-

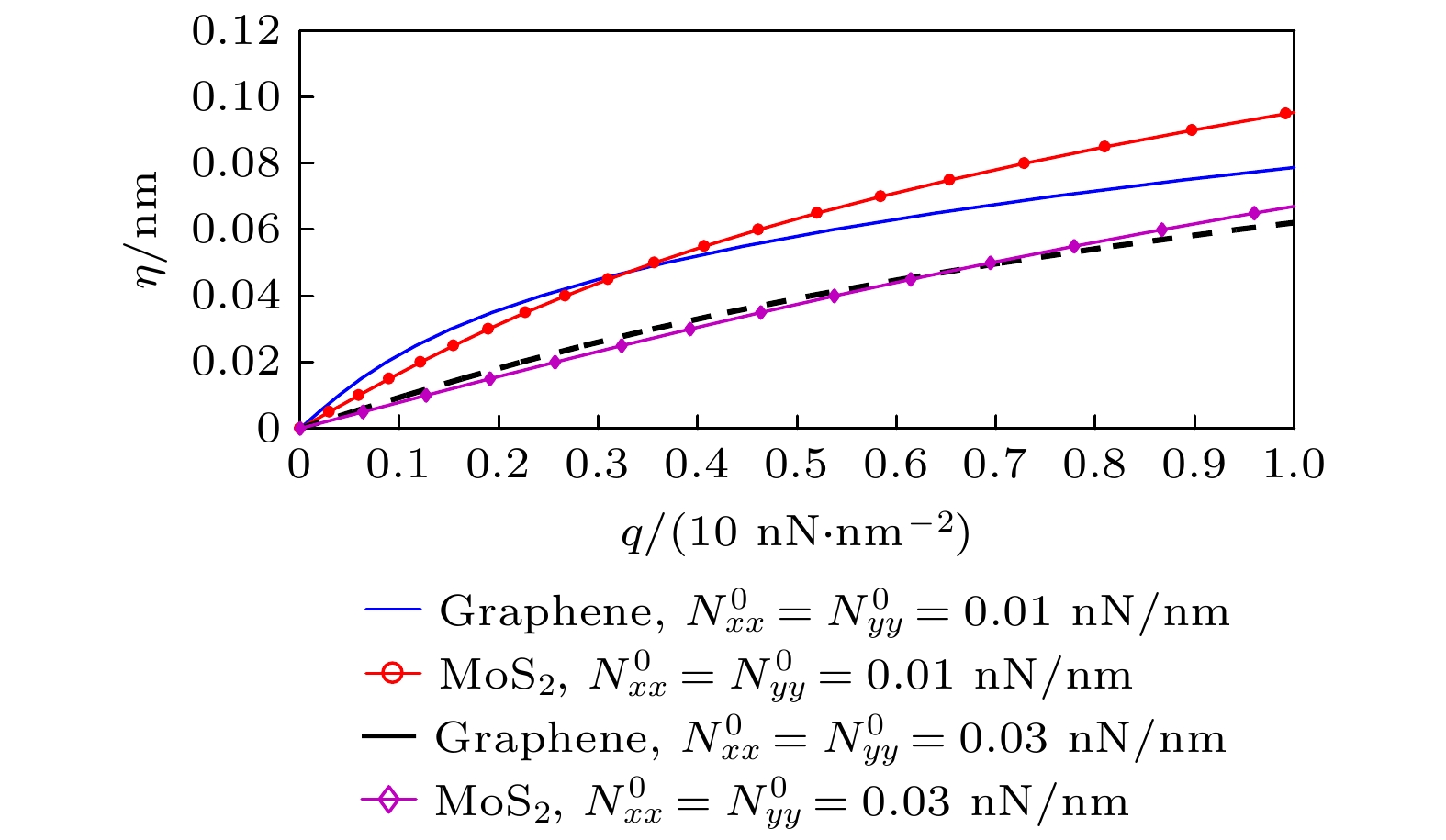

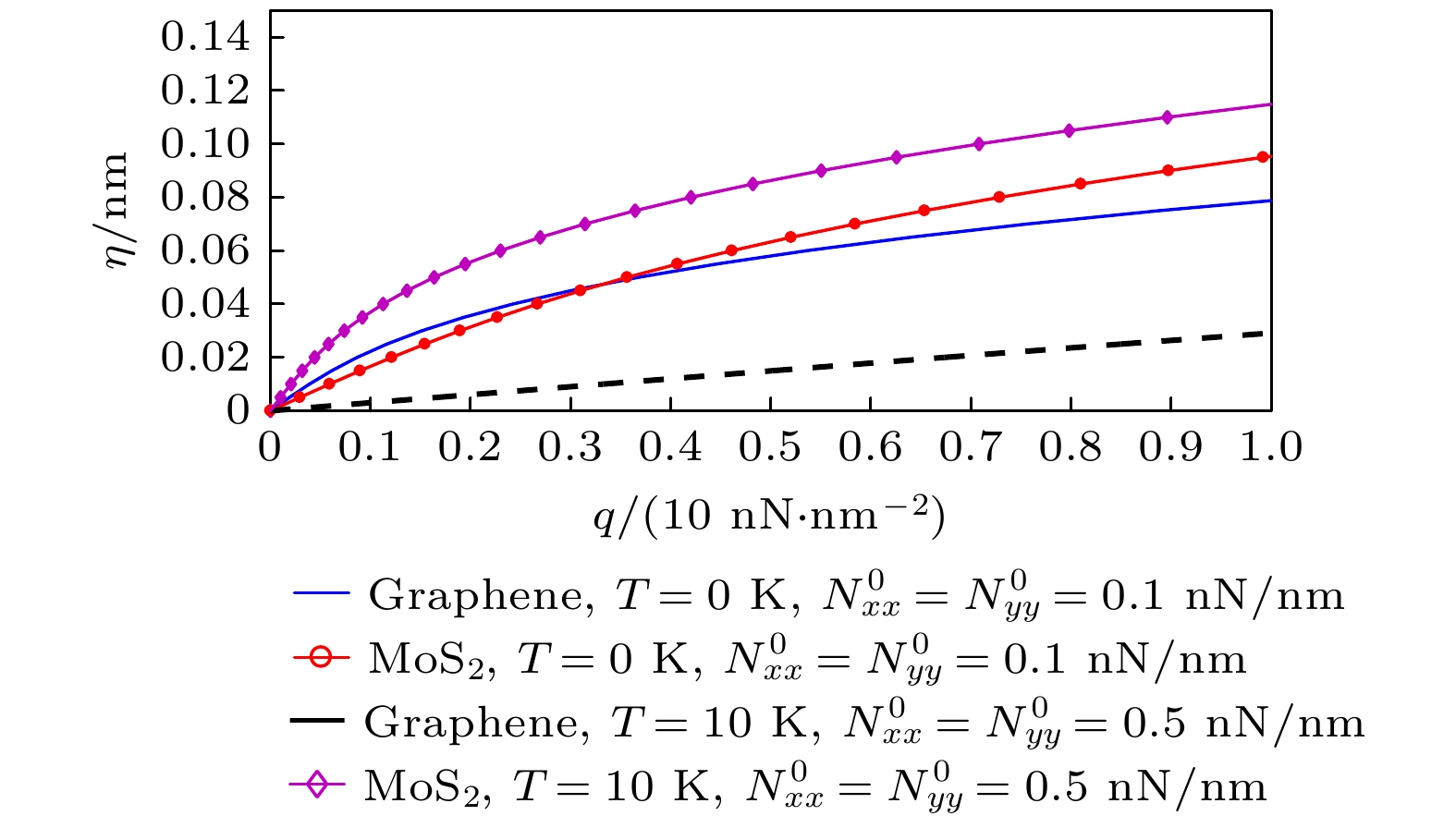

The single-layered molybdenum disulfide (

${\rm{Mo}}{{\rm{S}}_2}$ ) is a two-dimensional nanomaterial with wide potential applications due to its excellent electrical and frictional properties. However, there have been few investigations of its mechanical properties up to now, and researchers have not paid attention to its nonlinear mechanical properties under the multi-fields co-existing environment. The present paper proposed a nonlinear plate theory to model the effect of finite temperatures on the single-layered${\rm{Mo}}{{\rm{S}}_2}$ . It is similar to the classical plate theory that both the in-plane stretching deformation and the out-of-plane bending deformation are taken into account in the new theory. However, the new theory consists of two independent in-plane mechanical parameters and two independent out-of-plane mechanical parameters. Neither of the two out-of-plane mechanical parameters in the new theory, which describe the resistance of${\rm{Mo}}{{\rm{S}}_2}$ to the bending and the twisting, depends on the structure’s thickness. This reasonably avoids the Yakobson paradox: uncertainty stemming from the thickness of the single-layered two-dimensional structures will lead to the uncertainty of the structure’s out-of-plane stiffness. The new nonlinear plate equations are then solved approximately through the Galerkin method for the thermoelastic mechanical problems of the graphene and${\rm{Mo}}{{\rm{S}}_2}$ . The approximate analytic solutions clearly reveal the effects of temperature and structure stiffness on the deformations. Through comparing the results of two materials under combined temperature and load, it is found, for the immovable boundaries, that (1) the thermal stress, which is induced by the finite temperature, reduces the stiffness of${\rm{Mo}}{{\rm{S}}_2}$ , but increases the stiffness of graphene; (2) the significant difference between two materials is that the graphene’s in-plane stiffness is greater than the${\rm{Mo}}{{\rm{S}}_2}$ ’s, but the graphene’s out-of-plane stiffness is less than the${\rm{Mo}}{{\rm{S}}_2}$ ’s. Because the${\rm{Mo}}{{\rm{S}}_2}$ ’s bending stiffness is much greater than graphene’s, the graphene’s deformation is greater than MoS2’s with a small load. However, the graphene’s deformation is less than the${\rm{Mo}}{{\rm{S}}_2}$ ’s with a large load since the graphene’s in-plane stretching stiffness is greater than the MoS2’s. The present research shows that the applied axial force and ambient temperature can conveniently control the mechanical properties of single-layered two-dimensional nanostructures. The new theory provides the basis for the intensive research of the thermoelastic mechanical problems of${\rm{Mo}}{{\rm{S}}_2}$ , and one can easily apply the theory to other single-layered two-dimensional nanostructures.-

Keywords:

- single-layered MoS2 /

- graphene /

- thermal stress /

- nonlinear plate theory

[1] Tan C, Cao X, Wu X J, He Q, Yang J, Zhang X, Chen J, Zhao W, Han S, Nam G, Sindoro M, Zhang H 2017 Chem. Rev. 117 6225

Google Scholar

Google Scholar

[2] Pumera M, Sofer Z 2017 Adv. Mater. 29 1605299

Google Scholar

Google Scholar

[3] 王靖慧, 焦丽颖 2017 科学通报 62 2158

Google Scholar

Google Scholar

Wang J H, Jiao L Y 2017 Chin. Sci. Bull. 62 2158

Google Scholar

Google Scholar

[4] 王慧, 徐萌, 郑仁奎 2020 69 017301

Google Scholar

Google Scholar

Wang H, Xu M, Zheng R K 2020 Acta Phys. Sin. 69 017301

Google Scholar

Google Scholar

[5] Song X, Hu J, Zeng H 2013 J. Mater. Chem. C 1 2952

Google Scholar

Google Scholar

[6] Zhao J, Liu H, Yu Z, Quhe R, Zhou S, Wang Y, Liu C C, Zhong H, Han N, Lu J, Yao Y, Wu K 2016 Prog. Mater. Sci. 83 24

Google Scholar

Google Scholar

[7] 顾品超, 张楷亮, 冯玉林, 王芳, 苗银萍, 韩叶梅, 张韩霞 2016 65 018102

Google Scholar

Google Scholar

Gu P C, Zhang K L, Feng Y L, Wang F, Miao Y P, Han Y M, Zhang H X 2016 Acta Phys. Sin. 65 018102

Google Scholar

Google Scholar

[8] 魏争, 王琴琴, 郭玉拓, 李佳蔚, 时东霞, 张广宇 2018 67 128103

Google Scholar

Google Scholar

Wei Z, Wang Q Q, Guo Y T, Li J W, Shi D X, Zhang G Y 2018 Acta Phys. Sin. 67 128103

Google Scholar

Google Scholar

[9] Hong Y, Liu Z, Wang L, Zhou T, Ma W, Xu C, Feng S, Chen L, Chen M, Sun D, Sun D, Chen X, Chen H, Ren W 2020 Science 369 670

Google Scholar

Google Scholar

[10] 黄坤, 殷雅俊, 吴继业 2014 63 156201

Google Scholar

Google Scholar

Huang K, Yin Y J, Wu J Y 2014 Acta Phys. Sin. 63 156201

Google Scholar

Google Scholar

[11] 黄坤, 殷雅俊, 屈本宁, 吴继业 2014 力学学报 46 905

Google Scholar

Google Scholar

Huang K, Yin Y J, Qu B N, Wu J Y 2014 Chin. J. Theoret. Appl. Mechan. 46 905

Google Scholar

Google Scholar

[12] Cao K, Feng S, Han Y, Gao L, Lu Y 2020 Nat. Commun. 11 284

Google Scholar

Google Scholar

[13] Li X, Zhu H 2015 J. Materiomics 1 33

Google Scholar

Google Scholar

[14] Xiong S, Cao G 2016 Nanotechnology 27 105701

Google Scholar

Google Scholar

[15] Jiang J, Qi Z, Park H, Rabczuk T 2013 Nanotechnology 24 435705

Google Scholar

Google Scholar

[16] Late D, Shirodkar S, Waghmare U, Dravid V, Rao C 2014 Chemphyschem 15 1592

Google Scholar

Google Scholar

[17] Hu X, Yasaei P, Jokisaari J, Öğüt S, Salehi-Khojin A, Robert F, Klie R 2018 Phys. Rev. Lett. 120 055902

[18] Zhang R, Cao H, Jiang J 2020 Nanotechnology 31 405709

Google Scholar

Google Scholar

[19] Akinwande D, Brennan C, Bunch J, Egberts P, Felts J, Gao H, Huang R, Kim J, Li T, Li Y 2017 Extreme Mech. Lett. 23 42

[20] Wei Y, Yang R 2018 Natl. Sci. Rev. 6 324

[21] Chen S, Chrzan D C 2011 Phys. Rev. B 84 5409

[22] Jiang J, Wang B, Wang J 2015 J. Phys-Condens. Mat. 27 083001

Google Scholar

Google Scholar

[23] Zhou L, Cao G 2016 Phys. Chem. Chem. Phys. 18 1657

Google Scholar

Google Scholar

[24] Gao E, Xu Z 2015 J. Appl. Mech. 82 121012

Google Scholar

Google Scholar

[25] Audoly B, Pomeau Y 2010 Elasticity and Geometry: From Hair Curls to the Non-linear Response of Shells (New York: Oxford University Press) pp157-213

[26] Kudin K, Scuseria G, Yakobson B 2001 Phys. Rev. B 64 235406

Google Scholar

Google Scholar

[27] Landau L, Lifshitz E 1997 Theory of Elasticity 3rd (Oxford: Butterworth Heinemann) pp38−50

[28] O'NEILL B 2006 Elementary Differential Geometry (Singapore: Elsevier) pp364−376

[29] Eduard E, Krauthammer T 2001 Thin Plates and Shells: Theory, Analysis, and Applications (New York: Marcel Dekker) pp191−240

[30] 胡海昌 1981 弹性力学的变分原理及其应用 (北京: 科学出版社)pp322−342

Hu H 1981 Variational Principles of Theory of Elasticity with Applications (Beijing: Science Press) pp322−342 (in Chinese)

[31] Liu K, Yan Q, Chen M, Fan W, Sun Y, Suh J, Fu D, Lee S, Zhou J, Tongay S, Ji J, Neaton J, Wu J 2014 Nano Lett. 14 5097

Google Scholar

Google Scholar

[32] Cooper R C, Lee C, Marianetti C A, Wei X, Hone J, Kysar J W 2013 Phys. Rev. B 87 035423

Google Scholar

Google Scholar

[33] Xiong S, Cao G 2015 Nanotechnology 26 185705

Google Scholar

Google Scholar

[34] Luongo A, Egidio A 2005 Nonlinear. Dynam. 41 171

Google Scholar

Google Scholar

[35] Luongo A, D'Annibale F 2013 Int. J. Nonlin. Mech. 55 128

Google Scholar

Google Scholar

-

-

[1] Tan C, Cao X, Wu X J, He Q, Yang J, Zhang X, Chen J, Zhao W, Han S, Nam G, Sindoro M, Zhang H 2017 Chem. Rev. 117 6225

Google Scholar

Google Scholar

[2] Pumera M, Sofer Z 2017 Adv. Mater. 29 1605299

Google Scholar

Google Scholar

[3] 王靖慧, 焦丽颖 2017 科学通报 62 2158

Google Scholar

Google Scholar

Wang J H, Jiao L Y 2017 Chin. Sci. Bull. 62 2158

Google Scholar

Google Scholar

[4] 王慧, 徐萌, 郑仁奎 2020 69 017301

Google Scholar

Google Scholar

Wang H, Xu M, Zheng R K 2020 Acta Phys. Sin. 69 017301

Google Scholar

Google Scholar

[5] Song X, Hu J, Zeng H 2013 J. Mater. Chem. C 1 2952

Google Scholar

Google Scholar

[6] Zhao J, Liu H, Yu Z, Quhe R, Zhou S, Wang Y, Liu C C, Zhong H, Han N, Lu J, Yao Y, Wu K 2016 Prog. Mater. Sci. 83 24

Google Scholar

Google Scholar

[7] 顾品超, 张楷亮, 冯玉林, 王芳, 苗银萍, 韩叶梅, 张韩霞 2016 65 018102

Google Scholar

Google Scholar

Gu P C, Zhang K L, Feng Y L, Wang F, Miao Y P, Han Y M, Zhang H X 2016 Acta Phys. Sin. 65 018102

Google Scholar

Google Scholar

[8] 魏争, 王琴琴, 郭玉拓, 李佳蔚, 时东霞, 张广宇 2018 67 128103

Google Scholar

Google Scholar

Wei Z, Wang Q Q, Guo Y T, Li J W, Shi D X, Zhang G Y 2018 Acta Phys. Sin. 67 128103

Google Scholar

Google Scholar

[9] Hong Y, Liu Z, Wang L, Zhou T, Ma W, Xu C, Feng S, Chen L, Chen M, Sun D, Sun D, Chen X, Chen H, Ren W 2020 Science 369 670

Google Scholar

Google Scholar

[10] 黄坤, 殷雅俊, 吴继业 2014 63 156201

Google Scholar

Google Scholar

Huang K, Yin Y J, Wu J Y 2014 Acta Phys. Sin. 63 156201

Google Scholar

Google Scholar

[11] 黄坤, 殷雅俊, 屈本宁, 吴继业 2014 力学学报 46 905

Google Scholar

Google Scholar

Huang K, Yin Y J, Qu B N, Wu J Y 2014 Chin. J. Theoret. Appl. Mechan. 46 905

Google Scholar

Google Scholar

[12] Cao K, Feng S, Han Y, Gao L, Lu Y 2020 Nat. Commun. 11 284

Google Scholar

Google Scholar

[13] Li X, Zhu H 2015 J. Materiomics 1 33

Google Scholar

Google Scholar

[14] Xiong S, Cao G 2016 Nanotechnology 27 105701

Google Scholar

Google Scholar

[15] Jiang J, Qi Z, Park H, Rabczuk T 2013 Nanotechnology 24 435705

Google Scholar

Google Scholar

[16] Late D, Shirodkar S, Waghmare U, Dravid V, Rao C 2014 Chemphyschem 15 1592

Google Scholar

Google Scholar

[17] Hu X, Yasaei P, Jokisaari J, Öğüt S, Salehi-Khojin A, Robert F, Klie R 2018 Phys. Rev. Lett. 120 055902

[18] Zhang R, Cao H, Jiang J 2020 Nanotechnology 31 405709

Google Scholar

Google Scholar

[19] Akinwande D, Brennan C, Bunch J, Egberts P, Felts J, Gao H, Huang R, Kim J, Li T, Li Y 2017 Extreme Mech. Lett. 23 42

[20] Wei Y, Yang R 2018 Natl. Sci. Rev. 6 324

[21] Chen S, Chrzan D C 2011 Phys. Rev. B 84 5409

[22] Jiang J, Wang B, Wang J 2015 J. Phys-Condens. Mat. 27 083001

Google Scholar

Google Scholar

[23] Zhou L, Cao G 2016 Phys. Chem. Chem. Phys. 18 1657

Google Scholar

Google Scholar

[24] Gao E, Xu Z 2015 J. Appl. Mech. 82 121012

Google Scholar

Google Scholar

[25] Audoly B, Pomeau Y 2010 Elasticity and Geometry: From Hair Curls to the Non-linear Response of Shells (New York: Oxford University Press) pp157-213

[26] Kudin K, Scuseria G, Yakobson B 2001 Phys. Rev. B 64 235406

Google Scholar

Google Scholar

[27] Landau L, Lifshitz E 1997 Theory of Elasticity 3rd (Oxford: Butterworth Heinemann) pp38−50

[28] O'NEILL B 2006 Elementary Differential Geometry (Singapore: Elsevier) pp364−376

[29] Eduard E, Krauthammer T 2001 Thin Plates and Shells: Theory, Analysis, and Applications (New York: Marcel Dekker) pp191−240

[30] 胡海昌 1981 弹性力学的变分原理及其应用 (北京: 科学出版社)pp322−342

Hu H 1981 Variational Principles of Theory of Elasticity with Applications (Beijing: Science Press) pp322−342 (in Chinese)

[31] Liu K, Yan Q, Chen M, Fan W, Sun Y, Suh J, Fu D, Lee S, Zhou J, Tongay S, Ji J, Neaton J, Wu J 2014 Nano Lett. 14 5097

Google Scholar

Google Scholar

[32] Cooper R C, Lee C, Marianetti C A, Wei X, Hone J, Kysar J W 2013 Phys. Rev. B 87 035423

Google Scholar

Google Scholar

[33] Xiong S, Cao G 2015 Nanotechnology 26 185705

Google Scholar

Google Scholar

[34] Luongo A, Egidio A 2005 Nonlinear. Dynam. 41 171

Google Scholar

Google Scholar

[35] Luongo A, D'Annibale F 2013 Int. J. Nonlin. Mech. 55 128

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6669

- PDF Downloads: 83

- Cited By: 0

DownLoad:

DownLoad: