-

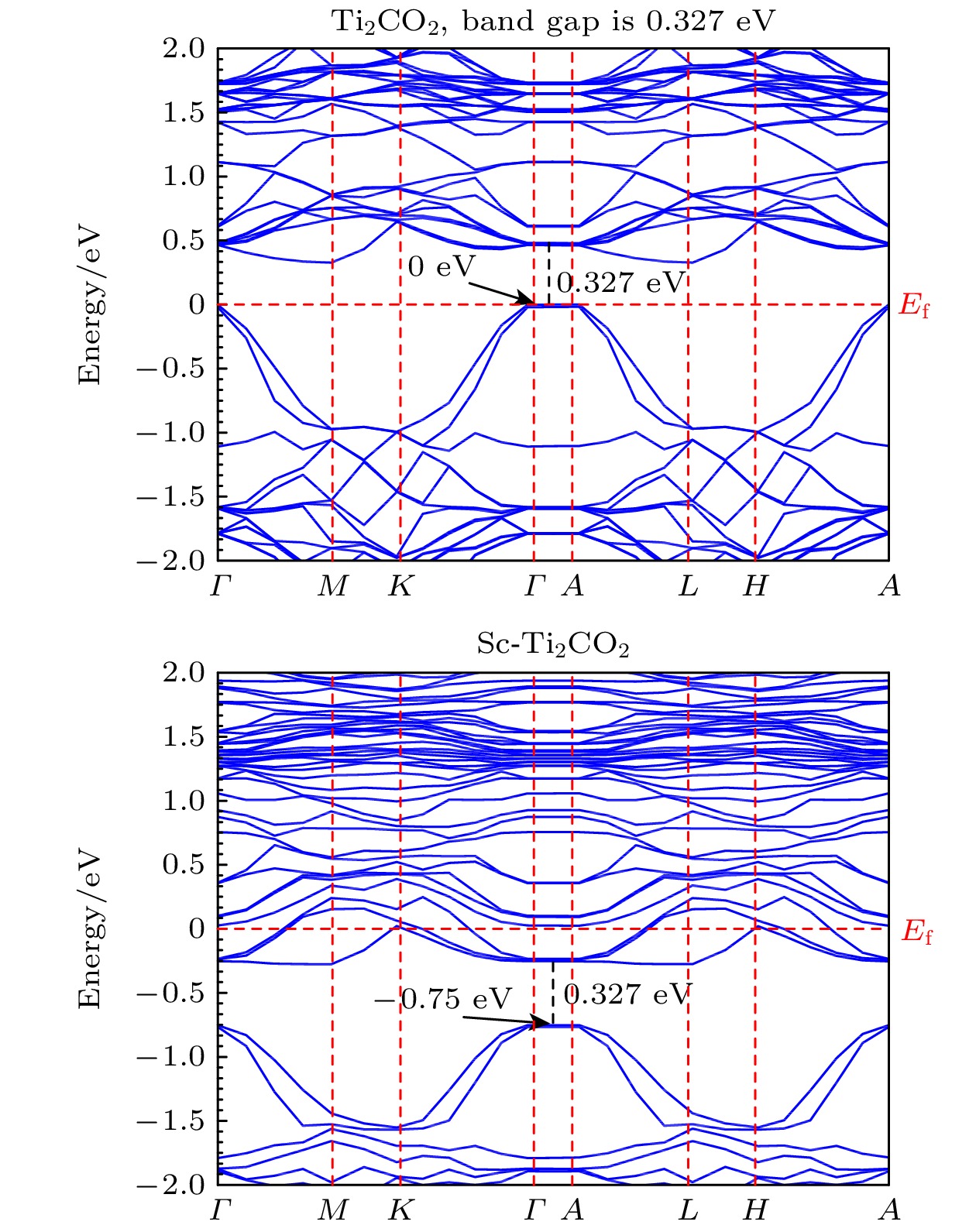

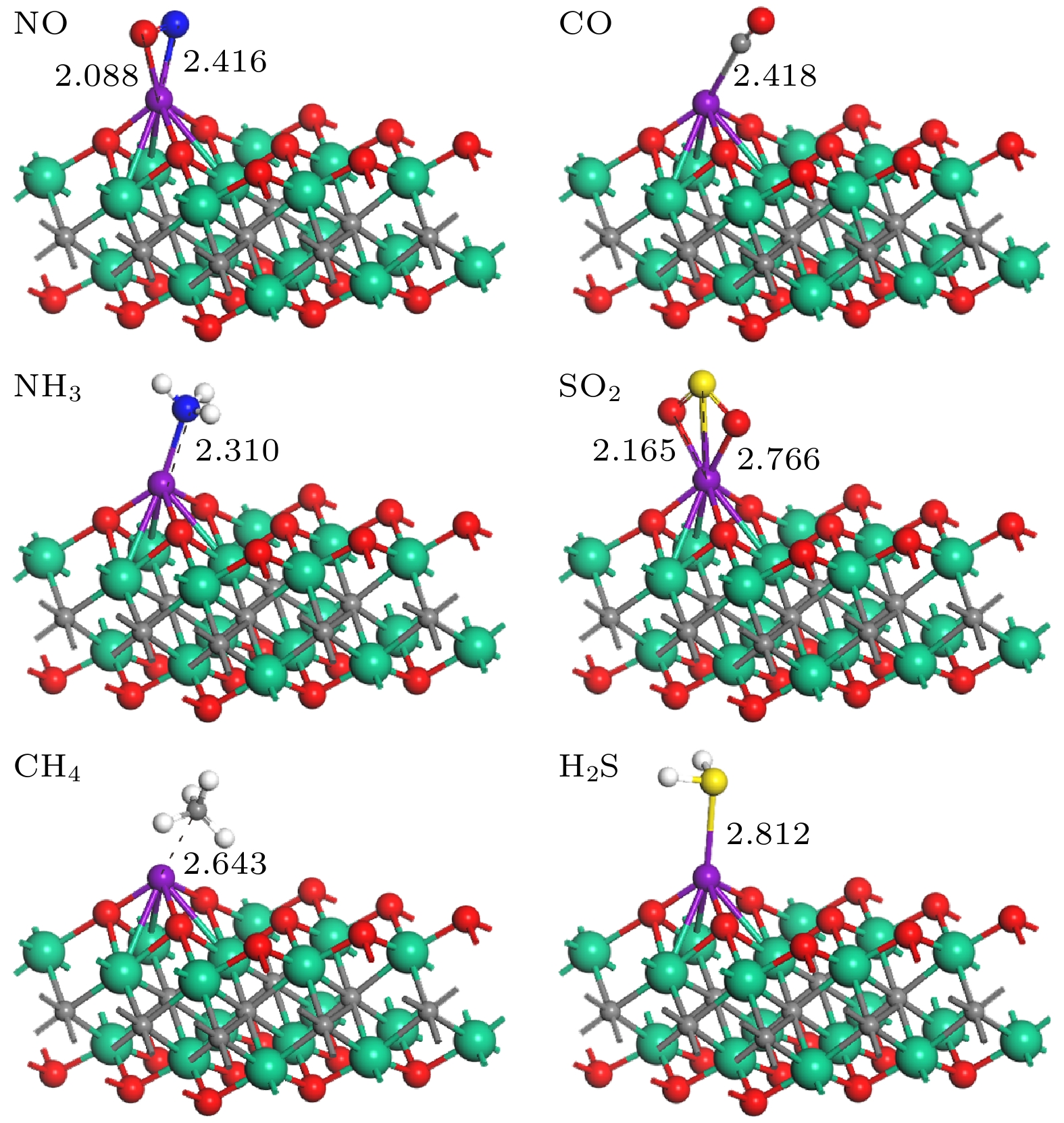

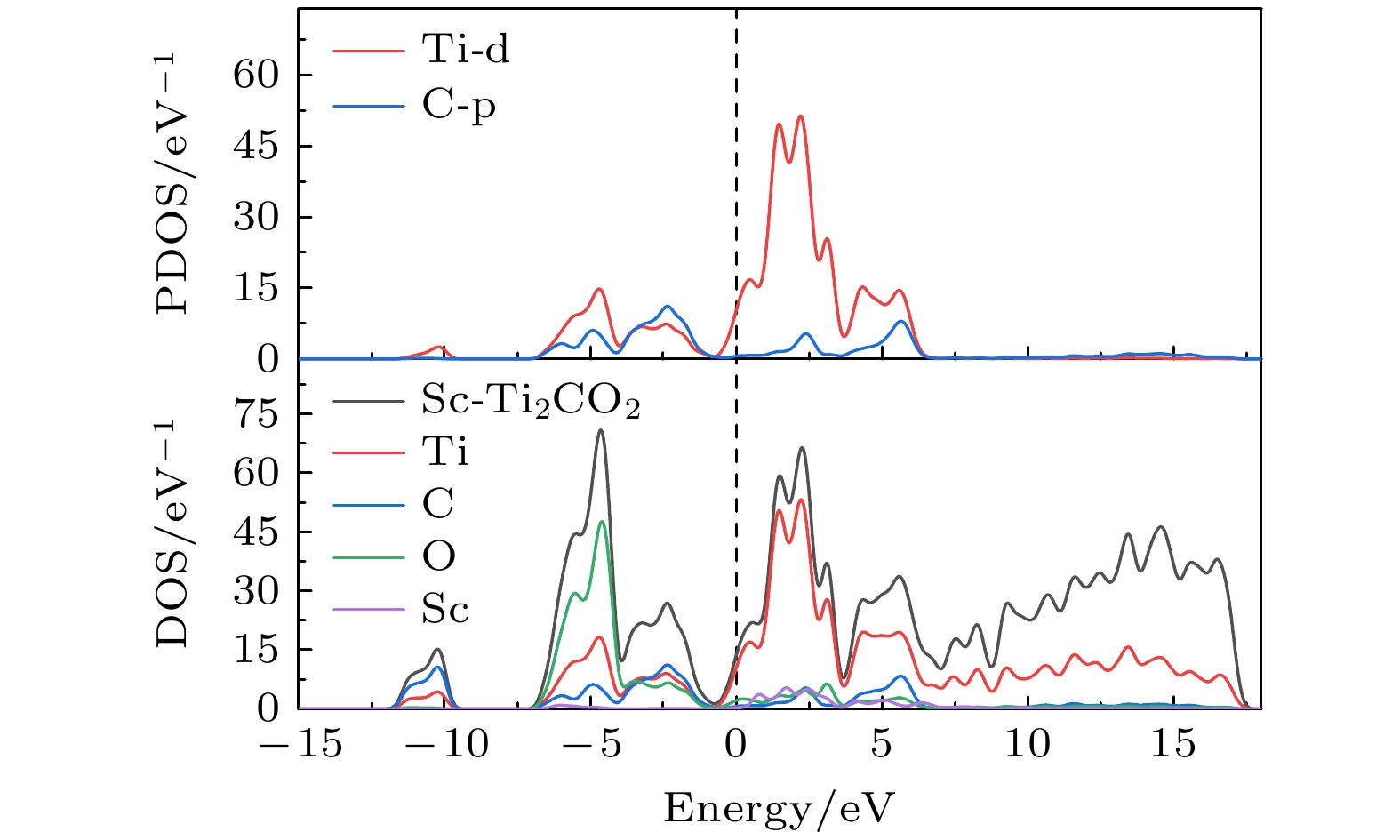

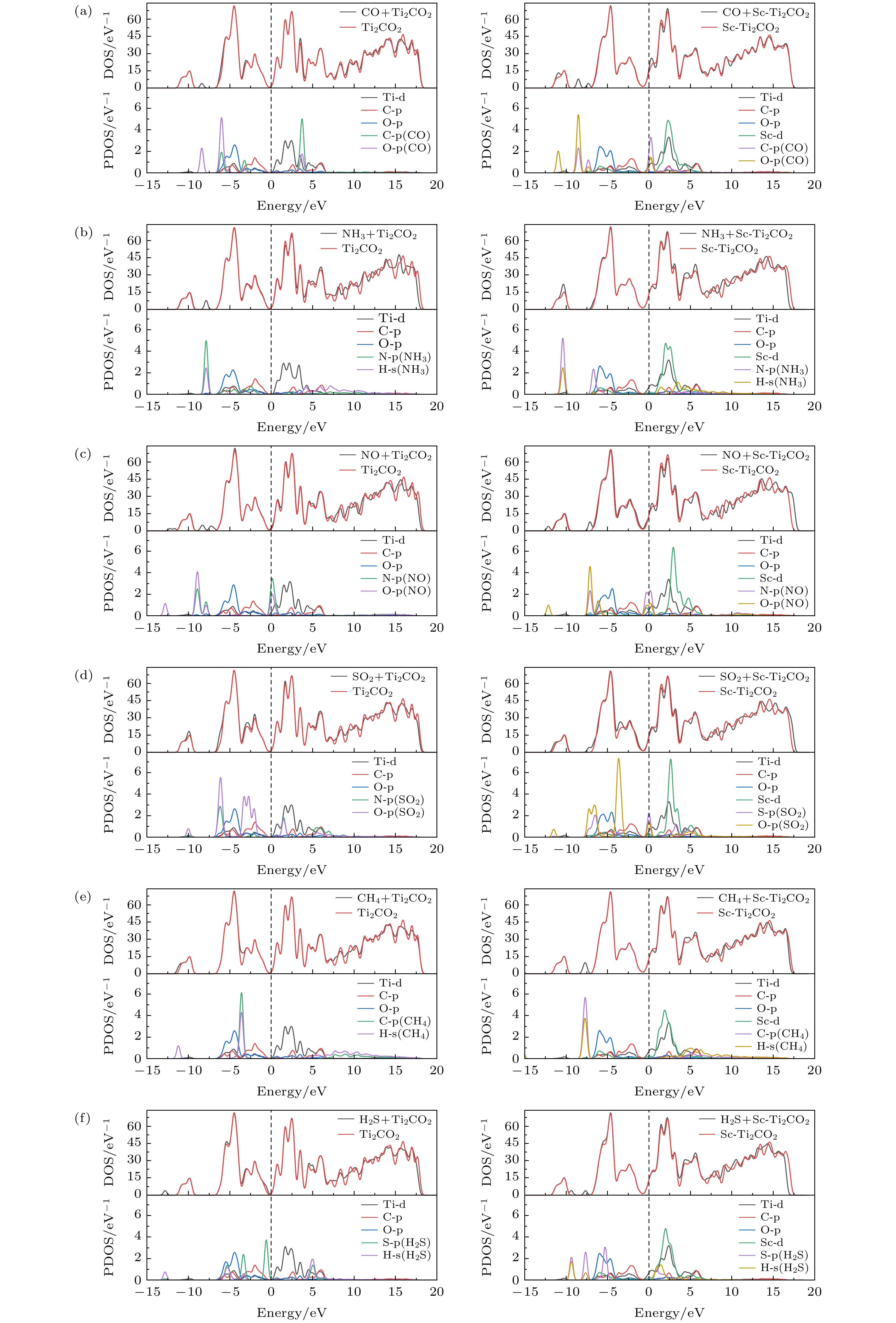

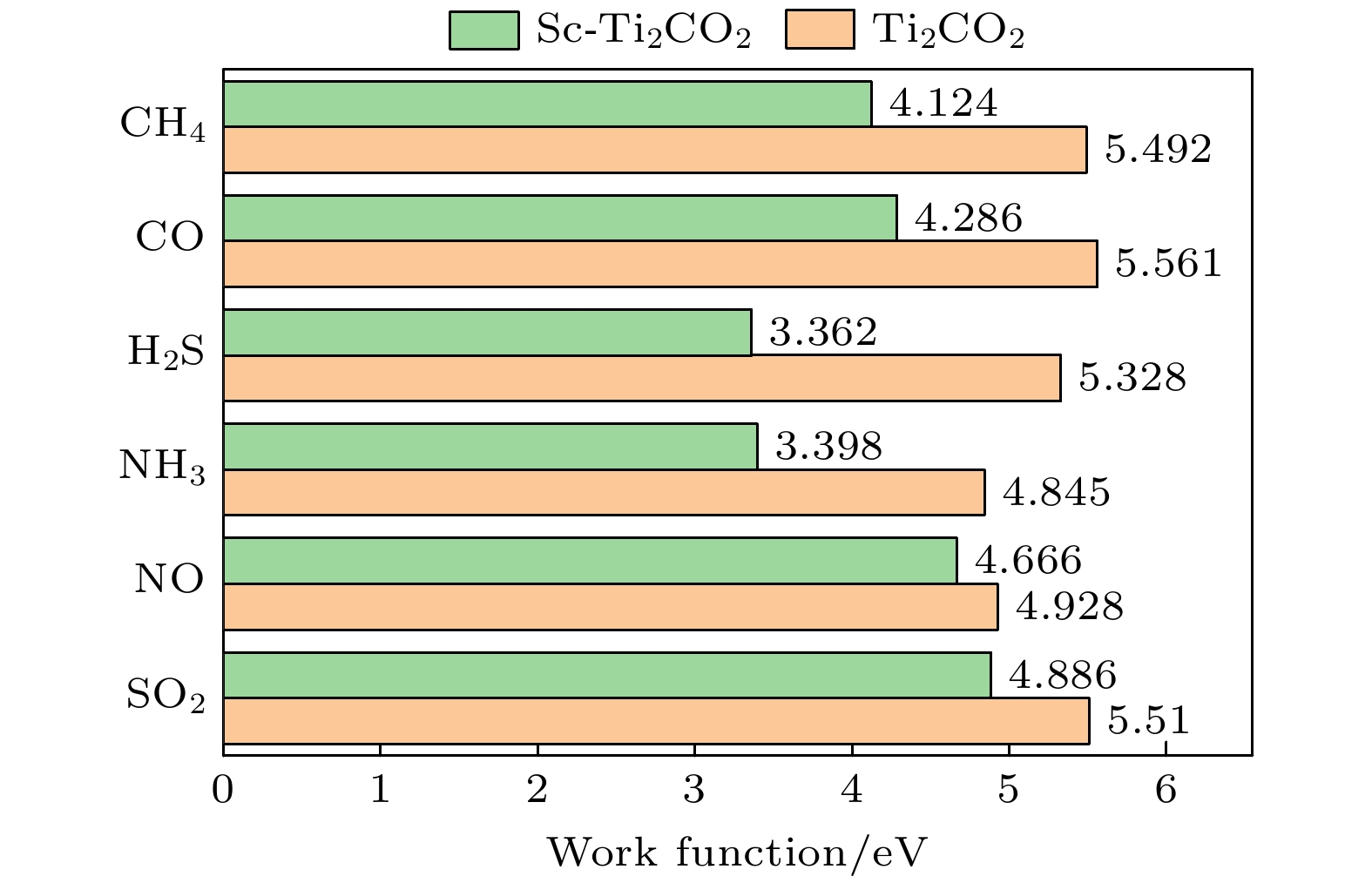

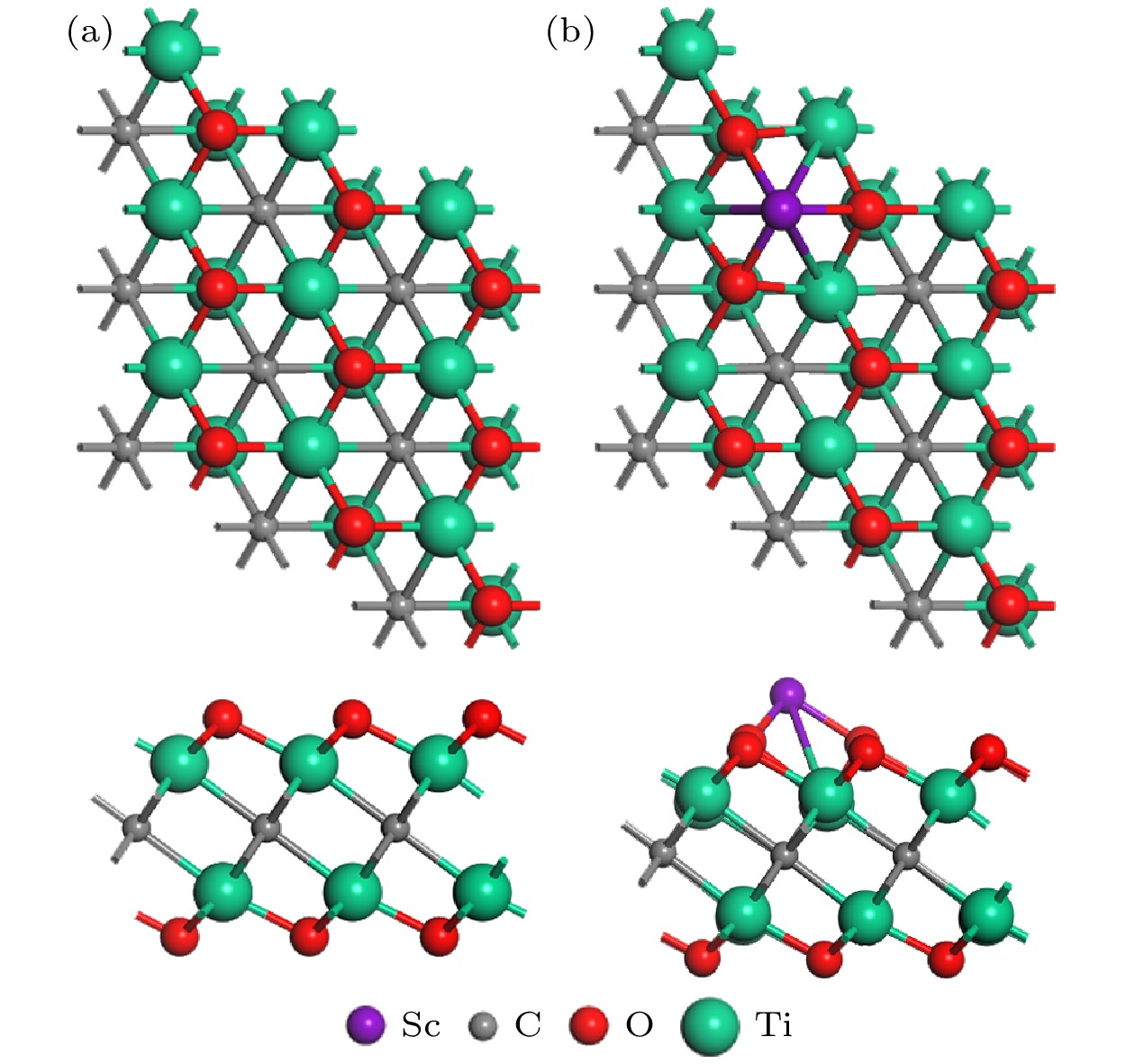

基于第一性原理计算研究了Ti2CO2和金属Sc修饰的Ti2CO2的几何结构和电子性质, 分析了不同有害气体(CO, NH3, NO, SO2, CH4, H2S)在这两种材料表面的吸附过程, 讨论了金属修饰对Ti2CO2二维过渡金属碳化物(MXene)电子性能和气体吸附性能的影响. 计算结果表明, Sc原子位于空心位C原子上方的结构具有较大的结合能, 但小于固体Sc的内聚能实验值(3.90 eV), Sc原子可以有效避免成簇. 表面Sc金属为气体吸附提供了活性位点. 通过分析不同气体的最佳吸附点位、吸附能等参数, 分析金属Sc修饰的Ti2CO2对这些气体的吸附效果. 其中对SO2的吸附效果更好, 吸附能从–0.314 eV提升到–2.043 eV, 其他气体的吸附效果均有改善. 通过电荷转移、态密度和功函数等参数解释了其吸附能增加的原因. 由于在表面引入了新的原子, 增大了材料的载流子密度和载流子迁移率, 从而提高了材料表面的电荷转移, 为金属Sc修饰的Ti2CO2材料的气敏性能提供理论参考.MXene materials have received increasing attention due to their unique properties and potential applications. Ti2CO2, as a typical MXene material that has been prepared, has been widely studied. The adsorption characteristics of two-dimensional materials for gas molecules can be significantly improved through transition metal modification. However, there are few studies on the use of transition metals to modify Ti2CO2. In this work, the adsorption processes of different harmful gases (CO, NH3, NO, SO2, CH4, H2S) on the surfaces of these two materials, i.e. Ti2CO2 and metal Sc modified Ti2CO2, are studied and analyzed based on first-principles density functional theory and generalized gradient method. The geometric optimization calculation of the metal-modified adsorption harmful gas structure is carried out, and the kinetic energy cutoff energy of the plane wave basis set is taken as 450 eV. The calculation results show that the structure in which Sc atoms are located above the C atoms in the hollow position has a large binding energy, but it is smaller than the experimental value of the cohesive energy of solid Sc (3.90 eV). Sc atoms can effectively avoid clustering. Surface Sc metal provides active sites for gas adsorption. By analyzing the optimal adsorption points, adsorption energy and other parameters of different gases, the adsorption effects of metal Sc-modified Ti2CO2 on these gases are analyzed. Among them, the adsorption effect of SO2 is better, the adsorption energy is increased from –0.314 eV to –2.043 eV, and the adsorption effects of other gases are improved. Due to the introduction of new atoms on the surface of Ti2CO2, the carrier density and carrier mobility of the material are increased, thereby improving the charge transfer on the surface of the material, which is beneficial to its sensitivity to gas molecules. The results of density of states and work function further verify that the carrier density and carrier mobility of Sc-Ti2CO2 are increased, which is beneficial to gas adsorption. It is expected that the metal Sc-modified Ti2CO2 becomes an excellent gas-sensing material for the detection of CO, NH3, NO, SO2, CH4 and H2S, and the present work can provide a reference for theoretically studying the gas-sensing performance of metal Sc-modified Ti2CO2 materials.

-

Keywords:

- MXene /

- first-principles /

- metal modification /

- gas sensors

[1] 徐强, 段康, 谢浩, 张秦蓉, 梁本权, 彭祯凯, 李卫 2021 70 157101

Google Scholar

Google Scholar

Xu Q, Duan K, Xie H, Zhang Q R, Liang B Q, Peng Z K, Li W 2021 Acta Phys. Sin. 70 157101

Google Scholar

Google Scholar

[2] 丁超, 李卫, 刘菊燕, 王琳琳, 蔡云, 潘沛锋 2018 67 213102

Google Scholar

Google Scholar

Ding C, Li W, Liu J Y, Wang L L, Cai Y, Pan P F 2018 Acta Phys. Sin. 67 213102

Google Scholar

Google Scholar

[3] Naguib M, Kurtoglu M, Presser V, Lu J, Niu J, Heon M, Barsoum M W 2011 Adv. Mater. 23 4248

Google Scholar

Google Scholar

[4] Anasori B, Lukatskaya M R, Gogotsi Y 2017 Nat. Rev. Mater. 2 1

[5] Naguib M, Mochalin V N, Barsoum M W, Gogotsi Y 2014 Adv. Mater. 26 992

Google Scholar

Google Scholar

[6] Verger L, Natu V, Carey M, Barsoum M W 2019 Trends Chem. 1 656

Google Scholar

Google Scholar

[7] Alhabeb M, Maleski K, Anasori B, Lelyukh P, Clark L, Sin S, Gogotsi Y 2017 Chem. Mater. 29 7633

Google Scholar

Google Scholar

[8] Chen J, Chen K, Tong D Y, Huang Y J, Zhang J W, Xue J M, Chen T 2015 Chem. Commun. 51 314

Google Scholar

Google Scholar

[9] Xu B Z, Zhu M S, Zhang W C, Zhen X, Pei Z X, Xue Q, Zhi C Y, Shi P 2016 Advanced Materials. 28 3411

Google Scholar

Google Scholar

[10] Li N, Chen X, Ong W J, MacFarlane D R, Zhao X, Cheetham A K, Sun C 2017 Acs Nano 11 10825

Google Scholar

Google Scholar

[11] Azofra L M, Li N, MacFarlane D R, Sun C 2016 Energy Environ. Sci. 9 2545

Google Scholar

Google Scholar

[12] Ren C E, Zhao M Q, Makaryan T, Halim J, Boota M, Kota S, Gogotsi Y 2016 Chem. Electro. Chem. 3 689

Google Scholar

Google Scholar

[13] Huang K, Li Z, Lin J, Han G, Huang P 2018 Chem. Soc. Rev. 47 5109

Google Scholar

Google Scholar

[14] Lee E, VahidMohammadi A, Prorok B C, Yoon Y S, Beidaghi M, Kim D J 2017 ACS Appl. Mater. Interfaces 9 37184

Google Scholar

Google Scholar

[15] Naguib M, Mashtalir O, Carle J, Presser V, Lu J, Hultman L, Barsoum M W 2012 ACS Nano 6 1322

Google Scholar

Google Scholar

[16] Tang Q, Zhou Z, Shen P W 2012 J. Am. Chem. So. 134 16909

Google Scholar

Google Scholar

[17] Xie Y, Naguib M, Mochalin V N, Barsoum M W, Gogotsi Y, Yu X, Kent P R 2014 J. Am. Chem. So. 136 6385

Google Scholar

Google Scholar

[18] Zhang Y Q, Zha X H, Luo K, Qiu N X, Zhou Y H, He J, Chai Z F, Huang Z R, Huang Q, Liang Y X, Du S Y 2019 J. Phys. Chem. C 123 6802

Google Scholar

Google Scholar

[19] Li X H, Zhang R Z, Cui H L 2020 ACS Omega 5 18403

Google Scholar

Google Scholar

[20] Zhang X, Zhang Z H, Li J L, Zhao X D, Wu D H, Zhou Z 2017 J. Mater. Chem. A 5 12899

Google Scholar

Google Scholar

[21] Yu X F, Li Y C, Cheng J B, Liu Z B, Li Q Z, Li W Z, Xiao B 2015 ACS Appl. Mater. Interfaces 7 13707

Google Scholar

Google Scholar

[22] 谢浩, 李卫, 任青颖, 郑加金, 解其云, 王祥夫 2023 微纳电子技术 60 549

Xie H, Li W, Ren Q Y, Zheng J J, Xie Q Y, Wang X F 2023 Micronanoelectron. Tech. 60 549

[23] Zhao J, Li W, Feng Y, Li J, Bai G, Xu J 2020 Appl. Phys. A 126 1

Google Scholar

Google Scholar

[24] Zhu C, Liang J X, Wang Y G, Li J 2022 Chin. J. Catal. 43 1830

Google Scholar

Google Scholar

[25] Hussain T, Vovusha H, Kaewmaraya T, Karton A, Amornkitbamrung V, Ahuja R 2018 Nanotechnology 29 415502

Google Scholar

Google Scholar

[26] Segall M D, Lindan P J, Probert M A, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys-Cond. Mat. 14 2717

Google Scholar

Google Scholar

[27] Perdew J P, Chevary J A, Vosko S H, Jackson K A, Pederson M R, Singh D J, Fiolhais C 1992 Phys. Rev. B 46 6671

Google Scholar

Google Scholar

[28] Zhou Q X, Wang L, Ju W W, Zhao Z H, Hou J, Yong Y L, Miao H Y 2023 Phys. Lett. A 477 128919

Google Scholar

Google Scholar

[29] Sun Q, Wang Q, Jena P, Kawazoe Y 2005 J. Am. Chem. So. 127 14582

Google Scholar

Google Scholar

[30] Philipsen P H T, Baerends E J 2006 Phys. Rev. B 54 5326

[31] 王怡然, 王丽芳, 袁东玉, 孔月月, 马淑红 2019 原子与分子 36 568

Google Scholar

Google Scholar

Wang Y R, Wang L F, Yuan D Y, Kong Y Y, Ma S H 2019 J. Atom. Mol. Phys. 36 568

Google Scholar

Google Scholar

[32] Li X H, Cui H L, Zhang R Z, Li S S 2020 Vacuum 179 109574

Google Scholar

Google Scholar

[33] Ali S, Xie Z, Xu H 2021 Chem. Phys. Chem. 22 2352

Google Scholar

Google Scholar

[34] Khazaei M, Arai M, Sasaki T, Ranjbar A, Liang Y, Yunoki S 2015 Phys. Rev. B 92 075411

Google Scholar

Google Scholar

[35] Peng S, Cho K, Qi P, Dai H 2004 Chem. Phys. Lett. 387 271

Google Scholar

Google Scholar

-

表 1 不同气体与Ti2CO2和Sc-Ti2CO2单层间的吸附能和电荷转移

Table 1. Adsorption energy and charge transfer between different gases and Ti2CO2 and Sc-Ti2CO2 monolayer.

基底材料 吸附气体 Ead/eV CT(e) Ti2CO2 NO –0.026 0.12 CO –0.238 0.04 NH3 –0.108 0.20 SO2 –0.314 0.04 CH4 –0.291 0.00 H2S –0.140 0.04 Sc-Ti2CO2 NO –1.421 –0.150 CO –0.735 –0.130 NH3 –1.385 0.310 SO2 –2.043 –0.170 CH4 –0.537 –0.380 H2S –0.898 0.320 -

[1] 徐强, 段康, 谢浩, 张秦蓉, 梁本权, 彭祯凯, 李卫 2021 70 157101

Google Scholar

Google Scholar

Xu Q, Duan K, Xie H, Zhang Q R, Liang B Q, Peng Z K, Li W 2021 Acta Phys. Sin. 70 157101

Google Scholar

Google Scholar

[2] 丁超, 李卫, 刘菊燕, 王琳琳, 蔡云, 潘沛锋 2018 67 213102

Google Scholar

Google Scholar

Ding C, Li W, Liu J Y, Wang L L, Cai Y, Pan P F 2018 Acta Phys. Sin. 67 213102

Google Scholar

Google Scholar

[3] Naguib M, Kurtoglu M, Presser V, Lu J, Niu J, Heon M, Barsoum M W 2011 Adv. Mater. 23 4248

Google Scholar

Google Scholar

[4] Anasori B, Lukatskaya M R, Gogotsi Y 2017 Nat. Rev. Mater. 2 1

[5] Naguib M, Mochalin V N, Barsoum M W, Gogotsi Y 2014 Adv. Mater. 26 992

Google Scholar

Google Scholar

[6] Verger L, Natu V, Carey M, Barsoum M W 2019 Trends Chem. 1 656

Google Scholar

Google Scholar

[7] Alhabeb M, Maleski K, Anasori B, Lelyukh P, Clark L, Sin S, Gogotsi Y 2017 Chem. Mater. 29 7633

Google Scholar

Google Scholar

[8] Chen J, Chen K, Tong D Y, Huang Y J, Zhang J W, Xue J M, Chen T 2015 Chem. Commun. 51 314

Google Scholar

Google Scholar

[9] Xu B Z, Zhu M S, Zhang W C, Zhen X, Pei Z X, Xue Q, Zhi C Y, Shi P 2016 Advanced Materials. 28 3411

Google Scholar

Google Scholar

[10] Li N, Chen X, Ong W J, MacFarlane D R, Zhao X, Cheetham A K, Sun C 2017 Acs Nano 11 10825

Google Scholar

Google Scholar

[11] Azofra L M, Li N, MacFarlane D R, Sun C 2016 Energy Environ. Sci. 9 2545

Google Scholar

Google Scholar

[12] Ren C E, Zhao M Q, Makaryan T, Halim J, Boota M, Kota S, Gogotsi Y 2016 Chem. Electro. Chem. 3 689

Google Scholar

Google Scholar

[13] Huang K, Li Z, Lin J, Han G, Huang P 2018 Chem. Soc. Rev. 47 5109

Google Scholar

Google Scholar

[14] Lee E, VahidMohammadi A, Prorok B C, Yoon Y S, Beidaghi M, Kim D J 2017 ACS Appl. Mater. Interfaces 9 37184

Google Scholar

Google Scholar

[15] Naguib M, Mashtalir O, Carle J, Presser V, Lu J, Hultman L, Barsoum M W 2012 ACS Nano 6 1322

Google Scholar

Google Scholar

[16] Tang Q, Zhou Z, Shen P W 2012 J. Am. Chem. So. 134 16909

Google Scholar

Google Scholar

[17] Xie Y, Naguib M, Mochalin V N, Barsoum M W, Gogotsi Y, Yu X, Kent P R 2014 J. Am. Chem. So. 136 6385

Google Scholar

Google Scholar

[18] Zhang Y Q, Zha X H, Luo K, Qiu N X, Zhou Y H, He J, Chai Z F, Huang Z R, Huang Q, Liang Y X, Du S Y 2019 J. Phys. Chem. C 123 6802

Google Scholar

Google Scholar

[19] Li X H, Zhang R Z, Cui H L 2020 ACS Omega 5 18403

Google Scholar

Google Scholar

[20] Zhang X, Zhang Z H, Li J L, Zhao X D, Wu D H, Zhou Z 2017 J. Mater. Chem. A 5 12899

Google Scholar

Google Scholar

[21] Yu X F, Li Y C, Cheng J B, Liu Z B, Li Q Z, Li W Z, Xiao B 2015 ACS Appl. Mater. Interfaces 7 13707

Google Scholar

Google Scholar

[22] 谢浩, 李卫, 任青颖, 郑加金, 解其云, 王祥夫 2023 微纳电子技术 60 549

Xie H, Li W, Ren Q Y, Zheng J J, Xie Q Y, Wang X F 2023 Micronanoelectron. Tech. 60 549

[23] Zhao J, Li W, Feng Y, Li J, Bai G, Xu J 2020 Appl. Phys. A 126 1

Google Scholar

Google Scholar

[24] Zhu C, Liang J X, Wang Y G, Li J 2022 Chin. J. Catal. 43 1830

Google Scholar

Google Scholar

[25] Hussain T, Vovusha H, Kaewmaraya T, Karton A, Amornkitbamrung V, Ahuja R 2018 Nanotechnology 29 415502

Google Scholar

Google Scholar

[26] Segall M D, Lindan P J, Probert M A, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys-Cond. Mat. 14 2717

Google Scholar

Google Scholar

[27] Perdew J P, Chevary J A, Vosko S H, Jackson K A, Pederson M R, Singh D J, Fiolhais C 1992 Phys. Rev. B 46 6671

Google Scholar

Google Scholar

[28] Zhou Q X, Wang L, Ju W W, Zhao Z H, Hou J, Yong Y L, Miao H Y 2023 Phys. Lett. A 477 128919

Google Scholar

Google Scholar

[29] Sun Q, Wang Q, Jena P, Kawazoe Y 2005 J. Am. Chem. So. 127 14582

Google Scholar

Google Scholar

[30] Philipsen P H T, Baerends E J 2006 Phys. Rev. B 54 5326

[31] 王怡然, 王丽芳, 袁东玉, 孔月月, 马淑红 2019 原子与分子 36 568

Google Scholar

Google Scholar

Wang Y R, Wang L F, Yuan D Y, Kong Y Y, Ma S H 2019 J. Atom. Mol. Phys. 36 568

Google Scholar

Google Scholar

[32] Li X H, Cui H L, Zhang R Z, Li S S 2020 Vacuum 179 109574

Google Scholar

Google Scholar

[33] Ali S, Xie Z, Xu H 2021 Chem. Phys. Chem. 22 2352

Google Scholar

Google Scholar

[34] Khazaei M, Arai M, Sasaki T, Ranjbar A, Liang Y, Yunoki S 2015 Phys. Rev. B 92 075411

Google Scholar

Google Scholar

[35] Peng S, Cho K, Qi P, Dai H 2004 Chem. Phys. Lett. 387 271

Google Scholar

Google Scholar

计量

- 文章访问数: 5406

- PDF下载量: 125

- 被引次数: 0

下载:

下载: