-

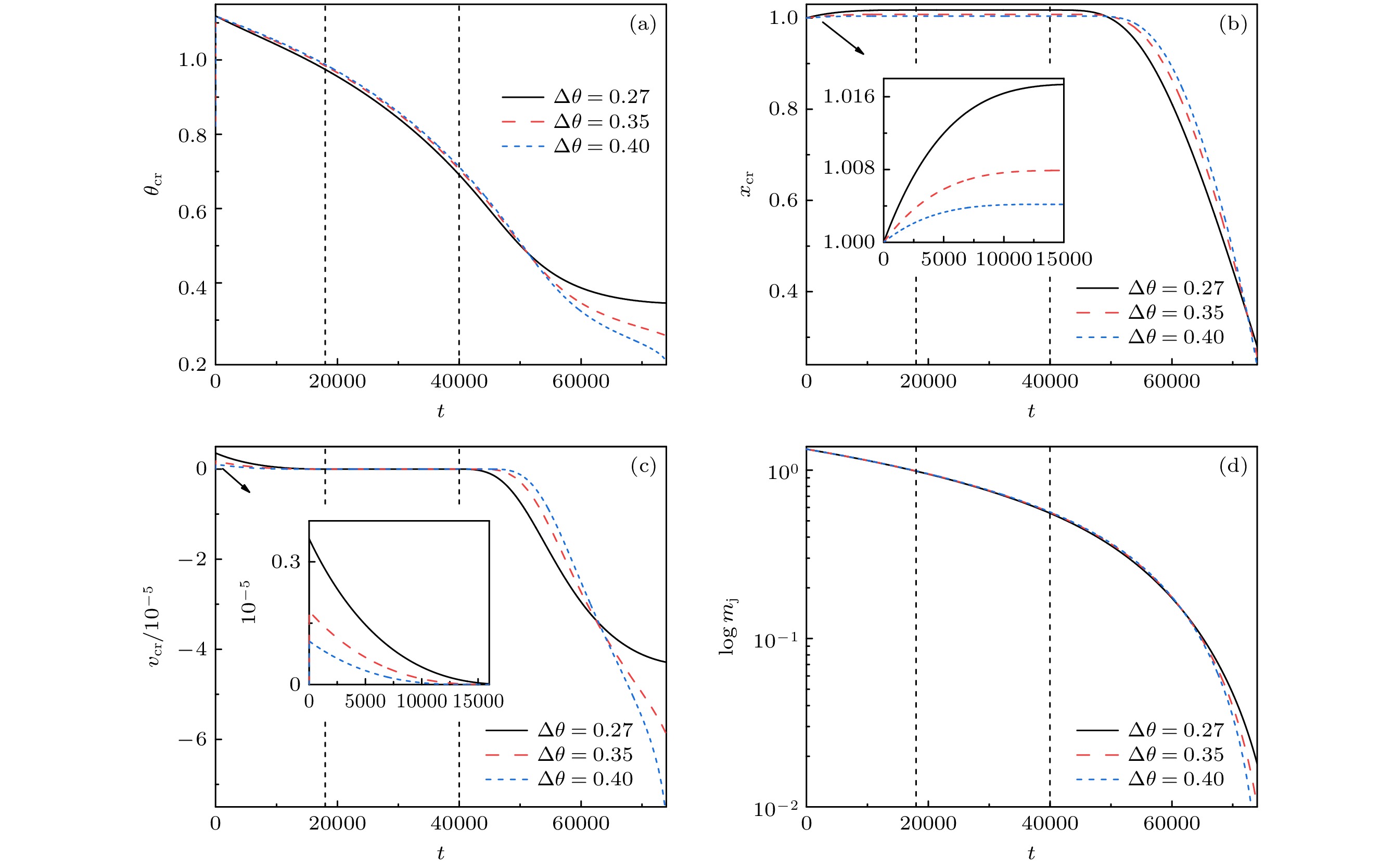

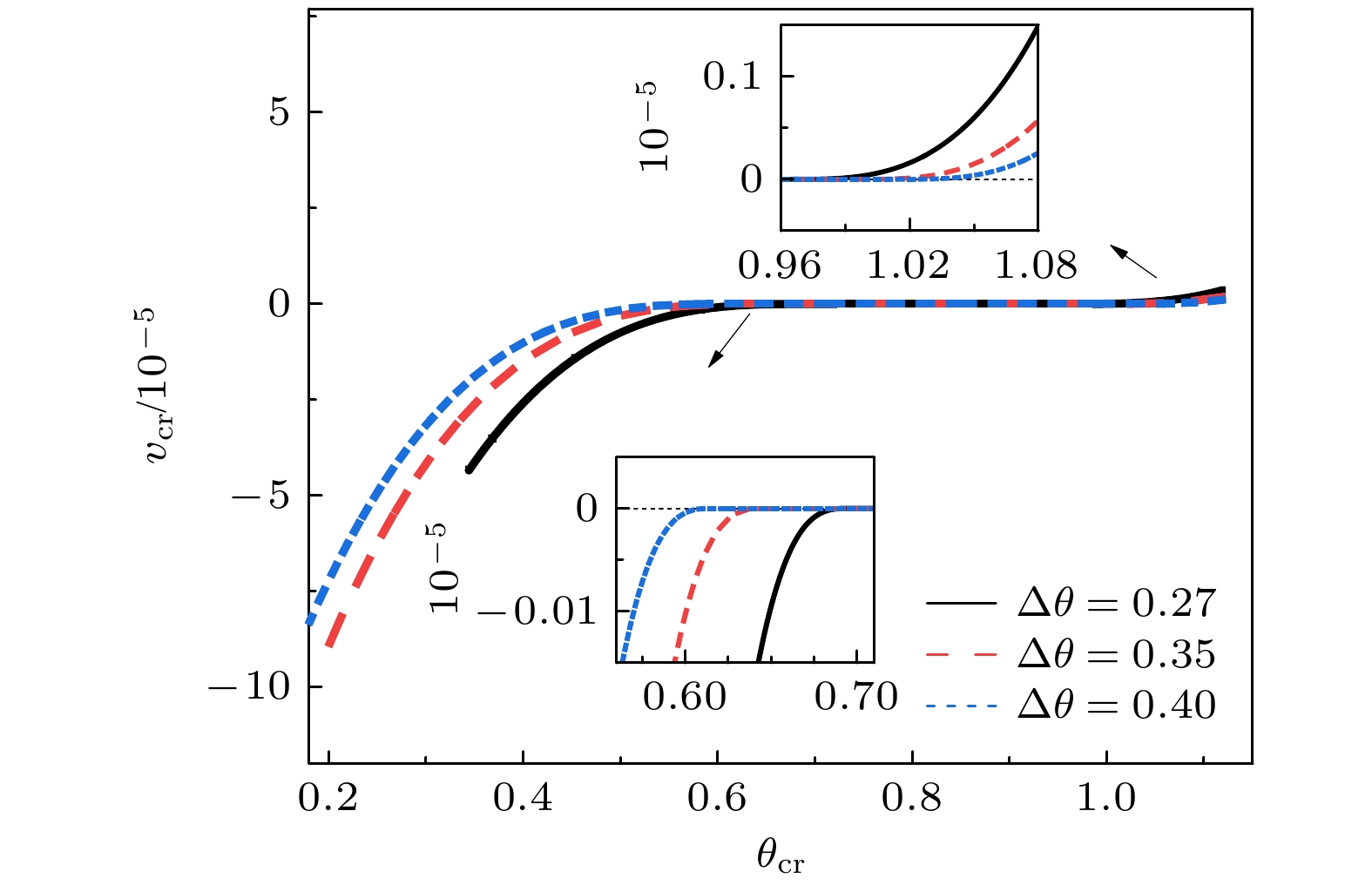

The evaporation process of drops on a solid surface is widely applied to daily life and industrial fields. Both contact angle hysteresis and the sensitivity of gas-liquid interfacial tension to temperature are important factors affecting the drop evaporation reflected in the contact line and contact angle. To investigate the internal mechanism, according to the lubrication theory and slip boundary conditions, we establish a mathematical model of the drop evaporation on a uniformly heated solid wall with considering the effect of contact angle hysteresis. This model is numerically solved by using a coordinate transformation method and Freefem++14.3, a highly efficient solver. The accuracy of the numerical calculation method is verified by comparing the numerical results with experimental results, and the grid independence is validated. The effect of contact angle hysteresis on the dynamics of evaporating drops is discussed, and the evaporation characteristics of drops with different tension sensitivities of the air-liquid interface to temperature are further investigated. The results show that the contact angle hysteresis has an apparent influence on the drop evaporation process which includes drop spreading stage, contact line pinning stage, and depinning stage. In the drop spreading stage, the increase in the hysteresis angle shortens the spreading time, and reduces the spreading velocity and radius, while in the contact line pinning stage, the pinning time is prolonged and the reduction of drop mass is significantly increased with hysteresis angle increasing. In the contact line depinning stage, the contact angle hysteresis reduces the contact angle, and a flatter shape emerges, thereby enhancing the ability to transfer heat and accelerating evaporation as well as shortening the depinning time. In addition, the large hysteresis angle leads to a large advancing contact angle and a small receding contact angle. The reduction in receding contact angle is more notable than the increment of advancing contact angle. The temperature sensitivity coefficient of the gas-liquid interfacial tension can be increased by reducing the receding contact angle, thereby improving the wettability of the drops on the wall enhancing the heat transfer and accelerating the evaporation. Regulating the contact angle hysteresis and the sensitivity of the interfacial tension to temperature can realize the manipulation of the drop movement, thus controlling the evaporation process.

-

Keywords:

- drop evaporation /

- dynamics /

- contact angle hysteresis /

- sensitivity of air-liquid interfacial tension to temperature

[1] Kavehpour P, Ovryn B, McKinley G H 2002 Colloids Surf., A 206 409

Google Scholar

Google Scholar

[2] Lee K S, Ivanova N, Starov V M, Hilal N, Dutschk V 2008 Adv. Colloid Interface Sci. 144 54

Google Scholar

Google Scholar

[3] Wijshoff H 2010 Phys. Rep. 491 77

Google Scholar

Google Scholar

[4] Putnam S A, Briones A M, Byrd L W, Ervin J S, Hanchak M S, White A, Jones J G 2012 Int. J. Heat Mass Transfer 55 5793

Google Scholar

Google Scholar

[5] Ye X M, Zhang X S, Li M L, Li C X 2018 Phys. Fluids 30 112103

Google Scholar

Google Scholar

[6] Lopes M C, Bonaccurso E 2012 Soft Matter 8 7875

Google Scholar

Google Scholar

[7] Kiper I, Fulcrand R, Pirat C, Simon G, Stutz B, Ramos S M M 2015 Colloids Surf., A 482 617

Google Scholar

Google Scholar

[8] Eral H B, Mannetje D, Oh J M 2013 Colloid. Polym. Sci. 291 247

Google Scholar

Google Scholar

[9] Neumann A W, Good R J 1972 J. Colloid Interface Sci. 38 341

Google Scholar

Google Scholar

[10] Johnson R E, Dettre R H 1964 Contact Angle, Wettability, and Adhesion (Washington: American Chemical Society) pp112−135

[11] Dettre R H, Johnson R E 1964 Contact Angle, Wettability, and Adhesion (Washington: American Chemical Society) pp136−144

[12] Yu H Z, Soolaman D M, Rowe A W, Banks J T 2004 ChemPhysChem 5 1035

Google Scholar

Google Scholar

[13] Li Y F, Sheng Y J, Tsao H K 2013 Langmuir 29 7802

Google Scholar

Google Scholar

[14] Trybala A, Okoye A, Semenov S, Agogo H, Rubio R G, Ortega F, Starov V M 2013 J. Colloid Interface Sci. 403 49

Google Scholar

Google Scholar

[15] Kulinich S A, Farzaneh M 2009 Appl. Surf. Sci. 255 4056

Google Scholar

Google Scholar

[16] Lin T S, Zeng Y H, Tsay R Y, Lin S Y 2016 J. Taiwan Inst. Chem. Eng. 62 54

Google Scholar

Google Scholar

[17] Kuznetsov G V, Feoktistov D V, Orlova E G, Batishcheva K A 2016 Colloid J. 78 335

Google Scholar

Google Scholar

[18] Ajaev V S 2005 J. Fluid Mech. 528 279

Google Scholar

Google Scholar

[19] Masoud H, Felske J D 2009 Phys. Rev. E 79 016301

Google Scholar

Google Scholar

[20] Semenov S, Starov V M, Rubio R G, Agogo H, Velarde M G 2012 Math. Modell. Nat. Phenom. 7 82

Google Scholar

Google Scholar

[21] Karapetsas G, Sahu K C, Matar O K 2013 Langmuir 29 8892

Google Scholar

Google Scholar

[22] Ye X M, Zhang X S, Li M L, Li C X, Dong S 2019 Int. J. Heat Mass Transfer 128 1263

Google Scholar

Google Scholar

[23] 叶学民, 李永康, 李春曦 2016 65 104704

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. Sin. 65 104704

Google Scholar

Google Scholar

[24] Karapetsas G, Craster R V, Matar O K 2011 J. Fluid Mech. 670 5

Google Scholar

Google Scholar

[25] 焦云龙, 刘小君, 逄明华, 刘焜 2015 65 016801

Google Scholar

Google Scholar

Jiao Y L, Liu X J, Pang M H, Liu K 2015 Acta Phys. Sin. 65 016801

Google Scholar

Google Scholar

[26] Nagy M, Škvarla J 2013 Acta Montan. Slovaca 18 125

[27] 王晓东, 彭晓峰, 陆建峰, 王补宣 2003 应用基础与工程科学学报 11 174

Google Scholar

Google Scholar

Wang X D, Peng X F, Wang B X 2003 Chin. J. Chem. Eng. 11 174

Google Scholar

Google Scholar

[28] Smith M K 1995 J. Fluid Mech. 294 209

Google Scholar

Google Scholar

[29] Craster R V, Matar O 2000 J. Fluid Mech. 425 235

Google Scholar

Google Scholar

[30] Ma C, Liu J, Xie S, Liu Y 2020 Chem. Eng. Sci. 214 115418

Google Scholar

Google Scholar

[31] Vasu B, Dubey A, Bég O A, Gorla R S R 2020 Comput. Biol. Med. 126 104025

Google Scholar

Google Scholar

[32] Jiménez Bolaños S, Vernescu B 2017 Phys. Fluids 29 057103

Google Scholar

Google Scholar

[33] 朱仙仙, 闵春华, 郭宇虹, 王坤, 解立垚 2021 热科学与技术 20 28

Zhu X X, Min C H, Guo Y H, Wang K, Xie L Y 2021 J. Therm. Sci. Tech. 20 28

[34] Hu H, Larson R G 2005 Langmuir 21 3963

Google Scholar

Google Scholar

[35] Gatapova E Y, Semenov A A, Zaitsev D V, Kabov O A 2014 Colloids Surf., A 441 776

Google Scholar

Google Scholar

[36] Chu F, Wu X, Zhu Y, Yuan Z 2017 Int. J. Heat Mass Transfer 111 836

Google Scholar

Google Scholar

[37] Bormashenko E, Musin A, Zinigrad M 2011 Colloids Surf., A 385 235

Google Scholar

Google Scholar

[38] Brutin D, Sobac B (Brutin D Ed.) 2015 Droplet Wetting and Evaporation (Oxford: Academic Press) pp25−30

-

表 1 不同Δθ对液滴演化时间的影响

Table 1. Effect of varied Δθ on the drop evolution time.

Δθ 钉扎时刻 去钉扎时刻 蒸干时刻 铺展阶段 钉扎阶段 去钉扎阶段 0.27 18910 39750 78000 0—18910 18910—39750 39750—78000 0.35 16530 43250 76200 0—16530 16530—43250 43250—76200 0.40 14620 45100 74600 0—14620 14620—45100 45100—74600 表 2 不同迟滞角下θa 和θr 变化

Table 2. Variation in θa and θr of drop with different Δθs

Δθ θa θr Δθa Δθr 0.27 0.966 0.696 0.106 –0.164 0.35 0.997 0.647 0.031 –0.049 0.40 1.016 0.616 0.019 –0.031 表 3 不同Ωlg时液滴演化过程中参数变化

Table 3. Varieties of parameters during drop evolution with different Ωlg.

Ωlg 钉扎时刻 去钉扎时刻 蒸干时刻 θe θa θr 0.003 18910 39750 78000 0.860 0.966 0.686 0.005 20280 40140 76700 0.837 0.942 0.672 0.01 22200 40260 71000 0.775 0.880 0.610 -

[1] Kavehpour P, Ovryn B, McKinley G H 2002 Colloids Surf., A 206 409

Google Scholar

Google Scholar

[2] Lee K S, Ivanova N, Starov V M, Hilal N, Dutschk V 2008 Adv. Colloid Interface Sci. 144 54

Google Scholar

Google Scholar

[3] Wijshoff H 2010 Phys. Rep. 491 77

Google Scholar

Google Scholar

[4] Putnam S A, Briones A M, Byrd L W, Ervin J S, Hanchak M S, White A, Jones J G 2012 Int. J. Heat Mass Transfer 55 5793

Google Scholar

Google Scholar

[5] Ye X M, Zhang X S, Li M L, Li C X 2018 Phys. Fluids 30 112103

Google Scholar

Google Scholar

[6] Lopes M C, Bonaccurso E 2012 Soft Matter 8 7875

Google Scholar

Google Scholar

[7] Kiper I, Fulcrand R, Pirat C, Simon G, Stutz B, Ramos S M M 2015 Colloids Surf., A 482 617

Google Scholar

Google Scholar

[8] Eral H B, Mannetje D, Oh J M 2013 Colloid. Polym. Sci. 291 247

Google Scholar

Google Scholar

[9] Neumann A W, Good R J 1972 J. Colloid Interface Sci. 38 341

Google Scholar

Google Scholar

[10] Johnson R E, Dettre R H 1964 Contact Angle, Wettability, and Adhesion (Washington: American Chemical Society) pp112−135

[11] Dettre R H, Johnson R E 1964 Contact Angle, Wettability, and Adhesion (Washington: American Chemical Society) pp136−144

[12] Yu H Z, Soolaman D M, Rowe A W, Banks J T 2004 ChemPhysChem 5 1035

Google Scholar

Google Scholar

[13] Li Y F, Sheng Y J, Tsao H K 2013 Langmuir 29 7802

Google Scholar

Google Scholar

[14] Trybala A, Okoye A, Semenov S, Agogo H, Rubio R G, Ortega F, Starov V M 2013 J. Colloid Interface Sci. 403 49

Google Scholar

Google Scholar

[15] Kulinich S A, Farzaneh M 2009 Appl. Surf. Sci. 255 4056

Google Scholar

Google Scholar

[16] Lin T S, Zeng Y H, Tsay R Y, Lin S Y 2016 J. Taiwan Inst. Chem. Eng. 62 54

Google Scholar

Google Scholar

[17] Kuznetsov G V, Feoktistov D V, Orlova E G, Batishcheva K A 2016 Colloid J. 78 335

Google Scholar

Google Scholar

[18] Ajaev V S 2005 J. Fluid Mech. 528 279

Google Scholar

Google Scholar

[19] Masoud H, Felske J D 2009 Phys. Rev. E 79 016301

Google Scholar

Google Scholar

[20] Semenov S, Starov V M, Rubio R G, Agogo H, Velarde M G 2012 Math. Modell. Nat. Phenom. 7 82

Google Scholar

Google Scholar

[21] Karapetsas G, Sahu K C, Matar O K 2013 Langmuir 29 8892

Google Scholar

Google Scholar

[22] Ye X M, Zhang X S, Li M L, Li C X, Dong S 2019 Int. J. Heat Mass Transfer 128 1263

Google Scholar

Google Scholar

[23] 叶学民, 李永康, 李春曦 2016 65 104704

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. Sin. 65 104704

Google Scholar

Google Scholar

[24] Karapetsas G, Craster R V, Matar O K 2011 J. Fluid Mech. 670 5

Google Scholar

Google Scholar

[25] 焦云龙, 刘小君, 逄明华, 刘焜 2015 65 016801

Google Scholar

Google Scholar

Jiao Y L, Liu X J, Pang M H, Liu K 2015 Acta Phys. Sin. 65 016801

Google Scholar

Google Scholar

[26] Nagy M, Škvarla J 2013 Acta Montan. Slovaca 18 125

[27] 王晓东, 彭晓峰, 陆建峰, 王补宣 2003 应用基础与工程科学学报 11 174

Google Scholar

Google Scholar

Wang X D, Peng X F, Wang B X 2003 Chin. J. Chem. Eng. 11 174

Google Scholar

Google Scholar

[28] Smith M K 1995 J. Fluid Mech. 294 209

Google Scholar

Google Scholar

[29] Craster R V, Matar O 2000 J. Fluid Mech. 425 235

Google Scholar

Google Scholar

[30] Ma C, Liu J, Xie S, Liu Y 2020 Chem. Eng. Sci. 214 115418

Google Scholar

Google Scholar

[31] Vasu B, Dubey A, Bég O A, Gorla R S R 2020 Comput. Biol. Med. 126 104025

Google Scholar

Google Scholar

[32] Jiménez Bolaños S, Vernescu B 2017 Phys. Fluids 29 057103

Google Scholar

Google Scholar

[33] 朱仙仙, 闵春华, 郭宇虹, 王坤, 解立垚 2021 热科学与技术 20 28

Zhu X X, Min C H, Guo Y H, Wang K, Xie L Y 2021 J. Therm. Sci. Tech. 20 28

[34] Hu H, Larson R G 2005 Langmuir 21 3963

Google Scholar

Google Scholar

[35] Gatapova E Y, Semenov A A, Zaitsev D V, Kabov O A 2014 Colloids Surf., A 441 776

Google Scholar

Google Scholar

[36] Chu F, Wu X, Zhu Y, Yuan Z 2017 Int. J. Heat Mass Transfer 111 836

Google Scholar

Google Scholar

[37] Bormashenko E, Musin A, Zinigrad M 2011 Colloids Surf., A 385 235

Google Scholar

Google Scholar

[38] Brutin D, Sobac B (Brutin D Ed.) 2015 Droplet Wetting and Evaporation (Oxford: Academic Press) pp25−30

Catalog

Metrics

- Abstract views: 10170

- PDF Downloads: 159

- Cited By: 0

DownLoad:

DownLoad: