-

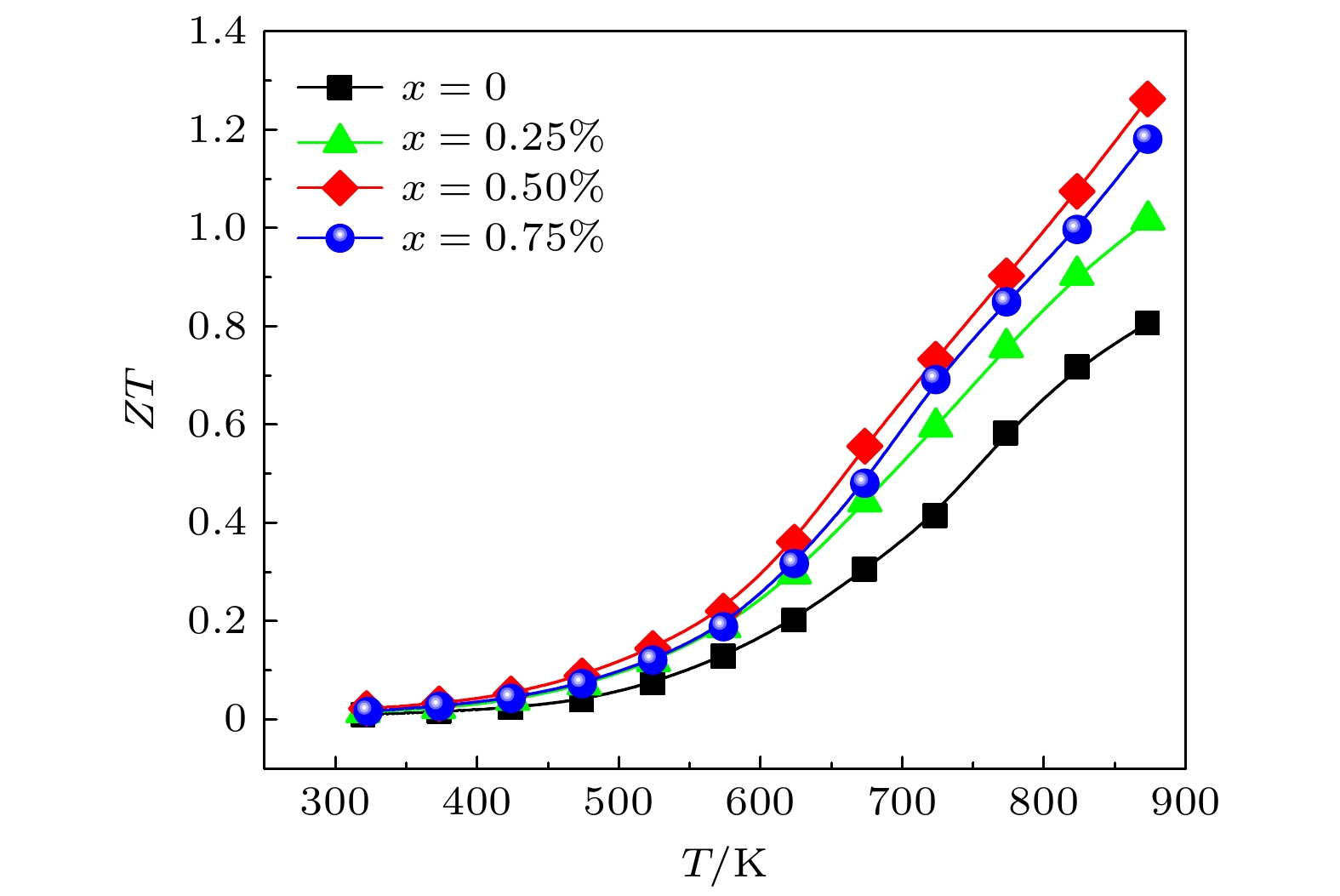

Thermoelectric material is a new type of functional material that can realize the direct conversion between heat energy and electric energy. It has received a lot of attention because it has wide practical applications. However, the applications of thermoelectric devices are limited by their low conversion efficiencies. The conversion efficiency is determined mainly by the thermoelectric properties of the material. In this work, a compound of CuGaTe2 chalcopyrite is selected as a research object, and a series of Ni-doped samples Cu1–xNixGaTe2 (x = 0–0.75%) is synthesized by the vacuum melting method. The temperature dependent thermal and electrical properties for Cu1–xNixGaTe2 (x = 0–0.75%) compounds are investigated. The results show that the Ni atom can effectively replace the Cu atom of the material, and thus leading the carrier concentration to decrease slightly and inducing the mobility to increase. At the same time, the Seebeck coefficient increases significantly after Ni doping: on the one hand, the increase is due to the decrease of the carrier concentration of the sample; on the other hand, the effective increase of the density of states near the Fermi level plays an important role in increasing Seebeck coefficient. Then, the thermal conductivity decreases effectively due to the enhancement of point defect scattering caused by Ni doping, and the minimum lattice thermal conductivity is reduced by ~30% in comparison with the matrix lattice thermal conductivity. Finally, the maximum ZT value for Cu0.095Ni0.005GaTe2 sample (ZT = 1.26 at 873 K) is obtained to be ~56% larger than that for CuGaTe2. This work indicates that the doping magnetic element Ni at Cu site is also one of the effective ways to improve the thermoelectric properties of CuGaTe2 materials.

-

Keywords:

- thermoelectric material /

- CuGaTe2 /

- density of state /

- ZT value /

- thermoelectric figure of merit

[1] Zhu T, Liu Y, Fu C, Heremans J P, Snyder J G, Zhao X 2017 Adv. Mater. 29 1605884

Google Scholar

Google Scholar

[2] Bell L E 2008 Science 321 1457

Google Scholar

Google Scholar

[3] Hsu K F, Loo S, Guo F, Chen W, Dyck J S, Uher C, Hogan T, Polychroniadis E K, Kanatzidis M G 2004 Science 303 818

Google Scholar

Google Scholar

[4] Zhao L D, Lo S H, Zhang Y S, Sun H, Tan G J, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2014 Nature 508 373

Google Scholar

Google Scholar

[5] Chen X Q, Liu J, Li J 2021 Innovation 2 100134

[6] Riffat S B, Ma X L 2003 Appl. Therm. Eng. 23 913

Google Scholar

Google Scholar

[7] Sun P, Kumar K R, Lyu M, Wang Z, Xiang J, Zhang W 2021 Innovation 2 100101

[8] Zhang J, Huang L, Zhu C, Zhou C, Jabar B, Li J, Zhu X, Wang L, Song C, Xin H, Li D, Qin X 2019 Adv. Mater. 31 1905210

Google Scholar

Google Scholar

[9] Shay J L, Wernick J H 1975 Ternary Chalcopyrite Semiconductors: Growth, Electronic Properties, and Applications (London: Pergamon Press Ltd.) p112

[10] Slack G A, Rowe D 1995 CRC Handbook of Thermoelectrics (Boca Raton: CRC Press) p280

[11] Ioffe A F, Stil'Bans L, Iordanishvili E, Stavitskaya T, Gelbtuch A, Vineyard G 1959 Phys. Today 12 42

[12] Shi X, Huang F, Liu M, Chen L 2009 Appl. Phys. Lett. 94 122103

Google Scholar

Google Scholar

[13] Cho J, Shi X, Salvador J R, Meisner G P, Yang J, Wang H, Wereszczak A A, Zhou X, Uher C 2011 Phys. Rev. B 84 085207

Google Scholar

Google Scholar

[14] Liu M L, Chen I W, Huang F Q, Chen L D 2009 Adv. Mater. 21 3808

Google Scholar

Google Scholar

[15] Shi X, Xi L, Fan J, Zhang W, Chen L 2010 Chem. Mater. 22 6029

Google Scholar

Google Scholar

[16] Liu R, Xi L, Liu H, Shi X, Zhang W, Chen L 2012 Chem. Commun. 48 3818

Google Scholar

Google Scholar

[17] Skoug E J, Cain J D, Morelli D T 2010 J. Alloys Compd. 506 18

Google Scholar

Google Scholar

[18] Skoug E J, Cain J D, Majsztrik P, Kirkham M, Lara-Curzio E, Morelli D T 2011 Sci. Adv. Mater. 3 602

Google Scholar

Google Scholar

[19] Liu H, Shi X, Xu F, Zhang L, Zhang W, Chen L, Li Q, Uher C, Day T, Snyder G J 2012 Nat. Mater. 11 422

Google Scholar

Google Scholar

[20] Plirdpring T, Kurosaki K, Kosuga A, Day T, Firdosy S, Ravi V, Snyder G J, Harnwunggmoung A, Sugahara T, Ohishi Y 2012 Adv. Mater. 24 3622

Google Scholar

Google Scholar

[21] Li Y, Meng Q, Deng Y, Zhou H, Gao Y, Li Y, Yang J, Cui J 2012 Appl. Phys. Lett. 100 231903

Google Scholar

Google Scholar

[22] Zeier WG, LaLonde A, Gibbs Z M, Heinrich C P, Panthöfer M, Snyder G J, Tremel W 2012 J. Am. Chem. Soc. 134 7147

Google Scholar

Google Scholar

[23] Parker D, Singh D J 2012 Phys. Rev. B 85 125209

Google Scholar

Google Scholar

[24] Wu W, Wu K, Ma Z, Sa R 2012 Chem. Phys. Lett. 537 62

Google Scholar

Google Scholar

[25] Kosuga A, Plirdpring T, Higashine R, Matsuzawa M, Kurosaki K, Yamanaka S 2012 Appl. Phys. Lett. 100 042108

Google Scholar

Google Scholar

[26] Yusufu A, Kurosaki K, Kosuga A, Sugahara T, Ohishi Y, Muta H, Yamanaka S 2011 Appl. Phys. Lett. 99 061902

Google Scholar

Google Scholar

[27] Kuhn B, Kaefer W, Fess K, Friemelt K, Turner C, Wendl M, Bucher E 1997 Phys. Status Solidi 162 661

Google Scholar

Google Scholar

[28] Zhang J, Qin X Y, Li D, Xin H X, Song C J, Li L L, Wang Z M, Guo G L, Wang L 2014 J. Alloys Compd. 586 285

Google Scholar

Google Scholar

[29] Cui J, Li Y, Du Z, Meng Q, Zhou H 2013 J. Mater. Chem. A 1 677

Google Scholar

Google Scholar

[30] Shen J W, Zhang X Y, Lin S Q, Li J, Chen Z W, Li W, Pei Y Z 2016 J. Mater. Chem. A 4 15464

Google Scholar

Google Scholar

[31] Ahmed F, Tsujii N, Mori T 2017 J. Mater. Chem. A 5 7545

Google Scholar

Google Scholar

[32] Kohn W, Sham L J 1965 Phys. Rev. 140 A1133

Google Scholar

Google Scholar

[33] Hohenberg P, Kohn W 1964 Phys. Rev. 136 B864

Google Scholar

Google Scholar

[34] Kresse G, Furthmuller J 1996 Phys. Rev. B 54 169

[35] Grimme S, Ehrlich S, Goerigk L 2011 J. Comput. Chem. 32 1456

Google Scholar

Google Scholar

[36] Moellmann J, Grimme S 2014 J. Phys. Chem. C 118 7615

Google Scholar

Google Scholar

[37] Cao Y, Su X, Meng F, Bailey T P, Zhao J, Xie H, He J, Uher C, Tang X 2020 Adv. Funct. Mater. 30 2005861

Google Scholar

Google Scholar

[38] Jonson M, Mahan G 1980 Phys. Rev. B 21 4223

Google Scholar

Google Scholar

[39] Xu R, Huang L, Zhang J, Li D, Liu J, Liu J, Fang J, Wang M, Tang G 2019 J. Mater. Chem. A 7 15757

Google Scholar

Google Scholar

-

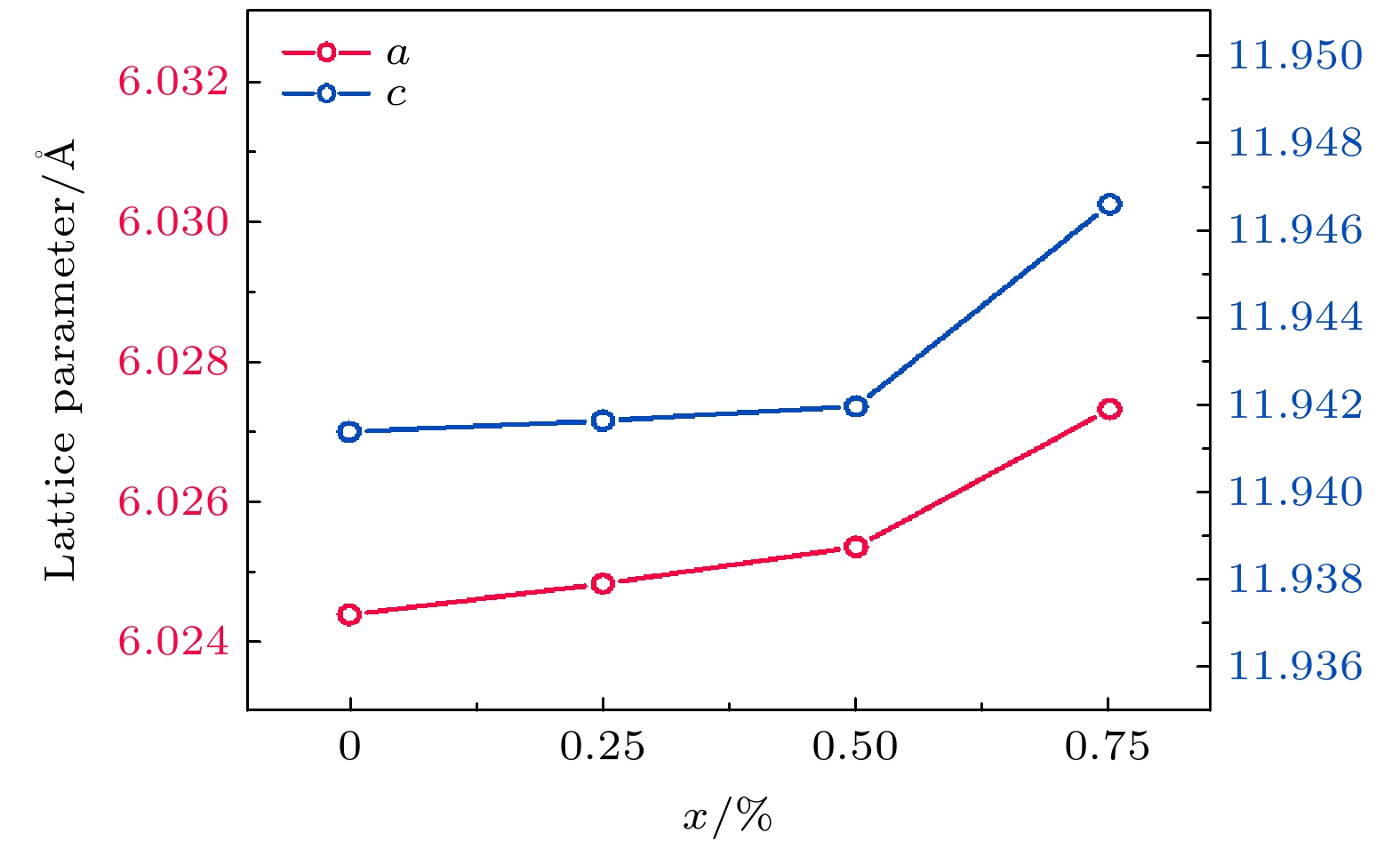

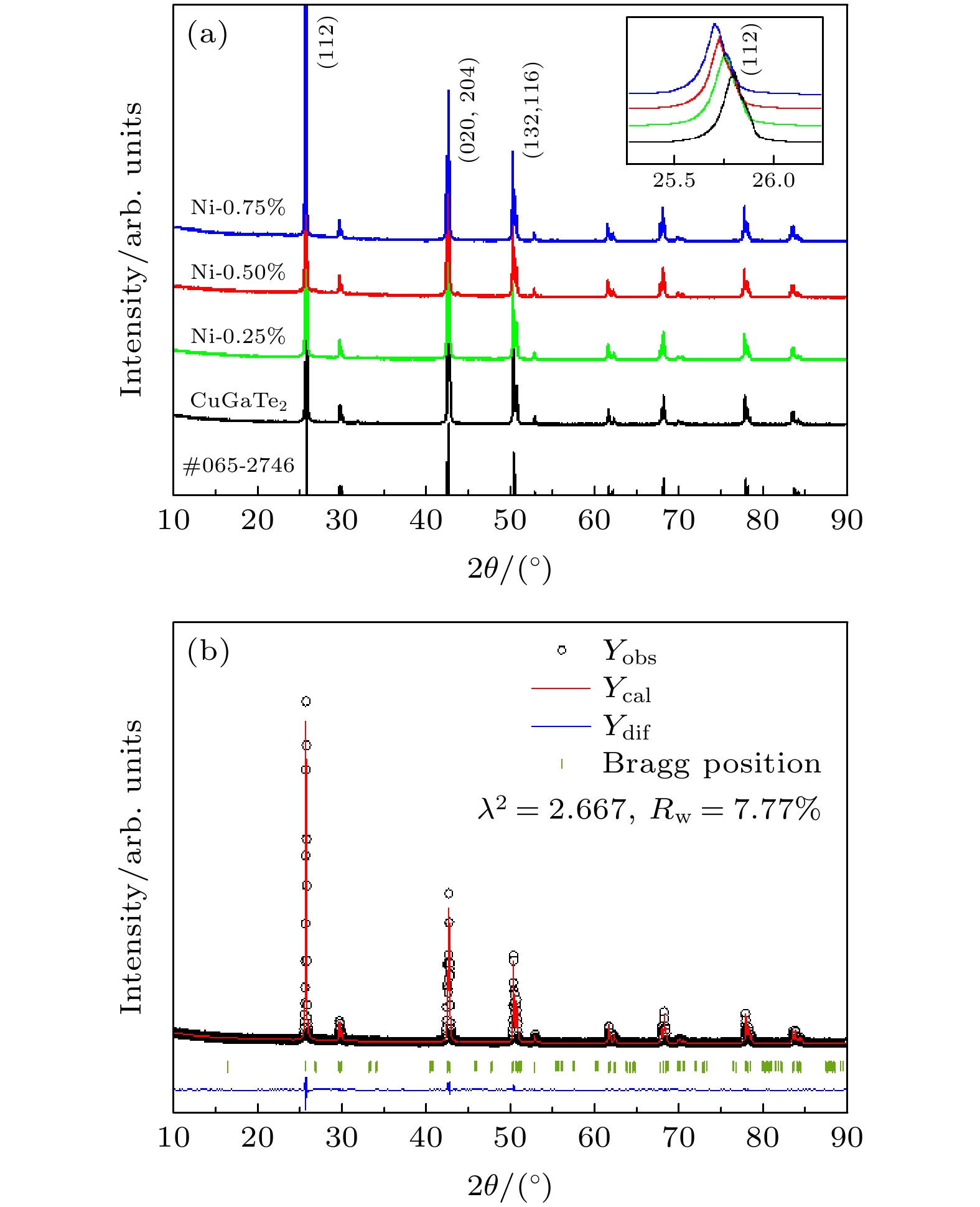

图 1 (a) Cu1–xNixGaTe2 (x = 0, 0.25%, 0.50%, 0.75%)样品室温下的XRD图谱, 其中, 在右上角附注(112)衍射峰的放大图; (b) Cu0.995Ni0.005GaTe2样品的XRD数据结构精修图, λ2和Rw为精修的误差参数

Figure 1. (a) XRD results of Cu1–xNixGaTe2 (x = 0, 0.25%, 0.50%, 0.75%) samples at room temperature, and the enlarged view of (112) diffraction peak is attached in the upper right corner; (b) results of refined XRD for Cu0.995Ni0.005GaTe2 sample, λ2 and Rw are the refined error parameters.

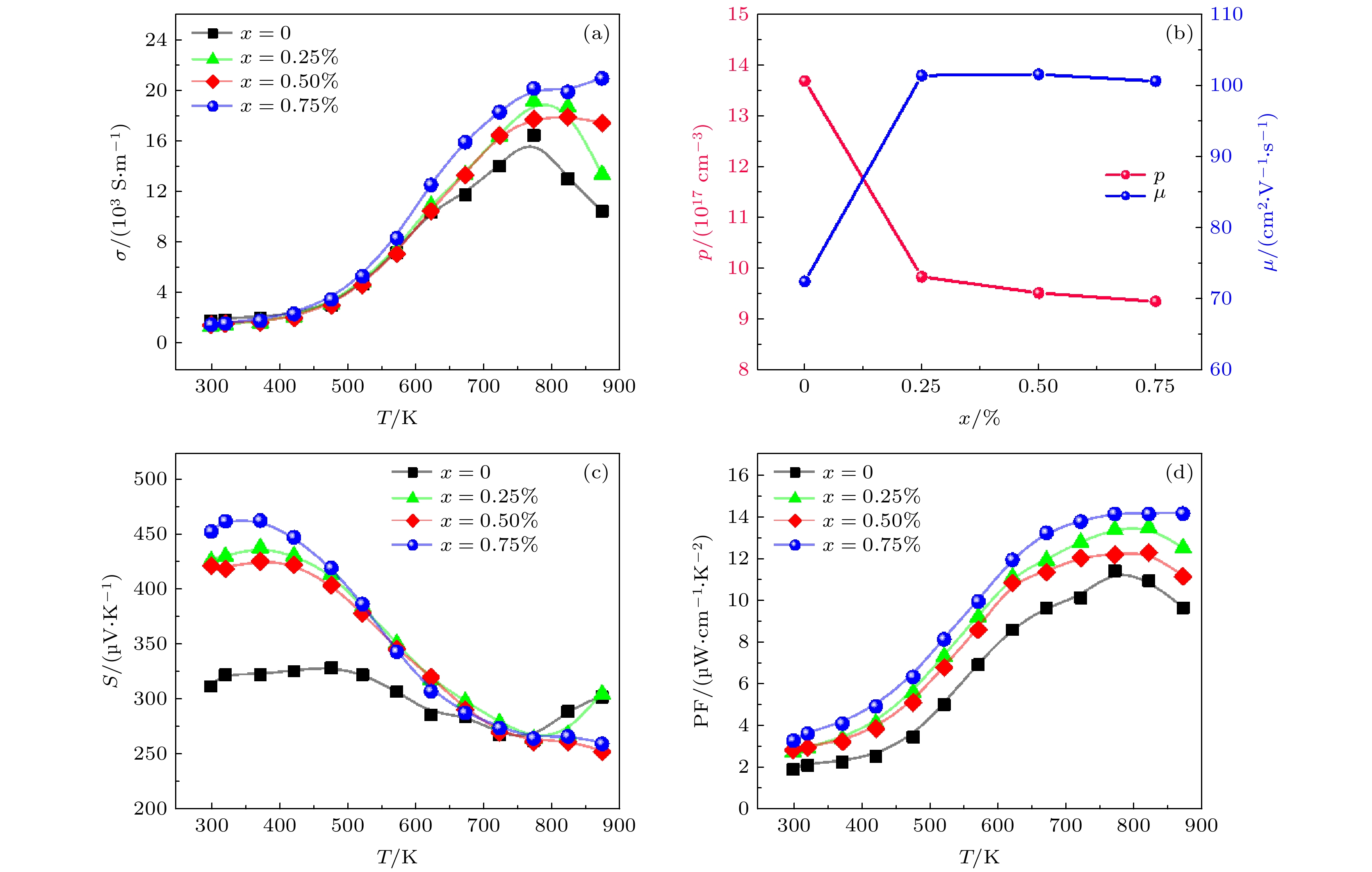

图 3 Cu1–xNixGaTe2 (x = 0, 0.25%, 0.50%, 0.75%)样品的 (a)电导率随温度的变化, (b)室温下载流子浓度和迁移率, (c) Seebeck系数和(d)功率因子随温度的变化

Figure 3. Electrical properties of Cu1–xNixGaTe2 (x = 0, 0.25%, 0.50%, 0.75%) samples: (a) Dependence of electrical conductivity with temperature; (b) carrier concentration and carrier mobility at room temperature; dependence of (c) Seebeck coefficient and (d) power factor with temperature.

-

[1] Zhu T, Liu Y, Fu C, Heremans J P, Snyder J G, Zhao X 2017 Adv. Mater. 29 1605884

Google Scholar

Google Scholar

[2] Bell L E 2008 Science 321 1457

Google Scholar

Google Scholar

[3] Hsu K F, Loo S, Guo F, Chen W, Dyck J S, Uher C, Hogan T, Polychroniadis E K, Kanatzidis M G 2004 Science 303 818

Google Scholar

Google Scholar

[4] Zhao L D, Lo S H, Zhang Y S, Sun H, Tan G J, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2014 Nature 508 373

Google Scholar

Google Scholar

[5] Chen X Q, Liu J, Li J 2021 Innovation 2 100134

[6] Riffat S B, Ma X L 2003 Appl. Therm. Eng. 23 913

Google Scholar

Google Scholar

[7] Sun P, Kumar K R, Lyu M, Wang Z, Xiang J, Zhang W 2021 Innovation 2 100101

[8] Zhang J, Huang L, Zhu C, Zhou C, Jabar B, Li J, Zhu X, Wang L, Song C, Xin H, Li D, Qin X 2019 Adv. Mater. 31 1905210

Google Scholar

Google Scholar

[9] Shay J L, Wernick J H 1975 Ternary Chalcopyrite Semiconductors: Growth, Electronic Properties, and Applications (London: Pergamon Press Ltd.) p112

[10] Slack G A, Rowe D 1995 CRC Handbook of Thermoelectrics (Boca Raton: CRC Press) p280

[11] Ioffe A F, Stil'Bans L, Iordanishvili E, Stavitskaya T, Gelbtuch A, Vineyard G 1959 Phys. Today 12 42

[12] Shi X, Huang F, Liu M, Chen L 2009 Appl. Phys. Lett. 94 122103

Google Scholar

Google Scholar

[13] Cho J, Shi X, Salvador J R, Meisner G P, Yang J, Wang H, Wereszczak A A, Zhou X, Uher C 2011 Phys. Rev. B 84 085207

Google Scholar

Google Scholar

[14] Liu M L, Chen I W, Huang F Q, Chen L D 2009 Adv. Mater. 21 3808

Google Scholar

Google Scholar

[15] Shi X, Xi L, Fan J, Zhang W, Chen L 2010 Chem. Mater. 22 6029

Google Scholar

Google Scholar

[16] Liu R, Xi L, Liu H, Shi X, Zhang W, Chen L 2012 Chem. Commun. 48 3818

Google Scholar

Google Scholar

[17] Skoug E J, Cain J D, Morelli D T 2010 J. Alloys Compd. 506 18

Google Scholar

Google Scholar

[18] Skoug E J, Cain J D, Majsztrik P, Kirkham M, Lara-Curzio E, Morelli D T 2011 Sci. Adv. Mater. 3 602

Google Scholar

Google Scholar

[19] Liu H, Shi X, Xu F, Zhang L, Zhang W, Chen L, Li Q, Uher C, Day T, Snyder G J 2012 Nat. Mater. 11 422

Google Scholar

Google Scholar

[20] Plirdpring T, Kurosaki K, Kosuga A, Day T, Firdosy S, Ravi V, Snyder G J, Harnwunggmoung A, Sugahara T, Ohishi Y 2012 Adv. Mater. 24 3622

Google Scholar

Google Scholar

[21] Li Y, Meng Q, Deng Y, Zhou H, Gao Y, Li Y, Yang J, Cui J 2012 Appl. Phys. Lett. 100 231903

Google Scholar

Google Scholar

[22] Zeier WG, LaLonde A, Gibbs Z M, Heinrich C P, Panthöfer M, Snyder G J, Tremel W 2012 J. Am. Chem. Soc. 134 7147

Google Scholar

Google Scholar

[23] Parker D, Singh D J 2012 Phys. Rev. B 85 125209

Google Scholar

Google Scholar

[24] Wu W, Wu K, Ma Z, Sa R 2012 Chem. Phys. Lett. 537 62

Google Scholar

Google Scholar

[25] Kosuga A, Plirdpring T, Higashine R, Matsuzawa M, Kurosaki K, Yamanaka S 2012 Appl. Phys. Lett. 100 042108

Google Scholar

Google Scholar

[26] Yusufu A, Kurosaki K, Kosuga A, Sugahara T, Ohishi Y, Muta H, Yamanaka S 2011 Appl. Phys. Lett. 99 061902

Google Scholar

Google Scholar

[27] Kuhn B, Kaefer W, Fess K, Friemelt K, Turner C, Wendl M, Bucher E 1997 Phys. Status Solidi 162 661

Google Scholar

Google Scholar

[28] Zhang J, Qin X Y, Li D, Xin H X, Song C J, Li L L, Wang Z M, Guo G L, Wang L 2014 J. Alloys Compd. 586 285

Google Scholar

Google Scholar

[29] Cui J, Li Y, Du Z, Meng Q, Zhou H 2013 J. Mater. Chem. A 1 677

Google Scholar

Google Scholar

[30] Shen J W, Zhang X Y, Lin S Q, Li J, Chen Z W, Li W, Pei Y Z 2016 J. Mater. Chem. A 4 15464

Google Scholar

Google Scholar

[31] Ahmed F, Tsujii N, Mori T 2017 J. Mater. Chem. A 5 7545

Google Scholar

Google Scholar

[32] Kohn W, Sham L J 1965 Phys. Rev. 140 A1133

Google Scholar

Google Scholar

[33] Hohenberg P, Kohn W 1964 Phys. Rev. 136 B864

Google Scholar

Google Scholar

[34] Kresse G, Furthmuller J 1996 Phys. Rev. B 54 169

[35] Grimme S, Ehrlich S, Goerigk L 2011 J. Comput. Chem. 32 1456

Google Scholar

Google Scholar

[36] Moellmann J, Grimme S 2014 J. Phys. Chem. C 118 7615

Google Scholar

Google Scholar

[37] Cao Y, Su X, Meng F, Bailey T P, Zhao J, Xie H, He J, Uher C, Tang X 2020 Adv. Funct. Mater. 30 2005861

Google Scholar

Google Scholar

[38] Jonson M, Mahan G 1980 Phys. Rev. B 21 4223

Google Scholar

Google Scholar

[39] Xu R, Huang L, Zhang J, Li D, Liu J, Liu J, Fang J, Wang M, Tang G 2019 J. Mater. Chem. A 7 15757

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8571

- PDF Downloads: 174

- Cited By: 0

DownLoad:

DownLoad: