-

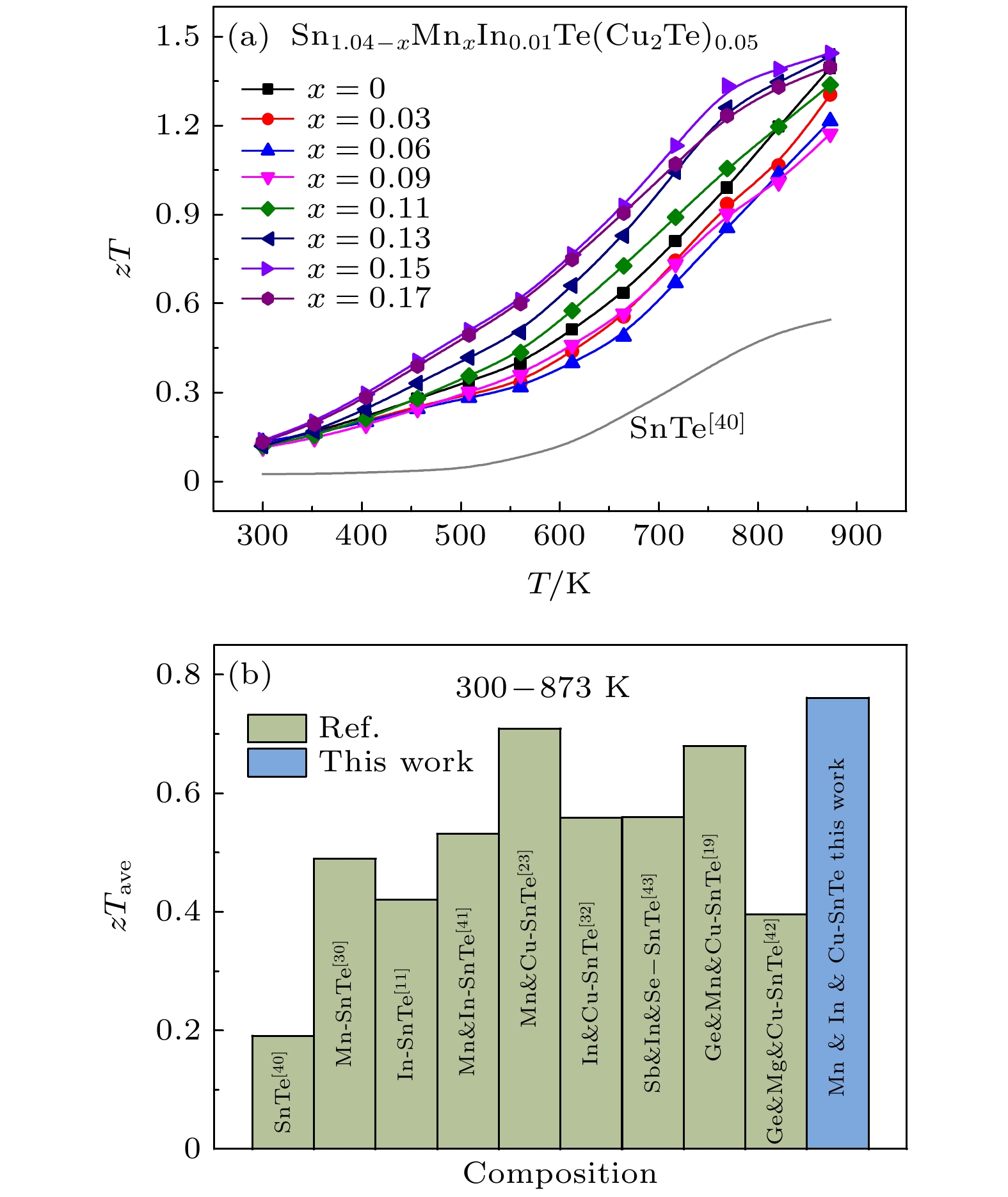

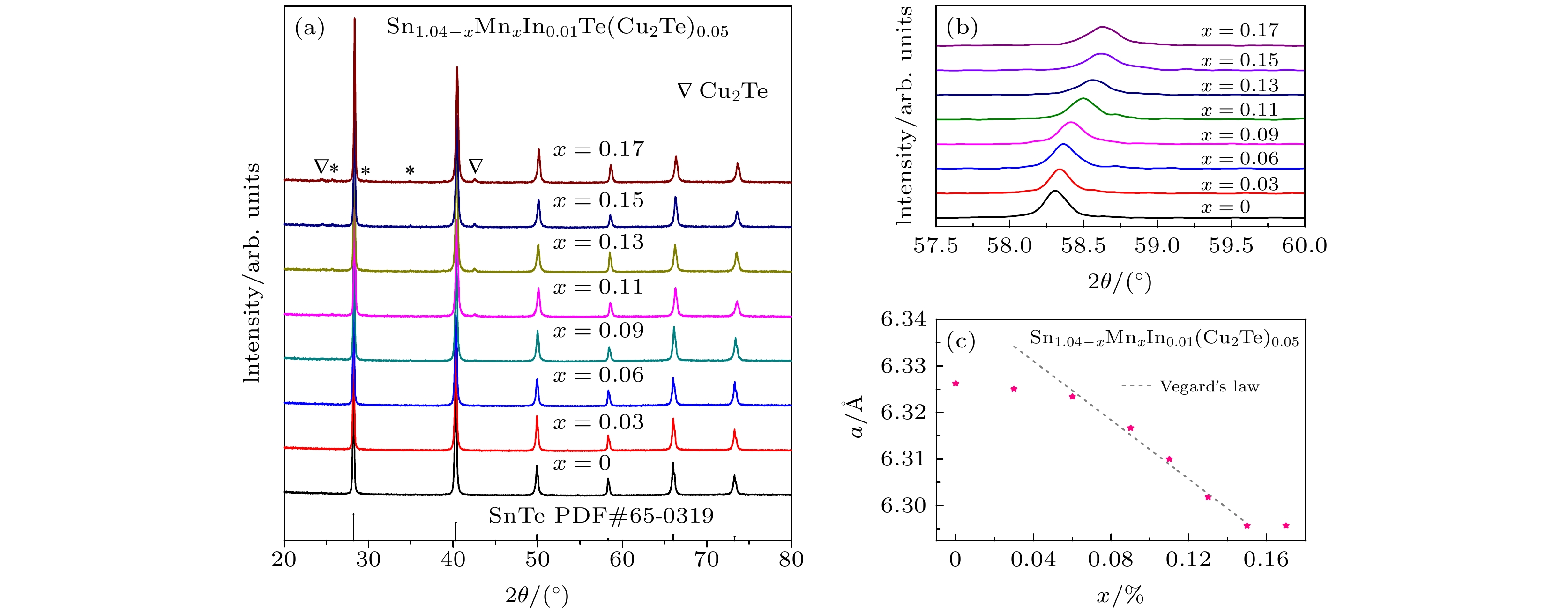

无铅硫族化合物SnTe因与PbTe具有相似的晶体结构和能带结构, 近些年受到广泛关注, 然而其较低的Seebeck系数、本征高Sn空位浓度以及高的热导率导致本征热电性能较差. 本文通过高温高压结合热压烧结的方式制备了Mn, In, Cu共掺杂的SnTe基热电材料. Mn带来的能带收敛和In引入的共振能级的共同作用提高了材料整个温度范围内的Seebeck系数, 优化了材料的功率因子. 此外, Mn合金化带来的点缺陷和Cu引入的间隙缺陷增强了声子散射, 有效降低了材料的晶格热导率. 多种策略结合下材料的电性能与热性能同时得到优化, 其中Sn0.89Mn0.15In0.01Te(Cu2Te)0.05样品在873 K时获得最大zT ≈ 1.45, 300—873 K的平均zT达到0.76. 多策略协同调控SnTe基热电材料时仍能较好地保持单策略所发挥的优异特性, 这为进一步改进SnTe基热电材料性能提供了可能.Lead-free chalcogenide SnTe has a similar crystal structure and energy band structure to high performance thermoelectric material PbTe, which has been widely concerned in recent years. However, due to its low Seebeck coefficient, high intrinsic Sn vacancy concentration and high thermal conductivity, its intrinsic thermoelectric performance is poor. In this study, Mn-In-Cu co-doping SnTe-based thermoelectric materials are prepared by hot pressing sintering at high-temperature and high-pressure. Indium (In) doping brings the resonant level in SnTe and increases the density of states which greatly improves Seebeck coefficient at room temperature; the Seebeck coefficient of Sn1.04In0.01Te(Cu2Te)0.05 reaches 70 μV·K–1 at room temperature. With adding manganese (Mn), the Seebeck coefficient at room temperature is well preserved, indicating that Mn doping has little effect on the resonant level brought by In doping. In addition, due to the band convergence brought by Mn doping, the high temperature Seebeck coefficient of the material is improved, the maximum Seebeck coefficient reaches 215 μV·K–1 for the sample with 17% Mn doping amount at 873 K. Owing to the combination of band convergence and resonant level, the Seebeck coefficient of the whole temperature range of the material increases, the power factor of the material is also greatly optimized, and all samples have a power factor of more than 1.0 mW·m–1·K–2 at room temperature. On the other hand, the point defects brought by Mn alloying and the interstitial defects introduced by copper (Cu) enhance the phonon scattering and effectively reduce the lattice thermal conductivity of the material, the lattice thermal conductivity decreases to 0.68 W·m–1·K–1 at 873 K. The electrical and thermal properties of the materials are optimized simultaneously under the combination of various strategies, the peak zT ≈ 1.45 is obtained at 873 K in the p-type Sn0.89Mn0.15In0.01Te(Cu2Te)0.05 sample and the average zT of 300–873 K reaches 0.76. In the process of multi-strategy coordinated regulation of SnTe-based thermoelectric materials, the excellent properties of single strategy can be well maintained, which provides a possibility for further improving the performance of SnTe-based thermoelectric materials.

-

Keywords:

- SnTe /

- high-temperature and high-pressure /

- doping /

- thermoelectric materials

[1] Wood C 1988 Rep. Prog. Phys. 51 459

Google Scholar

Google Scholar

[2] Biswas K, He J, Blum I D, Wu C I, Hogan T P, Seidman D N, Dravid V P, Kanatzidis M G 2012 Nature 489 414

Google Scholar

Google Scholar

[3] Pei Y, Shi X, LaLonde A, Wang H, Chen L, Snyder G J 2011 Nature 473 66

Google Scholar

Google Scholar

[4] Brebrick R F 1963 J. Phys. Chem. Solids 24 27

Google Scholar

Google Scholar

[5] Rogers L M 1968 J. Phys. D: Appl. Phys. 1 845

Google Scholar

Google Scholar

[6] Wu H, Chang C, Feng D, Xiao Y, Zhang X, Pei Y, Zheng L, Wu D, Gong S, Chen Y, He J, Kanatzidis M G, Zhao L D 2015 Energy Environ. Sci. 8 3298

Google Scholar

Google Scholar

[7] Banik A, Shenoy U S, Anand S, Waghmare U V, Biswas K 2015 Chem. Mater. 27 581

Google Scholar

Google Scholar

[8] Tan G, Shi F, Doak J W, Sun H, Zhao L D, Wang P, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2015 Energy Environ. Sci. 8 267

Google Scholar

Google Scholar

[9] Tan G, Zhao L D, Shi F, Doak J W, Lo S H, Sun H, Wolverton C, Dravid V P, Uher C, Kanatzidis M G 2014 J. Am. Chem. Soc. 136 7006

Google Scholar

Google Scholar

[10] Tan X J, Shao H Z, He J, Liu G Q, Xu J T, Jiang J, Jiang H C 2016 Phys. Chem. Chem. Phys. 18 7141

Google Scholar

Google Scholar

[11] Zhang Q, Liao B, Lan Y, Lukas K, Liu W, Esfarjani K, Opeil C, Broido D, Chen G, Ren Z 2013 Proc. Natl. Acad. Sci. U.S.A. 110 13261

Google Scholar

Google Scholar

[12] Ma Z, Lei J, Zhang D, Wang C, Wang J, Cheng Z, Wang Y 2019 ACS Appl. Mater. Interfaces 11 33792

Google Scholar

Google Scholar

[13] Bhat D K, Shenoy U S 2017 J. Phys. Chem. C 121 7123

Google Scholar

Google Scholar

[14] Banik A, Vishal B, Perumal S, Datta R, Biswas K 2016 Energy Environ. Sci. 9 2011

Google Scholar

Google Scholar

[15] Roychowdhury S, Biswas R K, Dutta M, Pati S K, Biswas K 2019 ACS Energy Lett. 4 1658

Google Scholar

Google Scholar

[16] Tan G, Hao S, Hanus R C, Zhang X, Anand S, Bailey T P, Rettie A J E, Su X, Uher C, Dravid V P, Snyder G J, Wolverton C, Kanatzidis M G 2018 ACS Energy Lett. 3 705

Google Scholar

Google Scholar

[17] Pei Y, Zheng L, Li W, Lin S, Chen Z, Wang Y, Xu X, Yu H, Chen Y, Ge B 2016 Adv. Electron. Mater. 2 1600019

Google Scholar

Google Scholar

[18] Hu L, Zhang Y, Wu H, Li J, Li Y, McKenna M, He J, Liu F, Pennycook S J, Zeng X 2018 Adv. Energy Mater. 8 1802116

Google Scholar

Google Scholar

[19] Tang J, Gao B, Lin S, Li J, Chen Z, Xiong F, Li W, Chen Y, Pei Y 2018 Adv. Funct. Mater. 28 1803586

Google Scholar

Google Scholar

[20] Tang J, Yao Z, Wu Y, Lin S, Xiong F, Li W, Chen Y, Zhu T, Pei Y 2020 Mater. Today Phys. 15 100247

Google Scholar

Google Scholar

[21] Xu X, Cui J, Yu Y, Zhu B, Huang Y, Xie L, Wu D, He J 2020 Energy Environ. Sci. 13 5135

Google Scholar

Google Scholar

[22] Blachnik R, Igel R 1974 Z. Naturforsch., B: Chem. Sci. 29 625

Google Scholar

Google Scholar

[23] Li W, Zheng L, Ge B, Lin S, Zhang X, Chen Z, Chang Y, Pei Y 2017 Adv. Mater. 29 1605887

Google Scholar

Google Scholar

[24] Li W, Chen Z, Lin S, Chang Y, Ge B, Chen Y, Pei Y 2015 J. Materiomics 1 307

Google Scholar

Google Scholar

[25] Wu Y, Chen Z, Nan P, Xiong F, Lin S, Zhang X, Chen Y, Chen L, Ge B, Pei Y 2019 Joule 3 1276

Google Scholar

Google Scholar

[26] Zak A K, Majid A W H, Abrishami M E, Yousefi R 2011 Solid State Sci. 13 251

Google Scholar

Google Scholar

[27] Sarker P, Sen S K, Mia M N H, Pervez M F, Mortuza A A, Hossain S, Mortuza M F, Ali M H, Nur S, Kabir H, Chowdhury M A M 2021 Ceram. Int. 47 3626

Google Scholar

Google Scholar

[28] Guo F, Cui B, Liu Y, Meng X, Cao J, Zhang Y, He R, Liu W, Wu H, Pennycook S J, Cai W, Sui J 2018 Small 14 1802615

Google Scholar

Google Scholar

[29] Acharya S, Pandey J, Soni A 2016 Appl. Phys. Lett. 109 133904

Google Scholar

Google Scholar

[30] Li S M, Li J Q, Yang L, Liu F S, Ao W Q, Li Y 2016 Mater. Des. 108 51

Google Scholar

Google Scholar

[31] Uher C 2016 Materials Aspect of Thermoelectricity (Vol. 1) (Boca Raton: CRC Press) p8

[32] 傅铁铮, 沈家骏, 忻佳展, 朱铁军 2019 硅酸盐学报 47 1467

Fu T Z, Shen J J, Qi J Z, Zhu T J 2019 J. Chin. Ceram. Soc. 47 1467

[33] Brebrick R F, Strauss A J 1963 Phys. Rev. 131 104

Google Scholar

Google Scholar

[34] Guo F, Cui B, Geng H, Zhang Y, Wu H, Zhang Q, Yu B, Pennycook S J, Cai W, Sui J 2019 Small 15 1902493

Google Scholar

Google Scholar

[35] Shenoy U S, Bhat D K 2020 J. Mater. Chem. C 8 2036

Google Scholar

Google Scholar

[36] Kim H S, Gibbs Z M, Tang Y, Wang H, Snyder G J 2015 APL Mater. 3 041516

Google Scholar

Google Scholar

[37] Callaway J 1959 Phys. Rev. 113 1046

Google Scholar

Google Scholar

[38] Hussain T, Li X, Danish M H, Rehman M U, Zhang J, Li D, Chen G, Tang G 2020 Nano Energy 73 104832

Google Scholar

Google Scholar

[39] Li W, He Q Y, Chen J F, Pan Z L, Wang T 2014 Chem. Phys. Lett. 616-617 196

Google Scholar

Google Scholar

[40] Guo F, Wu H, Zhu J, Yao H, Zhang Y, Cui B, Zhang Q, Yu B, Pennycook S J, Cai W, Chu C W, Sui J 2019 Proc. Natl. Acad. Sci. U.S.A. 116 21998

Google Scholar

Google Scholar

[41] Wang H, Hwang J, Zhang C, Wang T, Su W, Kim H, Kim J, Zhai J, Wang X, Park H, Kim W, Wang C 2017 J. Mater. Chem. A 5 14165

Google Scholar

Google Scholar

[42] Tang J, Yao Z, Chen Z, Lin S, Zhang X, Xiong F, Li W, Chen Y, Pei Y 2019 Mater. Today Phys. 9 100091

Google Scholar

Google Scholar

[43] Wang D, Zhang X, Yu Y, Xie L, Wang J, Wang G, He J, Zhou Y, Pang Q, Shao J, Zhao L D 2019 J. Alloys Compd. 773 571

Google Scholar

Google Scholar

-

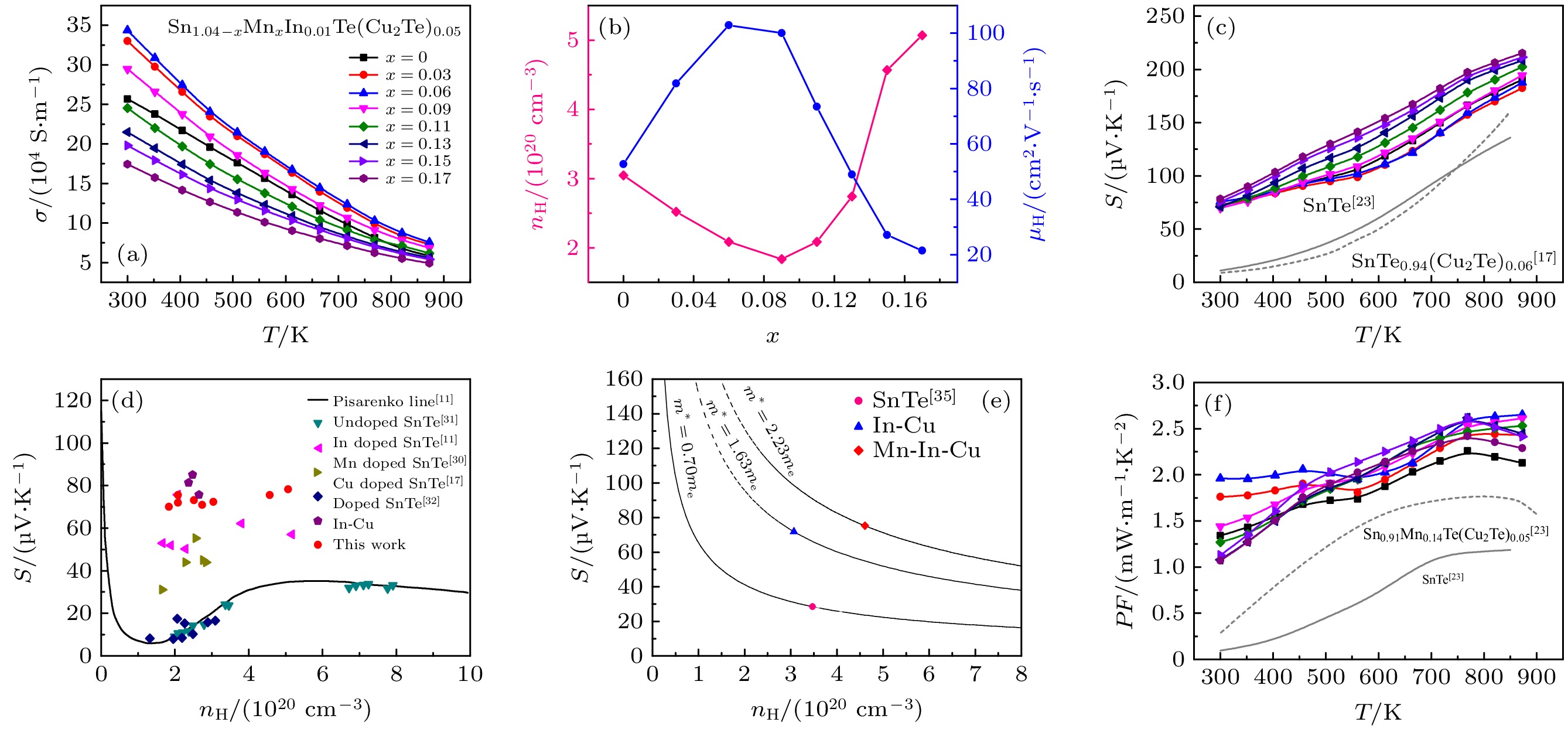

图 3 Sn1.04–xMnxIn0.01Te(Cu2Te)0.05(x = 0—0.17)样品的(a) 电导率随温度的变化, (b) 室温下载流子浓度和迁移率随x的变化, (c) Seebeck系数随温度的变化, (d) 室温下Seebeck系数与载流子浓度关系以及和相关研究的对比图[11,17,30-32], (e) 室温下有效质量对比图, (f) 功率因子随温度的变化

Fig. 3. Sn1.04–xMnxIn0.01Te(Cu2Te)0.05 (x = 0–0.17) samples: (a) Electrical conductivities as a function of temperature; (b) carrier concentration and mobility as a function of x at room temperature; (c) Seebeck coefficients as a function of temperature; (d) the relationship between Seebeck coefficient and carrier concentration at room temperature and comparison with the correlation studies[11,17,30-32]; (e) effective mass comparison at room temperature; (f) power factor as a function of temperature.

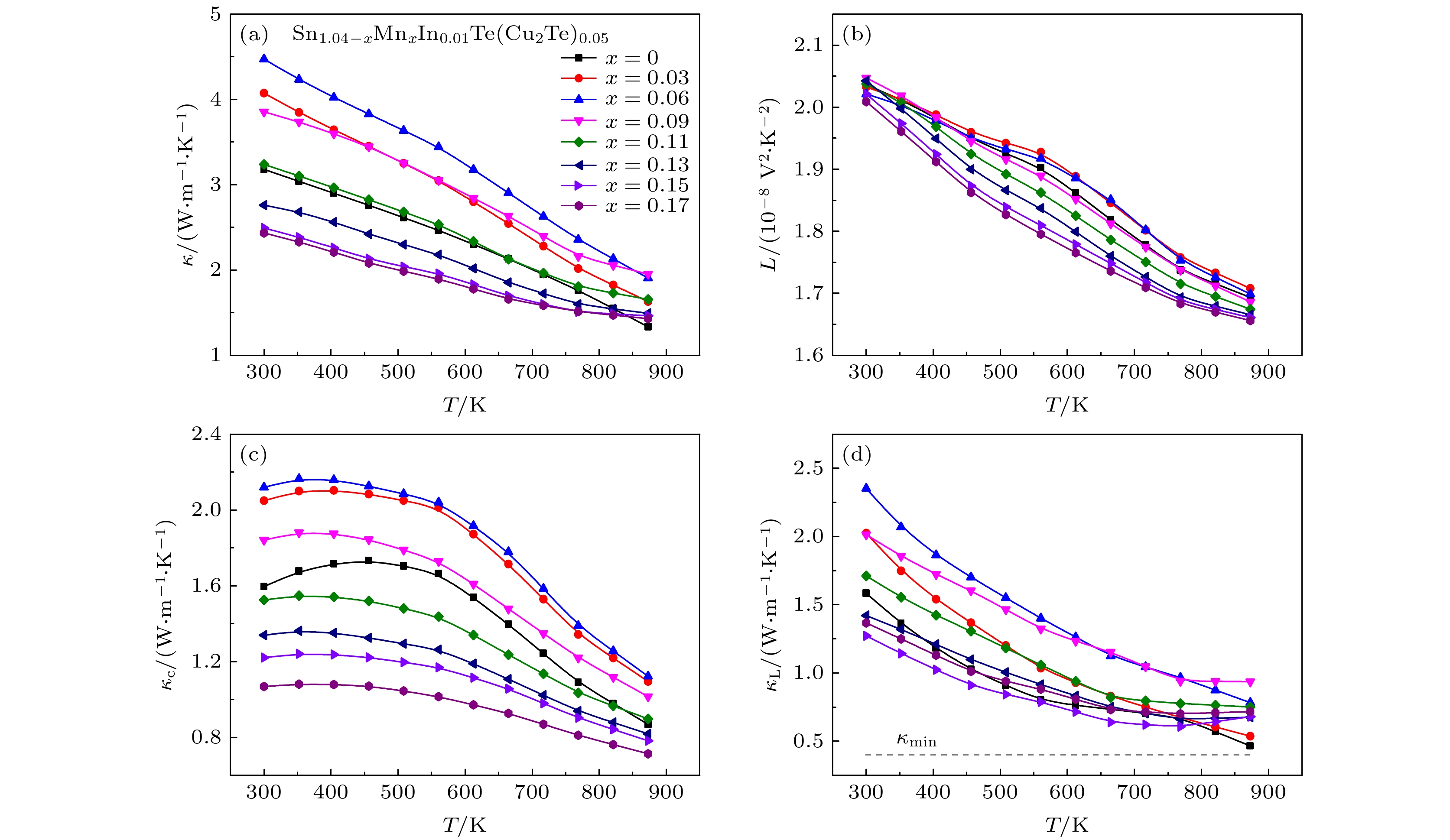

图 4 Sn1.04–xMnxIn0.01Te(Cu2Te)0.05 (x = 0—0.17)样品的(a) 总热导率、(b) 洛伦兹数、(c) 载流子热导率、(d) 晶格热导率随温度的变化

Fig. 4. Thermoelectric properties of Sn1.04–xMnxIn0.01Te(Cu2Te)0.05 (x = 0–0.17) as a function of temperature: (a) Total thermal conductivity; (b) Lorenz number; (c) carrier thermal conductivity; (d) lattice thermal conductivity.

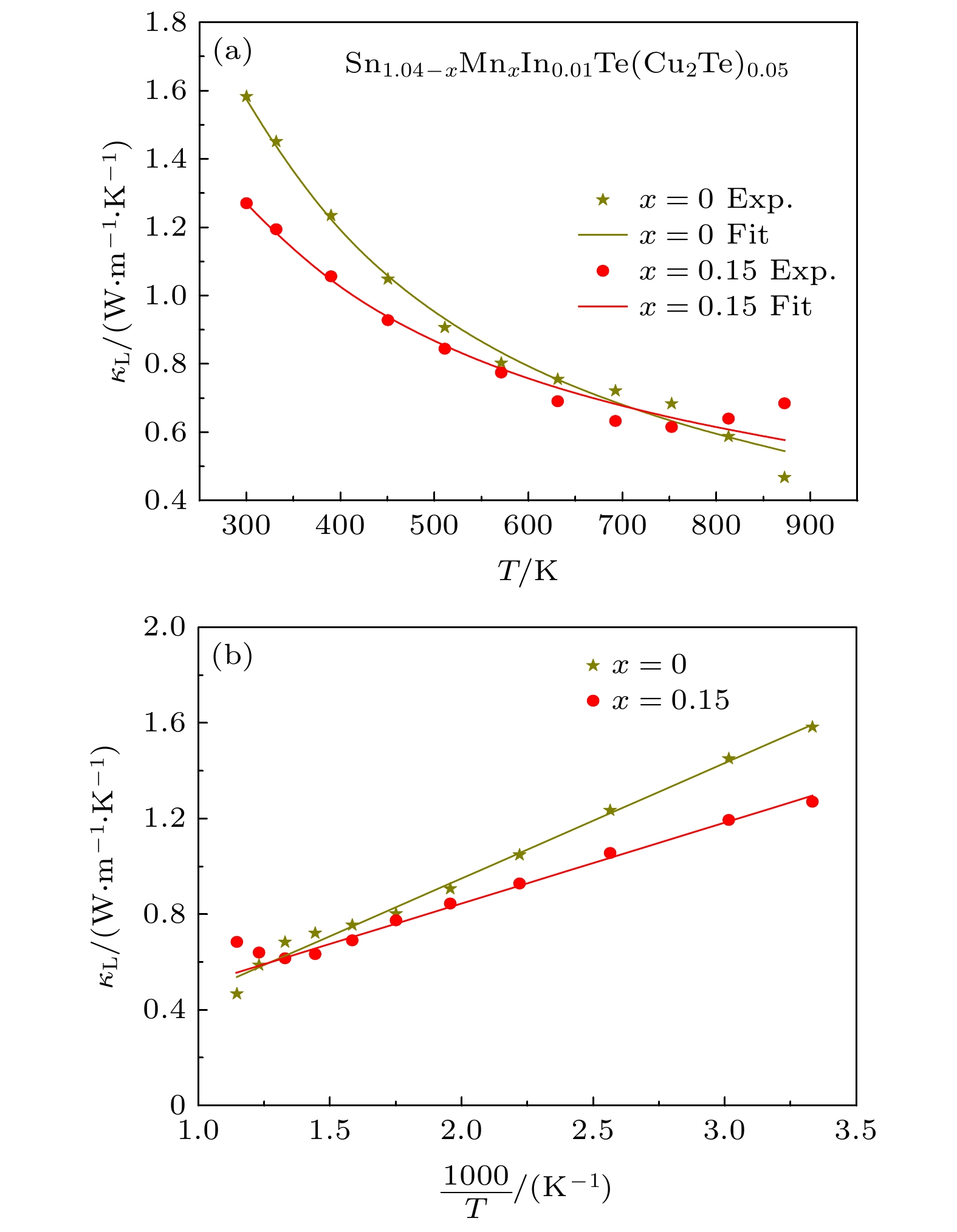

图 5 Sn1.04In0.01Te(Cu2Te)0.05样品和Sn0.89Mn0.15In0.01Te(Cu2Te)0.05样品的(a) 晶格热导率的实验值与拟合结果对比, (b) 晶格热导率与1000/T的函数关系图

Fig. 5. (a) Experimental and fitting results of lattice thermal conductivity for Sn1.04In0.01Te(Cu2Te)0.05 and Sn0.89Mn0.15In0.01Te(Cu2Te)0.05; (b) lattice thermal conductivity as a function of 1000/T for Sn1.04In0.01Te(Cu2Te)0.05 and Sn0.89Mn0.15In0.01Te(Cu2Te)0.05.

-

[1] Wood C 1988 Rep. Prog. Phys. 51 459

Google Scholar

Google Scholar

[2] Biswas K, He J, Blum I D, Wu C I, Hogan T P, Seidman D N, Dravid V P, Kanatzidis M G 2012 Nature 489 414

Google Scholar

Google Scholar

[3] Pei Y, Shi X, LaLonde A, Wang H, Chen L, Snyder G J 2011 Nature 473 66

Google Scholar

Google Scholar

[4] Brebrick R F 1963 J. Phys. Chem. Solids 24 27

Google Scholar

Google Scholar

[5] Rogers L M 1968 J. Phys. D: Appl. Phys. 1 845

Google Scholar

Google Scholar

[6] Wu H, Chang C, Feng D, Xiao Y, Zhang X, Pei Y, Zheng L, Wu D, Gong S, Chen Y, He J, Kanatzidis M G, Zhao L D 2015 Energy Environ. Sci. 8 3298

Google Scholar

Google Scholar

[7] Banik A, Shenoy U S, Anand S, Waghmare U V, Biswas K 2015 Chem. Mater. 27 581

Google Scholar

Google Scholar

[8] Tan G, Shi F, Doak J W, Sun H, Zhao L D, Wang P, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2015 Energy Environ. Sci. 8 267

Google Scholar

Google Scholar

[9] Tan G, Zhao L D, Shi F, Doak J W, Lo S H, Sun H, Wolverton C, Dravid V P, Uher C, Kanatzidis M G 2014 J. Am. Chem. Soc. 136 7006

Google Scholar

Google Scholar

[10] Tan X J, Shao H Z, He J, Liu G Q, Xu J T, Jiang J, Jiang H C 2016 Phys. Chem. Chem. Phys. 18 7141

Google Scholar

Google Scholar

[11] Zhang Q, Liao B, Lan Y, Lukas K, Liu W, Esfarjani K, Opeil C, Broido D, Chen G, Ren Z 2013 Proc. Natl. Acad. Sci. U.S.A. 110 13261

Google Scholar

Google Scholar

[12] Ma Z, Lei J, Zhang D, Wang C, Wang J, Cheng Z, Wang Y 2019 ACS Appl. Mater. Interfaces 11 33792

Google Scholar

Google Scholar

[13] Bhat D K, Shenoy U S 2017 J. Phys. Chem. C 121 7123

Google Scholar

Google Scholar

[14] Banik A, Vishal B, Perumal S, Datta R, Biswas K 2016 Energy Environ. Sci. 9 2011

Google Scholar

Google Scholar

[15] Roychowdhury S, Biswas R K, Dutta M, Pati S K, Biswas K 2019 ACS Energy Lett. 4 1658

Google Scholar

Google Scholar

[16] Tan G, Hao S, Hanus R C, Zhang X, Anand S, Bailey T P, Rettie A J E, Su X, Uher C, Dravid V P, Snyder G J, Wolverton C, Kanatzidis M G 2018 ACS Energy Lett. 3 705

Google Scholar

Google Scholar

[17] Pei Y, Zheng L, Li W, Lin S, Chen Z, Wang Y, Xu X, Yu H, Chen Y, Ge B 2016 Adv. Electron. Mater. 2 1600019

Google Scholar

Google Scholar

[18] Hu L, Zhang Y, Wu H, Li J, Li Y, McKenna M, He J, Liu F, Pennycook S J, Zeng X 2018 Adv. Energy Mater. 8 1802116

Google Scholar

Google Scholar

[19] Tang J, Gao B, Lin S, Li J, Chen Z, Xiong F, Li W, Chen Y, Pei Y 2018 Adv. Funct. Mater. 28 1803586

Google Scholar

Google Scholar

[20] Tang J, Yao Z, Wu Y, Lin S, Xiong F, Li W, Chen Y, Zhu T, Pei Y 2020 Mater. Today Phys. 15 100247

Google Scholar

Google Scholar

[21] Xu X, Cui J, Yu Y, Zhu B, Huang Y, Xie L, Wu D, He J 2020 Energy Environ. Sci. 13 5135

Google Scholar

Google Scholar

[22] Blachnik R, Igel R 1974 Z. Naturforsch., B: Chem. Sci. 29 625

Google Scholar

Google Scholar

[23] Li W, Zheng L, Ge B, Lin S, Zhang X, Chen Z, Chang Y, Pei Y 2017 Adv. Mater. 29 1605887

Google Scholar

Google Scholar

[24] Li W, Chen Z, Lin S, Chang Y, Ge B, Chen Y, Pei Y 2015 J. Materiomics 1 307

Google Scholar

Google Scholar

[25] Wu Y, Chen Z, Nan P, Xiong F, Lin S, Zhang X, Chen Y, Chen L, Ge B, Pei Y 2019 Joule 3 1276

Google Scholar

Google Scholar

[26] Zak A K, Majid A W H, Abrishami M E, Yousefi R 2011 Solid State Sci. 13 251

Google Scholar

Google Scholar

[27] Sarker P, Sen S K, Mia M N H, Pervez M F, Mortuza A A, Hossain S, Mortuza M F, Ali M H, Nur S, Kabir H, Chowdhury M A M 2021 Ceram. Int. 47 3626

Google Scholar

Google Scholar

[28] Guo F, Cui B, Liu Y, Meng X, Cao J, Zhang Y, He R, Liu W, Wu H, Pennycook S J, Cai W, Sui J 2018 Small 14 1802615

Google Scholar

Google Scholar

[29] Acharya S, Pandey J, Soni A 2016 Appl. Phys. Lett. 109 133904

Google Scholar

Google Scholar

[30] Li S M, Li J Q, Yang L, Liu F S, Ao W Q, Li Y 2016 Mater. Des. 108 51

Google Scholar

Google Scholar

[31] Uher C 2016 Materials Aspect of Thermoelectricity (Vol. 1) (Boca Raton: CRC Press) p8

[32] 傅铁铮, 沈家骏, 忻佳展, 朱铁军 2019 硅酸盐学报 47 1467

Fu T Z, Shen J J, Qi J Z, Zhu T J 2019 J. Chin. Ceram. Soc. 47 1467

[33] Brebrick R F, Strauss A J 1963 Phys. Rev. 131 104

Google Scholar

Google Scholar

[34] Guo F, Cui B, Geng H, Zhang Y, Wu H, Zhang Q, Yu B, Pennycook S J, Cai W, Sui J 2019 Small 15 1902493

Google Scholar

Google Scholar

[35] Shenoy U S, Bhat D K 2020 J. Mater. Chem. C 8 2036

Google Scholar

Google Scholar

[36] Kim H S, Gibbs Z M, Tang Y, Wang H, Snyder G J 2015 APL Mater. 3 041516

Google Scholar

Google Scholar

[37] Callaway J 1959 Phys. Rev. 113 1046

Google Scholar

Google Scholar

[38] Hussain T, Li X, Danish M H, Rehman M U, Zhang J, Li D, Chen G, Tang G 2020 Nano Energy 73 104832

Google Scholar

Google Scholar

[39] Li W, He Q Y, Chen J F, Pan Z L, Wang T 2014 Chem. Phys. Lett. 616-617 196

Google Scholar

Google Scholar

[40] Guo F, Wu H, Zhu J, Yao H, Zhang Y, Cui B, Zhang Q, Yu B, Pennycook S J, Cai W, Chu C W, Sui J 2019 Proc. Natl. Acad. Sci. U.S.A. 116 21998

Google Scholar

Google Scholar

[41] Wang H, Hwang J, Zhang C, Wang T, Su W, Kim H, Kim J, Zhai J, Wang X, Park H, Kim W, Wang C 2017 J. Mater. Chem. A 5 14165

Google Scholar

Google Scholar

[42] Tang J, Yao Z, Chen Z, Lin S, Zhang X, Xiong F, Li W, Chen Y, Pei Y 2019 Mater. Today Phys. 9 100091

Google Scholar

Google Scholar

[43] Wang D, Zhang X, Yu Y, Xie L, Wang J, Wang G, He J, Zhou Y, Pang Q, Shao J, Zhao L D 2019 J. Alloys Compd. 773 571

Google Scholar

Google Scholar

计量

- 文章访问数: 9396

- PDF下载量: 181

- 被引次数: 0

下载:

下载: