-

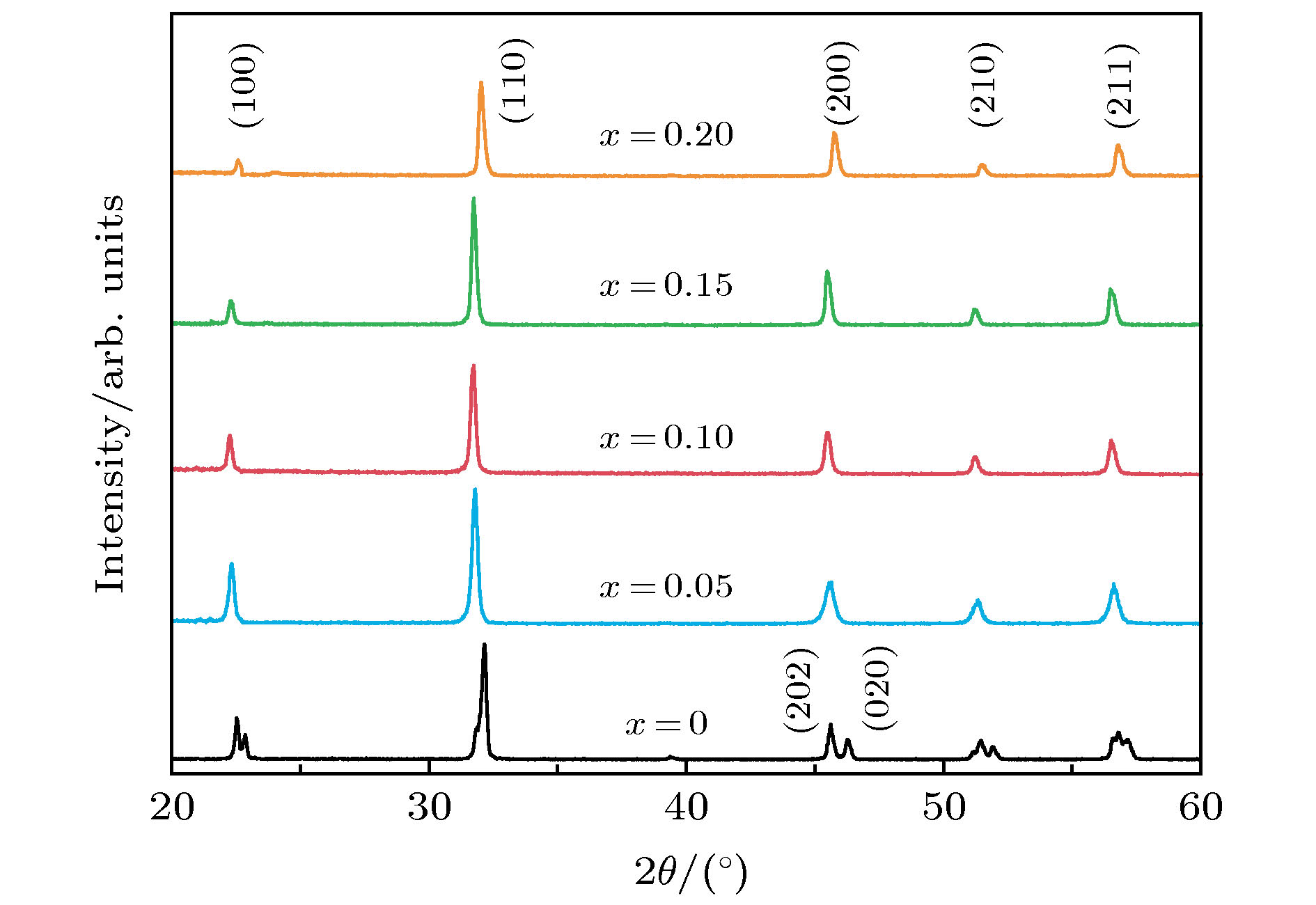

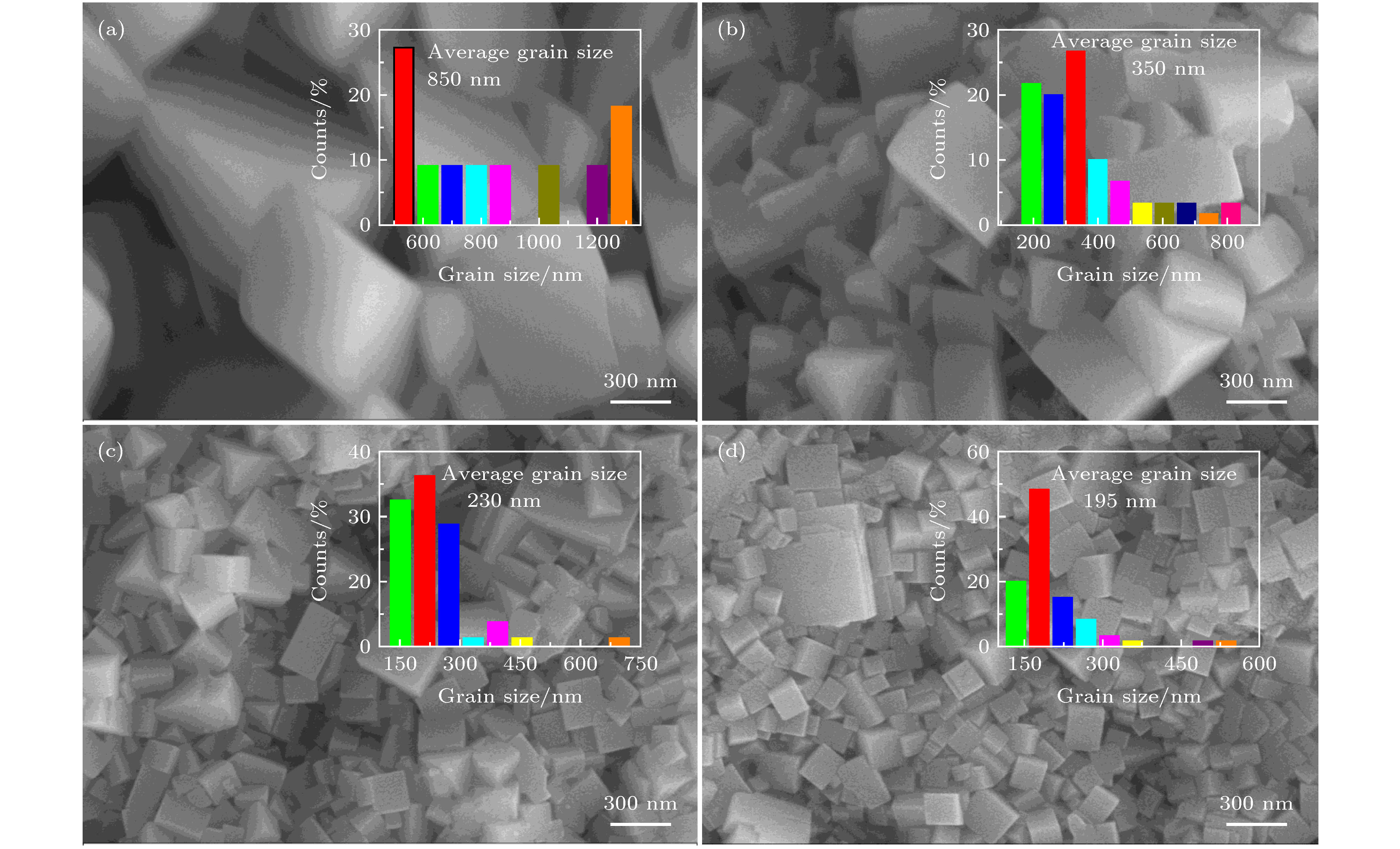

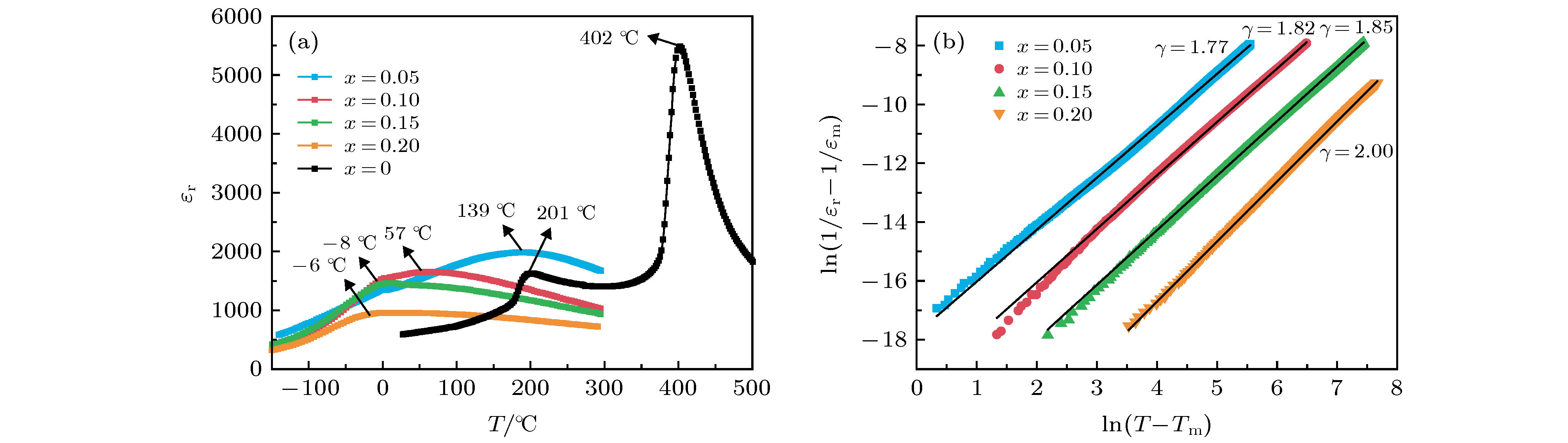

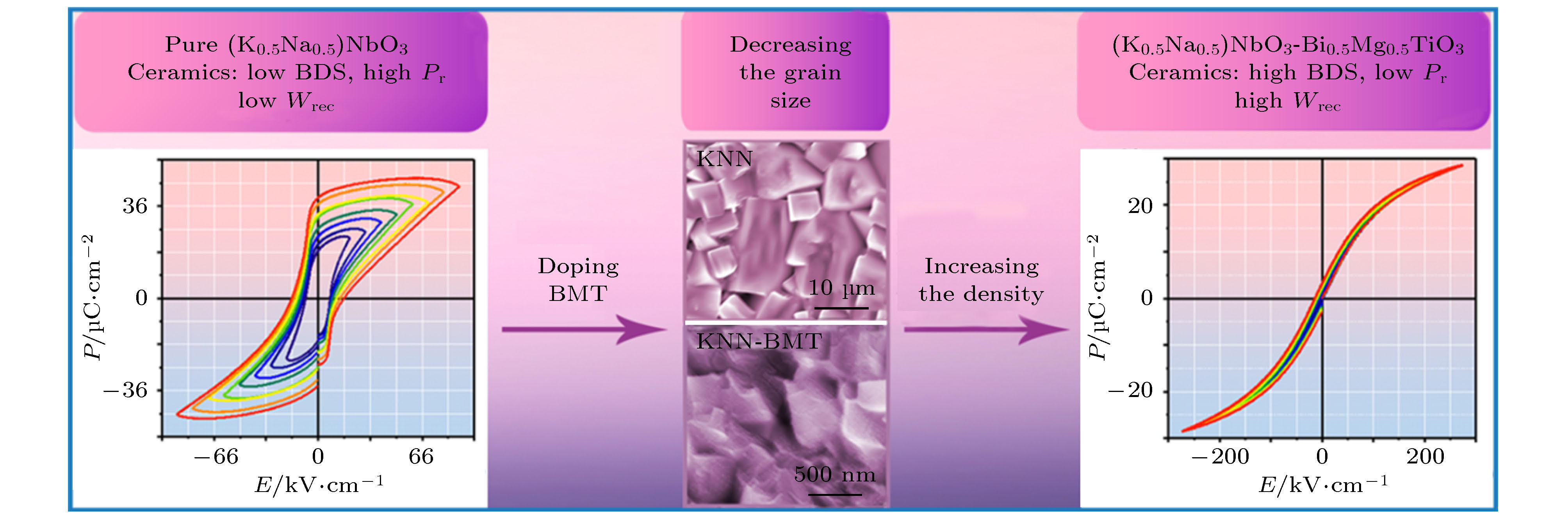

Lead-free dielectric ceramics with high energy-storage density and efficiency are ideal energy materials for sustainable development of the enery resource. In this paper, (1–x)K0.5Na0.5NbO3–xBi(Mg0.5Ti0.5)O3 ((1–x)KNN-xBMT, x = 0.05, 0.10, 0.15, 0.20) lead-free relaxor ferroelectric ceramics are prepared by the traditional solid-state method. The effects of BMT on the phase structure, microstructure, dielectric properties and energy storage behavior of KNN based ceramics are studied. With the increase of BMT content, the crystal structures of (1–x)KNN-xBMT ceramics gradually change from orthorhombic to pseudo-cubic phase, and transform into cubic phase finally. The addition of BMT can suppress grain growth of the ceramics, resulting in the average grain size decreasing from 850 to 195 nm when x increases from 0.05 to 0.20. Dielectric properties exhibit that the Curie temperature decreases with BMT content increasing, and dielectric peak at Curie temperature is broadened due to the addition of BMT. In addition, ferroelectric properties demonstrate that the addition of BMT reduces the remnant polarization (Pr) and coercive field (Ec) of the ceramics. The results indicate that (1–x)KNN-xBMT ceramics transform from ferroelectric to relaxor ferroelectric phase. Based on the calculation of hysteresis loop, the best energy storage performance is obtained at x = 0.15, of which the recoverable energy storage density (Wrec) and the energy storage efficiency (η) are 2.25 J·cm–3 and 84% at its dielectric breakdown strength of 275 kV·cm–1. Meanwhile, the ceramic with x = 0.15 exhibits good stability in a frequency range of 1–50 Hz, with an energy density variation of less than 5%, and temperature stability in a range of 25–125 ℃ with change of less than 8%. Moreover, based on direct measurement, the energy storage density (Wdis) of the ceramic with x = 0.15 is 1.54 J·cm–3, and the discharge time is only 88 ns. The research shows that (1–x)KNN-xBMT ceramics have a wide application prospect in the field of environmentally friendly capacitors with high energy storage density.

-

Keywords:

- K0.5Na0.5NbO3-base /

- energy storage /

- lead-free /

- relaxor ferroelectric /

- direct measurement

[1] Dang Z M, Yuan J K, Zha J W, Zhou T, Li S T, Hu G H 2012 Prog. Mater. Sci. 57 660

Google Scholar

Google Scholar

[2] Yao K, Chen S T, Rahimabady M, Mirshekarloo M S, Yu S H, Tay F E H, Sritharan T, Lu L 2011 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 58 1968

Google Scholar

Google Scholar

[3] Cao Y, Irwin P C, Younsi K 2004 IEEE Trans. Dielectr. Electr. Insul. 11 797

Google Scholar

Google Scholar

[4] Park M H, Kim H J, Kim Y J, Moon T, Kim K D, Hwang C S 2014 Adv. Energy Mater. 4 1400610

Google Scholar

Google Scholar

[5] Chu B J, Zhou X, Ren K L, Neese B, Lin M R, Wang Q, Bauer F, Zhang Q M 2006 Science 313 334

Google Scholar

Google Scholar

[6] Khanchaitit P, Han K, Gadinski M R, Li Q, Wang Q 2013 Nat. Commun. 26 1

Google Scholar

Google Scholar

[7] Li Q, Chen L, Gadinski M R, Zhang S, Zhang G, Li H, Haque A, Chen L, Jackson T, Wang Q 2015 Nature 523 576

Google Scholar

Google Scholar

[8] Xu B, Íñiguez J, Bellaiche L 2017 Nat. Commun. 8 15682

Google Scholar

Google Scholar

[9] Wang D W, Fan Z M, Zhou D, Khesro A, Murakami S, Feteira A, Zhao Q L, Tan X L, Reaney L M 2018 J. Mater. Chem. A 6 4133

Google Scholar

Google Scholar

[10] Wu J Y, Mahajan A, Riekehr L, Zhang H F, Yang B, Meng N, Zhang Z, Yan H X 2018 Nano Energy 50 723

Google Scholar

Google Scholar

[11] Parizi S S, Mellinger A, Caruntu G 2014 ACS Appl. Mater. Interfaces 6 17506

Google Scholar

Google Scholar

[12] Liu X H, Li Y, Hao X H 2019 J. Mater. Chem. A 7 11858

Google Scholar

Google Scholar

[13] Shen B Z, Li Y, Hao X H 2019 ACS Appl. Mater. Interfaces 11 34117

Google Scholar

Google Scholar

[14] Chen L M, Sun N N, Li Y, Zhang Q W, Zhang L W, Hao X H 2018 J. Am. Ceram. Soc. 101 2313

Google Scholar

Google Scholar

[15] Palneedi H, Peddigari M, Hwang G T, Jeong D Y, Ryu J 2018 Adv. Funct. Mater. 28 1803665

Google Scholar

Google Scholar

[16] He C J, An Y, Deng C G, Gu X R, Wang J M, Wu T, Liu Y W, Lu Y G 2019 Mod. Phys. Lett. B 33 1950323

Google Scholar

Google Scholar

[17] Yao Y, Li Y, Sun N N, Du J H, Li X W, Zhang L W, Zhang Q W, Hao X H 2018 Ceram. Int. 44 5961

Google Scholar

Google Scholar

[18] An Y, He C J, Deng C G, Chen Z Y, Chen H B, Wu T, Lu Y G, Gu X R, Wang J M, Liu Y W, Li Z Q 2020 Ceram. Int. 46 4664

Google Scholar

Google Scholar

[19] Sun N N, Li Y, Zhang Q W, Hao X H 2018 J. Mater. Chem. C 6 10693

Google Scholar

Google Scholar

[20] Hu Q Y, Jin L, Wang T, Li C C, Xing Z, Wei X Y 2015 J. Alloys Compd. 640 416

Google Scholar

Google Scholar

[21] Wang T, Jin L, Li C C, Hu Q Y, Wei X Y 2015 J. Am. Ceram. Soc. 98 559

Google Scholar

Google Scholar

[22] Shen Z B, Wang X H, LuoB C, Li L T 2015 J. Mater. Chem. A 3 18146

Google Scholar

Google Scholar

[23] Zhou M X, Liang R H, Zhou Z Y, Dong X L 2018 J. Mater. Chem. A 6 17896

Google Scholar

Google Scholar

[24] Zheng D G, Zuo R Z, Zhang D S, Li Y 2015 J. Am. Ceram. Soc. 98 2692

Google Scholar

Google Scholar

[25] Cao W P, Li W L, Dai X F, Zhang T D, Sheng J, Hou Y F, Fei W D 2016 J. Eur. Ceram. Soc. 36 593

Google Scholar

Google Scholar

[26] Tian Y, Jin L, Hu Q Y, Yu K, Zhuang Y Y, Viola G, Abrahams I, Xu Z, Wei X, Yan H X 2019 J. Mater. Chem. A 7 834

Google Scholar

Google Scholar

[27] Tian Y, Jin L, Zhang H F, Xu Z, Wei X Y, Viola G, Abrahams I, Yan H X 2017 J. Mater. Chem. A 5 17525

Google Scholar

Google Scholar

[28] Zhao L, Liu Q, Gao J, Zhang S J, Li J F 2017 Adv. Mater. 29 1701824

Google Scholar

Google Scholar

[29] Qiao X S, Zhang X S, Wu D, Chao X L, Yang Z P 2018 J. Adv. Dielectr. 8 1830006

Google Scholar

Google Scholar

[30] Shao T Q, Du H L, Ma H, Qu S B, Wang J, Wang J F, Wei X Y, Xu Z 2017 J. Mater. Chem. A 5 554

Google Scholar

Google Scholar

[31] Qu B Y, Du H L, Yang Z T 2016 J. Mater. Chem. C 4 1795

Google Scholar

Google Scholar

[32] Yang Z T, Du H L, Qu S B, Hou Y D, Ma H, Wang J F, Wang J, Wei X Y, Xu Z 2016 J. Mater. Chem. A 4 13778

Google Scholar

Google Scholar

[33] Yang Z T, Gao F, Du H L, Jin L, Yan L L, Hu Q Y, Yu Y, Qu S B, Wei X Y, Xu Z, Wang Y J 2019 Nano Energy 58 768

Google Scholar

Google Scholar

[34] Kosec M, Bobnar V, Hrovat M, Bernard J, Malic B, Holc J 2004 J. Mater. Res. 19 1849

Google Scholar

Google Scholar

[35] Malic B, Koruza J, Hrescak J, Bernard J, Wang K, Fisher J, Bencan A 2015 Materials 8 8117

Google Scholar

Google Scholar

[36] Hao X H, Wang Y, Zhang L, Zhang L W 2013 Appl. Phys. Lett. 102 163903

Google Scholar

Google Scholar

[37] 杜红亮, 杨泽田, 高峰, 靳立, 程花蕾, 屈少波 2018 无机材料学报 33 1046

Google Scholar

Google Scholar

Du H L, Yang Z T, Gao F, Jin L, Cheng H L, Qu S B 2018 J. Inorg. Mater. 33 1046

Google Scholar

Google Scholar

[38] Chen L M, Hao X H, Zhang Q W, An S L 2016 J. Mater. Sci.- Mater Electron. 27 4534

Google Scholar

Google Scholar

[39] Chen X F, Zhang H L, Cao F, Wang G S 2009 J. Appl. Phys. 106 034105

Google Scholar

Google Scholar

[40] Zhang H, Chen X, Cao F, Wang G, Dong X, Hu Z, Du T 2010 J. Am. Ceram. Soc. 93 4015

Google Scholar

Google Scholar

[41] Ahn C W, Amarsanaa G, Won S S, Chae S A, Lee D S, Kim I W 2015 ACS Appl. Mater. Interfaces 7 26381

Google Scholar

Google Scholar

[42] Zhang Q M, Li C, Liu H W, Tang Q 2015 J. Am. Ceram. Soc. 98 366

Google Scholar

Google Scholar

[43] Xu R, Xu Z, Feng Y J, He H L, Tian J J, Huang D 2016 J. Am. Ceram. Soc. 99 2984

Google Scholar

Google Scholar

[44] 李华梅, 李东杰, 陈学锋, 曹菲, 董显林 2008 57 7298

Google Scholar

Google Scholar

Li H M, Li D J, Chen X F, Cao F, Dong X L 2008 Acta Phys. Sin. 57 7298

Google Scholar

Google Scholar

[45] Xu R, Xu Z, Feng Y J, Wei X Y, Tian J J, Huang D 2016 J. Appl. Phys. 119 224103

Google Scholar

Google Scholar

[46] Zhu M K, Liu L Y, Hou Y D, Wang H, Yan H 2007 J. Am. Ceram. Soc. 90 120

Google Scholar

Google Scholar

[47] Qu B Y, Du H L, Yang Z T, Liu Q H 2017 J. Am. Ceram. Soc. 100 1517

Google Scholar

Google Scholar

[48] Deng C G, He C J, Chen Z Y, Chen H B, Mao R, Liu Y W, Zhu K J, Gao H F, Ding Y 2019 J. Appl. Phys. 126 085702

Google Scholar

Google Scholar

[49] 陈威, 曹万强 2012 61 097701

Google Scholar

Google Scholar

Chen W, Cao W Q 2012 Acta Phys. Sin. 61 097701

Google Scholar

Google Scholar

[50] Lv X, Wu J G 2019 J. Mater. Chem. C 7 2037

Google Scholar

Google Scholar

[51] Li J L, Li F, Xu Z, Zhang S J 2018 Adv. Mater. 30 1802155

Google Scholar

Google Scholar

[52] Xu R, Tian J J, Zhu Q S, Zhao T, Feng Y J, Wei X Y, Xu Z 2017 J. Am. Ceram. Soc. 100 3618

Google Scholar

Google Scholar

-

图 5 (a) (1 – x)KNN-xBMT陶瓷在–150 ℃至300 ℃以及KNN陶瓷在25 ℃至500 ℃的介电常数随温度的变化; (b) ln(1/εr–1/εm) 随ln(T–Tm)的变化

Figure 5. (a) Dielectric constant as a function of temperature in a temperature range of –150 ℃ to 300 ℃ for (1 – x)KNN-xBMT ceramics and 25 ℃ to 500 ℃ for pure KNN ceramics; (b) plots of ln(1/εr–1/εm) versus ln(T–Tm) of the (1–x)KNN-xBMT ceramics.

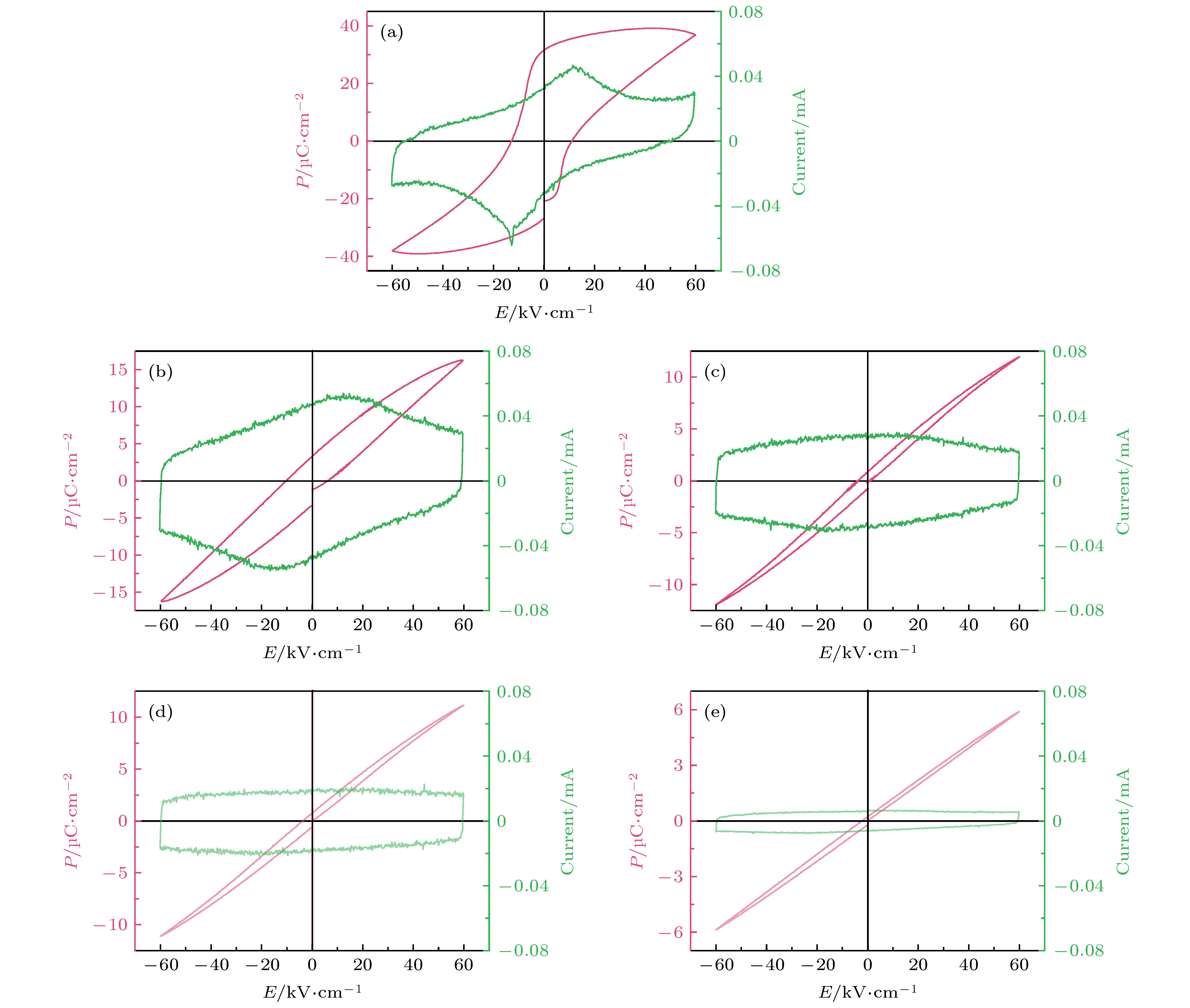

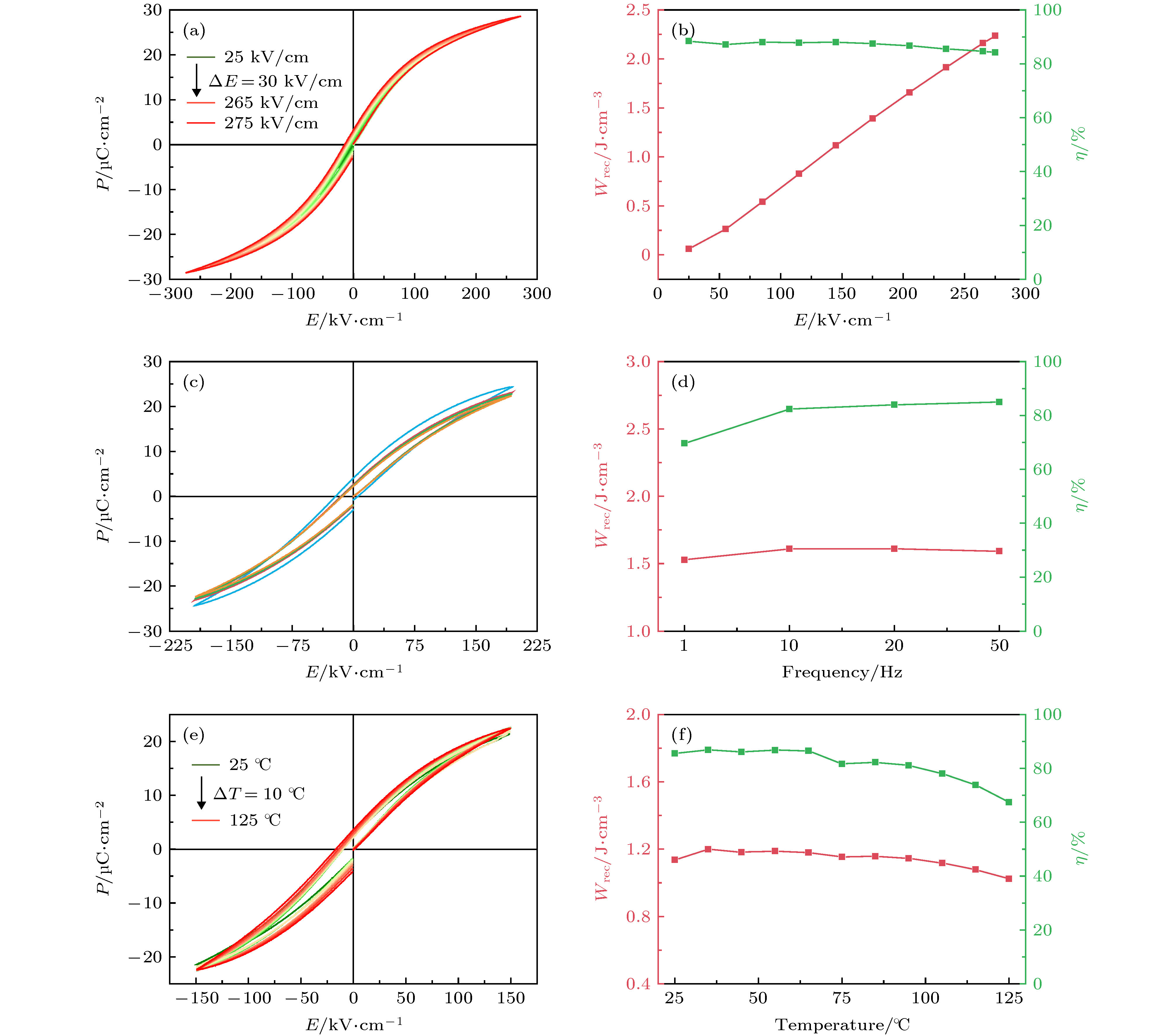

图 7 (1–x)KNN-xBMT陶瓷在击穿电场下的(a) P-E图以及(b)储能密度和储能效率; (1–x)KNN-xBMT陶瓷在185 kV·cm-1电场下的(c) P-E图以及(d)储能密度和储能效率

Figure 7. (a) P-E loops, (b) Wrec and η of (1–x)KNN-xBMT ceramics at the maximum applied electric fields; (c) P-E loops, (d) Wrec and η of (1–x)KNN-xBMT ceramics under 200 kV·cm–1 electric fields.

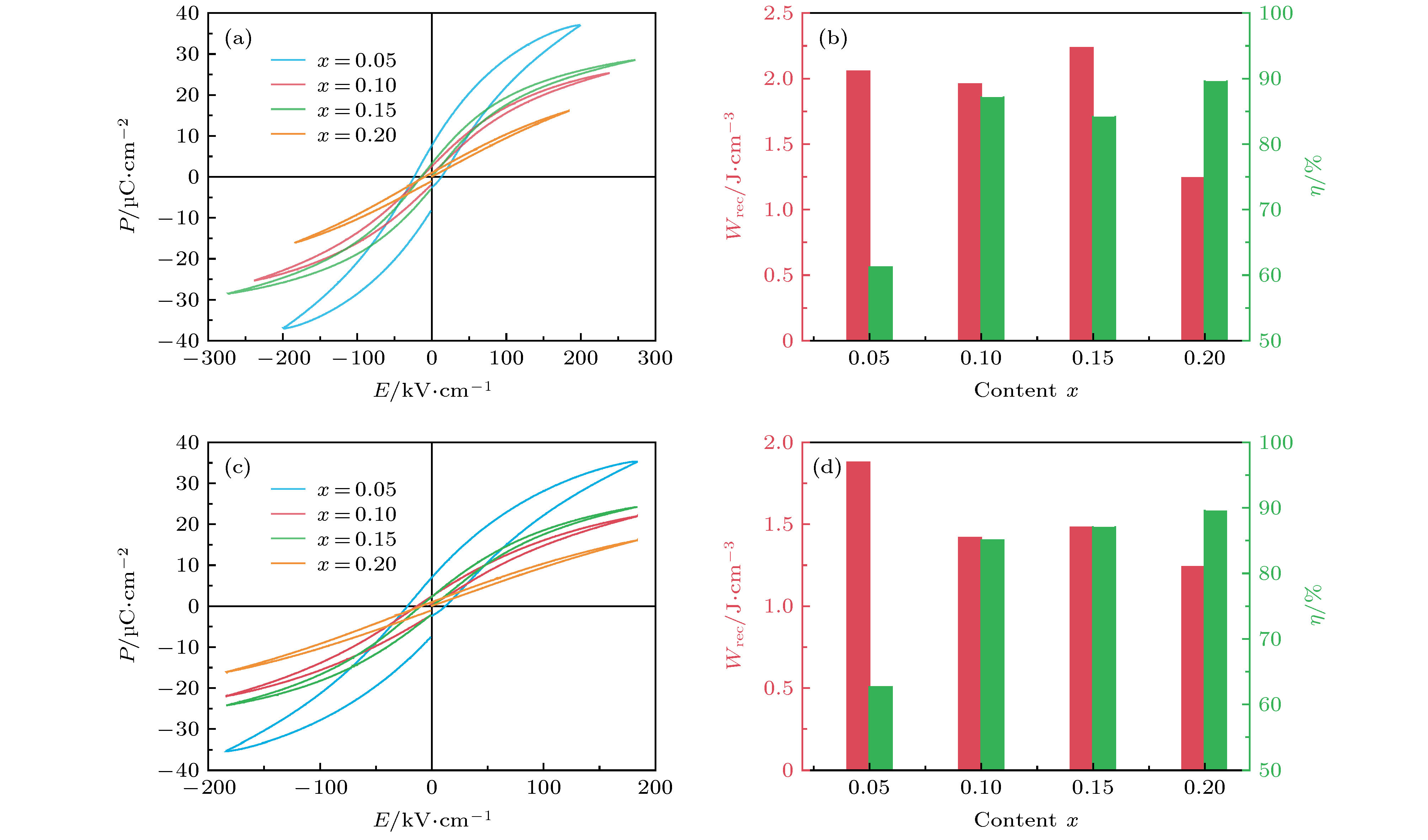

图 8 0.85KNN-0.15BMT陶瓷在不同电场下的(a) P-E图以及(b)储能密度和储能效率; 在不同频率下的(c) P-E图和(d)储能密度和储能效率; 在不同温度下的(e) P-E图和(f)储能密度和储能效率

Figure 8. (a) P-E loops and (b) Wrec and η under different electric fields, (c) P-E loops and (d) Wrec and η at different frequencies, (e) P-E loops and (f) Wrec and η at different temperatures of 0.85KNN-0.15BMT ceramics.

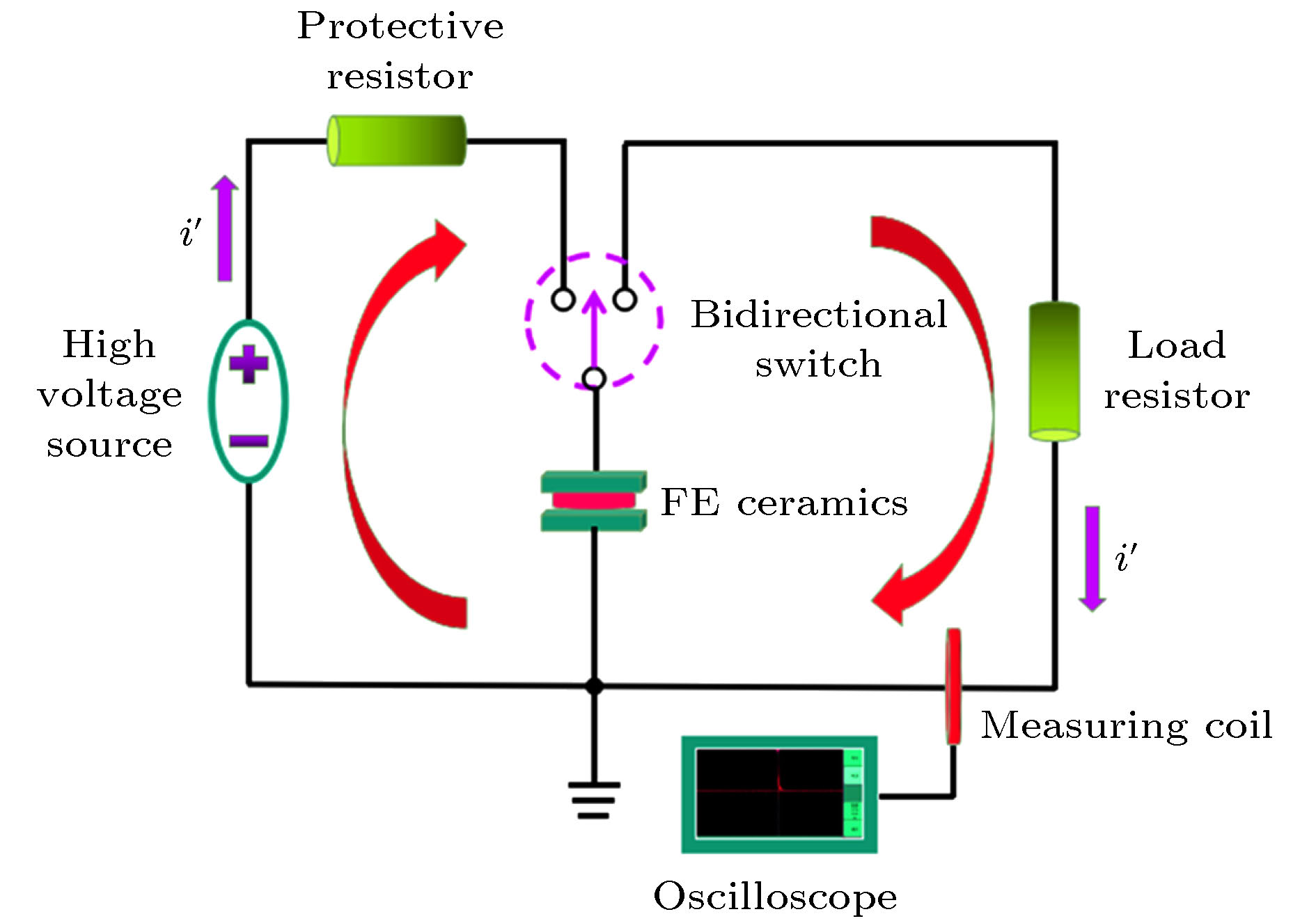

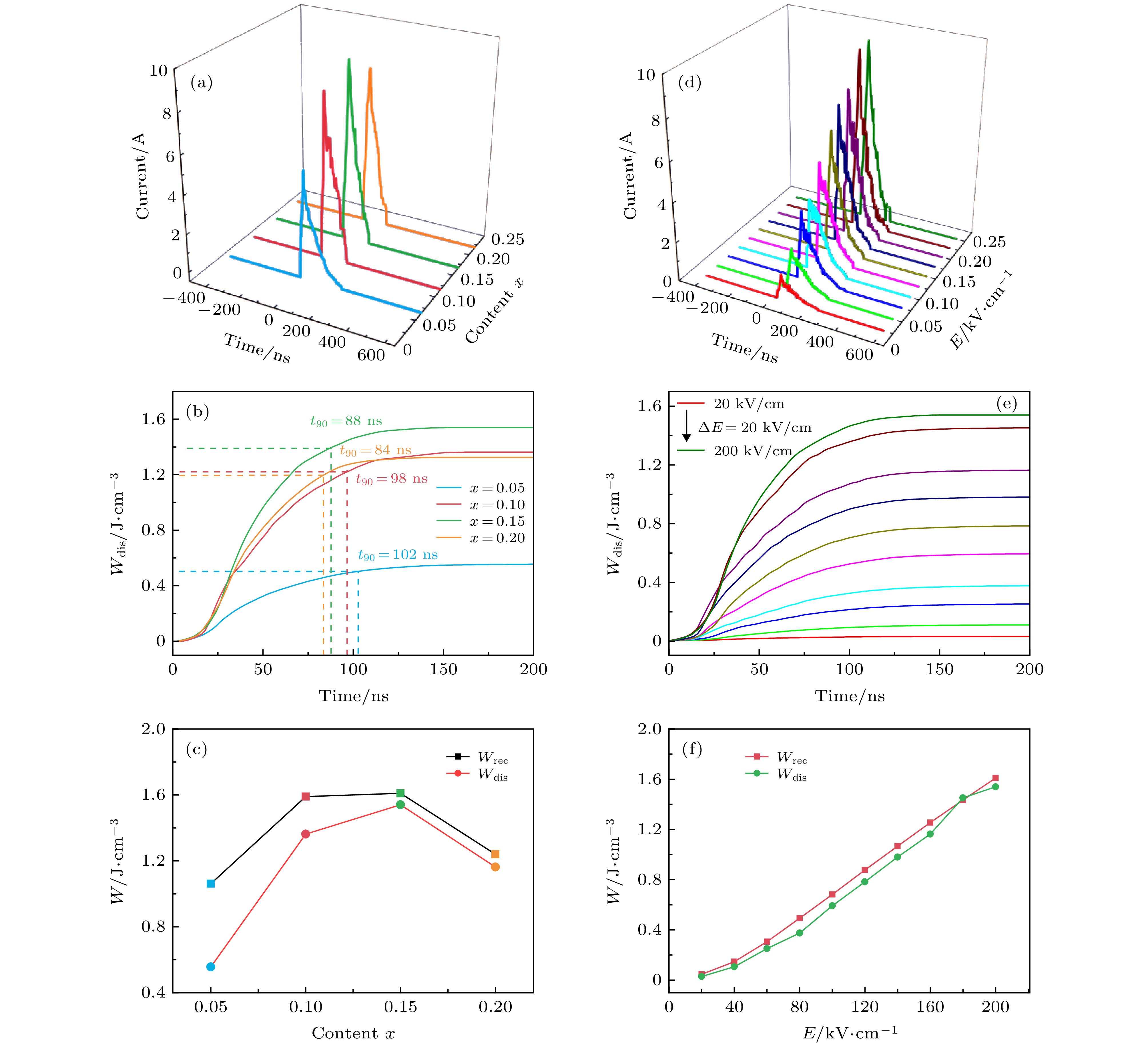

图 9 (1–x)KNN-xBMT陶瓷在最大击穿电场下直接测试的(a)放电电流随时间的变化, (b)放电储能密度和放电速率t90以及(c) Wdis和Wrec比较图; 0.85KNN-0.15BMT陶瓷在不同电场下直接测试的(d)放电电流随时间的变化, (e) 放电储能密度Wdis以及(f) Wdis和Wrec比较图

Figure 9. (a) Pulsed discharge current curves, (b) discharge energy density Wdis and discharge time t90, and (c) comparative figures of Wdis and Wrec under breakdown electric field of the (1–x)KNN-xBMT ceramics; (d) pulsed discharge current curves, (e) discharge energy density Wdis, and (f) the comparative figures of Wdis and Wrec under different electric fields of the 0.85KNN-0.15BMT ceramic

表 1 0.85 KNN-0.15 BMT陶瓷与其他部分无铅陶瓷储能性能的比较

Table 1. Comparison of energy storage properties of 0.85 KNN-0.15 BMT ceramics and other lead-free ceramics.

-

[1] Dang Z M, Yuan J K, Zha J W, Zhou T, Li S T, Hu G H 2012 Prog. Mater. Sci. 57 660

Google Scholar

Google Scholar

[2] Yao K, Chen S T, Rahimabady M, Mirshekarloo M S, Yu S H, Tay F E H, Sritharan T, Lu L 2011 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 58 1968

Google Scholar

Google Scholar

[3] Cao Y, Irwin P C, Younsi K 2004 IEEE Trans. Dielectr. Electr. Insul. 11 797

Google Scholar

Google Scholar

[4] Park M H, Kim H J, Kim Y J, Moon T, Kim K D, Hwang C S 2014 Adv. Energy Mater. 4 1400610

Google Scholar

Google Scholar

[5] Chu B J, Zhou X, Ren K L, Neese B, Lin M R, Wang Q, Bauer F, Zhang Q M 2006 Science 313 334

Google Scholar

Google Scholar

[6] Khanchaitit P, Han K, Gadinski M R, Li Q, Wang Q 2013 Nat. Commun. 26 1

Google Scholar

Google Scholar

[7] Li Q, Chen L, Gadinski M R, Zhang S, Zhang G, Li H, Haque A, Chen L, Jackson T, Wang Q 2015 Nature 523 576

Google Scholar

Google Scholar

[8] Xu B, Íñiguez J, Bellaiche L 2017 Nat. Commun. 8 15682

Google Scholar

Google Scholar

[9] Wang D W, Fan Z M, Zhou D, Khesro A, Murakami S, Feteira A, Zhao Q L, Tan X L, Reaney L M 2018 J. Mater. Chem. A 6 4133

Google Scholar

Google Scholar

[10] Wu J Y, Mahajan A, Riekehr L, Zhang H F, Yang B, Meng N, Zhang Z, Yan H X 2018 Nano Energy 50 723

Google Scholar

Google Scholar

[11] Parizi S S, Mellinger A, Caruntu G 2014 ACS Appl. Mater. Interfaces 6 17506

Google Scholar

Google Scholar

[12] Liu X H, Li Y, Hao X H 2019 J. Mater. Chem. A 7 11858

Google Scholar

Google Scholar

[13] Shen B Z, Li Y, Hao X H 2019 ACS Appl. Mater. Interfaces 11 34117

Google Scholar

Google Scholar

[14] Chen L M, Sun N N, Li Y, Zhang Q W, Zhang L W, Hao X H 2018 J. Am. Ceram. Soc. 101 2313

Google Scholar

Google Scholar

[15] Palneedi H, Peddigari M, Hwang G T, Jeong D Y, Ryu J 2018 Adv. Funct. Mater. 28 1803665

Google Scholar

Google Scholar

[16] He C J, An Y, Deng C G, Gu X R, Wang J M, Wu T, Liu Y W, Lu Y G 2019 Mod. Phys. Lett. B 33 1950323

Google Scholar

Google Scholar

[17] Yao Y, Li Y, Sun N N, Du J H, Li X W, Zhang L W, Zhang Q W, Hao X H 2018 Ceram. Int. 44 5961

Google Scholar

Google Scholar

[18] An Y, He C J, Deng C G, Chen Z Y, Chen H B, Wu T, Lu Y G, Gu X R, Wang J M, Liu Y W, Li Z Q 2020 Ceram. Int. 46 4664

Google Scholar

Google Scholar

[19] Sun N N, Li Y, Zhang Q W, Hao X H 2018 J. Mater. Chem. C 6 10693

Google Scholar

Google Scholar

[20] Hu Q Y, Jin L, Wang T, Li C C, Xing Z, Wei X Y 2015 J. Alloys Compd. 640 416

Google Scholar

Google Scholar

[21] Wang T, Jin L, Li C C, Hu Q Y, Wei X Y 2015 J. Am. Ceram. Soc. 98 559

Google Scholar

Google Scholar

[22] Shen Z B, Wang X H, LuoB C, Li L T 2015 J. Mater. Chem. A 3 18146

Google Scholar

Google Scholar

[23] Zhou M X, Liang R H, Zhou Z Y, Dong X L 2018 J. Mater. Chem. A 6 17896

Google Scholar

Google Scholar

[24] Zheng D G, Zuo R Z, Zhang D S, Li Y 2015 J. Am. Ceram. Soc. 98 2692

Google Scholar

Google Scholar

[25] Cao W P, Li W L, Dai X F, Zhang T D, Sheng J, Hou Y F, Fei W D 2016 J. Eur. Ceram. Soc. 36 593

Google Scholar

Google Scholar

[26] Tian Y, Jin L, Hu Q Y, Yu K, Zhuang Y Y, Viola G, Abrahams I, Xu Z, Wei X, Yan H X 2019 J. Mater. Chem. A 7 834

Google Scholar

Google Scholar

[27] Tian Y, Jin L, Zhang H F, Xu Z, Wei X Y, Viola G, Abrahams I, Yan H X 2017 J. Mater. Chem. A 5 17525

Google Scholar

Google Scholar

[28] Zhao L, Liu Q, Gao J, Zhang S J, Li J F 2017 Adv. Mater. 29 1701824

Google Scholar

Google Scholar

[29] Qiao X S, Zhang X S, Wu D, Chao X L, Yang Z P 2018 J. Adv. Dielectr. 8 1830006

Google Scholar

Google Scholar

[30] Shao T Q, Du H L, Ma H, Qu S B, Wang J, Wang J F, Wei X Y, Xu Z 2017 J. Mater. Chem. A 5 554

Google Scholar

Google Scholar

[31] Qu B Y, Du H L, Yang Z T 2016 J. Mater. Chem. C 4 1795

Google Scholar

Google Scholar

[32] Yang Z T, Du H L, Qu S B, Hou Y D, Ma H, Wang J F, Wang J, Wei X Y, Xu Z 2016 J. Mater. Chem. A 4 13778

Google Scholar

Google Scholar

[33] Yang Z T, Gao F, Du H L, Jin L, Yan L L, Hu Q Y, Yu Y, Qu S B, Wei X Y, Xu Z, Wang Y J 2019 Nano Energy 58 768

Google Scholar

Google Scholar

[34] Kosec M, Bobnar V, Hrovat M, Bernard J, Malic B, Holc J 2004 J. Mater. Res. 19 1849

Google Scholar

Google Scholar

[35] Malic B, Koruza J, Hrescak J, Bernard J, Wang K, Fisher J, Bencan A 2015 Materials 8 8117

Google Scholar

Google Scholar

[36] Hao X H, Wang Y, Zhang L, Zhang L W 2013 Appl. Phys. Lett. 102 163903

Google Scholar

Google Scholar

[37] 杜红亮, 杨泽田, 高峰, 靳立, 程花蕾, 屈少波 2018 无机材料学报 33 1046

Google Scholar

Google Scholar

Du H L, Yang Z T, Gao F, Jin L, Cheng H L, Qu S B 2018 J. Inorg. Mater. 33 1046

Google Scholar

Google Scholar

[38] Chen L M, Hao X H, Zhang Q W, An S L 2016 J. Mater. Sci.- Mater Electron. 27 4534

Google Scholar

Google Scholar

[39] Chen X F, Zhang H L, Cao F, Wang G S 2009 J. Appl. Phys. 106 034105

Google Scholar

Google Scholar

[40] Zhang H, Chen X, Cao F, Wang G, Dong X, Hu Z, Du T 2010 J. Am. Ceram. Soc. 93 4015

Google Scholar

Google Scholar

[41] Ahn C W, Amarsanaa G, Won S S, Chae S A, Lee D S, Kim I W 2015 ACS Appl. Mater. Interfaces 7 26381

Google Scholar

Google Scholar

[42] Zhang Q M, Li C, Liu H W, Tang Q 2015 J. Am. Ceram. Soc. 98 366

Google Scholar

Google Scholar

[43] Xu R, Xu Z, Feng Y J, He H L, Tian J J, Huang D 2016 J. Am. Ceram. Soc. 99 2984

Google Scholar

Google Scholar

[44] 李华梅, 李东杰, 陈学锋, 曹菲, 董显林 2008 57 7298

Google Scholar

Google Scholar

Li H M, Li D J, Chen X F, Cao F, Dong X L 2008 Acta Phys. Sin. 57 7298

Google Scholar

Google Scholar

[45] Xu R, Xu Z, Feng Y J, Wei X Y, Tian J J, Huang D 2016 J. Appl. Phys. 119 224103

Google Scholar

Google Scholar

[46] Zhu M K, Liu L Y, Hou Y D, Wang H, Yan H 2007 J. Am. Ceram. Soc. 90 120

Google Scholar

Google Scholar

[47] Qu B Y, Du H L, Yang Z T, Liu Q H 2017 J. Am. Ceram. Soc. 100 1517

Google Scholar

Google Scholar

[48] Deng C G, He C J, Chen Z Y, Chen H B, Mao R, Liu Y W, Zhu K J, Gao H F, Ding Y 2019 J. Appl. Phys. 126 085702

Google Scholar

Google Scholar

[49] 陈威, 曹万强 2012 61 097701

Google Scholar

Google Scholar

Chen W, Cao W Q 2012 Acta Phys. Sin. 61 097701

Google Scholar

Google Scholar

[50] Lv X, Wu J G 2019 J. Mater. Chem. C 7 2037

Google Scholar

Google Scholar

[51] Li J L, Li F, Xu Z, Zhang S J 2018 Adv. Mater. 30 1802155

Google Scholar

Google Scholar

[52] Xu R, Tian J J, Zhu Q S, Zhao T, Feng Y J, Wei X Y, Xu Z 2017 J. Am. Ceram. Soc. 100 3618

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 11095

- PDF Downloads: 338

- Cited By: 0

DownLoad:

DownLoad: