-

α-PbO2相TiO2高压相具有适宜的带隙能和可见光范围的光催化能力, 是一种适用于可见光、高效且环保的光催化材料. 本文使用金刚石对顶压砧对锐钛矿纳米球进行加压-卸压处理得到了α-PbO2相TiO2高压相. 利用透射电子显微镜对比初始样品和卸压样品, 观察结果表明晶粒发生了明显形变, 高分辨图显示其晶粒中存在大量[100]方向层错和形变孪晶, 其中亚微米级晶粒中形成了透镜形片层结构的形变孪晶带; 纳米级晶粒中形成了扇形多重形变孪晶. 研究表明高压下锐钛矿TiO2可以发生明显的形变, 其形变的微观机制与金属类似, 主要为形变孪晶和层错滑移, 形变孪晶的形成存在明显的尺寸效应. 这些结果为TiO2高压相变的尺寸效应研究提供了一个新的切入点, 同时还为制备孪晶α-PbO2相TiO2高压相提供了方法.

-

关键词:

- 高压 /

- α-PbO2相TiO2 /

- 形变孪晶 /

- 尺寸效应

The high-pressure α-PbO2 phase of TiO2 has suitable band gap and photocatalytic capability in the visible light range, which is an environmentally friendly and efficient photocatalytic material. In this work, α-PbO2 phase of TiO2 is obtained by the pressure-relief treatment of anatase nanospheres through using diamond anvil cell, and transmission electron microscope (TEM) observation shows the obvious deformation of TiO2 nanospheres. High-esolution TEM shows that there are a large number of stacking faults along the [100] direction and deformation twins in the grain. Specifically, the deformation twin band with lens lamellar structure is formed in the submicron grain. The fan-shaped multiple deformation twins are formed in the nanocrystalline grains. This study shows that anatase TiO2 can be deformed under high pressure, and its micro mechanism of deformation is similar to metal’s, mainly including deformation twins and stacking fault slip. There is obvious size effect in the formation of deformation twins. These results provide a new breakthrough point for the study of the size effect of high-pressure phase transformation of TiO2, and also point out an experimental direction for preparing the twin high-pressure α-PbO2 phase.-

Keywords:

- high pressure /

- α-PbO2 phase TiO2 /

- deformation twin /

- size effect

[1] Yang H G, Sun C H, Qiao S Z, Zou J, Liu G, Smith S C, Chen H M, Lu G Q 2008 Nature 453 638

Google Scholar

Google Scholar

[2] Etgar L, Zhang W, Gabriel S, Hickey S G, Nazeeruddin M K, Eychmuller A, Liu B, Gratzel M 2012 Adv. Mater. 24 2202

Google Scholar

Google Scholar

[3] Asahi R, Morikawa T, Ohwaki T, Aoki K, Taga Y 2001 Science 293 269

Google Scholar

Google Scholar

[4] Chen X, Mao S S 2007 Chem. Rev. 107 2891

Google Scholar

Google Scholar

[5] Chen X B, Liu L, Huang F Q 2015 Chem. Rev. 44 1861

Google Scholar

Google Scholar

[6] Dachille F, Dimons P Y, Roy R 1968 Am. Mineral. 53 1929

[7] Ohsaka T, Yamaoka S, Shimomura O 1979 Solid State Commun. 30 345

Google Scholar

Google Scholar

[8] Lagarec K, Desgreniers S 1995 Solid State Commun. 94 519

Google Scholar

Google Scholar

[9] Arlt T, Bermejo M, Blanco M A, Gerward L, Jiang J, Olsen J S, Recio J M 2000 Phys. Rev. B 61 14414

Google Scholar

Google Scholar

[10] Simons P Y, Dachille F 1967 Acta Crystallogr. 23 334

Google Scholar

Google Scholar

[11] Jamieson J C, Olinger B 1968 Science 161 893

Google Scholar

Google Scholar

[12] Hearne G R, Zhao J, Dawe A M, Pischedda V, Maaza, Nieuwoudt M K, Kibasomba P, Nemraoui O, Comins J D, Witcomb M J 2004 Phys. Rev. B 70 134102

Google Scholar

Google Scholar

[13] Swamy V, Kuznetsov A, Dubrovinsky L S, Caruso R A, Shchukin D G, Muddle B C 2005 Phys. Rev. B 71 184302

Google Scholar

Google Scholar

[14] Pischedda V, Hearne G R, Dawe A M, Lowther J E 2006 Phys. Rev. Lett. 96 035509

Google Scholar

Google Scholar

[15] Swamy V, Kuznetsov A, Dubrovinsky L S, McMillan P F, Prakapenka V B, Shen G, Muddle B C 2006 Phys. Rev. Lett. 96 135702

Google Scholar

Google Scholar

[16] Swamy V, Kuznetsov A Y, Dubrovinsky L S, Kurnosov A, Prakapenka V B 2009 Phys. Rev. Lett. 103 075505

Google Scholar

Google Scholar

[17] Wang Y J, Zhao Y S, Zhang J Z, Xu H W, Wang L P, Luo S N, Daemen L L 2008 J. Phys. Condens. Mater. 20 125224

Google Scholar

Google Scholar

[18] Sekiya T, Ohta S, Kamei S, Hanakawa M, Kurita S 2001 J. Phys. Chem. Solids 62 717

Google Scholar

Google Scholar

[19] Li Q J, Cheng B Y, Yang X, Liu R, Liu B, Liu J, Chen Z Q, Zou B, Cui T, Liu B B 2013 J. Phys. Chem. C 117 8516

Google Scholar

Google Scholar

[20] Huang Y W, Chen F J, Li X, Yuan Y, Dong H N, Samanta S, Yu Z H, Rahman S, Zhang J, Yang K, Yan S, Wang L 2016 J. Appl. Phys. 119 215903

Google Scholar

Google Scholar

[21] Sun Q B, Huston L Q, Frankcombe T J, Bradby J E, Lu T, Yu D H, Zhou C, Fu Z X, Liu Y 2017 Cryst. Growth Des. 17 2529

Google Scholar

Google Scholar

[22] Razavi-Khosroshahi H, Edalati K, Arita M, Horita Z, Fuji M 2016 Scripta Materialia 124 59

Google Scholar

Google Scholar

[23] Razavi-Khosroshahi H, Edalati K, Hirayama M, Emami H, Arita M, Yamauchi M, Hagiwara H, Ida S, Ishihara T, Akiba E, Horita Z, Fuji M 2016 ACS Catal. 6 5103

Google Scholar

Google Scholar

[24] Chao L, Zhang X, Duan G, Jian T, Liu Q 2014 J. Mater. Sci. Technol. 30 41

Google Scholar

Google Scholar

[25] Meyers M A, Andrade U, Chokshi A H T 1995 Metal Mater Trans 26 2881

Google Scholar

Google Scholar

[26] Song M, Zhou G, Lu N, Lee J, Nakouzi E, Wang H, Li D S 2020 Science 367 40

Google Scholar

Google Scholar

[27] Liao X Z, Zhao Y H, Srinivasan S G, Zhu Y T, Valiev R Z, Gunderov D V 2004 Appl. Phys. Lett. 84 592

Google Scholar

Google Scholar

[28] Zhu Y T, Liao X Z, Valiev R Z 2005 Appl. Phys. Lett. 86 103112

Google Scholar

Google Scholar

[29] Tian Y, Xu B, Yu D, Ma Y, Wang Y, Jiang Y, Hu W, Tang C, Gao Y, Luo K, Zhao Z, Wang L M, Wen B, He J, Liu Z 2013 Nature 493 385

Google Scholar

Google Scholar

[30] Huang Q, Yu D, Xu B, Hu W, Ma Y, Wang Y, Zhao Z, Wen B, He J, Liu Z, Tian Y 2014 Nature 510 250

Google Scholar

Google Scholar

[31] Hall E O 1951 Proc. Phys. Soc. London B 64 747

Google Scholar

Google Scholar

[32] Petch N J 1953 J. Iron Steel Ins. 174 25

[33] Tse J S, Klug D D, Gao F M 2006 Phys. Rev. B 73 140102

Google Scholar

Google Scholar

[34] Halperin W P 1986 Rev. Mod. Phys. 58 533

Google Scholar

Google Scholar

[35] Gerberich W W, Mook W M, Perrey C R, Carter C B, Baskes M I, Mukherjee R, Gidwani A, Heberlein J, Mc- Murry P H, Girshick S L 2003 J. Mech. Phys. Solids. 51 979

Google Scholar

Google Scholar

[36] Xu J, Teng F, Xu C Y, Yang Y, Yang L M, Kan Y D 2015 J. Phys. Chem. C 119 13011

Google Scholar

Google Scholar

-

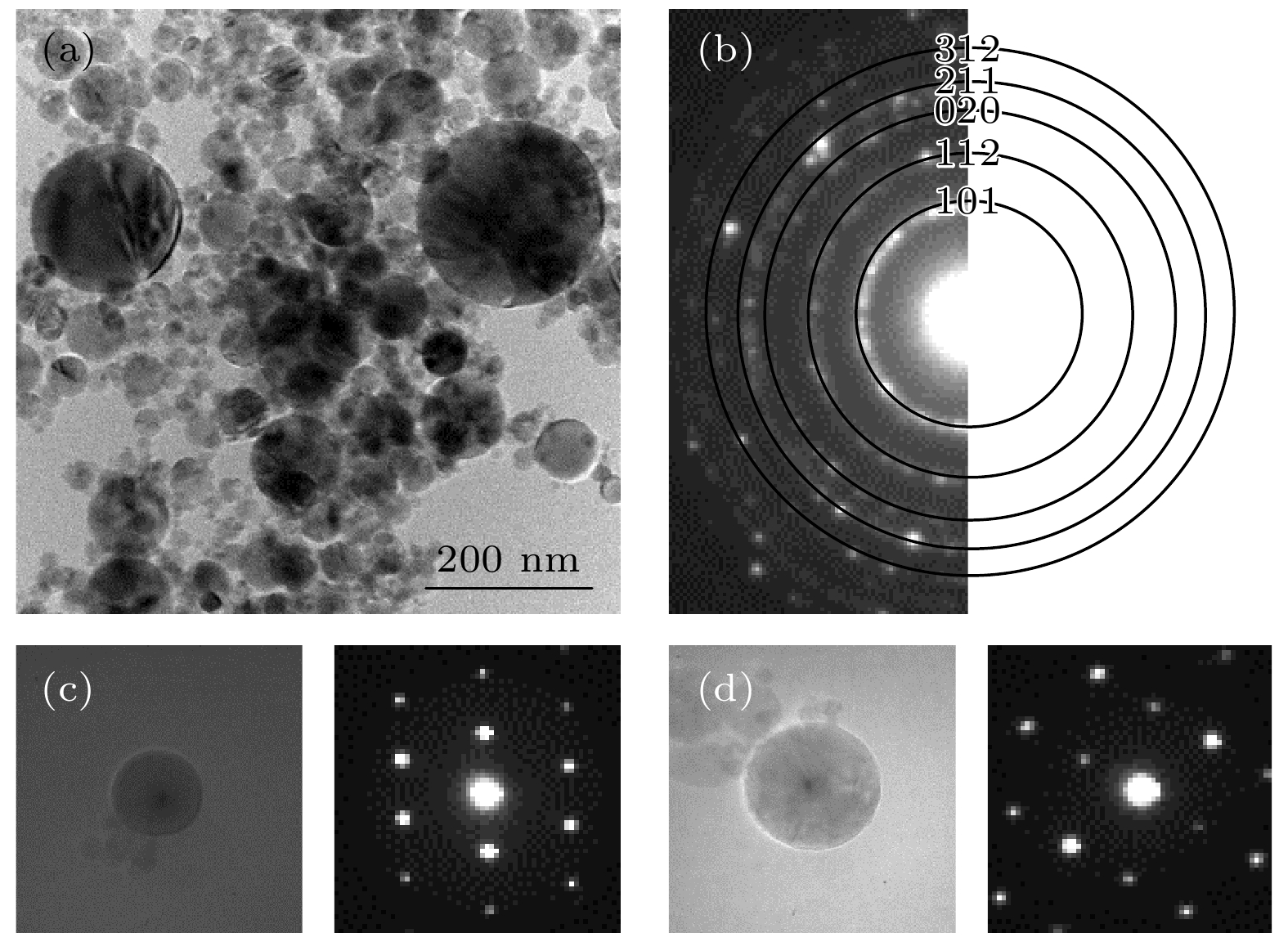

图 1 (a) 原始TiO2样品TEM明场像; (b) 原始TiO2样品SAED环; (c) 原始样品单晶球的TEM明场像和[010]方向SAED花样, 单晶球直径72 nm; (d) 原始样品单晶球的TEM明场像和[131]方向SAED花样, 单晶球直径63 nm

Fig. 1. (a) TEM bright field image of the TiO2 sample uncompressed; (b) SAED patterns of the TiO2 sample uncompressed; (c) TEM bright field image and SAED patterns are acquired from the single-crystalline along the [110] zone axis, the diameter dimension of single-crystalline is 72 nm; (d) TEM bright field image and SAED patterns are acquired from the single-crystalline along the [131] zone axis, the diameter dimension of single-crystalline is 63 nm.

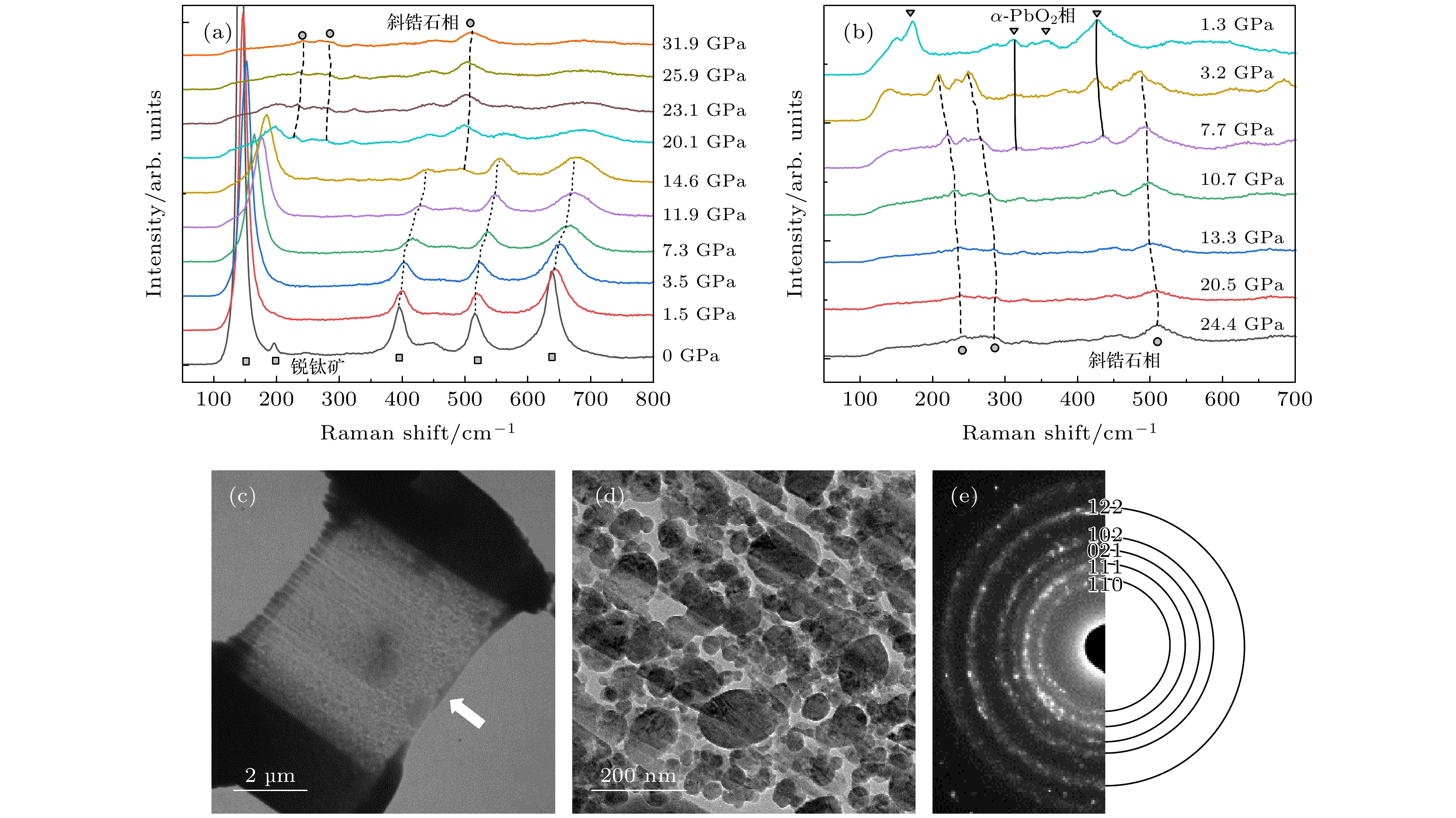

图 2 (a) TiO2加压过程拉曼光谱; (b) TiO2卸压过程拉曼光谱; (c) TEM截面样品低倍形貌, 加压方向如白色箭头所示; (d) 卸压TiO2样品TEM明场像; (e) 卸压TiO2样品SAED环

Fig. 2. (a) Raman spectra for TiO2 upon compression; (b) Raman spectra for TiO2 upon decompression; (c) TEM image of section samples, the pressurization direction is shown by the white arrow; (d) TEM bright field image of the TiO2 sample decompressed; (e) SAED patterns of the TiO2 sample decompressed.

图 3 (a) 1#晶粒[010]方向TEM明场像, 6条孪晶界TB1—TB6位置如箭头所示; (b) 1#晶粒TB2的HRTEM; (c) 1#晶粒内TB2的FFT; (d) 2#晶粒[111]方向TEM明场像, 2条孪晶界TB1和TB2位置如箭头所示; (e) 2#晶粒内TB2的HRTEM; (f) 2#晶粒TB2的FFT; (g) 3#晶粒[111]方向TEM明场像, 1条孪晶界TB位置如箭头所示; (h) 3#晶粒TB的HRTEM; (i) 3#晶粒内TB的FFT

Fig. 3. (a) TEM bright field image of grain 1 along the [010] zone axis, the positions of six twin boundaries TB1—TB6 are shown by the arrow; (b) HRTEM of TB2 in grain 1; (c) FFT of TB2 in grain 1; (d) TEM bright field image of grain 2 along the [111] zone axis, the positions of two twin boundaries TB1 and TB2 are shown by the arrow; (e) HRTEM of TB2 in grain 2; (f) FFT of TB2 in grain 2; (g) TEM bright field image of grain 3 along the [111] zone axis, the positions of twin boundary TB is shown by the arrow; (h) HRTEM of TB in grain 3; (i) FFT of TB in grain 3.

图 4 (a) 4#晶粒TEM明场像, 晶界GB1, GB2和孪晶界TB1, TB2如图中箭头所示; (b) 4#晶粒TB1和TB2 [111]方向HRTEM; (c) 4#晶粒TB1处FFT; (d) 4#晶粒内TB2处FFT; (e) 5#晶粒TEM明场像, 2条晶界GB1和GB2如图中白色箭头所示, (f) 5#晶粒GB1和GB2交界处[111]方向HRTEM; (g) 5#晶粒内[121]方向有序层错FFT; (h) 5#晶粒内[211]方向有序层错FFT

Fig. 4. (a) TEM bright field image of grain 4, the positions of two grain boundaries GB1&GB2 and two twin boundaries TB1&TB2 are shown by the arrow; (b) HRTEM of TB1&TB2 from grain 4 along the [111] zone axis; (c) FFT of TB1 in grain 4; (d) FFT of TB2 in grain 4; (e) TEM bright field image of grain 5, positions of two grain boundaries GB1&GB2 are shown by the arrow; (f) HRTEM of GB1&GB2 from grain 5 along the [111] zone axis; (g) FFT of [121] periodic stacking fault in grain 5; (h) FFT of [211] periodic stacking fault in grain 5.

图 5 (a) 6#晶粒TEM明场像, 2条晶界位置如白色箭头所示; (b) 6#晶粒内[100]方向层错的HRTEM; (c) 7#晶粒TEM明场像, 2条晶界位置白色箭头所示; (d) 7#晶粒内[100]方向层错的HRTEM

Fig. 5. (a) TEM bright field image of grain 6, the positions of two grain boundaries GB1&GB2 are shown by the arrow; (b) HRTEM of stacking fault along the [100] zone axis in grain 6; (c) TEM bright field image of grain 7, the positions of two grain boundaries GB1&GB2 are shown by the arrow; (d) HRTEM of stacking fault along the [100] zone axis in grain 7.

-

[1] Yang H G, Sun C H, Qiao S Z, Zou J, Liu G, Smith S C, Chen H M, Lu G Q 2008 Nature 453 638

Google Scholar

Google Scholar

[2] Etgar L, Zhang W, Gabriel S, Hickey S G, Nazeeruddin M K, Eychmuller A, Liu B, Gratzel M 2012 Adv. Mater. 24 2202

Google Scholar

Google Scholar

[3] Asahi R, Morikawa T, Ohwaki T, Aoki K, Taga Y 2001 Science 293 269

Google Scholar

Google Scholar

[4] Chen X, Mao S S 2007 Chem. Rev. 107 2891

Google Scholar

Google Scholar

[5] Chen X B, Liu L, Huang F Q 2015 Chem. Rev. 44 1861

Google Scholar

Google Scholar

[6] Dachille F, Dimons P Y, Roy R 1968 Am. Mineral. 53 1929

[7] Ohsaka T, Yamaoka S, Shimomura O 1979 Solid State Commun. 30 345

Google Scholar

Google Scholar

[8] Lagarec K, Desgreniers S 1995 Solid State Commun. 94 519

Google Scholar

Google Scholar

[9] Arlt T, Bermejo M, Blanco M A, Gerward L, Jiang J, Olsen J S, Recio J M 2000 Phys. Rev. B 61 14414

Google Scholar

Google Scholar

[10] Simons P Y, Dachille F 1967 Acta Crystallogr. 23 334

Google Scholar

Google Scholar

[11] Jamieson J C, Olinger B 1968 Science 161 893

Google Scholar

Google Scholar

[12] Hearne G R, Zhao J, Dawe A M, Pischedda V, Maaza, Nieuwoudt M K, Kibasomba P, Nemraoui O, Comins J D, Witcomb M J 2004 Phys. Rev. B 70 134102

Google Scholar

Google Scholar

[13] Swamy V, Kuznetsov A, Dubrovinsky L S, Caruso R A, Shchukin D G, Muddle B C 2005 Phys. Rev. B 71 184302

Google Scholar

Google Scholar

[14] Pischedda V, Hearne G R, Dawe A M, Lowther J E 2006 Phys. Rev. Lett. 96 035509

Google Scholar

Google Scholar

[15] Swamy V, Kuznetsov A, Dubrovinsky L S, McMillan P F, Prakapenka V B, Shen G, Muddle B C 2006 Phys. Rev. Lett. 96 135702

Google Scholar

Google Scholar

[16] Swamy V, Kuznetsov A Y, Dubrovinsky L S, Kurnosov A, Prakapenka V B 2009 Phys. Rev. Lett. 103 075505

Google Scholar

Google Scholar

[17] Wang Y J, Zhao Y S, Zhang J Z, Xu H W, Wang L P, Luo S N, Daemen L L 2008 J. Phys. Condens. Mater. 20 125224

Google Scholar

Google Scholar

[18] Sekiya T, Ohta S, Kamei S, Hanakawa M, Kurita S 2001 J. Phys. Chem. Solids 62 717

Google Scholar

Google Scholar

[19] Li Q J, Cheng B Y, Yang X, Liu R, Liu B, Liu J, Chen Z Q, Zou B, Cui T, Liu B B 2013 J. Phys. Chem. C 117 8516

Google Scholar

Google Scholar

[20] Huang Y W, Chen F J, Li X, Yuan Y, Dong H N, Samanta S, Yu Z H, Rahman S, Zhang J, Yang K, Yan S, Wang L 2016 J. Appl. Phys. 119 215903

Google Scholar

Google Scholar

[21] Sun Q B, Huston L Q, Frankcombe T J, Bradby J E, Lu T, Yu D H, Zhou C, Fu Z X, Liu Y 2017 Cryst. Growth Des. 17 2529

Google Scholar

Google Scholar

[22] Razavi-Khosroshahi H, Edalati K, Arita M, Horita Z, Fuji M 2016 Scripta Materialia 124 59

Google Scholar

Google Scholar

[23] Razavi-Khosroshahi H, Edalati K, Hirayama M, Emami H, Arita M, Yamauchi M, Hagiwara H, Ida S, Ishihara T, Akiba E, Horita Z, Fuji M 2016 ACS Catal. 6 5103

Google Scholar

Google Scholar

[24] Chao L, Zhang X, Duan G, Jian T, Liu Q 2014 J. Mater. Sci. Technol. 30 41

Google Scholar

Google Scholar

[25] Meyers M A, Andrade U, Chokshi A H T 1995 Metal Mater Trans 26 2881

Google Scholar

Google Scholar

[26] Song M, Zhou G, Lu N, Lee J, Nakouzi E, Wang H, Li D S 2020 Science 367 40

Google Scholar

Google Scholar

[27] Liao X Z, Zhao Y H, Srinivasan S G, Zhu Y T, Valiev R Z, Gunderov D V 2004 Appl. Phys. Lett. 84 592

Google Scholar

Google Scholar

[28] Zhu Y T, Liao X Z, Valiev R Z 2005 Appl. Phys. Lett. 86 103112

Google Scholar

Google Scholar

[29] Tian Y, Xu B, Yu D, Ma Y, Wang Y, Jiang Y, Hu W, Tang C, Gao Y, Luo K, Zhao Z, Wang L M, Wen B, He J, Liu Z 2013 Nature 493 385

Google Scholar

Google Scholar

[30] Huang Q, Yu D, Xu B, Hu W, Ma Y, Wang Y, Zhao Z, Wen B, He J, Liu Z, Tian Y 2014 Nature 510 250

Google Scholar

Google Scholar

[31] Hall E O 1951 Proc. Phys. Soc. London B 64 747

Google Scholar

Google Scholar

[32] Petch N J 1953 J. Iron Steel Ins. 174 25

[33] Tse J S, Klug D D, Gao F M 2006 Phys. Rev. B 73 140102

Google Scholar

Google Scholar

[34] Halperin W P 1986 Rev. Mod. Phys. 58 533

Google Scholar

Google Scholar

[35] Gerberich W W, Mook W M, Perrey C R, Carter C B, Baskes M I, Mukherjee R, Gidwani A, Heberlein J, Mc- Murry P H, Girshick S L 2003 J. Mech. Phys. Solids. 51 979

Google Scholar

Google Scholar

[36] Xu J, Teng F, Xu C Y, Yang Y, Yang L M, Kan Y D 2015 J. Phys. Chem. C 119 13011

Google Scholar

Google Scholar

计量

- 文章访问数: 7027

- PDF下载量: 214

- 被引次数: 0

下载:

下载: