-

热电材料无需提供其他能量就能直接实现热能和电能的相互转换, 是一种新型能源材料, 然而当前热电材料的发展现状严重制约了热电器件的工程化应用, 提高现有热电材料的热电性能或研发具有优异性能的新型热电材料是热电领域永恒的研究主题. 近年来, MAX及其衍生MXene相材料由于特有的结构性能而逐渐进入了科研工作者的视线, MAX 相的晶体结构由Mn+1Xn 结构单元与A 元素单原子面交替堆垛排列而成, MAX中A层原子被刻蚀之后可以制备得到对应的衍生二维MXene相, MAX及其衍生MXene相陶瓷兼具金属和陶瓷的特性, 具有良好的导热导电性能, 有望成为一种非常有前景的热电材料. 本文简要综述了近年来MAX相及其衍生MXene相材料的制备技术和热电性能的发展现状, 并针对MAX及其衍生MXene相材料的特性提出了一些改善热电性能的可行性方案, 据此展望了MAX相以及MXene材料在未来的发展方向和前景.Thermoelectric materials, a kind of new energy material, can directly convert heat energy into electric energy, and vice versa, without needing any other energy conversion. However, the present development status of thermoelectric materials severely restricts their engineering applications in thermoelectric devices. Improving the thermoelectric performances of existing thermoelectric materials and exploring new thermoelectric materials with excellent performance are eternal research topics in thermoelectricity field. In recent years, the MAX phases and their derived MXene phases have gradually received the attention of researchers due to their unique microstructures and properties. The crystal structure of MAX phases is comprised of Mn+1Xn structural units and the single atomic plane of A stacked alternately. The two-dimensional MXene phase derived can be prepared after the atoms in the A-layer of MAX have been etched. The MAX phases and their derived MXene phases have both metal feature and ceramic feature, and also have good thermal conductivity and electric conductivity, and they are anticipated to be the promising thermoelectric materials. In this paper, the present development status of the preparation technology and the thermoelectric properties of MAX phases and MXene are reviewed. Finally, some feasible schemes to improve the thermoelectric properties of MAX and its derived MXene phase materials are proposed, and the development direction and prospect of MAX phases and MXene are prospected as well.

-

Keywords:

- thermoelectric materials /

- MAX /

- MXene /

- review

[1] Doman LE A V 2016 International Energy Outlook 2016

[2] 李宜 2019 博士学位论文 (济南: 山东大学)

Yi L 2019 Ph. D. Dissertation (Jinan: Shandong University) (in Chinese)

[3] Chu S, Majumdar A 2012 Nature 488 294

Google Scholar

Google Scholar

[4] Liu W, Hu J, Zhang S, Deng M, Han C G, Liu Y 2017 Mater. Today Phys. 1 50

Google Scholar

Google Scholar

[5] Enescu D, Virjoghe E O 2014 Renewable Sustainable Energy Rev. 38 903

Google Scholar

Google Scholar

[6] Zhang Y, Heo Y J, Park M, Park S J Polymers 2019 11 167

[7] Bell L E 2008 Science 321 1457

Google Scholar

Google Scholar

[8] Zhao L D, Lo S H, Zhang Y S, Sun H, Tan G J, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2014 Nature 508 373

Google Scholar

Google Scholar

[9] Barsoum M W 2000 Prog. Solid State Chem. 28 201

Google Scholar

Google Scholar

[10] W B M 2013 MAX Phases: Properties of Machinable Ternary Carbides and Nitrides (Berlin: Wiley VCH) pp13–64

[11] Ching W Y, Mo Y, Aryal S, Rulis P 2013 J. Am. Ceram. Soc. 96 2292

Google Scholar

Google Scholar

[12] Naguib M, Kurtoglu M, Presser V, Lu J, Niu J J, Heon M, Hultman L, Gogotsi Y, Barsoum M W 2011 Adv. Mater. 23 4248

Google Scholar

Google Scholar

[13] 郑丽雅, 周延春, 冯志海 2013 宇航材料工艺 43 1

Zheng L Y, Zhou Y C, Feng Z H 2013 Aero. Mater. Tech. 2013 43 1

[14] Ying G, He X, Li M, Du S, Han W, He F 2011 J. Alloys Compd. 509 8022

Google Scholar

Google Scholar

[15] Hong X, Mei B, Zhu J, Zhou W 2004 J. Mater. Sci. 39 1589

Google Scholar

Google Scholar

[16] Barsoum M W, Brodkin D, El-Raghy T 1997 Scr. Mater. 36 535

Google Scholar

Google Scholar

[17] Cetinkaya S, Eroglu S 2012 Ceram. Int. 38 6445

Google Scholar

Google Scholar

[18] Tian W, Wang P, Zhang G, Kan Y, Li Y, Yan D 2006 Scr. Mater. 54 841

Google Scholar

Google Scholar

[19] Barsoum M W, El-Raghy T, Ali M 2000 Metall. Mater. Trans. A 31 1857

Google Scholar

Google Scholar

[20] Liu A, Yang Q, Ren X, Meng F, Gao L, Gao M, Yang Y, Ma T, Wu G 2020 Ceram. Int. 46 6934

Google Scholar

Google Scholar

[21] Champagne A, Battaglia J L, Ouisse T, Ricci F, Kusiak A, Pradere C, Natu V, Dewandre A, Verstraete M J, Barsoum M W, Charlier J C 2020 J. Phys. Chem. C 124 24017

Google Scholar

Google Scholar

[22] Palmquist J P, Jansson U, Seppänen T, Persson P O Å, Birch J, Hultman L, Isberg P 2002 Appl. Phys. Lett. 81 835

Google Scholar

Google Scholar

[23] Palmquist J P, Li S, Persson P O Å, Emmerlich J, Wilhelmsson O, Högberg H, Katsnelson M I, Johansson B, Ahuja R, Eriksson O, Hultman L, Jansson U 2004 Phys. Rev. B 70 165401

Google Scholar

Google Scholar

[24] Racault C, Langlais F, Bernard C 1994 J. Mater. Sci. 29 5023

Google Scholar

Google Scholar

[25] Fakih H, Jacques S, Dezellus O, Berthet M P, Bosselet F, Sacerdote-Peronnet M, Viala J C 2008 J. Phase Equilib. Diffus. 29 239

Google Scholar

Google Scholar

[26] Medkour Y, Roumili A, Maouche D, Louail L, Haddadi K 2009 Eur. Phys. J. B 68 193

Google Scholar

Google Scholar

[27] Mauchamp V, Yu W, Gence L, Piraux L, Cabioc'h T, Gauthier V, Eklund P, Dubois S 2013 Phys. Rev. B 87 235105

Google Scholar

Google Scholar

[28] Ouisse T, Shi L, Piot B A, Hackens B, Mauchamp V, Chaussende D 2015 Phys. Rev. B 92 045133

Google Scholar

Google Scholar

[29] Flatten T, Matthes F, Petruhins A, Salikhov R, Wiedwald U, Farle M, Rosen J, Bürgler D E, Schneider C M 2019 Appl. Phys. Lett. 115 094101

Google Scholar

Google Scholar

[30] Schuster J C, Nowotny H, Vaccaro C 1980 J. Solid State Chem. 32 213

Google Scholar

Google Scholar

[31] Schneider J M, Sun Z, Mertens R, Uestel F, Ahuja R 2004 Solid State Commun. 130 445

Google Scholar

Google Scholar

[32] Drulis M K, Drulis H, Gupta S, Barsoum M W, El-Raghy T 2006 J. Appl. Phys. 99 093502

Google Scholar

Google Scholar

[33] Bai Y L, He X D, Zhu C C, Chen G Q 2012 J. Am. Ceram. Soc. 95 358

Google Scholar

Google Scholar

[34] Vovk R V, Khadzhai G Y, Prikhna T A, Gevorkyan E S, Kislitsa M V, Soloviev A L, Goulatis I L, Chroneos A 2018 J. Mater. Sci. -Mater. Electron. 29 11478

Google Scholar

Google Scholar

[35] Hu C, Sakka Y, Tanaka H, Nishimura T, Grasso S 2011 J. Am. Ceram. Soc. 94 410

Google Scholar

Google Scholar

[36] Cai P, He Q, Yang L, Huang Z, Liu X, Yin J, Huang Y 2019 Ceram. Int. 45 9799

Google Scholar

Google Scholar

[37] Yoo H I, Barsoum M W, El-Raghy T 2000 Nature 407 581

[38] Finkel P, Seaman B, Harrell K, Palma J, Hettinger J D, Lofland S E, Ganguly A, Barsoum M W, Sun Z, Li S, Ahuja R 2004 Phys. Rev. B 70 085104

Google Scholar

Google Scholar

[39] Chen K, Chen Y, Zhang J, Song Y, Zhou X, Li M, Fan X, Zhou J, Huang Q 2021 Ceram. Int. 47 7582

Google Scholar

Google Scholar

[40] Sonntag J 2010 J. Phys. Condens. Matter 22 235501

Google Scholar

Google Scholar

[41] Xu C, Wang L, Liu Z, Chen L, Guo J, Kang N, Ma X L, Cheng H M, Ren W 2015 Nat. Mater. 14 1135

Google Scholar

Google Scholar

[42] Zhang F, Zhang Z, Wang H, Chan C H, Chan N Y, Chen X X, Dai J Y 2017 Phys. Rev. Mater. 1 034002

Google Scholar

Google Scholar

[43] Du Z G, Yang S B, Li S M, Lou J, Zhang S Q, Wang S, Li B, Gong Y J, Song L, Zou X L, Ajayan P M 2020 Nature 577 492

Google Scholar

Google Scholar

[44] Zhou J, Zha X H, Chen F Y, Ye Q, Eklund P, Du S Y, Huang Q 2016 Angew. Chem. Int. Ed. 55 5008

Google Scholar

Google Scholar

[45] Zhou J, Zha X, Zhou X, Chen F, Gao G, Wang S, Shen C, Chen T, Zhi C, Eklund P, Du S, Xue J, Shi W, Chai Z, Huang Q 2017 ACS Nano 11 3841

Google Scholar

Google Scholar

[46] Zhou J, Zha X H, Yildizhan M, Eklund P, Xue J M, Liao M Y, Persson P O A, Du S Y, Huang Q 2019 ACS Nano 13 1195

Google Scholar

Google Scholar

[47] Naguib M, Halim J, Lu J, Cook K M, Hultman L, Gogotsi Y, Barsoum M W 2013 J. Am. Chem. Soc. 135 15966

Google Scholar

Google Scholar

[48] Anasori B, Xie Y, Beidaghi M, Lu J, Hosler B C, Hultman L, Kent P R C, Gogotsi Y, Barsoum M W 2015 ACS Nano 9 9507

Google Scholar

Google Scholar

[49] Lipatov A, Alhabeb M, Lukatskaya M R, Boson A, Gogotsi Y, Sinitskii A 2016 Adv. Electron. Mater. 2 1600255

Google Scholar

Google Scholar

[50] Feng A H, Yu Y, Wang Y, Jiang F, Yu Y, Mi L, Song L X 2017 Mater. Des. 114 161

Google Scholar

Google Scholar

[51] Zhang B, Zhu J F, Shi P, Wu W L, Wang F 2019 Ceram. Int. 45 8395

Google Scholar

Google Scholar

[52] Sun Z, Yuan M, Lin L, Yang H, Nan C, Li H, Sun G, Yang X 2019 ACS Mater. Lett. 1 628

Google Scholar

Google Scholar

[53] Lukatskaya M R, Halim J, Dyatkin B, Naguib M, Buranova Y S, Barsoum M W, Gogotsi Y 2014 Angew. Chem. Int. Ed. 53 4877

Google Scholar

Google Scholar

[54] Yang S, Zhang P, Wang F, Ricciardulli A G, Lohe M R, Blom P W M, Feng X 2018 Angew. Chem. Int. Ed. 57 15491

Google Scholar

Google Scholar

[55] Pang S Y, Wong Y T, Yuan S G, Liu Y, Tsang M K, Yang Z B, Huang H T, Wong W T, Hao J H 2019 J. Am. Chem. Soc. 141 9610

Google Scholar

Google Scholar

[56] Sun W, Shah S A, Chen Y, Tan Z, Gao H, Habib T, Radovic M, Green M J 2017 J. Mater. Chem. A 5 21663

Google Scholar

Google Scholar

[57] Song M, Pang S Y, Guo F, Wong M C, Hao J 2020 Adv. Sci. 7 2001546

Google Scholar

Google Scholar

[58] Li X L, Li M, Yang Q, Liang G J, Huang Z D, Ma L T, Wang D H, Mo F N, Dong B B, Huang Q, Zhi C Y 2020 Adv. Energy Mater. 10 2001394

Google Scholar

Google Scholar

[59] Chertopalov S, Mochalin V N 2018 ACS Nano 12 6109

Google Scholar

Google Scholar

[60] Natu V, Pai R, Sokol M, Carey M, Kalra V, Barsoum M W 2020 Chem. 6 616

Google Scholar

Google Scholar

[61] Mei J, Ayoko G A, Hu C F, Sun Z Q 2020 Chem. Eng. J. 395 125111

Google Scholar

Google Scholar

[62] Li M, Lu J, Luo K, Li Y B, Chang K K, Chen K, Zhou J, Rosen J, Hultman L, Eklund P, Persson P O A, Du S Y, Chai Z F, Huang Z R, Huang Q 2019 J. Am. Chem. Soc. 141 4730

Google Scholar

Google Scholar

[63] Li Y, Shao H, Lin Z, Lu J, Liu L, Duployer B, Persson P O Å, Eklund P, Hultman L, Li M, Chen K, Zha X-H, Du S, Rozier P, Chai Z, Raymundo-Piñero E, Taberna P-L, Simon P, Huang Q 2020 Nat. Mater. 19 894

Google Scholar

Google Scholar

[64] Kamysbayev V, Filatov A S, Hu H C, Rui X, Lagunas F, Wang D, Klie R F, Talapin D V 2020 Science 369 979

Google Scholar

Google Scholar

[65] Shi H, Zhang P, Liu Z, Park S, Lohe M R, Wu Y, Shaygan Nia A, Yang S, Feng X 2021 Angew. Chem. Int. Ed. 60 8689

Google Scholar

Google Scholar

[66] Karmakar S, Saha-Dasgupta T 2020 Phys. Rev. Mater. 4 124007

Google Scholar

Google Scholar

[67] Jing Z A, Wang H Y, Feng X H, Xiao B, Ding Y C, Wu K, Cheng Y H 2019 J. Phys. Chem. Lett. 10 5721

Google Scholar

Google Scholar

[68] Liu P, Ding W J, Liu J, Shen L L, Jiang F X, Liu P P, Zhu Z Y, Zhang G, Liu C C, Xu J K 2020 J. Alloys Compd. 829 154634

Google Scholar

Google Scholar

[69] Ding W, Liu P, Bai Z, Wang Y, Liu G, Jiang Q, Jiang F, Liu P, Liu C, Xu J 2020 Adv. Mater. Interfaces 7 2001340

Google Scholar

Google Scholar

[70] Guan X, Feng W, Wang X Z, Venkatesh R, Ouyang J Y 2020 ACS Appl. Mater. Interfaces 12 13013

Google Scholar

Google Scholar

[71] Li X H, Zhang R Z, Cui H L 2020 ACS Omega 5 18403

Google Scholar

Google Scholar

[72] Bafekry A, Nguyen C V, Stampfl C, Akgenc B, Ghergherehchi M 2020 Phys. Status Solidi B 257 2000343

Google Scholar

Google Scholar

[73] Bafekry A, Akgenc B, Ghergherehchi M, Peeters F M 2020 J. Phys. Condens. Matter 32 355701

Google Scholar

Google Scholar

[74] Zhang H, Hu T, Wang X, Zhou Y 2020 J. Mater. Sci. Technol. 38 205

Google Scholar

Google Scholar

[75] Tao Q, Dahlqvist M, Lu J, Kota S, Meshkian R, Halim J, Palisaitis J, Hultman L, Barsoum M W, Persson P O Å, Rosen J 2017 Nat. Commun. 8 14949

Google Scholar

Google Scholar

[76] Meshkian R, Dahlqvist M, Lu J, Wickman B, Halim J, Thörnberg J, Tao Q Z, Li S X, Intikhab S, Snyder J, Barsoum M W, Yildizhan M, Palisaitis J, Hultman L, Persson P, Rosen J 2018 Adv. Mater. 30 1706409

Google Scholar

Google Scholar

[77] Meshkian R, Lind H, Halim J, El Ghazaly A, Thörnberg J, Tao Q, Dahlqvist M, Palisaitis J, Persson P O Å, Rosen J 2019 ACS Appl. Nano Mater. 2 6209

Google Scholar

Google Scholar

[78] Kim H, Anasori B, Gogotsi Y, Alshareef H N 2017 Chem. Mater. 29 6472

Google Scholar

Google Scholar

[79] Guo J, Legum B, Anasori B, Wang K, Lelyukh P, Gogotsi Y, Randall C A 2018 Adv. Mater. 30 1801846

Google Scholar

Google Scholar

[80] Khazaei M, Arai M, Sasaki T, Chung C Y, Venkataramanan N S, Estili M, Sakka Y, Kawazoe Y 2013 Adv. Funct. Mater. 23 2185

Google Scholar

Google Scholar

[81] Khazaei M, Arai M, Sasaki T, Estili M, Sakka Y 2014 Phys. Chem. Chem. Phys. 16 7841

Google Scholar

Google Scholar

[82] Zha X H, Luo K, Li Q, Huang Q, He J, Wen X, Du S 2015 EPL 111 26007

Google Scholar

Google Scholar

[83] Zha X H, Zhou J, Zhou Y H, Huang Q, He J, Francisco J S, Luo K, Du S Y 2016 Nanoscale 8 6110

Google Scholar

Google Scholar

[84] Luo K, Zha X H, Zhou Y H, Guo Z S, Lin C T, Huang Q, Zhou S H, Zhang R F, Du S Y 2018 RSC Adv. 8 22452

Google Scholar

Google Scholar

[85] Zhang X, Zhao X D, Wu D H, Jing Y, Zhou Z 2015 Nanoscale 7 16020

Google Scholar

Google Scholar

[86] Xie Y, Kent P R C 2013 Phys. Rev. B 87 235441

Google Scholar

Google Scholar

[87] Zha X H, Huang Q, He J, He H M, Zhai J Y, Francisco J S, Du S Y 2016 Sci. Rep. 6 1

Google Scholar

Google Scholar

[88] Xu X, Ge X, Liu X, Li L, Fu K, Dong Y, Meng F, Si R, Zhang M 2020 Ceram. Int. 46 13377

Google Scholar

Google Scholar

[89] Miranda A, Halim J, Barsoum M W, Lorke A 2016 Appl. Phys. Lett. 108 033102

Google Scholar

Google Scholar

[90] Jing H, Yeo H, Lyu B, Ryou J, Choi S, Park J H, Lee B H, Kim Y H, Lee S 2021 ACS Nano 15 1388

Google Scholar

Google Scholar

[91] Gao L G, Wang N, Cao J M, Li Y, Ma T L 2020 Surf. Interfaces 20 100604

Google Scholar

Google Scholar

[92] Mostafaei A, Faizabadi E, Semiromi E H 2019 Physica E 114 113559

Google Scholar

Google Scholar

[93] Zhang Y G, Sa B S, Zhou J, Sun Z M 2021 Comput. Mater. Sci. 186 110013

Google Scholar

Google Scholar

[94] Li L H 2016 Comput. Mater. Sci. 124 8

Google Scholar

Google Scholar

[95] Si C, Jin K H, Zhou J, Sun Z, Liu F 2016 Nano Lett. 16 6584

Google Scholar

Google Scholar

[96] Khazaei M, Ranjbar A, Arai M, Yunoki S 2016 Phys. Rev. B 94 125152

Google Scholar

Google Scholar

[97] Anasori B, Shi C, Moon E J, Xie Y, Voigt C A, Kent P R C, May S J, Billinge S J L, Barsoum M W, Gogotsi Y 2016 Nanoscale Horiz. 1 227

Google Scholar

Google Scholar

[98] Je M, Lee Y, Chung Y C 2016 Thin Solid Films 619 131

Google Scholar

Google Scholar

[99] Bai X, Zha X H, Qiao Y, Qiu N, Zhang Y, Luo K, He J, Li Q, Huang Q, Francisco J S, Lin C T, Du S 2020 Nanoscale 12 3795

Google Scholar

Google Scholar

-

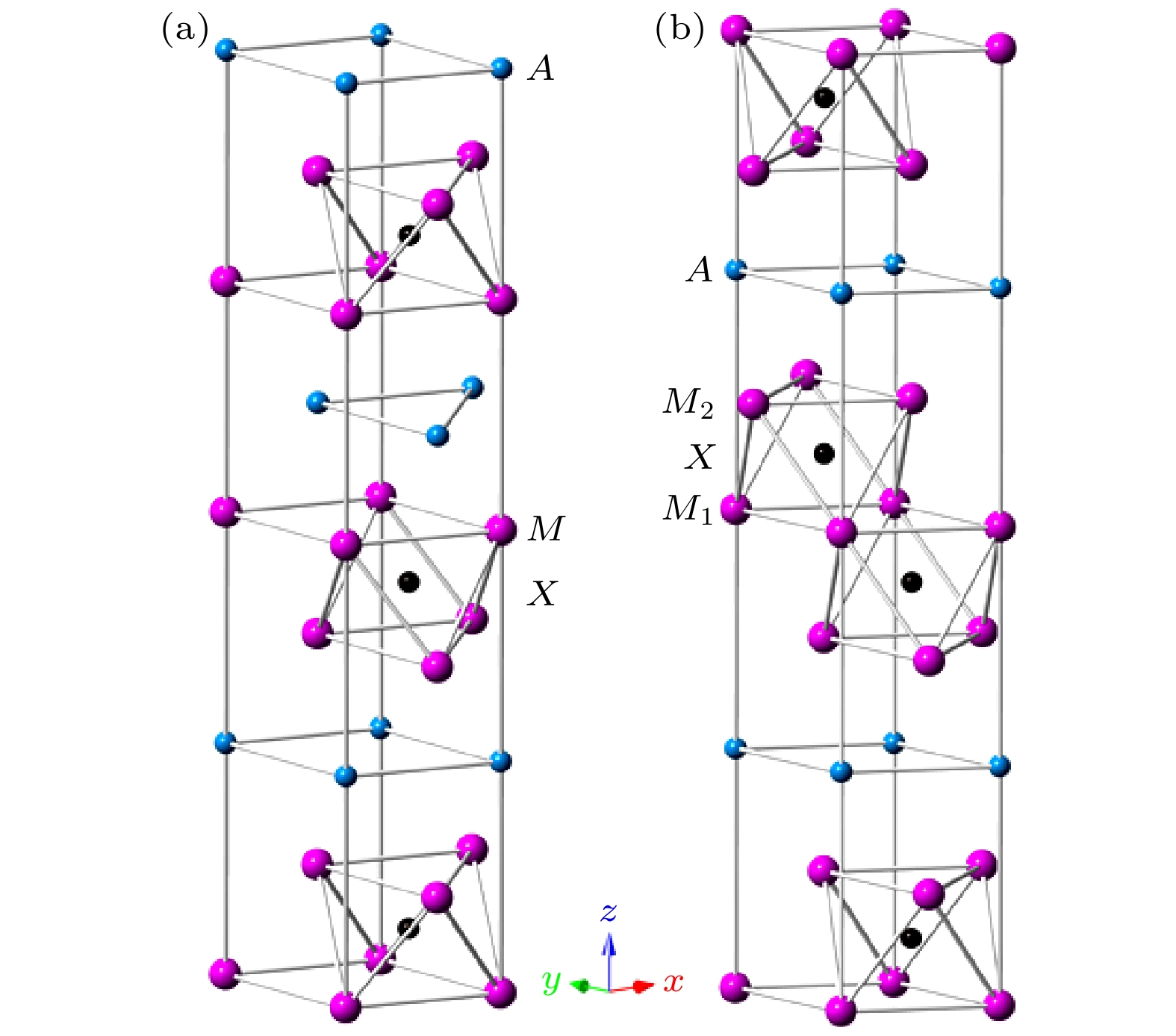

图 3 Cr2AlC的组织和性能 (a)晶体结构; (b)热导率; (c)测量电阻率; (d)预测面外电阻率[21]

Fig. 3. Microtructure and properties of Cr2AlC: (a) Atomic structure; (b) thermal conductivity, compared to the values found in the literature; (c) measurements resistivity; (d) predicted out-of-plane resistivity. Plane reprinted with permission from Ref. [21]. Copyright © 2020 American Chemical Society.

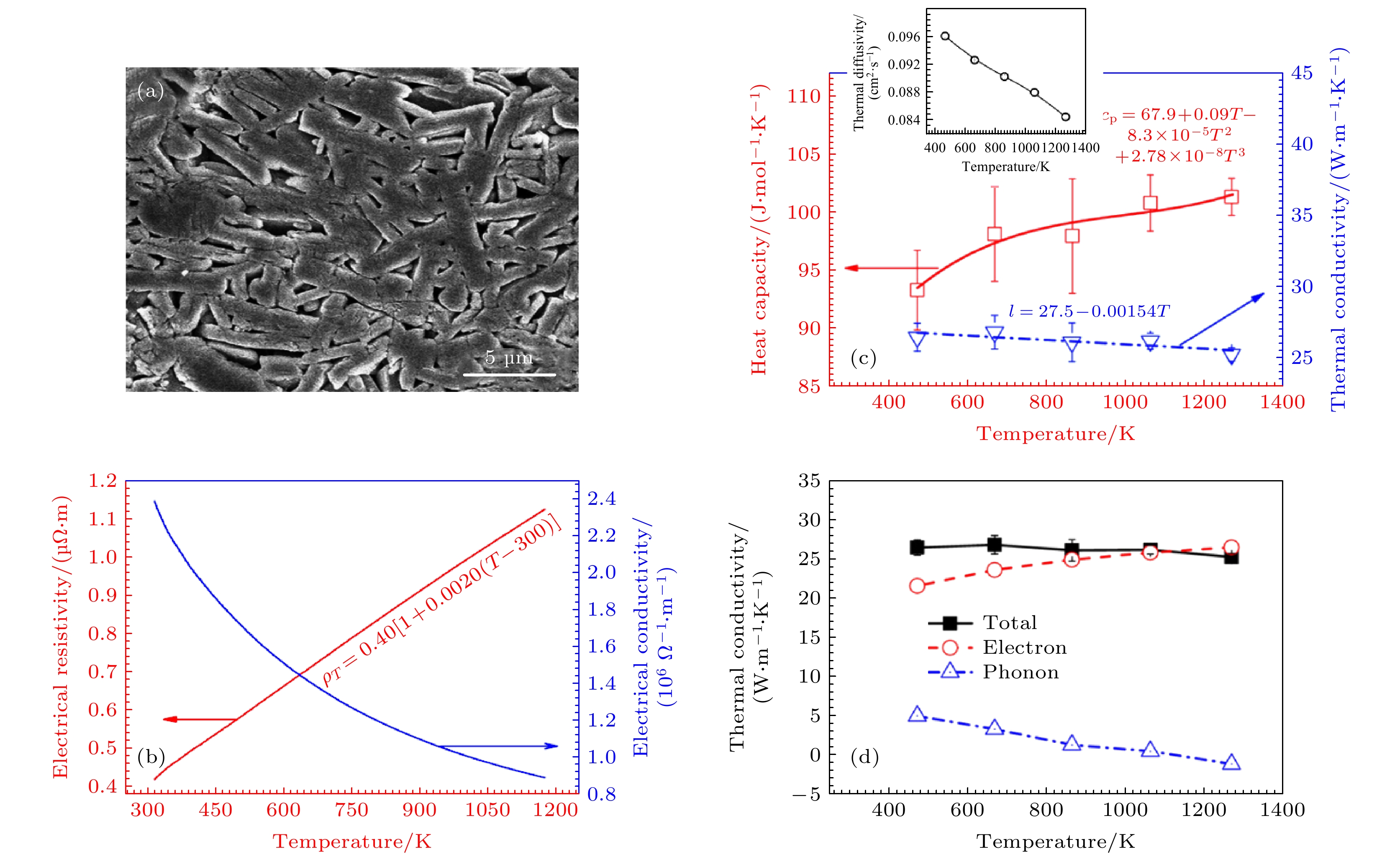

图 4 Ti2AlC的组织和性能 (a)蚀刻表面; (b)电导率和电阻率; (c)热导率、热容和热扩散率; (d)总热导率、电子热导率和声子热导率[33]

Fig. 4. Microtructure and properties of Cr2AlC: (a) Etched surface; (b) electrical conductivity and resistivity; (c) thermal conductivity, heat capacity, and thermal diffusivity; (d) total, electronic and phonon thermal conductivity. Plane reprinted with permission from Ref. [33]. Copyright © 2011 John Wiley and Sons.

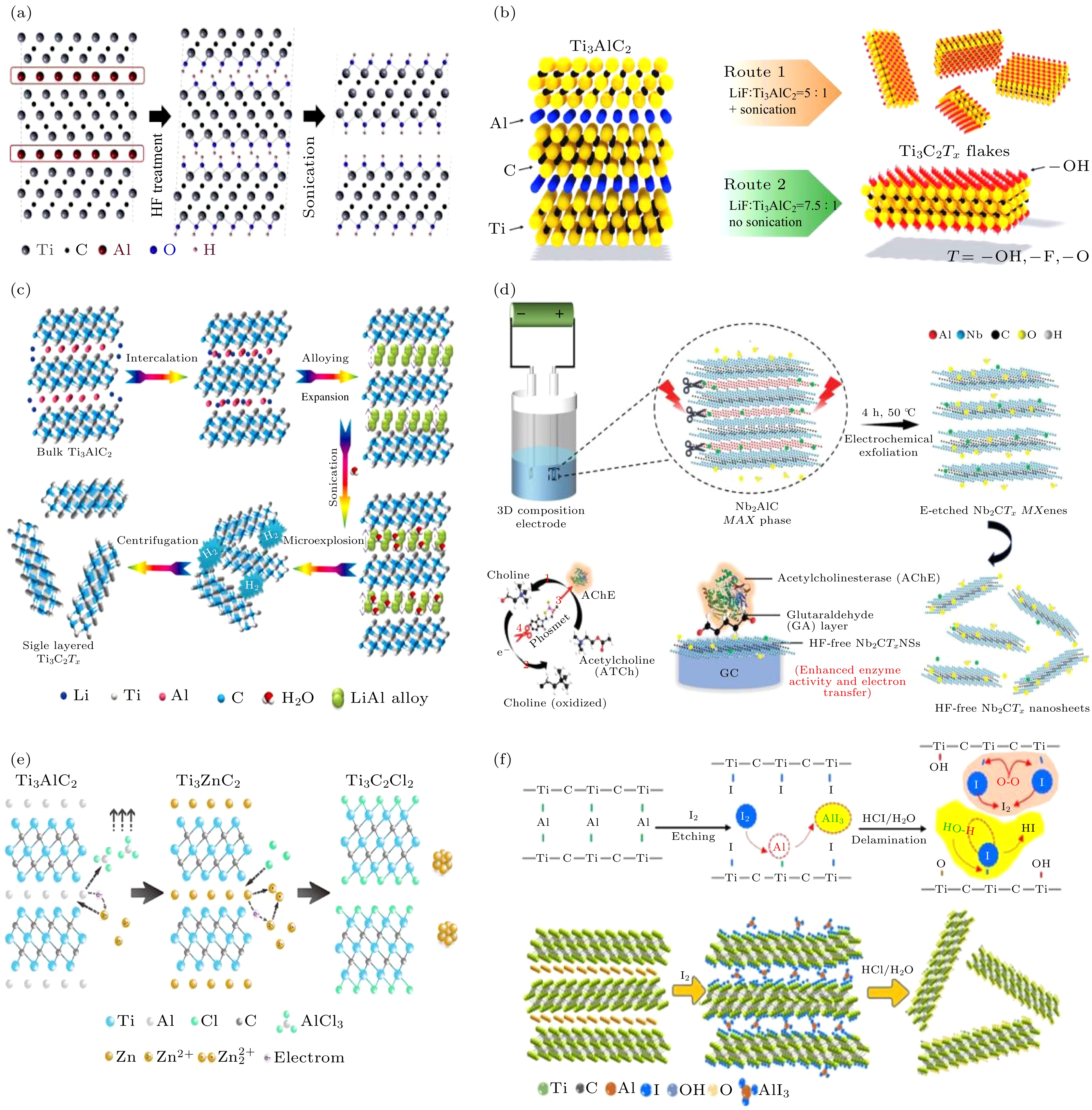

图 6 MXene的制备方法 (a) HF刻蚀法[12]; (b) LiF+HCl刻蚀法[49]; (c) Li扩张法[52]; (d)电化学刻蚀法[57]; (e)路易斯酸刻蚀法[62]; (f)碘刻蚀法[65]

Fig. 6. Preparation methods of MXene: (a) Etching method via HF[12]; (b) etching method via LiF+HCl[49]; (c) lithiation expansion[52]; (d) electrochemical etching[57]; (e) Lewis acid etching[62]; (f) iodine‐assisted etching[65]. Panel (a) reprinted from Ref. [12], Copyright 2011 John Wiley and Sons. Panel (b) reprinted from Ref. [49] with the permission of John Wiley and Sons. Panel (c) reprinted with permission from Ref. [52]. Copyright © 2019 American Chemical Society. Panel (e) reprinted with permission from Ref. [62], Copyright © 2019 American Chemical Society. Panel (f) reprinted from Ref. [65] with the permission of John Wiley and Sons

图 7 MXene的界面工程及热电性能 (a)−(c) Ti3C2Tx/SWCNTs (M/S), Ti3C2Tx-SWCNTs-Ti3C2Tx (MSM)和 SWCNTs-Ti3C2Tx-SWCNTs (SMS) 多层膜及能量过滤效应示意图[69]; (d)−(f) 3种结构下对应的功率因子随SWCNTs百分比的变化图[69]; (g) MXene和PEDOT复合后形成内建电场示意图; MXene/PEDOT:PSS中不同MXene质量分数下的(h)塞贝克系数和电导率以及(i)功率因子[70]

Fig. 7. Interface engineering and thermoelectric properties of MXene. The schematic energy diagrams of (a) Ti3C2Tx/SWCNTs (M/S), (b) Ti3C2Tx-SWCNTs-Ti3C2Tx (MSM), and (c) SWCNTs-Ti3C2Tx-SWCNTs (SMS) showing the different energy-filtering effects[69]-. Power factor of (d) Ti3C2Tx/SWCNTs (M/S), (e) Ti3C2Tx-SWCNTs-Ti3C2Tx (MSM), and (f) SWCNTs-Ti3C2Tx-SWCNTs (SMS) films[69]. (g) Schematic diagrams for the interfacial effect between MXene and PEDOT[70]. (h) Seebeck coefficient and electrical conductivity and (i) power factor of MXene/PEDOT: PSS as a function of the MXene loading[70]. Panels (a)−(f) are reprinted from Ref. [69] with the permission of John Wiley and Sons. Panels (g)−(i) are adapted with permission from Ref. [70], Copyright © 2020 American Chemical Society.

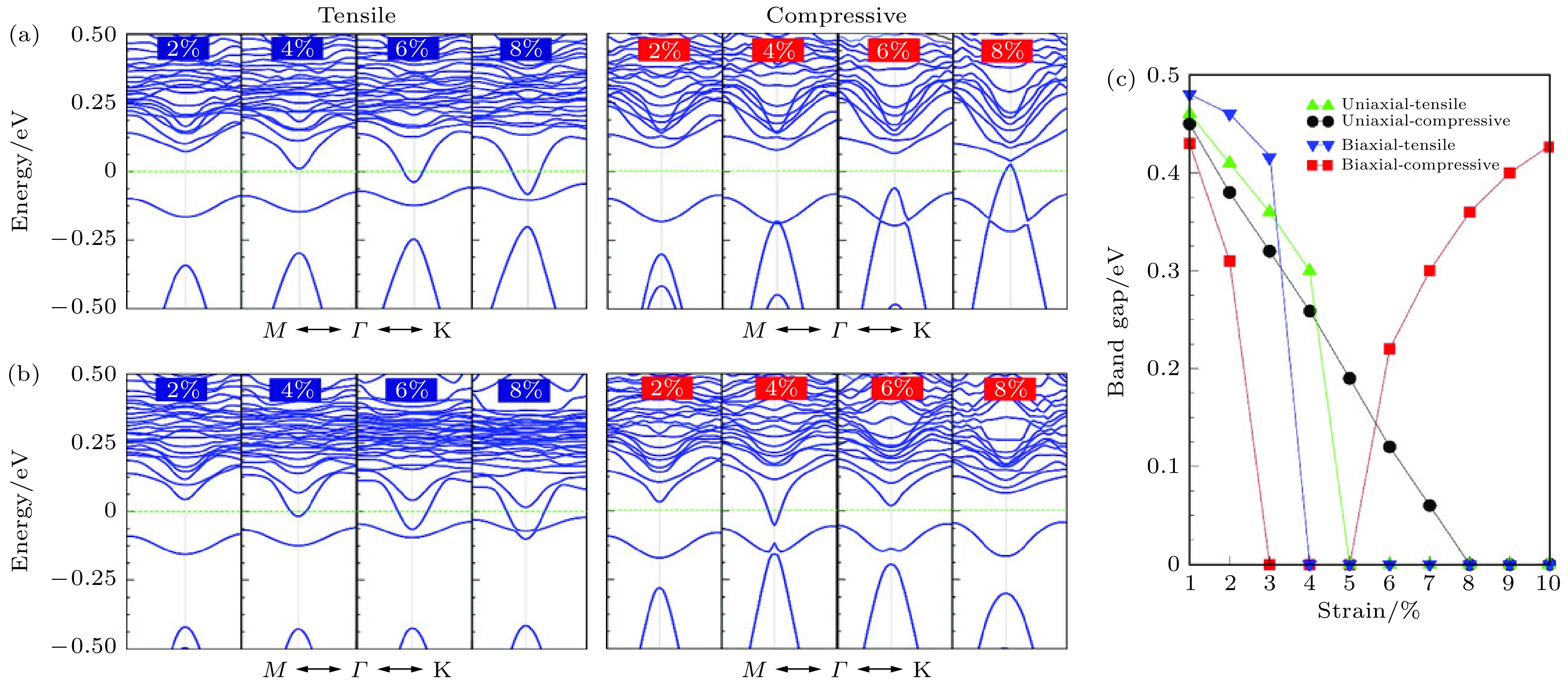

图 8 含有0.81% O空位的Ti2CO2在(a)单轴和(b)双轴应变下的电子能带结构; (c) Ti2CO2带隙随应力的变化[72]

Fig. 8. Electronic band structure of the O-vacacy Ti2CO2 structure (for 0.81% defect concentration) as a function of (a) uniaxial and (b) biaxial strain. (c) Variation of band gap with respect to strain. Reprinted from Ref. [72], Copyright © 2020 John Wiley and Sons

图 10 MXene的合金化工程及热电性能 Mo基MXene的 (a)电导率、(b)塞贝克系数和(c)功率因子随温度变化图[78]; (d) Cr基MXene的理论晶格和电子热导率[67]; (e) Cr基MXene的理论ZT值[67]; (f) TiMo基MXene的理论晶格和电子热导率[66]; (g) TiMo基MXene的理论ZT值[66]

Fig. 10. Alloying engineering and thermoelectric properties of MXene. Temperature dependent thermoelectric properties of Mo-based MXene papers during the first thermal cycle: (a) Electrical conductivity; (b) Seebeck coefficient; (c) thermoelectric power factor[78]. (d) Lattice and electron thermal conductivities of Cr-based MXene [67]. (e) Thermoelectric figure of merit (ZT) of Cr-based MXene [67]. (f) Temperature-dependent electronic and lattice thermal conductivities of TiMo-based MXene [66]. (g) Thermoelectric figure of merit (ZT) effificiency for passivated TiMo-based MXene [66]. Panels (a) (c) are reprinted with permission from Ref. [78], Copyright © 2017 American Chemical Society. Panels (d), (e) are reprinted with permission from Ref. [67], Copyright © 2019 American Chemical Society. Panels (f), (g) are reprinted from Ref. [66] with permission from American Physical Society.

图 11 MXene体系热电性能研究现状, 图中表示的是M位元素组成, 紫色代表理论具有一定的热电性能, 蓝色代表实验上成功制备的MXene相, 红色代表实际已经测得热电性能, 下划线代表具有潜在热电性能的体系

Fig. 11. Status of thermoelectric research of MXene system. Purple elements represent the constituent MXene have certain thermoelectric properties theoretically. Blue elements represent the constituent MXene synthesized experimentally. Red represents the thermoelectric properties of theses MXene being reported. The lanthanides on the underscore represent a class of MXene that may have thermoelectric properties.

物相种类 测试温度

/K热膨胀系数

/(10-6 K-1)热导率

/(W·m–1·K–1)电导率

/(106 S·m–1)塞贝克系数/(μV·K–1) 211相 Cr2AlC 473 12.50 17.5 1.8 — Ti2AlC 300 (8.10 ± 0.50) 46.0 2.8 — Nb2AlC 300 8.10 20.0 — Ti2SnC 300 10.00 ± 2.00 — 14.0 — Ti2SC 300 8.40 60..0 1.8 –12.7 312相 Ti3AlC2 85 9.00 ± 0.20 26.5 0.22 Ti3SiC2 300 9.20 46.0 — 413相 Nb4AlC3 300 5.75 13.5 — MXene 带隙/eV 迁移率/(cm2·V–1·s–1) 计算方法/实验值 参考文献 Sc2CF2 1.0 1000—5000 (e)

200—500 (h)PBE [80-83] 1.85 HSE06 [82] Sc2(OH)2 0.45 2000 (e)

50—240 (h)PBE [80-83] 0.845 HSE06 [82] Sc2CO2 1.8 PBE [80, 82] 2.87 HSE06 [82] Sc3(CN)F2 1.18 200—1300 (e)

80—1000 (h)HSE06 [84] Ti2CO2 0.17—0.26 250—610 (e)

20000—74000 (h)PBE [80-82, 85] 0.9 70—150 (e)

10000—40000 (h)HSE06 [82, 86, 87] 1.03 2—900 (e)

4000—8000 (h)HSE06 [88] Ti3C2Tx(T = O, OH, F) 0.7±0.2 (e) Experimental [89] 1.06 (e) Experimental [90] 0.66 Experimental [91] Zr2CO2 0.88—0.97 PBE [80, 82] 0.66 PBE [81] 1.70 150 (e)

1400—17500 (h)HSE06 [82, 87] 1.58 14—376 (e)

770—1950 (h)HSE06 [88] 1.34 mBJ [92] Hf2CO2 0.8—1.0 PBE [80-82] 1.66 77—330 (e)

1000—34000 (h)HSE06 [82, 87] 1.78 24—700 (e)

620—1300 (h)HSE06 [88] (Zr0.5Hf0.5)2CO2 1.74 45—1460 (e)

1500—6200 (h)PBE [93] Mo2CF2 0.25—0.30 PBE [81, 82] 0.86 HSE06 [82] Mo2CCl2 0.05 PBE [81] Mo2C(OH)2 0.1 PBE [81] W2CO2 0.0683 HSE06 [82] Mo2TiC2O2 0.04 PBE [94, 95] 0.10—0.17 HSE06 [94-96] Mo2TiC2(OH)2 0.05 PBE [97] Cr2CF(OH) 0.383 PBE [98] Cr2CF2 1.105 PBE [98] Cr2C(OH)2 0.396 PBE GGA [98] Mo2ZrC2O2 0.066 PBE [95] 0.11—0.13 HSE06 [95, 96] Mo2HfC2O2 0.154 PBE [95] 0.20—0.24 HSE06 [95, 96] W2TiC2O2 0.29 HSE06 [96] W2ZrC2O2 0.28 HSE06 [96] W2HfC2O2 0.41 HSE06 [96] Lu2CF2 2.07 200—1000 (e)

14—6000 (h)HSE06 [99] Lu2C(OH)2 1.28 100000—200000 (e)

12—14000 (h)HSE06 [99] -

[1] Doman LE A V 2016 International Energy Outlook 2016

[2] 李宜 2019 博士学位论文 (济南: 山东大学)

Yi L 2019 Ph. D. Dissertation (Jinan: Shandong University) (in Chinese)

[3] Chu S, Majumdar A 2012 Nature 488 294

Google Scholar

Google Scholar

[4] Liu W, Hu J, Zhang S, Deng M, Han C G, Liu Y 2017 Mater. Today Phys. 1 50

Google Scholar

Google Scholar

[5] Enescu D, Virjoghe E O 2014 Renewable Sustainable Energy Rev. 38 903

Google Scholar

Google Scholar

[6] Zhang Y, Heo Y J, Park M, Park S J Polymers 2019 11 167

[7] Bell L E 2008 Science 321 1457

Google Scholar

Google Scholar

[8] Zhao L D, Lo S H, Zhang Y S, Sun H, Tan G J, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2014 Nature 508 373

Google Scholar

Google Scholar

[9] Barsoum M W 2000 Prog. Solid State Chem. 28 201

Google Scholar

Google Scholar

[10] W B M 2013 MAX Phases: Properties of Machinable Ternary Carbides and Nitrides (Berlin: Wiley VCH) pp13–64

[11] Ching W Y, Mo Y, Aryal S, Rulis P 2013 J. Am. Ceram. Soc. 96 2292

Google Scholar

Google Scholar

[12] Naguib M, Kurtoglu M, Presser V, Lu J, Niu J J, Heon M, Hultman L, Gogotsi Y, Barsoum M W 2011 Adv. Mater. 23 4248

Google Scholar

Google Scholar

[13] 郑丽雅, 周延春, 冯志海 2013 宇航材料工艺 43 1

Zheng L Y, Zhou Y C, Feng Z H 2013 Aero. Mater. Tech. 2013 43 1

[14] Ying G, He X, Li M, Du S, Han W, He F 2011 J. Alloys Compd. 509 8022

Google Scholar

Google Scholar

[15] Hong X, Mei B, Zhu J, Zhou W 2004 J. Mater. Sci. 39 1589

Google Scholar

Google Scholar

[16] Barsoum M W, Brodkin D, El-Raghy T 1997 Scr. Mater. 36 535

Google Scholar

Google Scholar

[17] Cetinkaya S, Eroglu S 2012 Ceram. Int. 38 6445

Google Scholar

Google Scholar

[18] Tian W, Wang P, Zhang G, Kan Y, Li Y, Yan D 2006 Scr. Mater. 54 841

Google Scholar

Google Scholar

[19] Barsoum M W, El-Raghy T, Ali M 2000 Metall. Mater. Trans. A 31 1857

Google Scholar

Google Scholar

[20] Liu A, Yang Q, Ren X, Meng F, Gao L, Gao M, Yang Y, Ma T, Wu G 2020 Ceram. Int. 46 6934

Google Scholar

Google Scholar

[21] Champagne A, Battaglia J L, Ouisse T, Ricci F, Kusiak A, Pradere C, Natu V, Dewandre A, Verstraete M J, Barsoum M W, Charlier J C 2020 J. Phys. Chem. C 124 24017

Google Scholar

Google Scholar

[22] Palmquist J P, Jansson U, Seppänen T, Persson P O Å, Birch J, Hultman L, Isberg P 2002 Appl. Phys. Lett. 81 835

Google Scholar

Google Scholar

[23] Palmquist J P, Li S, Persson P O Å, Emmerlich J, Wilhelmsson O, Högberg H, Katsnelson M I, Johansson B, Ahuja R, Eriksson O, Hultman L, Jansson U 2004 Phys. Rev. B 70 165401

Google Scholar

Google Scholar

[24] Racault C, Langlais F, Bernard C 1994 J. Mater. Sci. 29 5023

Google Scholar

Google Scholar

[25] Fakih H, Jacques S, Dezellus O, Berthet M P, Bosselet F, Sacerdote-Peronnet M, Viala J C 2008 J. Phase Equilib. Diffus. 29 239

Google Scholar

Google Scholar

[26] Medkour Y, Roumili A, Maouche D, Louail L, Haddadi K 2009 Eur. Phys. J. B 68 193

Google Scholar

Google Scholar

[27] Mauchamp V, Yu W, Gence L, Piraux L, Cabioc'h T, Gauthier V, Eklund P, Dubois S 2013 Phys. Rev. B 87 235105

Google Scholar

Google Scholar

[28] Ouisse T, Shi L, Piot B A, Hackens B, Mauchamp V, Chaussende D 2015 Phys. Rev. B 92 045133

Google Scholar

Google Scholar

[29] Flatten T, Matthes F, Petruhins A, Salikhov R, Wiedwald U, Farle M, Rosen J, Bürgler D E, Schneider C M 2019 Appl. Phys. Lett. 115 094101

Google Scholar

Google Scholar

[30] Schuster J C, Nowotny H, Vaccaro C 1980 J. Solid State Chem. 32 213

Google Scholar

Google Scholar

[31] Schneider J M, Sun Z, Mertens R, Uestel F, Ahuja R 2004 Solid State Commun. 130 445

Google Scholar

Google Scholar

[32] Drulis M K, Drulis H, Gupta S, Barsoum M W, El-Raghy T 2006 J. Appl. Phys. 99 093502

Google Scholar

Google Scholar

[33] Bai Y L, He X D, Zhu C C, Chen G Q 2012 J. Am. Ceram. Soc. 95 358

Google Scholar

Google Scholar

[34] Vovk R V, Khadzhai G Y, Prikhna T A, Gevorkyan E S, Kislitsa M V, Soloviev A L, Goulatis I L, Chroneos A 2018 J. Mater. Sci. -Mater. Electron. 29 11478

Google Scholar

Google Scholar

[35] Hu C, Sakka Y, Tanaka H, Nishimura T, Grasso S 2011 J. Am. Ceram. Soc. 94 410

Google Scholar

Google Scholar

[36] Cai P, He Q, Yang L, Huang Z, Liu X, Yin J, Huang Y 2019 Ceram. Int. 45 9799

Google Scholar

Google Scholar

[37] Yoo H I, Barsoum M W, El-Raghy T 2000 Nature 407 581

[38] Finkel P, Seaman B, Harrell K, Palma J, Hettinger J D, Lofland S E, Ganguly A, Barsoum M W, Sun Z, Li S, Ahuja R 2004 Phys. Rev. B 70 085104

Google Scholar

Google Scholar

[39] Chen K, Chen Y, Zhang J, Song Y, Zhou X, Li M, Fan X, Zhou J, Huang Q 2021 Ceram. Int. 47 7582

Google Scholar

Google Scholar

[40] Sonntag J 2010 J. Phys. Condens. Matter 22 235501

Google Scholar

Google Scholar

[41] Xu C, Wang L, Liu Z, Chen L, Guo J, Kang N, Ma X L, Cheng H M, Ren W 2015 Nat. Mater. 14 1135

Google Scholar

Google Scholar

[42] Zhang F, Zhang Z, Wang H, Chan C H, Chan N Y, Chen X X, Dai J Y 2017 Phys. Rev. Mater. 1 034002

Google Scholar

Google Scholar

[43] Du Z G, Yang S B, Li S M, Lou J, Zhang S Q, Wang S, Li B, Gong Y J, Song L, Zou X L, Ajayan P M 2020 Nature 577 492

Google Scholar

Google Scholar

[44] Zhou J, Zha X H, Chen F Y, Ye Q, Eklund P, Du S Y, Huang Q 2016 Angew. Chem. Int. Ed. 55 5008

Google Scholar

Google Scholar

[45] Zhou J, Zha X, Zhou X, Chen F, Gao G, Wang S, Shen C, Chen T, Zhi C, Eklund P, Du S, Xue J, Shi W, Chai Z, Huang Q 2017 ACS Nano 11 3841

Google Scholar

Google Scholar

[46] Zhou J, Zha X H, Yildizhan M, Eklund P, Xue J M, Liao M Y, Persson P O A, Du S Y, Huang Q 2019 ACS Nano 13 1195

Google Scholar

Google Scholar

[47] Naguib M, Halim J, Lu J, Cook K M, Hultman L, Gogotsi Y, Barsoum M W 2013 J. Am. Chem. Soc. 135 15966

Google Scholar

Google Scholar

[48] Anasori B, Xie Y, Beidaghi M, Lu J, Hosler B C, Hultman L, Kent P R C, Gogotsi Y, Barsoum M W 2015 ACS Nano 9 9507

Google Scholar

Google Scholar

[49] Lipatov A, Alhabeb M, Lukatskaya M R, Boson A, Gogotsi Y, Sinitskii A 2016 Adv. Electron. Mater. 2 1600255

Google Scholar

Google Scholar

[50] Feng A H, Yu Y, Wang Y, Jiang F, Yu Y, Mi L, Song L X 2017 Mater. Des. 114 161

Google Scholar

Google Scholar

[51] Zhang B, Zhu J F, Shi P, Wu W L, Wang F 2019 Ceram. Int. 45 8395

Google Scholar

Google Scholar

[52] Sun Z, Yuan M, Lin L, Yang H, Nan C, Li H, Sun G, Yang X 2019 ACS Mater. Lett. 1 628

Google Scholar

Google Scholar

[53] Lukatskaya M R, Halim J, Dyatkin B, Naguib M, Buranova Y S, Barsoum M W, Gogotsi Y 2014 Angew. Chem. Int. Ed. 53 4877

Google Scholar

Google Scholar

[54] Yang S, Zhang P, Wang F, Ricciardulli A G, Lohe M R, Blom P W M, Feng X 2018 Angew. Chem. Int. Ed. 57 15491

Google Scholar

Google Scholar

[55] Pang S Y, Wong Y T, Yuan S G, Liu Y, Tsang M K, Yang Z B, Huang H T, Wong W T, Hao J H 2019 J. Am. Chem. Soc. 141 9610

Google Scholar

Google Scholar

[56] Sun W, Shah S A, Chen Y, Tan Z, Gao H, Habib T, Radovic M, Green M J 2017 J. Mater. Chem. A 5 21663

Google Scholar

Google Scholar

[57] Song M, Pang S Y, Guo F, Wong M C, Hao J 2020 Adv. Sci. 7 2001546

Google Scholar

Google Scholar

[58] Li X L, Li M, Yang Q, Liang G J, Huang Z D, Ma L T, Wang D H, Mo F N, Dong B B, Huang Q, Zhi C Y 2020 Adv. Energy Mater. 10 2001394

Google Scholar

Google Scholar

[59] Chertopalov S, Mochalin V N 2018 ACS Nano 12 6109

Google Scholar

Google Scholar

[60] Natu V, Pai R, Sokol M, Carey M, Kalra V, Barsoum M W 2020 Chem. 6 616

Google Scholar

Google Scholar

[61] Mei J, Ayoko G A, Hu C F, Sun Z Q 2020 Chem. Eng. J. 395 125111

Google Scholar

Google Scholar

[62] Li M, Lu J, Luo K, Li Y B, Chang K K, Chen K, Zhou J, Rosen J, Hultman L, Eklund P, Persson P O A, Du S Y, Chai Z F, Huang Z R, Huang Q 2019 J. Am. Chem. Soc. 141 4730

Google Scholar

Google Scholar

[63] Li Y, Shao H, Lin Z, Lu J, Liu L, Duployer B, Persson P O Å, Eklund P, Hultman L, Li M, Chen K, Zha X-H, Du S, Rozier P, Chai Z, Raymundo-Piñero E, Taberna P-L, Simon P, Huang Q 2020 Nat. Mater. 19 894

Google Scholar

Google Scholar

[64] Kamysbayev V, Filatov A S, Hu H C, Rui X, Lagunas F, Wang D, Klie R F, Talapin D V 2020 Science 369 979

Google Scholar

Google Scholar

[65] Shi H, Zhang P, Liu Z, Park S, Lohe M R, Wu Y, Shaygan Nia A, Yang S, Feng X 2021 Angew. Chem. Int. Ed. 60 8689

Google Scholar

Google Scholar

[66] Karmakar S, Saha-Dasgupta T 2020 Phys. Rev. Mater. 4 124007

Google Scholar

Google Scholar

[67] Jing Z A, Wang H Y, Feng X H, Xiao B, Ding Y C, Wu K, Cheng Y H 2019 J. Phys. Chem. Lett. 10 5721

Google Scholar

Google Scholar

[68] Liu P, Ding W J, Liu J, Shen L L, Jiang F X, Liu P P, Zhu Z Y, Zhang G, Liu C C, Xu J K 2020 J. Alloys Compd. 829 154634

Google Scholar

Google Scholar

[69] Ding W, Liu P, Bai Z, Wang Y, Liu G, Jiang Q, Jiang F, Liu P, Liu C, Xu J 2020 Adv. Mater. Interfaces 7 2001340

Google Scholar

Google Scholar

[70] Guan X, Feng W, Wang X Z, Venkatesh R, Ouyang J Y 2020 ACS Appl. Mater. Interfaces 12 13013

Google Scholar

Google Scholar

[71] Li X H, Zhang R Z, Cui H L 2020 ACS Omega 5 18403

Google Scholar

Google Scholar

[72] Bafekry A, Nguyen C V, Stampfl C, Akgenc B, Ghergherehchi M 2020 Phys. Status Solidi B 257 2000343

Google Scholar

Google Scholar

[73] Bafekry A, Akgenc B, Ghergherehchi M, Peeters F M 2020 J. Phys. Condens. Matter 32 355701

Google Scholar

Google Scholar

[74] Zhang H, Hu T, Wang X, Zhou Y 2020 J. Mater. Sci. Technol. 38 205

Google Scholar

Google Scholar

[75] Tao Q, Dahlqvist M, Lu J, Kota S, Meshkian R, Halim J, Palisaitis J, Hultman L, Barsoum M W, Persson P O Å, Rosen J 2017 Nat. Commun. 8 14949

Google Scholar

Google Scholar

[76] Meshkian R, Dahlqvist M, Lu J, Wickman B, Halim J, Thörnberg J, Tao Q Z, Li S X, Intikhab S, Snyder J, Barsoum M W, Yildizhan M, Palisaitis J, Hultman L, Persson P, Rosen J 2018 Adv. Mater. 30 1706409

Google Scholar

Google Scholar

[77] Meshkian R, Lind H, Halim J, El Ghazaly A, Thörnberg J, Tao Q, Dahlqvist M, Palisaitis J, Persson P O Å, Rosen J 2019 ACS Appl. Nano Mater. 2 6209

Google Scholar

Google Scholar

[78] Kim H, Anasori B, Gogotsi Y, Alshareef H N 2017 Chem. Mater. 29 6472

Google Scholar

Google Scholar

[79] Guo J, Legum B, Anasori B, Wang K, Lelyukh P, Gogotsi Y, Randall C A 2018 Adv. Mater. 30 1801846

Google Scholar

Google Scholar

[80] Khazaei M, Arai M, Sasaki T, Chung C Y, Venkataramanan N S, Estili M, Sakka Y, Kawazoe Y 2013 Adv. Funct. Mater. 23 2185

Google Scholar

Google Scholar

[81] Khazaei M, Arai M, Sasaki T, Estili M, Sakka Y 2014 Phys. Chem. Chem. Phys. 16 7841

Google Scholar

Google Scholar

[82] Zha X H, Luo K, Li Q, Huang Q, He J, Wen X, Du S 2015 EPL 111 26007

Google Scholar

Google Scholar

[83] Zha X H, Zhou J, Zhou Y H, Huang Q, He J, Francisco J S, Luo K, Du S Y 2016 Nanoscale 8 6110

Google Scholar

Google Scholar

[84] Luo K, Zha X H, Zhou Y H, Guo Z S, Lin C T, Huang Q, Zhou S H, Zhang R F, Du S Y 2018 RSC Adv. 8 22452

Google Scholar

Google Scholar

[85] Zhang X, Zhao X D, Wu D H, Jing Y, Zhou Z 2015 Nanoscale 7 16020

Google Scholar

Google Scholar

[86] Xie Y, Kent P R C 2013 Phys. Rev. B 87 235441

Google Scholar

Google Scholar

[87] Zha X H, Huang Q, He J, He H M, Zhai J Y, Francisco J S, Du S Y 2016 Sci. Rep. 6 1

Google Scholar

Google Scholar

[88] Xu X, Ge X, Liu X, Li L, Fu K, Dong Y, Meng F, Si R, Zhang M 2020 Ceram. Int. 46 13377

Google Scholar

Google Scholar

[89] Miranda A, Halim J, Barsoum M W, Lorke A 2016 Appl. Phys. Lett. 108 033102

Google Scholar

Google Scholar

[90] Jing H, Yeo H, Lyu B, Ryou J, Choi S, Park J H, Lee B H, Kim Y H, Lee S 2021 ACS Nano 15 1388

Google Scholar

Google Scholar

[91] Gao L G, Wang N, Cao J M, Li Y, Ma T L 2020 Surf. Interfaces 20 100604

Google Scholar

Google Scholar

[92] Mostafaei A, Faizabadi E, Semiromi E H 2019 Physica E 114 113559

Google Scholar

Google Scholar

[93] Zhang Y G, Sa B S, Zhou J, Sun Z M 2021 Comput. Mater. Sci. 186 110013

Google Scholar

Google Scholar

[94] Li L H 2016 Comput. Mater. Sci. 124 8

Google Scholar

Google Scholar

[95] Si C, Jin K H, Zhou J, Sun Z, Liu F 2016 Nano Lett. 16 6584

Google Scholar

Google Scholar

[96] Khazaei M, Ranjbar A, Arai M, Yunoki S 2016 Phys. Rev. B 94 125152

Google Scholar

Google Scholar

[97] Anasori B, Shi C, Moon E J, Xie Y, Voigt C A, Kent P R C, May S J, Billinge S J L, Barsoum M W, Gogotsi Y 2016 Nanoscale Horiz. 1 227

Google Scholar

Google Scholar

[98] Je M, Lee Y, Chung Y C 2016 Thin Solid Films 619 131

Google Scholar

Google Scholar

[99] Bai X, Zha X H, Qiao Y, Qiu N, Zhang Y, Luo K, He J, Li Q, Huang Q, Francisco J S, Lin C T, Du S 2020 Nanoscale 12 3795

Google Scholar

Google Scholar

计量

- 文章访问数: 15847

- PDF下载量: 593

- 被引次数: 0

下载:

下载: