-

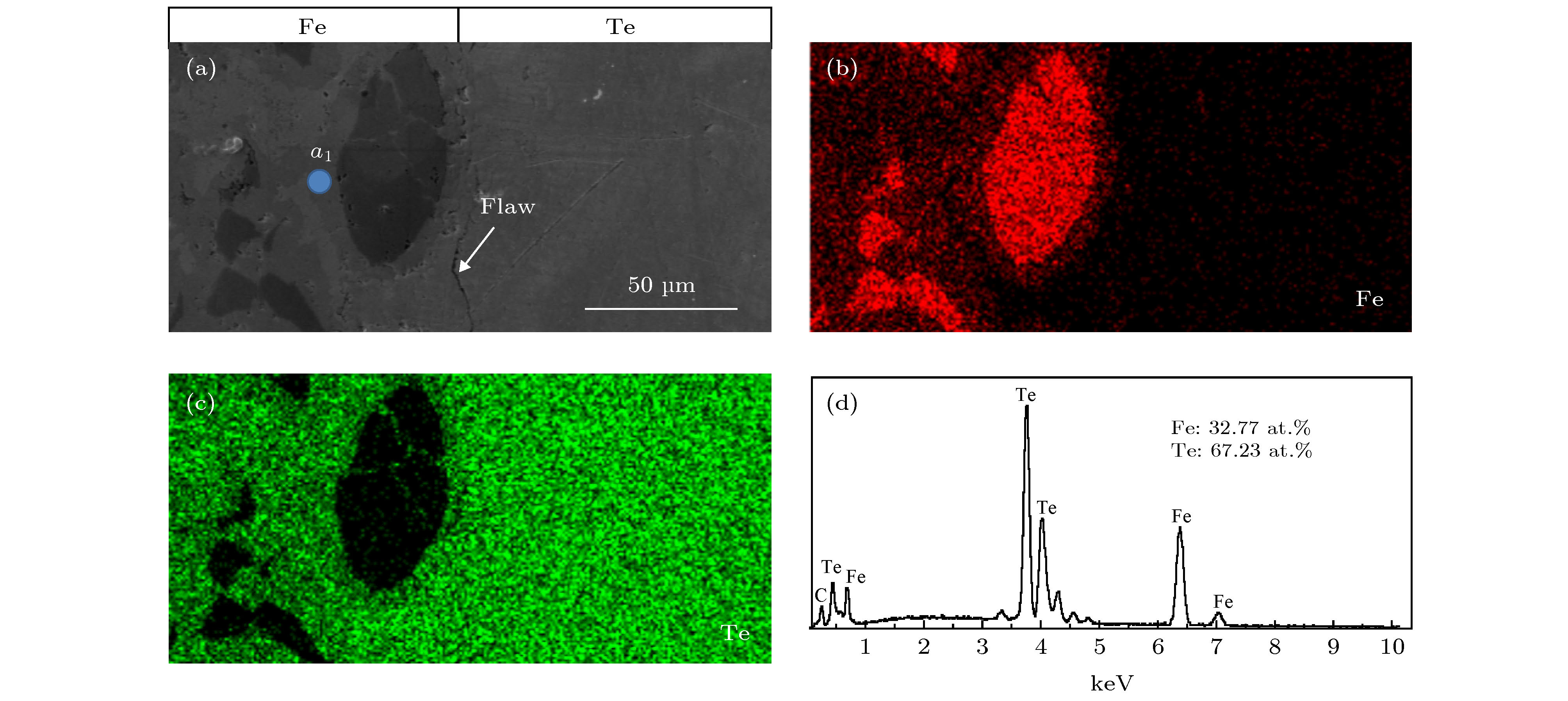

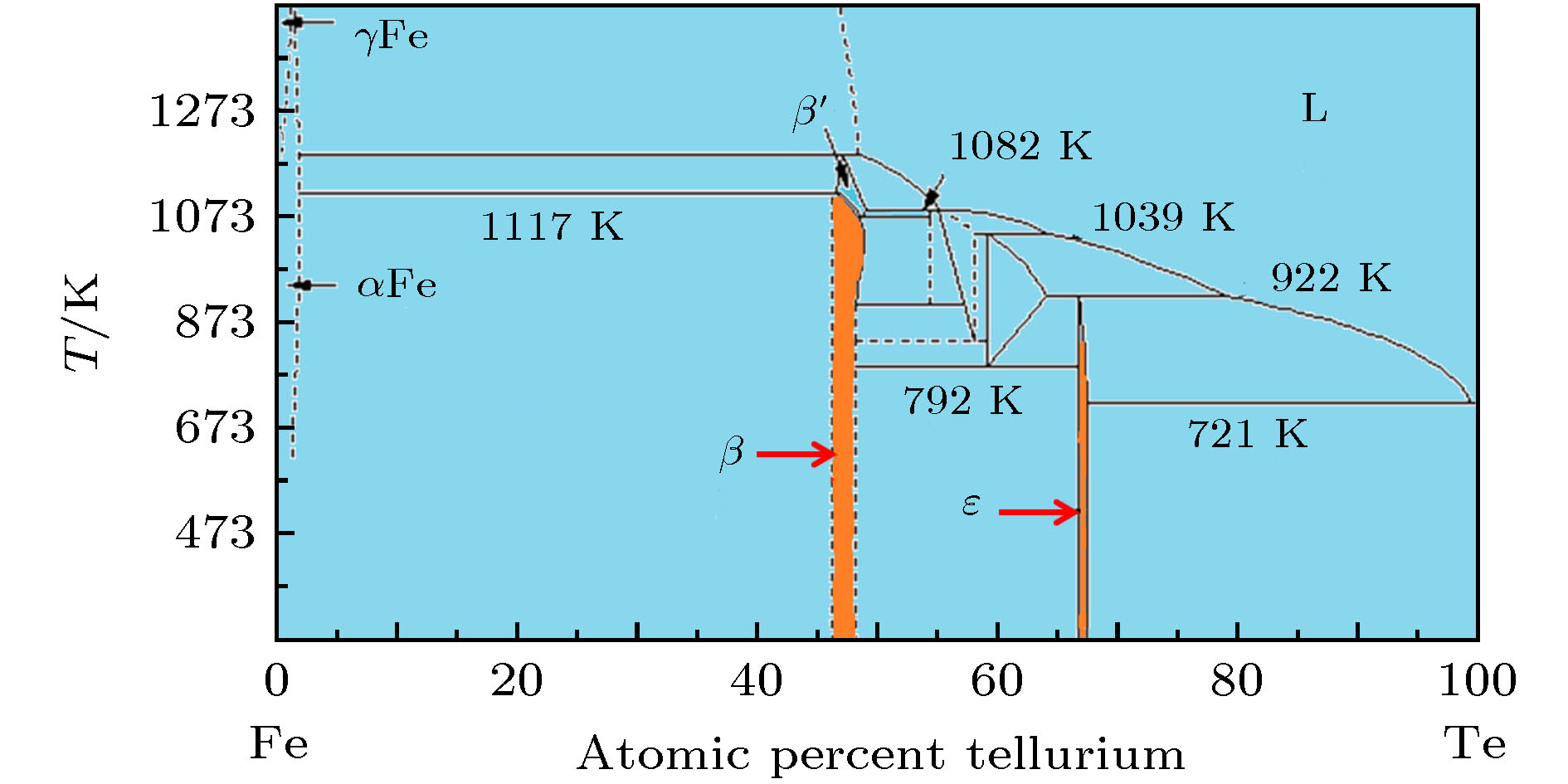

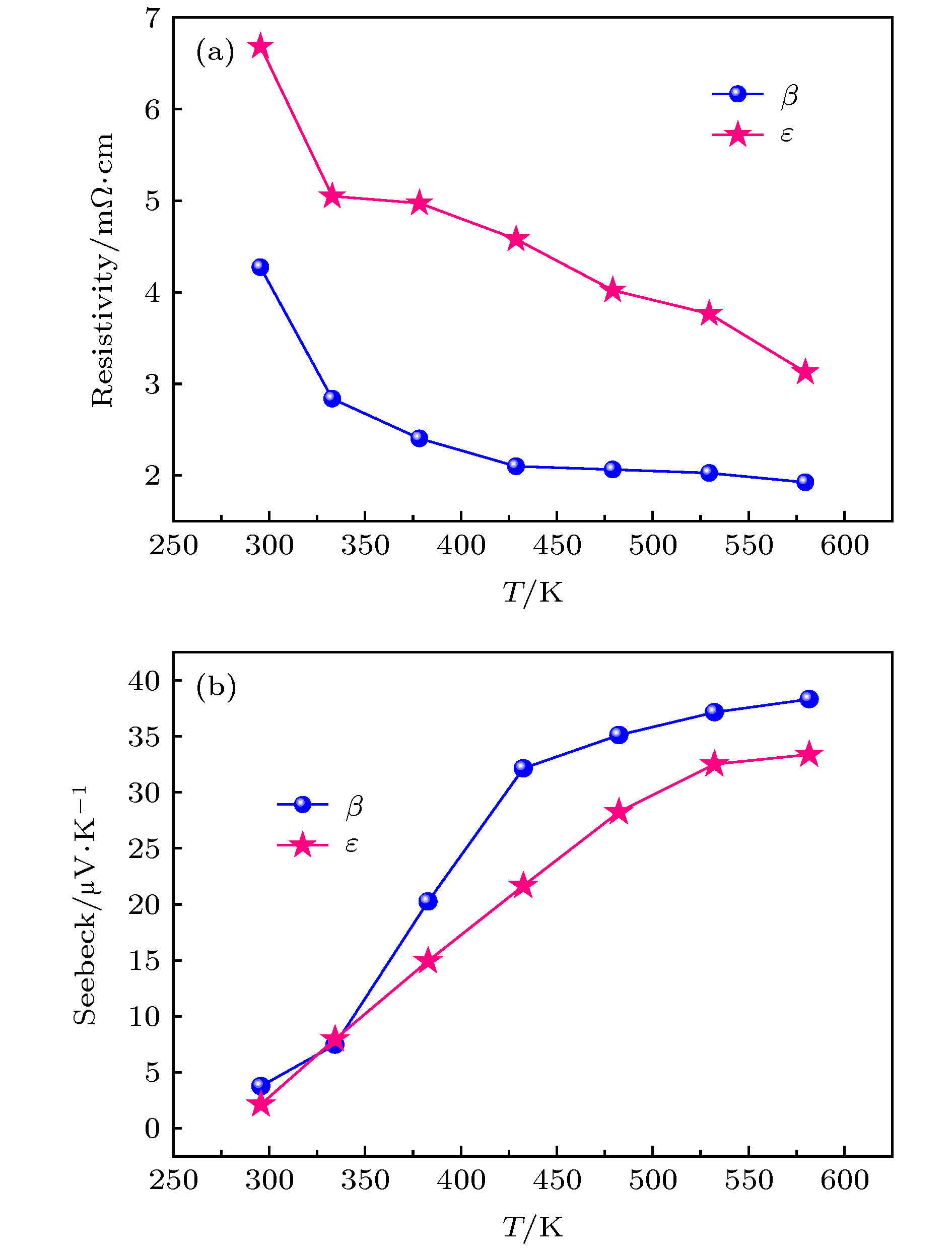

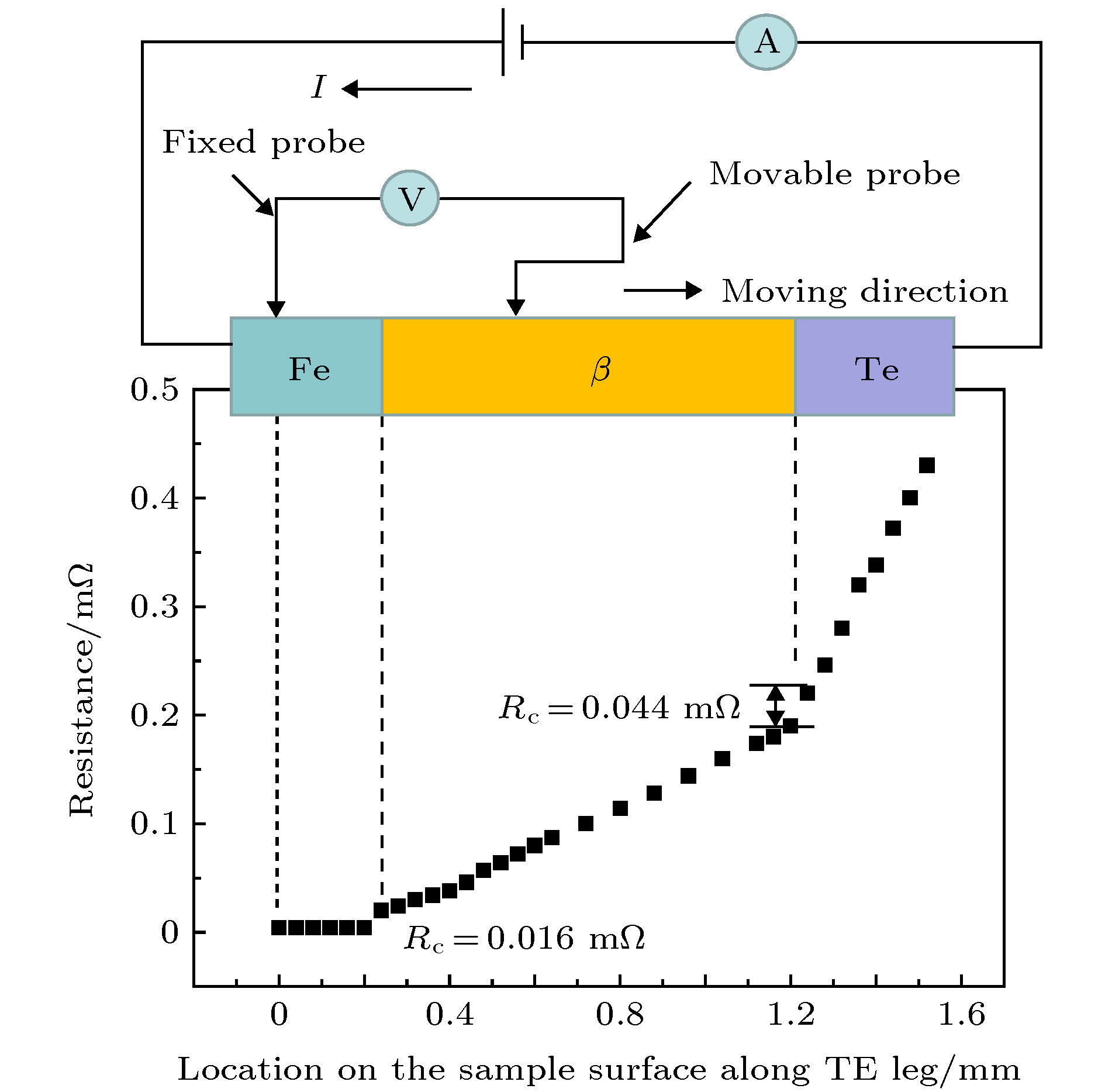

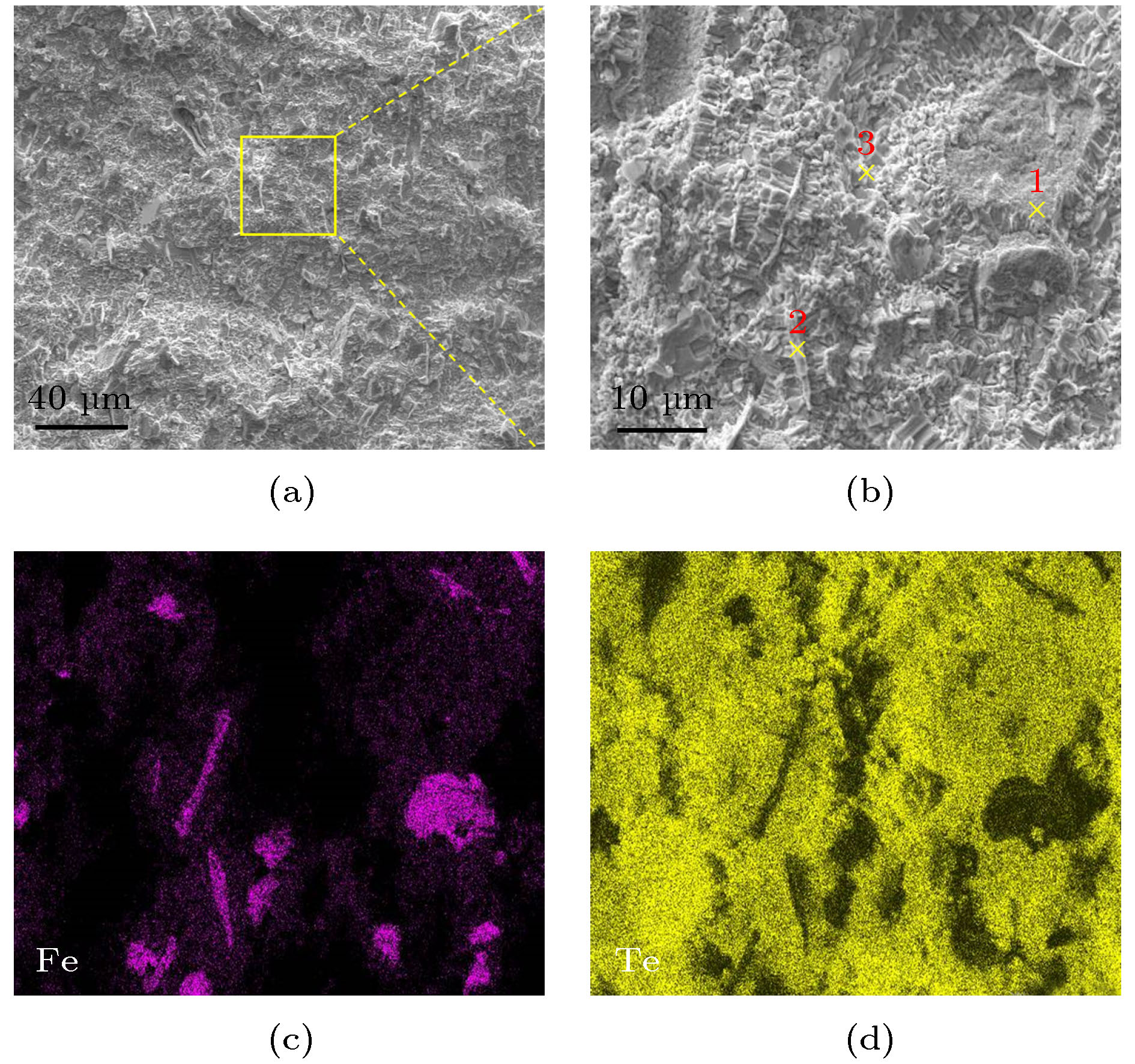

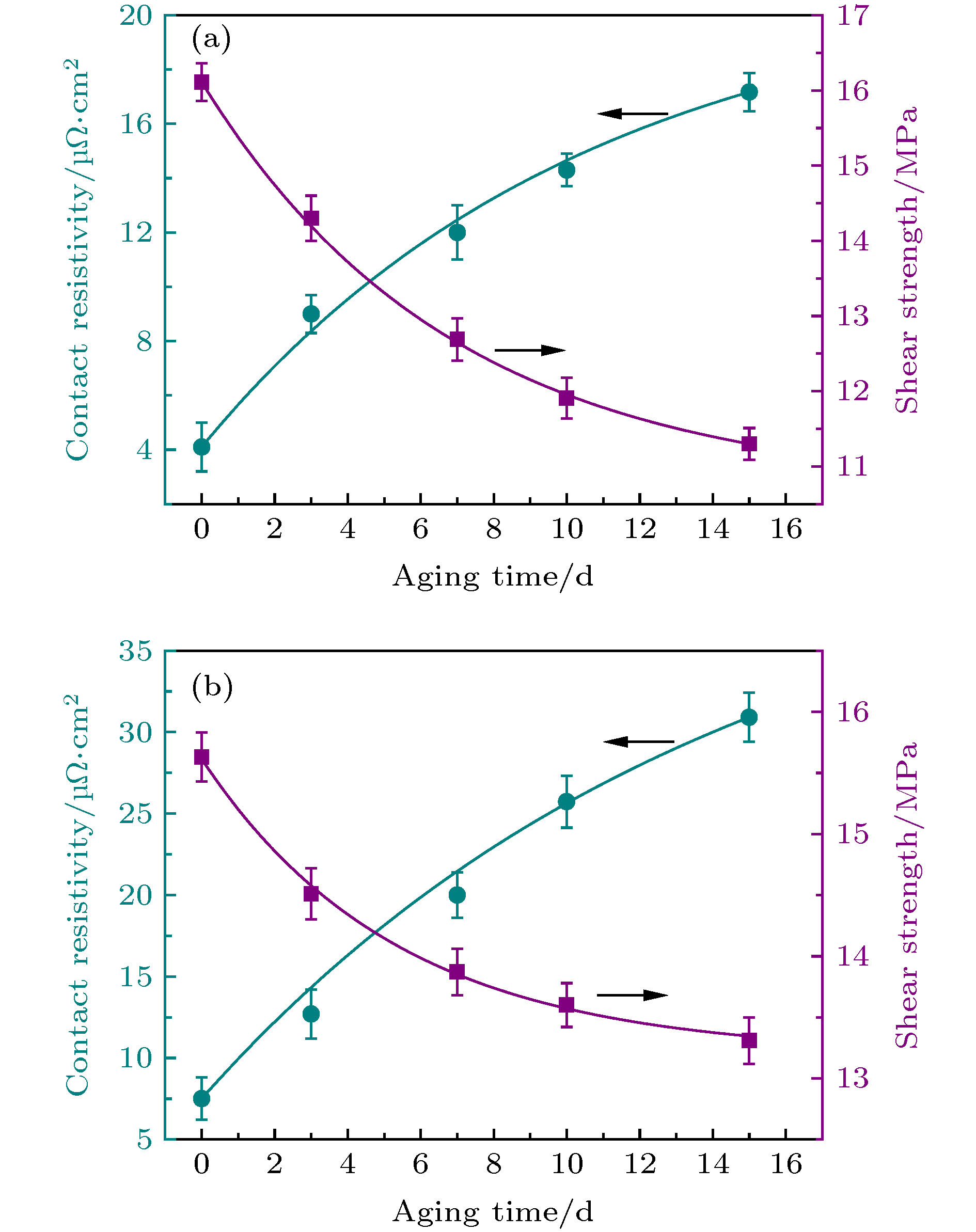

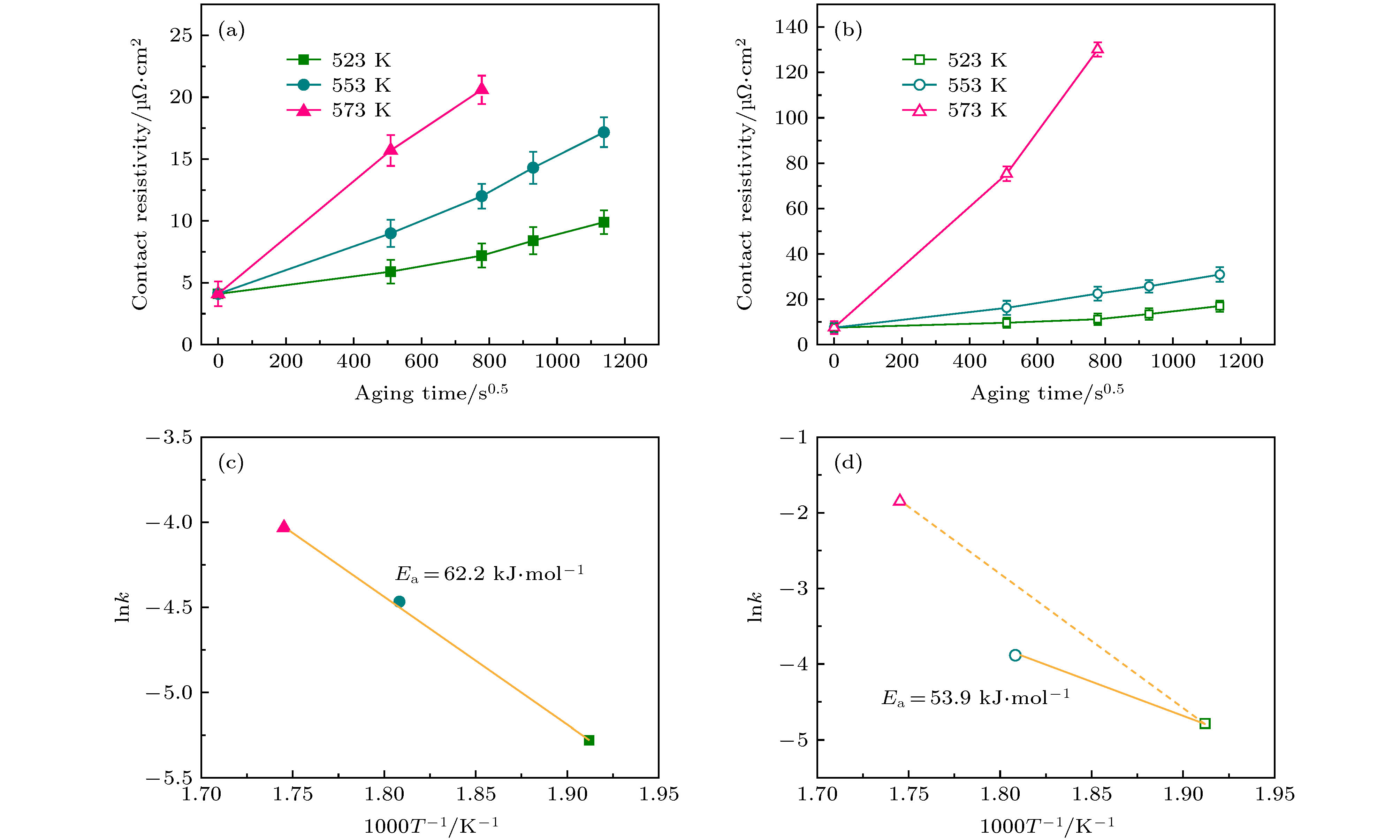

Te基热电材料以其优异的热电性能得到科研工作者的广泛关注, 但该领域关于器件制备和连接界面方面的研究尚属空白. 本研究基于成分梯度、载流子浓度梯度构成的多元梯度势场对界面粒子传输过程的协同调控机制, 在热电材料Te和电极Fe之间引入β(FeTe)作为阻隔层, 设计制备了Te/β(FeTe)/Fe梯度连接结构, 并对界面新相、接触电阻和机械性能进行了研究. 研究结果表明, 中间合金层β(FeTe)与热电材料和电极材料的界面组织结构致密, 有效阻隔了界面元素间严重的交互扩散. 该β(FeTe)-Te间形成了约40 μm的反应层, β(FeTe)与Fe和Te间的接触电阻分别为4.1和7.54 μΩ·cm2, 剪切强度分别为16.11和15.63 MPa. 时效温度对梯度连接结构的服役寿命和性能影响显著, Te/β(FeTe)/Fe的界面组织在553 K温度下时效15 d, 界面性能保持稳定; 当时效温度升至573 K时, 由于高温下材料的不稳定性, 导致性能随着退火时间的延长急剧下降, 并在10 d之后完全破坏, 这表明其最佳工作温度不得高于553 K. 该梯度连接结构成功实现了抑制界面元素过度扩散、降低界面残余应力以及提升界面工作稳定性和服役寿命等目的, 其设计思路和研究结果对半导体领域器件的制备具有重要借鉴意义.Owing to their excellent performances, Te-based thermoelectric materials have been extensively concerned. However little attention has been paid to the bonding interfaces with electrodes, which play an important role in their practical applications. Excessive element mutual diffusion occurs across the bonding interfaces when Te is connected with metallic electrode, such as copper, aluminum, iron, etc, which will impair its transport performance and life especially when they serve in the higher temperature environments. Seeking proper barriers is the key to solving the interface problem. In this work, a gradient bonding structure of Te/FeTe/Fe is prepared in one step by the spark plasma sintering (SPS) method, in which a metallic layer of FeTe, referred to as β(FeTe) phase, is introduced as barrier. The interface microstructure, element distribution, and new phases are analyzed, and the joint properties including contact resistance and shearing strength after being aged are evaluated. The results show that the introduction of β(FeTe) phase can promote the boding of Fe/β(FeTe)/Te and thus inhibiting the excessive element diffusion across the interfaces, which is due to the formation of ε(FeTe2) phase between β(FeTe) phase and Te. The contact resistance of Fe/β(FeTe) and β(FeTe)/Te are 4.1 μΩ·cm2 and 7.54 μΩ·cm2, respectively, and the shearing strength are 16.11 MPa and 15.63 MPa, respectively. The annealing temperature has significant effect on the performance of the gradient bonding structure. It has been indicated that the whole joint still owns good performance after being annealed at 553 K for 15 days, while it decreases sharply when the temperature is increased to 573 K. Hence, the optimal service temperature of Te/β(FeTe)/Fe should not be higher than 553 K. The gradient bonding structure is successfully achieved, thus attaining the purposes of inhibiting interface elements from excessively diffuse, reducing interface residual stress, and improving interface working stability and service life. So the design ideas and research results in this work have great reference significance for the study on semiconductor devices.

-

Keywords:

- Te /

- thermoelectric material /

- gradient bonding structure /

- thermal stability

[1] He W, Zhang G, Zhang X X, Ji J, Li G Q, Zhao X D 2015 Appl. Energy 143 1

Google Scholar

Google Scholar

[2] Pothin R, Ayral R M, Berche A, Ziolkowski P, Oppitz G, Jund P 2018 Mater. Res. Bull. 101 90

Google Scholar

Google Scholar

[3] Yang R Y, Chen S P, Fan W H, Gao X F, Long Y, Wang W X, Munir Z A 2017 J. Alloys Compd. 704 545

Google Scholar

Google Scholar

[4] Kaszyca K, Schmidt M, Chmielewski M, Pietrzak K, Zybala R 2018 Mater. Today: Proc. 5 10277

Google Scholar

Google Scholar

[5] Liu W S, Jie Q, Kim H S, Ren Z F 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[6] Li F, Huang X Y, Jiang W, Chen L D 2013 J. Electron. Mater. 42 1219

Google Scholar

Google Scholar

[7] Ferrario A, Battiston S, Boldrini S, Sakamoto T, Miorin E, Famengo A, Miozzo A, Fiameni S, Iida T, Fabrizio M 2015 Mater. Today: Proc. 2 573

Google Scholar

Google Scholar

[8] Wang X, Wang H C, Su W B, Mehmood F, Zhai J Z, Wang T, Chen T T, Wang C L 2019 Renewable Energy 141 88

Google Scholar

Google Scholar

[9] An D C, Chen S P, Lu Z X, Li R, Chen W, Fan W H, Wang W X, Wu Y C 2019 ACS Appl. Mater. Interfaces 11 27788

Google Scholar

Google Scholar

[10] Peng H, Kioussis N, Snyder G J 2014 Phys. Rev. B 89 195206

Google Scholar

Google Scholar

[11] Qian X, Xiao Y, Zheng L, Qin B C, Zhou Y M, Pei Y L, Yuan B F, Gong S K, Zhao L D 2017 RSC Adv. 7 17682

Google Scholar

Google Scholar

[12] Arai K, Matsubara M, Sawada Y, Sakamoto T, Kineri T, Kogo Y, Iida T, Nishio K 2012 J. Electron. Mater. 41 1771

Google Scholar

Google Scholar

[13] Valery V K 2006 Reliability Issues in Electrical Contacts (Boca Raton: CRC Press) pp205−259

[14] Rowe D M 2006 Thermoelectrics Handbook (London: Taylor & Francis Group press) pp13−20

[15] Liu W, Zhang Q, Yin K, Chi H, Zhou X Y, Tang X F, Uher C 2013 J. Solid State Chem. 203 333

Google Scholar

Google Scholar

[16] Hsieh H C, Wang C H, Lin W C, Chakroborty S, Lee T H, Chu H S, Wu A T 2017 J. Alloys Compd. 728 1023

Google Scholar

Google Scholar

[17] Singh A, Bhattacharya S, Thinaharan C, Aswal D K, Gupta S K, Yakhmi J V, Bhanumurthy K 2009 J. Phys. D: Appl. Phys. 42 015502

Google Scholar

Google Scholar

[18] Li H Y, Jing H Y, Han Y D, Lu G Q, Xu L Y, Liu T 2016 Mater. Des. 89 604

Google Scholar

Google Scholar

[19] Ferreres X R, Yamini S A, Nancarrow M, Zhang C 2016 Mater. Des. 107 90

Google Scholar

Google Scholar

[20] 胡晓凯, 张双猛, 赵府, 刘勇, 刘玮书 2019 无机材料学报 34 269

Google Scholar

Google Scholar

Hu X K, Zhang S M, Zhao F, Liu Y, Liu W S 2019 J. Inorg. Mater. 34 269

Google Scholar

Google Scholar

-

表 1 梯度连接结构Te/β(FeTe)/Fe和 Te/ε(FeTe2)/Fe区域成分扫描结果

Table 1. EDS point scanning results of Te/β(FeTe)/Fe and Fe/ε(FeTe2)/Fe.

Point number Fe /at.% Te /at.% b1 0 100.00 b2 29.92 70.08 b3 50.30 49.70 b4 100.00 0 b5 31.05 68.95 b6 17.10 82.90 表 2 β(FeTe)-Te界面断口特征点EDS成分扫描结果

Table 2. EDS scanning results of characteristic points of β(FeTe)-Te fracture interface.

Point number Fe/at.% Te/at.% 1 24.66 75.34 2 60.17 39.83 3 2.54 97.46 -

[1] He W, Zhang G, Zhang X X, Ji J, Li G Q, Zhao X D 2015 Appl. Energy 143 1

Google Scholar

Google Scholar

[2] Pothin R, Ayral R M, Berche A, Ziolkowski P, Oppitz G, Jund P 2018 Mater. Res. Bull. 101 90

Google Scholar

Google Scholar

[3] Yang R Y, Chen S P, Fan W H, Gao X F, Long Y, Wang W X, Munir Z A 2017 J. Alloys Compd. 704 545

Google Scholar

Google Scholar

[4] Kaszyca K, Schmidt M, Chmielewski M, Pietrzak K, Zybala R 2018 Mater. Today: Proc. 5 10277

Google Scholar

Google Scholar

[5] Liu W S, Jie Q, Kim H S, Ren Z F 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[6] Li F, Huang X Y, Jiang W, Chen L D 2013 J. Electron. Mater. 42 1219

Google Scholar

Google Scholar

[7] Ferrario A, Battiston S, Boldrini S, Sakamoto T, Miorin E, Famengo A, Miozzo A, Fiameni S, Iida T, Fabrizio M 2015 Mater. Today: Proc. 2 573

Google Scholar

Google Scholar

[8] Wang X, Wang H C, Su W B, Mehmood F, Zhai J Z, Wang T, Chen T T, Wang C L 2019 Renewable Energy 141 88

Google Scholar

Google Scholar

[9] An D C, Chen S P, Lu Z X, Li R, Chen W, Fan W H, Wang W X, Wu Y C 2019 ACS Appl. Mater. Interfaces 11 27788

Google Scholar

Google Scholar

[10] Peng H, Kioussis N, Snyder G J 2014 Phys. Rev. B 89 195206

Google Scholar

Google Scholar

[11] Qian X, Xiao Y, Zheng L, Qin B C, Zhou Y M, Pei Y L, Yuan B F, Gong S K, Zhao L D 2017 RSC Adv. 7 17682

Google Scholar

Google Scholar

[12] Arai K, Matsubara M, Sawada Y, Sakamoto T, Kineri T, Kogo Y, Iida T, Nishio K 2012 J. Electron. Mater. 41 1771

Google Scholar

Google Scholar

[13] Valery V K 2006 Reliability Issues in Electrical Contacts (Boca Raton: CRC Press) pp205−259

[14] Rowe D M 2006 Thermoelectrics Handbook (London: Taylor & Francis Group press) pp13−20

[15] Liu W, Zhang Q, Yin K, Chi H, Zhou X Y, Tang X F, Uher C 2013 J. Solid State Chem. 203 333

Google Scholar

Google Scholar

[16] Hsieh H C, Wang C H, Lin W C, Chakroborty S, Lee T H, Chu H S, Wu A T 2017 J. Alloys Compd. 728 1023

Google Scholar

Google Scholar

[17] Singh A, Bhattacharya S, Thinaharan C, Aswal D K, Gupta S K, Yakhmi J V, Bhanumurthy K 2009 J. Phys. D: Appl. Phys. 42 015502

Google Scholar

Google Scholar

[18] Li H Y, Jing H Y, Han Y D, Lu G Q, Xu L Y, Liu T 2016 Mater. Des. 89 604

Google Scholar

Google Scholar

[19] Ferreres X R, Yamini S A, Nancarrow M, Zhang C 2016 Mater. Des. 107 90

Google Scholar

Google Scholar

[20] 胡晓凯, 张双猛, 赵府, 刘勇, 刘玮书 2019 无机材料学报 34 269

Google Scholar

Google Scholar

Hu X K, Zhang S M, Zhao F, Liu Y, Liu W S 2019 J. Inorg. Mater. 34 269

Google Scholar

Google Scholar

计量

- 文章访问数: 11259

- PDF下载量: 178

- 被引次数: 0

下载:

下载: