-

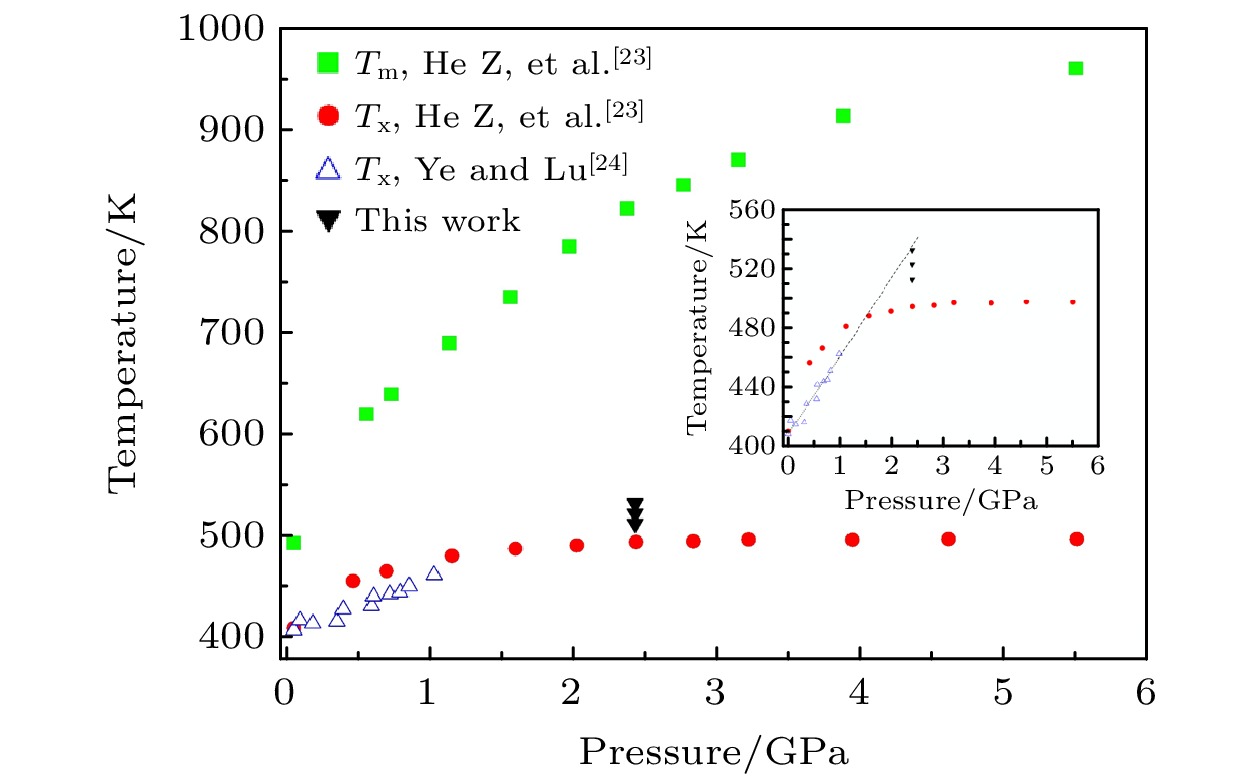

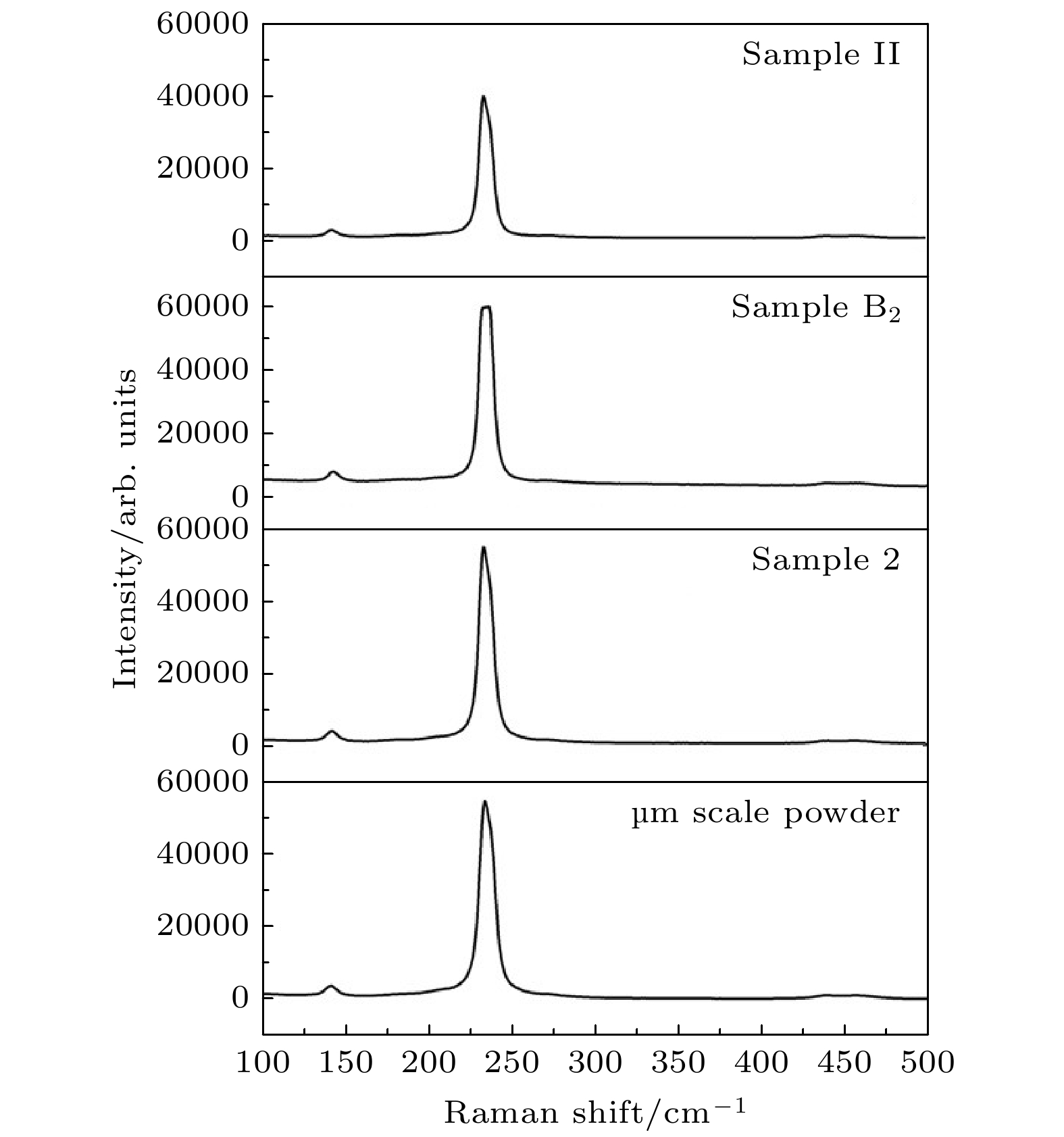

Amorphous selenium (Se) can be easily prepared by quenching the melt, which indicates that the Se possesses the good glass-forming ability. However, crystallization occurs after rapidly compressing the melt within about 20 ms. In this work, we investigate the mechanism of rapid compression-induced crystallization from Se melt. Compressing Se melt experiments are carried out at the following temperatures: 513, 523 and 533 K. The melt is rapidly compressed under 2.4 GPa for about 20 ms. Different holding times, i.e. 0, 30, 60 min after solidification are adopted. The samples are quenched to room temperature and then unloaded to ambient pressure. The X-ray diffraction analysis of the recovered sample indicates that the crystallization product is the t-Se. It is found that with the prolongation of holding time, the grain size increases due to the continuous aggregation growth of crystal grains. By comparing with the isothermal crystallization products of amorphous Se and ultrafine Se powder, it is suggested that the rapid compression-induced solidification product should be t-Se crystalline. The speculation that the solidification product is amorphous Se and it crystallizes in the cooling process does not hold true. The amorphous Se cannot be prepared through the rapid compression process on a millisecond scale. It is related to the thermal stability of amorphous Se under high pressure. It is reported that the dependence of crystallization temperature Tx on pressure i.e. dTx/dP for amorphous Se is about 40–50 K/GPa in a range of 0.1 MPa–1 GPa. However, the Tx of amorphous Se is almost constant in a range of 2–6 GPa. It means that the thermal stability of amorphous Se against crystallization does not increase with increasing pressure after 2 GPa. In this work, the temperature of 513–533 K in the experiments is higher than the Tx of amorphous Se. Therefore, the t-Se crystal is the stable phase and amorphous Se is unstable. The Se melt tends to crystallize in the supercooled liquid state after rapid compression. It is interesting to investigate the mechanism of dTx/dP curve discontinuous change at around 2 GPa in the future. Both the Se melt after rapid compression and the amorphous Se before crystallization are in supercooled liquid state. We speculate that high pressure may result in the microstructure transition in supercooled liquid state Se.

-

Keywords:

- high pressure /

- selenium /

- crystallization /

- compression-induced solidification

[1] Huang H Y, Abbaszadeh S 2020 IEEE Sens. J. 20 1694

Google Scholar

Google Scholar

[2] Matsuura M, Suzuki K 1979 J. Mater. Sci. 14 395

Google Scholar

Google Scholar

[3] Fan G J, Guo F Q, Hu Z Q, Quan M X, Lu K 1997 Phys. Rev. B 55 11010

Google Scholar

Google Scholar

[4] 邵胜子, 陈泽祥 2011 电子元器件应用 8 28

Google Scholar

Google Scholar

Shao Z S, Chen Z X 2011 Electr. Comp. Devic. Appl. 8 28

Google Scholar

Google Scholar

[5] Sun H, Zhu X H, Yang D Y, Wangyang P H, Gao X Y, Tian H B 2016 Mater. Lett. 183 94

Google Scholar

Google Scholar

[6] Singh A K, Kennedy G C 1975 J. Appl. Phys. 46 3861

Google Scholar

Google Scholar

[7] Mohan M, Singh A K 1993 Philos. Mag. B 67 705

Google Scholar

Google Scholar

[8] Zhang H Y, Hu Z Q, Lu K 1995 Nanostruct. Mater. 5 41

Google Scholar

Google Scholar

[9] Tonchev D, Mani H, Belev G, Kostova I, Kasap S 2014 18th International School on Condensed Matter Physics-Challenges of Nanoscale Science-Theory, Materials, Applications Varna, Bulgaria, September 1−6, 2014 p012007

[10] Abbaszadeh S, Rom K, Bubon O 2012 J. Non-Cryst. Solids 358 2389

Google Scholar

Google Scholar

[11] Yu T Y, Pan F M, Chang C Y, Lin J S, Huang W H 2015 J. Appl. Phys. 118 044509

Google Scholar

Google Scholar

[12] Ohkawa Y J, Miyakawa K, Matsubara T, Kikuchi K, Tanioka K, Kubota M, Egami N, Kobayashi A 2011 Phys. Status Solidi C 8 2818

Google Scholar

Google Scholar

[13] Mao H K, Chen B, Chen J, Li K, Lin J F, Yang W, Zheng H 2016 Matter. Radiat. Extremes 1 59

Google Scholar

Google Scholar

[14] Degtyareva O, Hernández E R, Serrano J, Somayazulu M, Mao H K, Gregoryanz E, Hemley R J 2007 J. Chem. Phys. 126 084503

Google Scholar

Google Scholar

[15] Li X, Huang X L, Wang X, Liu M K, Wu G, Huang Y P, He X, Li F F, Zhou Q, Liu B B, Cui T 2018 Phys. Chem. Chem. Phys. 20 6116

Google Scholar

Google Scholar

[16] Bridgman P W 1941 Phys. Rev. 60 351

Google Scholar

Google Scholar

[17] McCann D R, Cartz L 1972 J. Chem. Phys. 56 2552

Google Scholar

Google Scholar

[18] Liu H Z, Wang L H, Xiao X H, Carlo F D, Feng J, Mao H K, Hemley R J 2008 PNAS 105 13229

Google Scholar

Google Scholar

[19] He Z, Wang Z G, Zhu H Y, Liu X R, Peng J P, Hong S M 2014 Appl. Phys. Lett. 105 011901

Google Scholar

Google Scholar

[20] Hong S M, Chen L Y, Liu X R, Wu X H, Su L 2005 Rev. Sci. Instrum. 76 053905

Google Scholar

Google Scholar

[21] 刘秀茹, 王明友, 张豆豆, 张晨然, 何竹, 陈丽英, 沈如, 洪时明 2014 高压 28 385

Google Scholar

Google Scholar

Liu X R, Wang M Y, Zhang D D, Zhang C R, He Z, Chen L Y, Shen R, Hong S M 2014 Chin. J. High Pressure Phys. 28 385

Google Scholar

Google Scholar

[22] Hu Y, Su L, Liu X R, Sun Z Y, Lv S J, Yuan C S, Jia R, Shen R, Hong S M 2010 Chin. Phys. Lett. 27 038101

Google Scholar

Google Scholar

[23] He Z, Liu X R, Zhang D D, Zhang L J, Hong S M 2014 Solid State Commun. 197 30

Google Scholar

Google Scholar

[24] Ye F, Lu K 1998 Acta Mater. 46 5965

Google Scholar

Google Scholar

[25] Dai R C, Luo L B, Zhang Z M, Ding Z J 2011 Mater. Res. Bull. 46 350

Google Scholar

Google Scholar

[26] Akahama Y, Kobayashi M, Kawamura M H 1993 Phys. Rev. B 47 20

Google Scholar

Google Scholar

-

图 5 (a) 非晶硒样品的XRD图谱, 包括常压制备的非晶硒XRD图谱、非晶硒常温快压后回收样品的XRD图谱; (b)在513, 523, 533 K温度下非晶硒等温结晶样品的XRD图谱

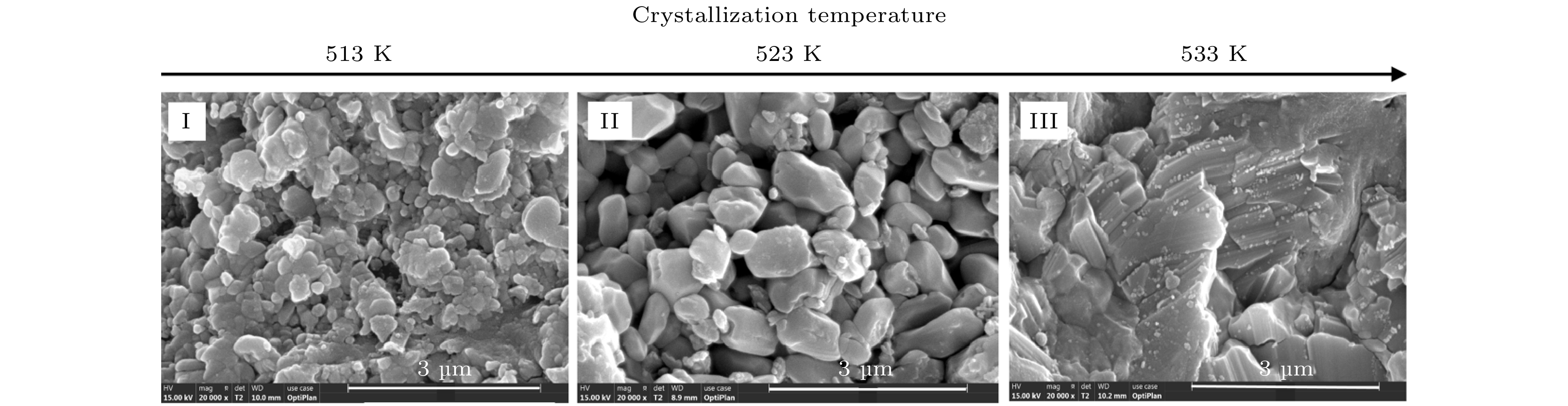

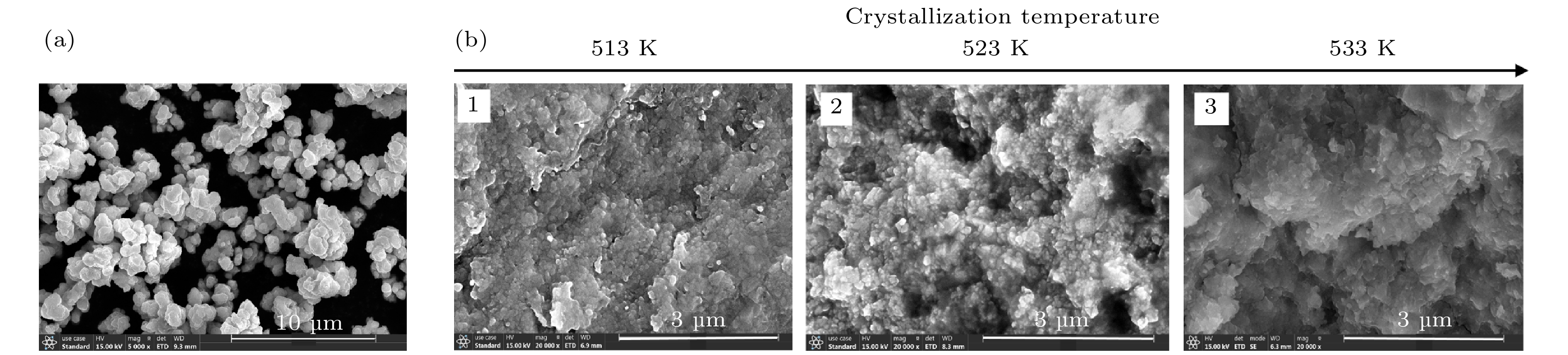

Figure 5. (a) XRD patterns of amorphous selenium (a-Se) sample and the compressed a-Se which is recovered after rapidly compressed at room temperature; (b) XRD patterns of Sample I, Sample II, Sample III, which are the isothermal crystallization products of a-Se at 513, 523, and 533 K, respectively.

图 9 Sample A1, Sample B1, Sample C1, Sample I, Sample II, Sample III衍射谱的精修结果, 图中黑色点表示衍射实验数据, 红色曲线为计算的衍射峰, 蓝色曲线为实验数据与计算数据的偏差, 紫色的短线表示

t-Se相衍射峰的位置 Figure 9. XRD patterns of Sample A1, Sample B1, Sample C1, Sample I, Sample II, Sample III. Symbols: experimental data (black dots), calculated diffraction pattern (red line), residuals of the refinement (blue solid line), and peak positions of t-Se (purple vertical bar).

图 10 非晶硒的晶化起始温度Tx和晶化产物t-Se的熔化温度Tm随压力的变化关系, 其中, Ye和Lu[24]的数据测量实验的升温速率为8.7 K/min, He等[23]的数据测量实验的升温速率为8.6 K/min, 内插图清楚地显示了400—560 K温度范围内的关系曲线

Figure 10. Onset crystallization temperature (Tx) of a-Se and the melting temperature (Tm) of a-Se crystallization product i.e. t-Se as a function of the applied pressure. Data from Ye and Lu[24] was measured under the heating rate of 8.7 K/min. Data from He et al.[23] was measured under the heating rate of 8.6 K/min. The pressure and temperature conditions in this work are shown. The inset figure displays clearly the data in the range of 400–560 K.

表 1 Sample A1, Sample B1, Sample C1, Sample I, Sample II, Sample III的XRD谱中部分衍射晶面的信息, 包括衍射峰的相对强度I、晶面间距d、半峰宽FWHM

Table 1. Diffraction peaks parameters of Sample A1, Sample B1, Sample C1, Sample I, Sample II, Sample III, including the relative peak intensity (I), interplanar distance (d) and peak width at half-height (FWHM).

(100) (101) (110) (012) (111) I/% d/nm FWHM/(°) I/% d/nm FWHM/(°) I/% d/nm FWHM/(°) I/% d/nm FWHM/(°) I/% d/nm FWHM/(°) μm powder 43.7 3.795 0.446 100 3.013 0.353 13.9 2.187 0.593 30.4 2.074 0.453 19.2 2.002 0.592 Sample A1 25.3 3.793 0.316 100 3.010 0.187 8.6 2.186 0.474 15.3 2.077 0.292 13.4 2.001 0.395 Sample B1 24.8 3.779 0.251 100 3.004 0.166 7.7 2.182 0.301 24.6 2.072 0.215 9.5 1.997 0.323 Sample C1 34.7 3.785 0.231 100 3.010 0.182 10.5 2.184 0.292 38.5 2.075 0.243 13.5 1.999 0.323 Sample I 39.5 3.785 0.290 100 3.010 0.218 11.6 2.185 0.447 20.7 2.077 0.349 14.1 2.000 0.435 Sample II 51.7 3.789 0.324 100 3.007 0.238 10.4 2.185 0.521 19.7 2.077 0.349 12.2 1.999 0.489 Sample III 33.2 3.789 0.326 100 3.007 0.244 10.0 2.183 0.500 24.4 2.078 0.376 13.3 2.000 0.487 -

[1] Huang H Y, Abbaszadeh S 2020 IEEE Sens. J. 20 1694

Google Scholar

Google Scholar

[2] Matsuura M, Suzuki K 1979 J. Mater. Sci. 14 395

Google Scholar

Google Scholar

[3] Fan G J, Guo F Q, Hu Z Q, Quan M X, Lu K 1997 Phys. Rev. B 55 11010

Google Scholar

Google Scholar

[4] 邵胜子, 陈泽祥 2011 电子元器件应用 8 28

Google Scholar

Google Scholar

Shao Z S, Chen Z X 2011 Electr. Comp. Devic. Appl. 8 28

Google Scholar

Google Scholar

[5] Sun H, Zhu X H, Yang D Y, Wangyang P H, Gao X Y, Tian H B 2016 Mater. Lett. 183 94

Google Scholar

Google Scholar

[6] Singh A K, Kennedy G C 1975 J. Appl. Phys. 46 3861

Google Scholar

Google Scholar

[7] Mohan M, Singh A K 1993 Philos. Mag. B 67 705

Google Scholar

Google Scholar

[8] Zhang H Y, Hu Z Q, Lu K 1995 Nanostruct. Mater. 5 41

Google Scholar

Google Scholar

[9] Tonchev D, Mani H, Belev G, Kostova I, Kasap S 2014 18th International School on Condensed Matter Physics-Challenges of Nanoscale Science-Theory, Materials, Applications Varna, Bulgaria, September 1−6, 2014 p012007

[10] Abbaszadeh S, Rom K, Bubon O 2012 J. Non-Cryst. Solids 358 2389

Google Scholar

Google Scholar

[11] Yu T Y, Pan F M, Chang C Y, Lin J S, Huang W H 2015 J. Appl. Phys. 118 044509

Google Scholar

Google Scholar

[12] Ohkawa Y J, Miyakawa K, Matsubara T, Kikuchi K, Tanioka K, Kubota M, Egami N, Kobayashi A 2011 Phys. Status Solidi C 8 2818

Google Scholar

Google Scholar

[13] Mao H K, Chen B, Chen J, Li K, Lin J F, Yang W, Zheng H 2016 Matter. Radiat. Extremes 1 59

Google Scholar

Google Scholar

[14] Degtyareva O, Hernández E R, Serrano J, Somayazulu M, Mao H K, Gregoryanz E, Hemley R J 2007 J. Chem. Phys. 126 084503

Google Scholar

Google Scholar

[15] Li X, Huang X L, Wang X, Liu M K, Wu G, Huang Y P, He X, Li F F, Zhou Q, Liu B B, Cui T 2018 Phys. Chem. Chem. Phys. 20 6116

Google Scholar

Google Scholar

[16] Bridgman P W 1941 Phys. Rev. 60 351

Google Scholar

Google Scholar

[17] McCann D R, Cartz L 1972 J. Chem. Phys. 56 2552

Google Scholar

Google Scholar

[18] Liu H Z, Wang L H, Xiao X H, Carlo F D, Feng J, Mao H K, Hemley R J 2008 PNAS 105 13229

Google Scholar

Google Scholar

[19] He Z, Wang Z G, Zhu H Y, Liu X R, Peng J P, Hong S M 2014 Appl. Phys. Lett. 105 011901

Google Scholar

Google Scholar

[20] Hong S M, Chen L Y, Liu X R, Wu X H, Su L 2005 Rev. Sci. Instrum. 76 053905

Google Scholar

Google Scholar

[21] 刘秀茹, 王明友, 张豆豆, 张晨然, 何竹, 陈丽英, 沈如, 洪时明 2014 高压 28 385

Google Scholar

Google Scholar

Liu X R, Wang M Y, Zhang D D, Zhang C R, He Z, Chen L Y, Shen R, Hong S M 2014 Chin. J. High Pressure Phys. 28 385

Google Scholar

Google Scholar

[22] Hu Y, Su L, Liu X R, Sun Z Y, Lv S J, Yuan C S, Jia R, Shen R, Hong S M 2010 Chin. Phys. Lett. 27 038101

Google Scholar

Google Scholar

[23] He Z, Liu X R, Zhang D D, Zhang L J, Hong S M 2014 Solid State Commun. 197 30

Google Scholar

Google Scholar

[24] Ye F, Lu K 1998 Acta Mater. 46 5965

Google Scholar

Google Scholar

[25] Dai R C, Luo L B, Zhang Z M, Ding Z J 2011 Mater. Res. Bull. 46 350

Google Scholar

Google Scholar

[26] Akahama Y, Kobayashi M, Kawamura M H 1993 Phys. Rev. B 47 20

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8486

- PDF Downloads: 93

- Cited By: 0

DownLoad:

DownLoad: