-

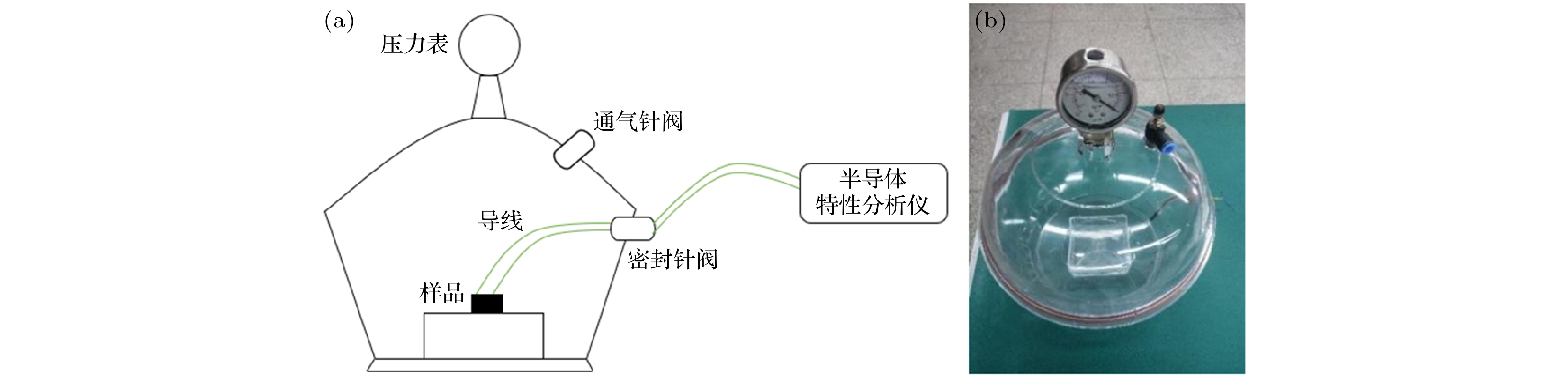

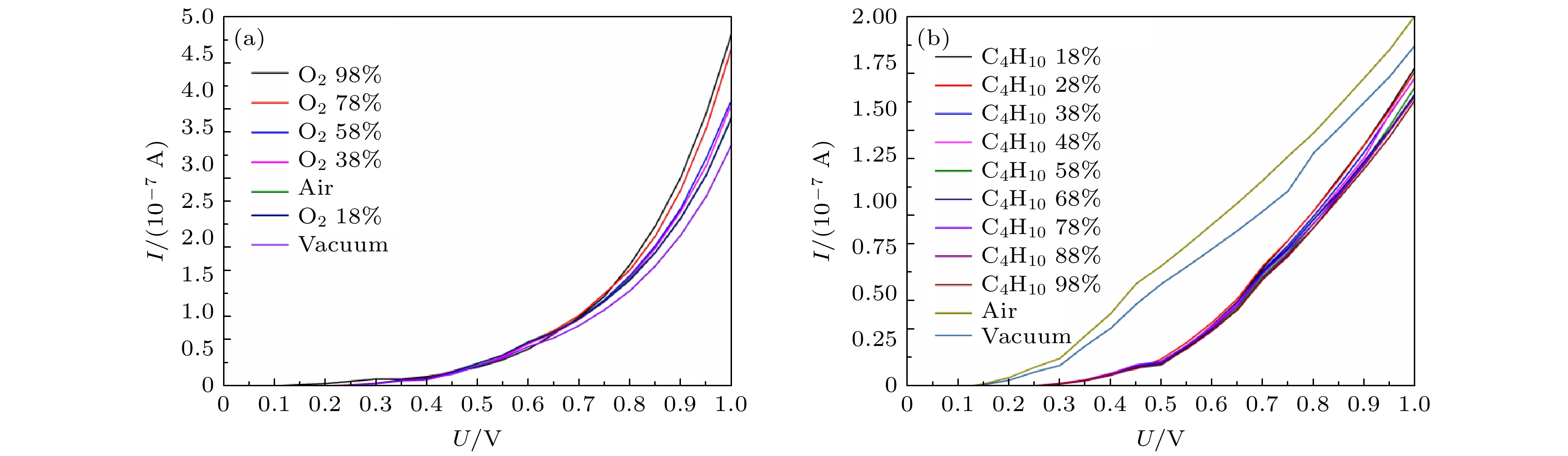

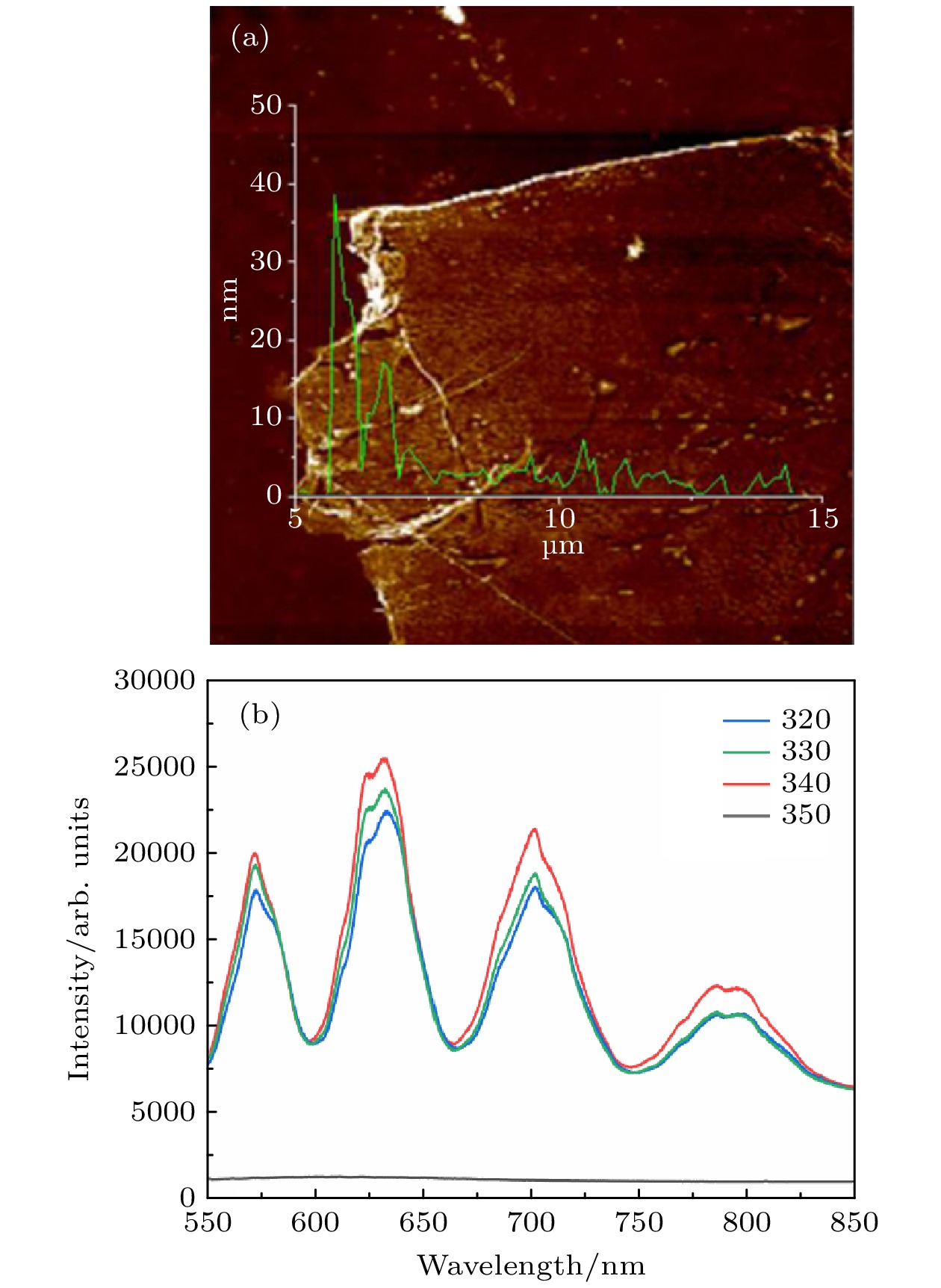

As a type of two-dimensional (2D) semiconductor material, 2D germanium selenide (GeSe) exhibits excellent optoelectronic properties, and has potential applications in optoelectronic devices. The GeSe is a layered material with weak van der Waals interaction. Because of the high brittleness of GeSe, it is not easy to obtain 2D GeSe samples only by mechanical peeling technique. In order to obtain a thinner GeSe sheet, we use heat treatment to thin the bulk GeSe at a high temperature in vacuum. The GeSe samples obtained by mechanical peeling are placed in a tubular furnace with a pressure of 5 × 10-4 Pa for high temperature heating and thinning. In order to explore the better thinning effect, we set four temperatures to be at 320, 330, 340 and 350 ℃, respectively. After high temperature thinning, the samples are characterized and observed by atomic force microscope (AFM), scanning electron microscope (SEM), Raman spectrometer and photoluminescence (PL) spectrometer. From the above experiments, the GeSe nanosheet with a thickness of about 5 nm is prepared by mechanical peeling and high temperature thinning technology. Then, the electrical conductivities of GeSe nanosheets in oxygen (O2) and butane (C4H10) with different concentrations are evaluated by our designed experimental device. The results show that with the increase of oxygen concentration, the electrical conductivity of GeSe nanosheets increases. When the GeSe nanosheet is in butane gas, its conductivity under the same voltage decreases with the increase of the concentration of butane gas. In order to further analyze the mechanism of gas adsorption on GeSe nanosheets, we carry out the first-principles calculations. Our calculation results show that the adsorption energy of GeSe nanosheets for oxygen and butane is –4.555 eV and –4.865 eV, respectively. It is shown that both adsorption systems have a certain stability. The adsorption energy of C4H10 is smaller than that of O2, which corresponds to the smaller layer spacing of C4H10 than that of O2 on GeSe surface. From Bader analysis, it is shown that 0.262e is transferred from the surface of GeSe nanosheet to O2 molecule, which is much larger than 0.022e transferred from GeSe to C4H10 molecule. It can be inferred that the bond formed between GeSe and O2 molecule is covalent bond, while GeSe adsorption C4H10 is very fragile hydrogen bond adsorption. In an ideal condition (single atomic GeSe layer, no Se vacancy, and the device preparation process is vacuum), our calculation results show that C4H10 still has a weak ability to obtain electrons from the GeSe nanosheet. However, the complex conditions such as the actual layer thickness, the appearance of Se vacancy and the adsorption of O2 molecules on the surface leads to the difference between the experimental results and the theoretical calculations, which can be attributed to the adsorption of O2 molecules on the GeSe surface from the air during the processing of GeSe thinning and device fabrication. Owing to the high density of Se vacancies in the thin film, the high density of O2 adsorption is caused. Thus, butane gas is easy to lose electrons on the GeSe surface due to the O2 adsorption. In other words, electrons are transferred from butane gas molecules to the surface of GeSe film and neutralized with holes, which reduces the concentration of carriers and the concentration of holes in GeSe film, thus reducing the conductivity. Our research will contribute to the application of GeSe nanosheets in optoelectronic devices at the atmosphere of oxygen and butane.

-

Keywords:

- GeSe nanosheet /

- electrical conductance /

- gas adsorption /

- first-principle

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[3] Xia F, Wang H, Xiao D, Dubey M, Ramasubramaniam A 2014 Nat. Photonics 8 899

Google Scholar

Google Scholar

[4] Jing Y, Zhang X, Zhou Z 2016 Wiley Interdiscip. Rev. Comput. Mol. Sci. 6 5

Google Scholar

Google Scholar

[5] Mao Y L, Stocks G M, Zhong J X 2010 New J. Phys. 12 033046

Google Scholar

Google Scholar

[6] Xu C S, Yuan J M, Wang D D, Mao Y L 2018 Mater. Res. Express 6 036305

Google Scholar

Google Scholar

[7] Mao Y L, Zhong J X 2008 Nanotechnology 19 205708

Google Scholar

Google Scholar

[8] Salvo P, Melai B, Calisi N, Paoletti C, Bellagambi F G, Kirchhain A, Trivella M G, Fuoco R, Francesco F D 2017 Sens. Actuators, B 256 976

[9] Chu K, Wang X H, Li Y B, Huang D J, Geng Z R, Zhao X L, Liu H, Zhuang H 2018 Mater. Des. 140 85

Google Scholar

Google Scholar

[10] Prashantha K, Roger F 2017 J. Macromol. Sci. Part A Pure Appl. Chem. 54 24

Google Scholar

Google Scholar

[11] Zhang C, Man B Y, Yang C, Jiang S Z, Liu M H, Chen C S, Xu S C, Sun Z C, Gao X G, Chen X F 2013 Nanotechnology 24 395603

Google Scholar

Google Scholar

[12] Sun Z C, Yang C, Liu M, Chen C S, Xu S C, Zhang C, Man B Y 2014 Appl. Surf. Sci. 315 368

Google Scholar

Google Scholar

[13] Stankovich S, Dikin D A, Piner R D, Kohlhaas K A, Kleinhammes A, Jia YY, Wu Y, Nguyen S T, Ruoff R S 2007 Carbon 45 1558

Google Scholar

Google Scholar

[14] Foo M E, Gopinath S C B 2017 Biomed. Pharmacother. 94 354

Google Scholar

Google Scholar

[15] Mao Y L, Mao X, Zhao H Q, Zhang N D, Shi X, Yuan J M 2018 Sci. Rep. 8 17671

Google Scholar

Google Scholar

[16] Hu Y W, Long L B, Mao Y L, Zhong J X 2018 Appl. Surf. Sci. 442 390

Google Scholar

Google Scholar

[17] Zhang S L, Xie M Q, Li F Y, Yan Z, Li Y F, Kan E, Liu W, Chen Z F, Zeng H B 2016 Angew. Chem. 55 1666

Google Scholar

Google Scholar

[18] Dutta S N, Jeffrey G A 1965 Inorg. Chem. 4 1363

Google Scholar

Google Scholar

[19] Mao Y L, Xu C S, Yuan J M, Zhao H Q 2018 Phys. Chem. Chem. Phys. 20 6929

Google Scholar

Google Scholar

[20] Vaughn I D D, Patel R J, Hickner M A, Schaak R E 2010 J. Am. Chem. Soc. 132 15170

Google Scholar

Google Scholar

[21] Mao Y L, Guo G, Yuan J M, Zhong J X 2019 Appl. Surf. Sci. 464 236

Google Scholar

Google Scholar

[22] Zhao H Q, Mao Y L, Mao X, Shi X, X C S, Wang C X, Zhang S M, Zhou D H 2018 Adv. Funct. Mater. 28 1704855

Google Scholar

Google Scholar

[23] Shi G S, Kioupakis E 2015 Nano Lett. 15 6926

Google Scholar

Google Scholar

[24] Xue D J, Tan J H, Hu J S, Hu W P, Guo Y G, Wan L J 2012 Adv. Mater. 24 4528

Google Scholar

Google Scholar

[25] Zhang S L, Liu S G, Huang S P, Cai B, Xie M Q, Qu L H, Zou Y S, Hu Z Y, Yu X C, Zeng H B 2015 Sci. China Mater. 58 929

[26] Liu L, Yang Q, Ye H Y, Chen X P, Zhang G Q 2017 International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems Dresden, Germany, May 2–5, 2017 p1

[27] Mao Y L, Long L B, Yuan J M, Zhong J X, Zhao H Q 2018 Chem. Phys. Lett. 706 501

Google Scholar

Google Scholar

[28] Kresse G, Joubert D P 1999 Phys. Rev. B 59 1758

[29] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[30] Ceperley D M, Alder B J 1980 Phys. Rev. Lett. 45 566

Google Scholar

Google Scholar

[31] Matthias E, Gustavo E S 1999 J. Chem. Phys. 110 5029

Google Scholar

Google Scholar

[32] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[33] Fei R X, Li W B, Li J, Yang L 2015 Appl. Phys. Lett. 107 173104

Google Scholar

Google Scholar

[34] Tkatchenko A, Scheffler M 2009 Phys. Rev. Lett. 102 073005

Google Scholar

Google Scholar

[35] Savin A, Nesper R, Wengert S, Fassler T F 1997 Angew. Chem. Int. Ed. 36 1808

Google Scholar

Google Scholar

-

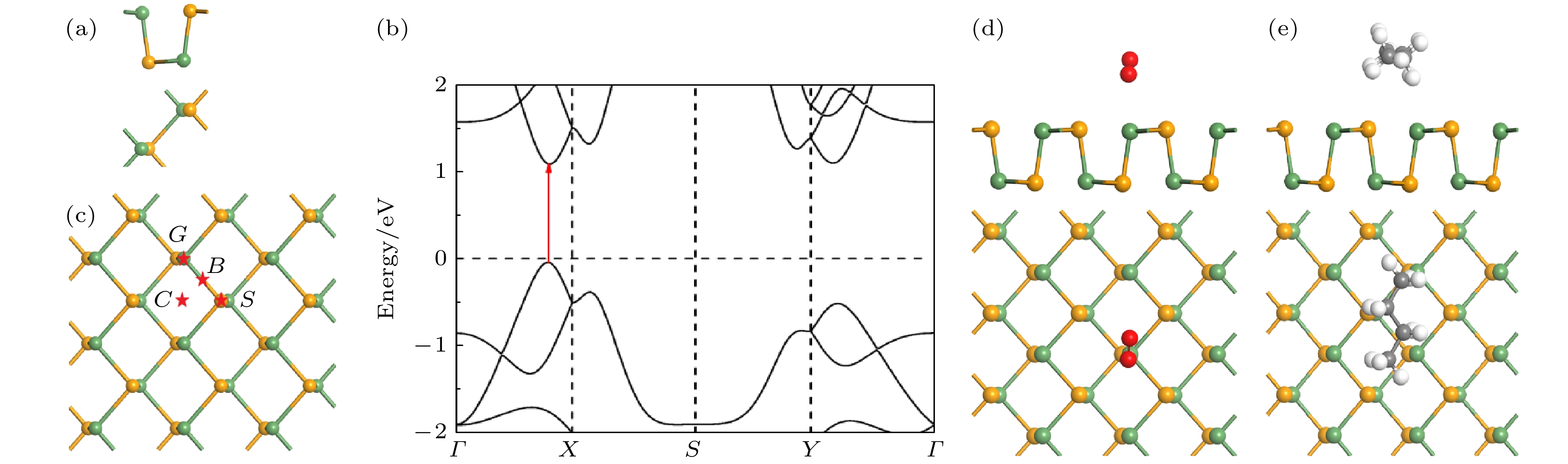

图 3 (a) GeSe单胞的结构; (b) GeSe单层的能带结构; (c) GeSe上吸附位点G点, S点, C点和B点的示意图; (d) GeSe吸附氧气最稳定的吸附结构示意图(侧视图与俯视图); (e) GeSe吸附丁烷最稳定的吸附结构示意图(侧视图与俯视图). 黄色, 绿色, 红色, 黑色和白色的球分别代表着Se, Ge, O, C和H原子

Figure 3. (a) Optimized structure of GeSe monolayer; (b) band structures of GeSe monolayer; (c) considered positions for gas molecules adsorption: G site, S site, C site and B site on GeSe monolayer, respectively; (d) obtained stable adsorption configuration (side and top view) for O2 on GeSe monolayer; (e) obtained stable adsorption configuration (side and top view) for C4H10 on GeSe monolayer. The yellow, green, red, black and white balls denote Se, Ge, O, C and H atoms, respectively.

图 4 (a) GeSe纳米片吸附不同浓度的氧气时电压-电流特性曲线; (b) GeSe纳米片吸附不同浓度的丁烷气时电压-电流特性曲线

Figure 4. (a) Voltage-current characteristic curve when germanium selenide device adsorbs different concentrations of oxygen; (b) voltage-current characteristic curve when germanium selenide device adsorbs different concentrations of butane gas.

图 5 GeSe吸附(a)氧气和(b)丁烷的差分电荷密度图, 等值面分别取0.01和0.0009e/A3. 其中蓝色原子为硒原子, 棕色原子为锗原子, 红色为氧原子, 黑色为碳原子, 粉色为氢原子; 黄色部分表示得到电子, 绿色部分表示失去电子. GeSe吸附(c)氧气和(d)丁烷的电子局域图, 左边是ELF (e/A3) 的参考值

Figure 5. Charge density difference for the configurations of (a) O2 and (b) C4H10 on GeSe monolayer. The plotted isosurface is 0.01e/A3 and 0.0009e/A3, respectively. Blue atoms are selenium atoms, brown atoms are germanium atoms, red are oxygen atoms, black are carbon atoms, and pink are hydrogen atoms. In the differential charge density graph, the yellow part indicates the gain of electrons, and the green part indicates the loss of electrons. Electron localization function (ELF) for configurations of (c) O2 and (d) C4H10 adsorbed on GeSe monolayer, respectively. The ELF value is listed at the left side with a unit of e/A3.

表 1 吸附能(Ea), GeSe与气体分子之间的电荷转移量(ρ)以及它们之间的最近距离(d )

Table 1. Calculated adsorption energy (Ea), the charge transfer (ρ) between gas molecules and monolayer GeSe, and the nearest distance (d ) between them.

Gas molecule Ea/eV d /Å ρ/e style O2 –4.555 2.687 0.262 acceptor C4H10 –4.865 2.404 0.022 acceptor -

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[3] Xia F, Wang H, Xiao D, Dubey M, Ramasubramaniam A 2014 Nat. Photonics 8 899

Google Scholar

Google Scholar

[4] Jing Y, Zhang X, Zhou Z 2016 Wiley Interdiscip. Rev. Comput. Mol. Sci. 6 5

Google Scholar

Google Scholar

[5] Mao Y L, Stocks G M, Zhong J X 2010 New J. Phys. 12 033046

Google Scholar

Google Scholar

[6] Xu C S, Yuan J M, Wang D D, Mao Y L 2018 Mater. Res. Express 6 036305

Google Scholar

Google Scholar

[7] Mao Y L, Zhong J X 2008 Nanotechnology 19 205708

Google Scholar

Google Scholar

[8] Salvo P, Melai B, Calisi N, Paoletti C, Bellagambi F G, Kirchhain A, Trivella M G, Fuoco R, Francesco F D 2017 Sens. Actuators, B 256 976

[9] Chu K, Wang X H, Li Y B, Huang D J, Geng Z R, Zhao X L, Liu H, Zhuang H 2018 Mater. Des. 140 85

Google Scholar

Google Scholar

[10] Prashantha K, Roger F 2017 J. Macromol. Sci. Part A Pure Appl. Chem. 54 24

Google Scholar

Google Scholar

[11] Zhang C, Man B Y, Yang C, Jiang S Z, Liu M H, Chen C S, Xu S C, Sun Z C, Gao X G, Chen X F 2013 Nanotechnology 24 395603

Google Scholar

Google Scholar

[12] Sun Z C, Yang C, Liu M, Chen C S, Xu S C, Zhang C, Man B Y 2014 Appl. Surf. Sci. 315 368

Google Scholar

Google Scholar

[13] Stankovich S, Dikin D A, Piner R D, Kohlhaas K A, Kleinhammes A, Jia YY, Wu Y, Nguyen S T, Ruoff R S 2007 Carbon 45 1558

Google Scholar

Google Scholar

[14] Foo M E, Gopinath S C B 2017 Biomed. Pharmacother. 94 354

Google Scholar

Google Scholar

[15] Mao Y L, Mao X, Zhao H Q, Zhang N D, Shi X, Yuan J M 2018 Sci. Rep. 8 17671

Google Scholar

Google Scholar

[16] Hu Y W, Long L B, Mao Y L, Zhong J X 2018 Appl. Surf. Sci. 442 390

Google Scholar

Google Scholar

[17] Zhang S L, Xie M Q, Li F Y, Yan Z, Li Y F, Kan E, Liu W, Chen Z F, Zeng H B 2016 Angew. Chem. 55 1666

Google Scholar

Google Scholar

[18] Dutta S N, Jeffrey G A 1965 Inorg. Chem. 4 1363

Google Scholar

Google Scholar

[19] Mao Y L, Xu C S, Yuan J M, Zhao H Q 2018 Phys. Chem. Chem. Phys. 20 6929

Google Scholar

Google Scholar

[20] Vaughn I D D, Patel R J, Hickner M A, Schaak R E 2010 J. Am. Chem. Soc. 132 15170

Google Scholar

Google Scholar

[21] Mao Y L, Guo G, Yuan J M, Zhong J X 2019 Appl. Surf. Sci. 464 236

Google Scholar

Google Scholar

[22] Zhao H Q, Mao Y L, Mao X, Shi X, X C S, Wang C X, Zhang S M, Zhou D H 2018 Adv. Funct. Mater. 28 1704855

Google Scholar

Google Scholar

[23] Shi G S, Kioupakis E 2015 Nano Lett. 15 6926

Google Scholar

Google Scholar

[24] Xue D J, Tan J H, Hu J S, Hu W P, Guo Y G, Wan L J 2012 Adv. Mater. 24 4528

Google Scholar

Google Scholar

[25] Zhang S L, Liu S G, Huang S P, Cai B, Xie M Q, Qu L H, Zou Y S, Hu Z Y, Yu X C, Zeng H B 2015 Sci. China Mater. 58 929

[26] Liu L, Yang Q, Ye H Y, Chen X P, Zhang G Q 2017 International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems Dresden, Germany, May 2–5, 2017 p1

[27] Mao Y L, Long L B, Yuan J M, Zhong J X, Zhao H Q 2018 Chem. Phys. Lett. 706 501

Google Scholar

Google Scholar

[28] Kresse G, Joubert D P 1999 Phys. Rev. B 59 1758

[29] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[30] Ceperley D M, Alder B J 1980 Phys. Rev. Lett. 45 566

Google Scholar

Google Scholar

[31] Matthias E, Gustavo E S 1999 J. Chem. Phys. 110 5029

Google Scholar

Google Scholar

[32] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[33] Fei R X, Li W B, Li J, Yang L 2015 Appl. Phys. Lett. 107 173104

Google Scholar

Google Scholar

[34] Tkatchenko A, Scheffler M 2009 Phys. Rev. Lett. 102 073005

Google Scholar

Google Scholar

[35] Savin A, Nesper R, Wengert S, Fassler T F 1997 Angew. Chem. Int. Ed. 36 1808

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5743

- PDF Downloads: 91

- Cited By: 0

DownLoad:

DownLoad: