H B 2009 Phys. Rev. B 79 172103

Google Scholar

Google Scholar

[18] Zhou H B, Liu Y L, Jin S 2010 Nucl. Fusi. 50 115010

Google Scholar

Google Scholar

[19] Alkhamees A, Liu Y L, Zhou H B 2009 J. Nucl. Mater. 393 508

Google Scholar

Google Scholar

[20] 梁晋洁, 高宁, 李玉红 2020 69 116102

Google Scholar

Google Scholar

Liang J J, Gao N, Li Y H 2020 Acta Phys. Sin. 69 116102

Google Scholar

Google Scholar

[21] 朱琪, 王升涛, 赵福祺, 潘昊 2020 69 036201

Google Scholar

Google Scholar

Zhu Q, Wang S T, Zhao F Q, Pan H 2020 Acta Phys. Sin. 69 036201

Google Scholar

Google Scholar

[22] 梁晋洁, 高宁, 李玉红 2020 69 036101

Google Scholar

Google Scholar

Liang J J, Gao N, Li Y H 2020 Acta Phys. Sin. 69 036101

Google Scholar

Google Scholar

[23] 梁林云, 吕广宏 2013 62 182801

Google Scholar

Google Scholar

Liang L Y, Lü G H 2013 Acta Phys. Sin. 62 182801

Google Scholar

Google Scholar

[24] 李然然, 张一帆, 耿殿程, 张高伟, 渡边英雄, 韩文妥, 万发荣 2019 68 216101

Google Scholar

Google Scholar

Li R R, Zhang Y F, Geng D C, Zhang G W, Watanabe Hideo, Han W T, Wan F R 2019 Acta Phys. Sin. 68 216101

Google Scholar

Google Scholar

[25] Hu S Y, Henager C H, Heinisch H L 2009 J. Nucl. Mater. 392 292

Google Scholar

Google Scholar

[26] Rokkam S, El-Azab A, Millett P 2009 Model Simul. Mater.Sci. Eng. 17 064002

Google Scholar

Google Scholar

[27] Millett P C, Rokkam S, El-Azab A 2009 Model Simul. Mater. Sci. Eng. 17 064003

Google Scholar

Google Scholar

[28] Zhao B J, Zhao Y H, Sun Y Y, Yang W K, Hou H 2019 Acta Metall. Sin. 55 593

[29] Yan Z W, Shi S J, Li Y S, Chen J, Maqbool S 2020 Phys. Chem. Chem. Phys. 22 3611

Google Scholar

Google Scholar

[30] Provatas N, Elder K 2010 Phase-field Methods in Materials Science and Engineering (Germany: Weinheim Wiley-VCH) pp2−5

[31] Hu S Y, Henager C H 2010 Acta Mater. 58 3230

Google Scholar

Google Scholar

[32] Li Y, Hu S, Sun X 2010 J. Nucl. Mater. 407 119

Google Scholar

Google Scholar

[33] Simeone D, Ribis J, Luneville L 2018 J. Mater. Res. 33 440

Google Scholar

Google Scholar

[34] Ortiz C J, Caturla M J 2007 Phys. Rev. B 75 184101

Google Scholar

Google Scholar

[35] Bacon D J, Gao F, Osetsky Y N 2000 J. Nucl. Mater. 276 1

Google Scholar

Google Scholar

[36] Souidi A, Becquart C S, Domain C 2006 J. Nucl. Mater. 355 89

Google Scholar

Google Scholar

[37] Boisse J, Domain C, Becquart C S 2014 J. Nucl. Mater. 455 10

Google Scholar

Google Scholar

[38] 徐恒均 2009 材料科学基础(第一版)(北京: 北京工业大学出版社) 第205−214页

Xu H J 2009 Foundations of Materials Science (Vol.1) (Beijjing: Beijing University of Technology Press) pp205−214 (in Chinese)

[39] Wong K L, Lee H J, Shim J H, Sadigh B, Wirth B D 2009 J. Nucl. Mater 386 227

[40] Norris, D I R 1972 Radiation Effects 14 1

Google Scholar

Google Scholar

[41] Getto E, Jiao Z, Monterrosa A M 2015 J. Nucl.Mater. 462 458

Google Scholar

Google Scholar

[42] Toloczko M B, Garner F A, Voyevodin V N 2014 J. Nucl.Mater. 453 323

Google Scholar

Google Scholar

[43] Brailsford A D, Bullough R, Hayns M R 1978 J. Nucl. Mater. 60 246

计量

- 文章访问数: 8037

- PDF下载量: 152

- 被引次数: 0

下载:

下载: