-

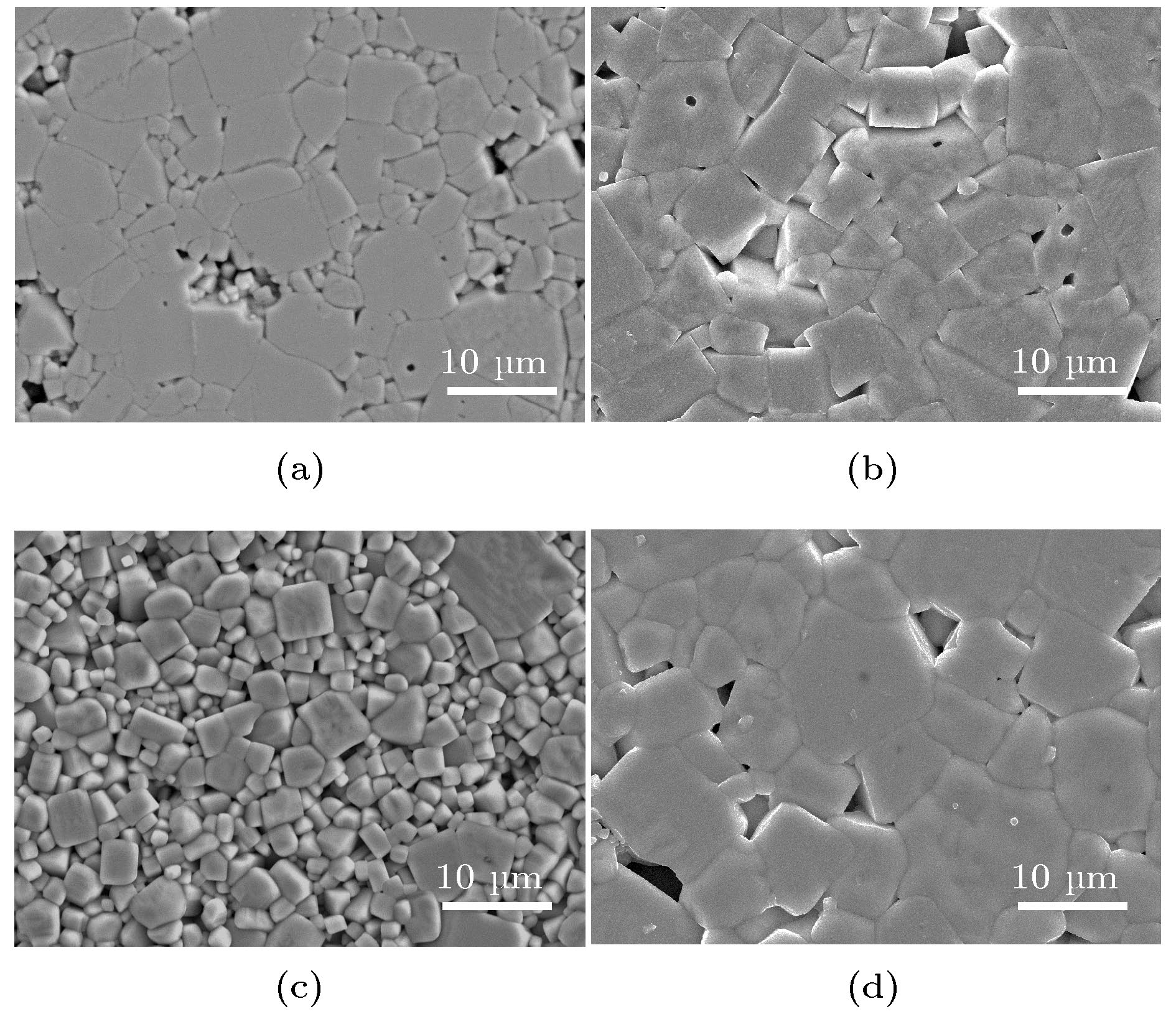

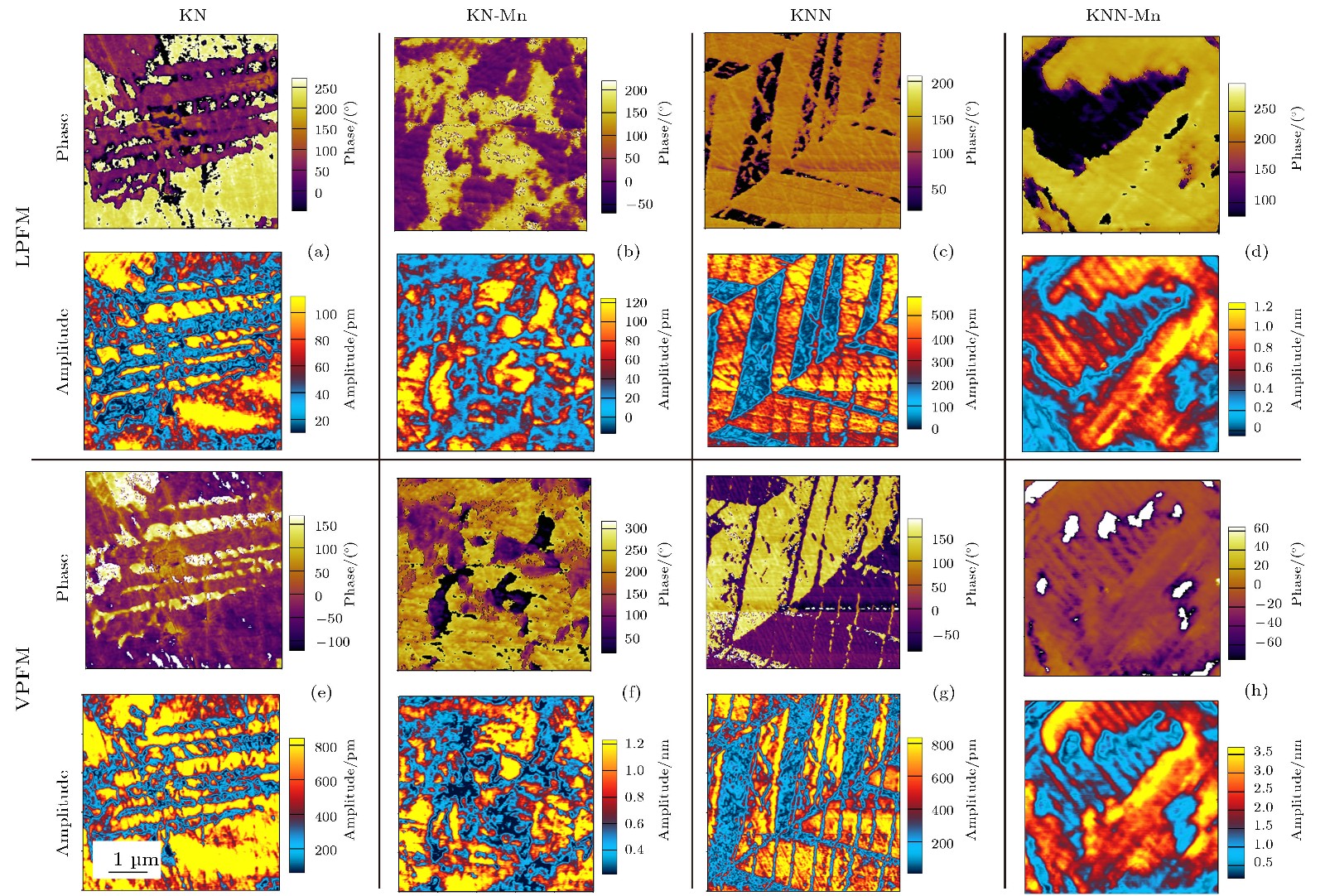

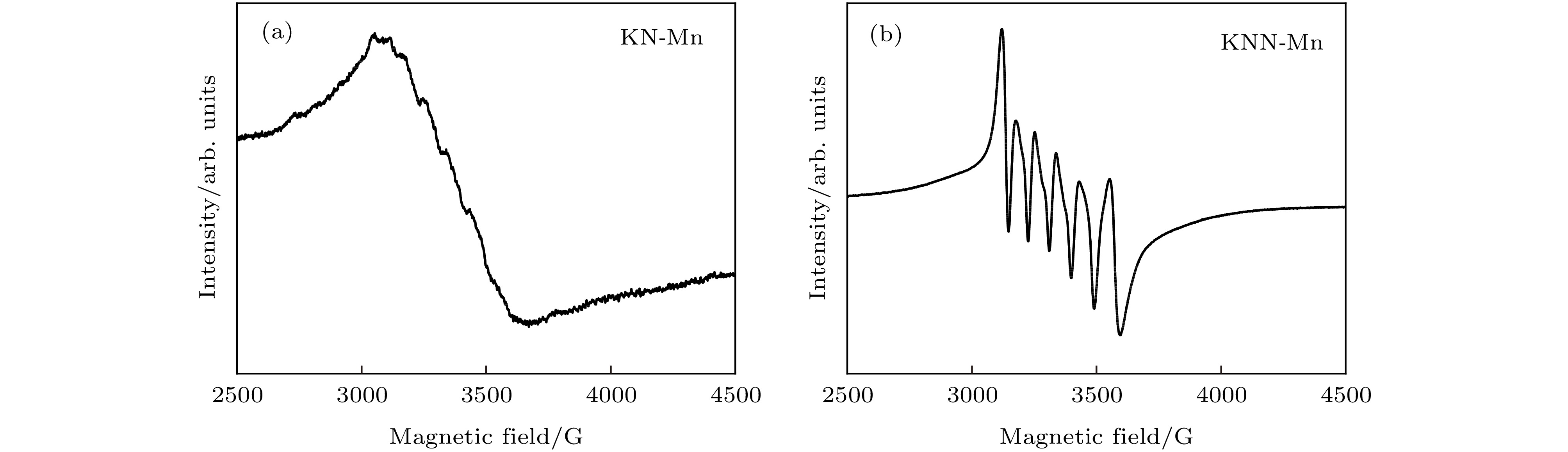

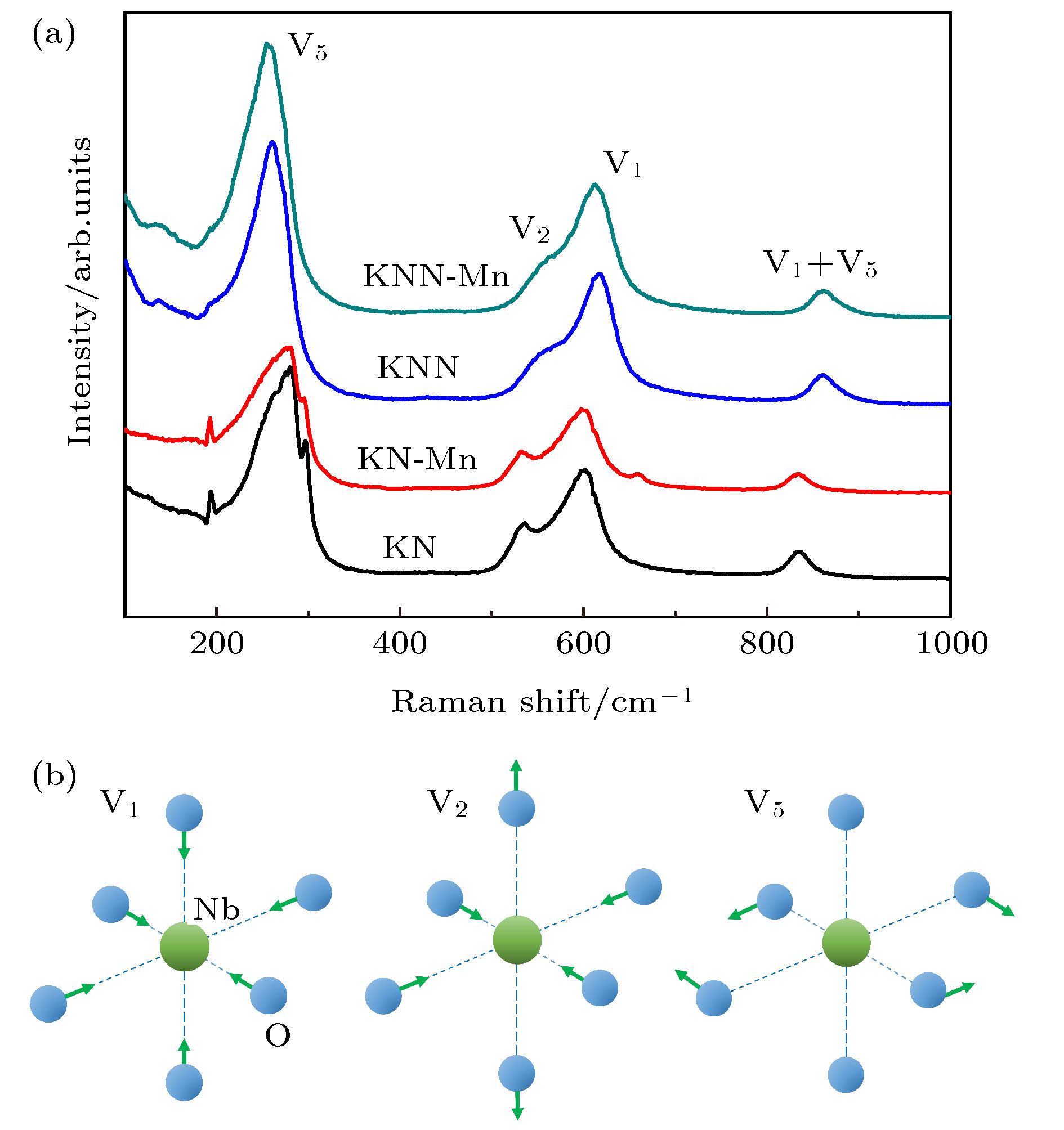

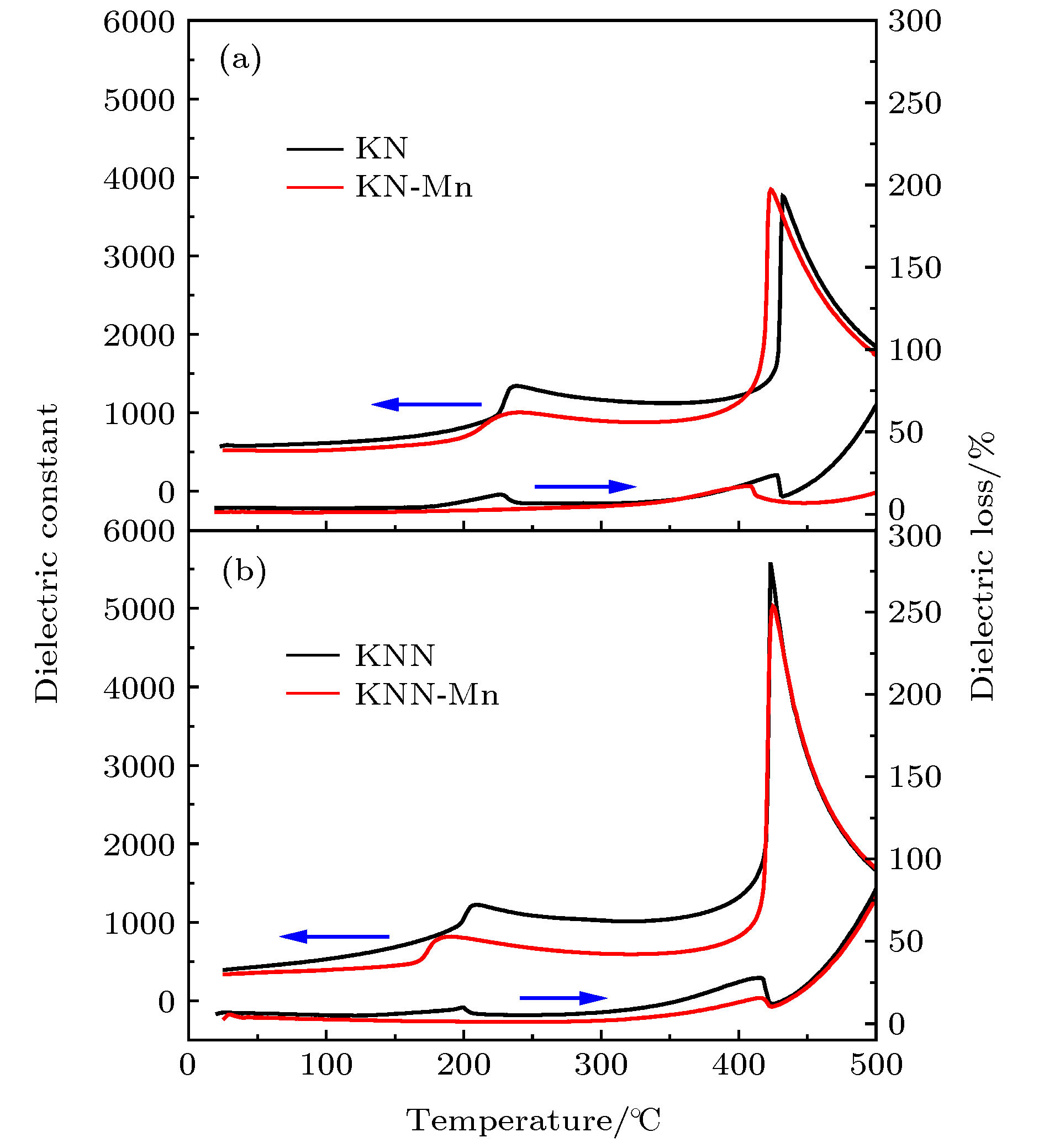

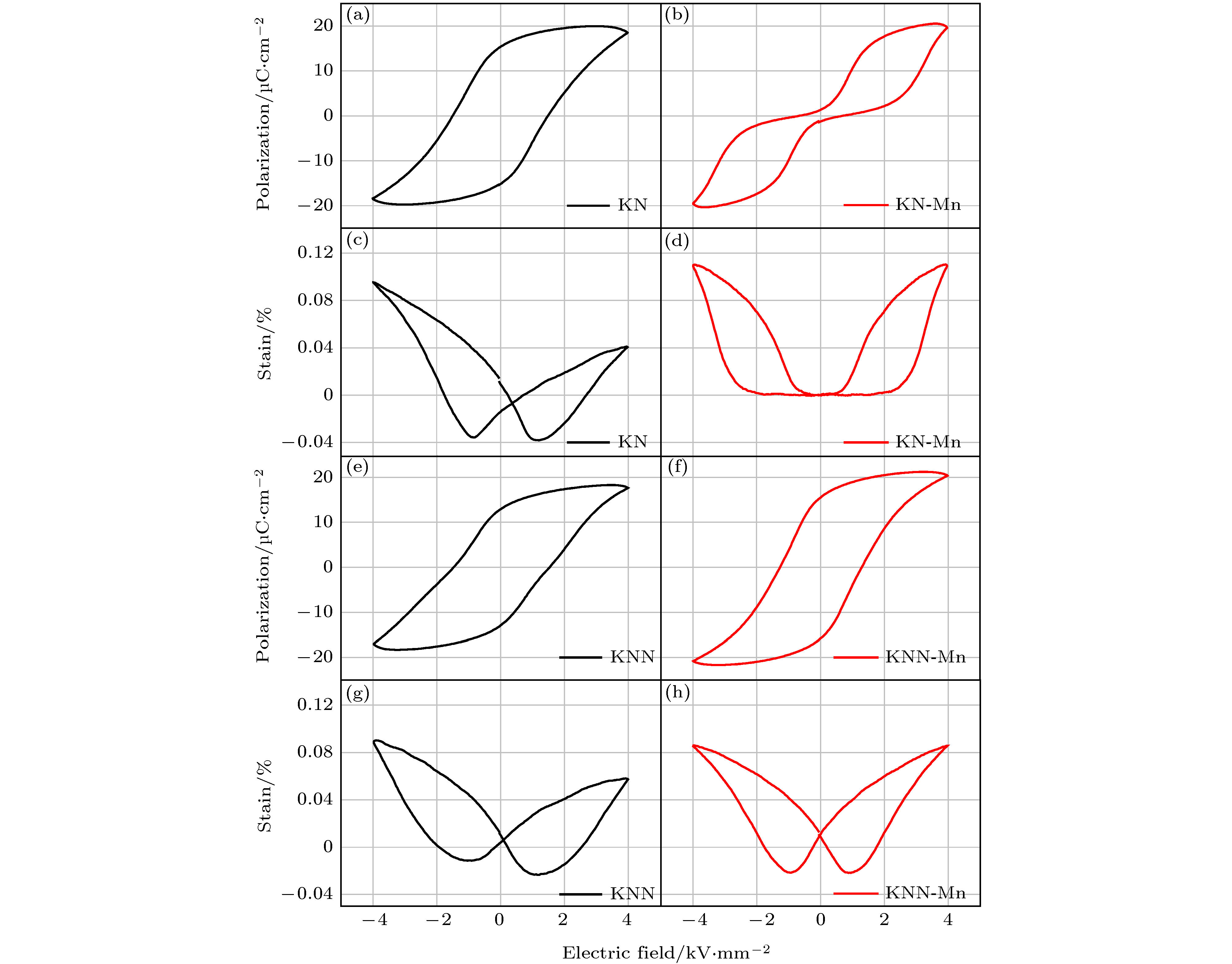

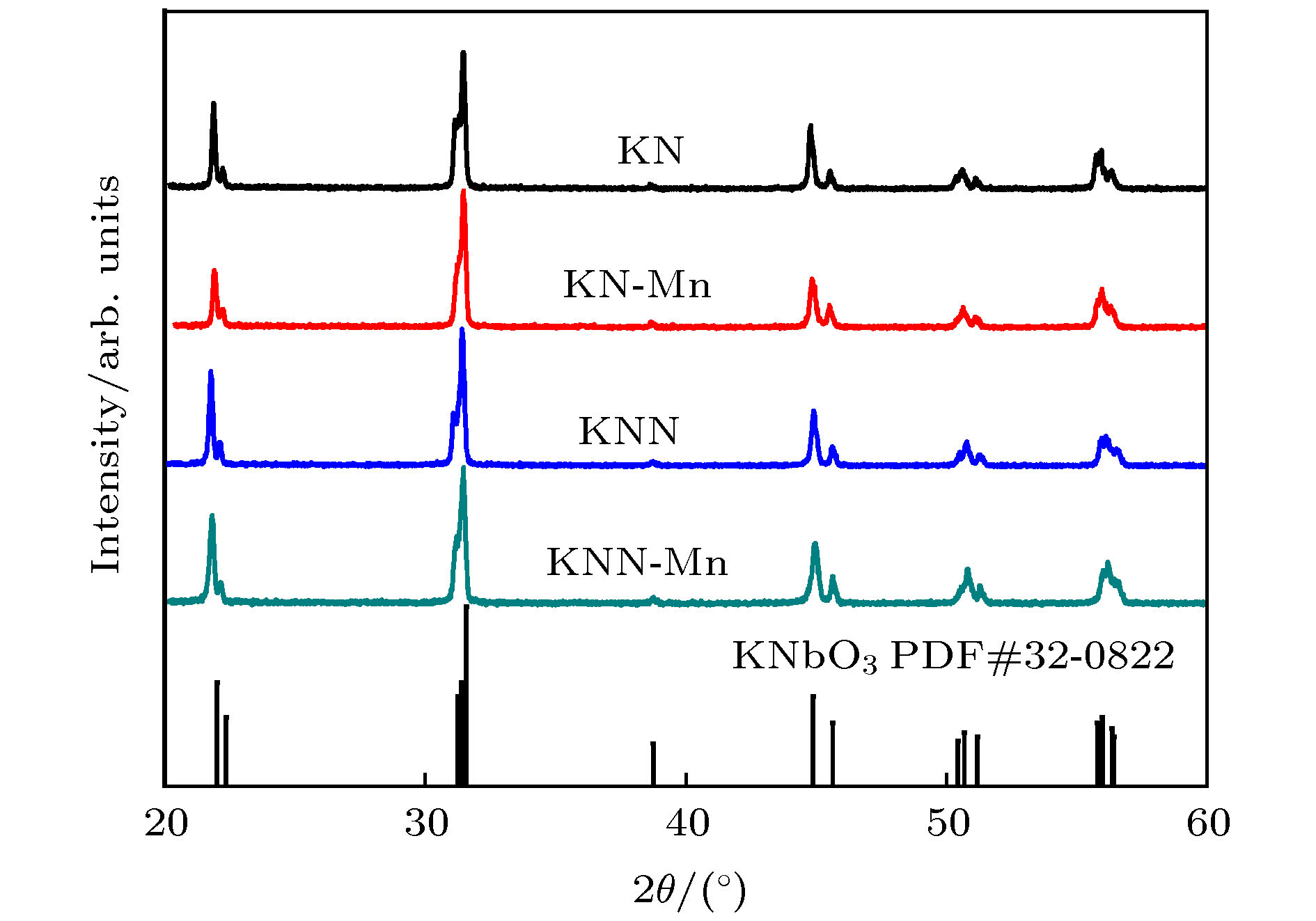

(K0.5Na0.5)NbO3基无铅压电陶瓷具有出色的综合铁电压电性能, 已经初步满足了部分实际应用场景的需求. 近期的研究发现, 某些元素的掺杂对优化(K0.5Na0.5)NbO3基陶瓷的机电耦合性能起着至关重要的作用. 本文将MnO2添加到KNbO3和(K0.5Na0.5)NbO3两种压电陶瓷中, 对比研究了Mn掺杂对两种陶瓷微观结构和宏观电学性能的不同影响, 分析了造成这些差异的微观物理机理. 实验结果表明, 掺杂后的两种陶瓷中均存在Mn2+. Mn掺杂会使KNbO3陶瓷的铁电畴尺寸减小、居里温度降低、拉曼光谱中的振动峰宽化、相变过程变得弥散, 并呈现出束腰电滞回线和可回复的双极场致应变曲线; 在(K0.5Na0.5)NbO3陶瓷中掺杂Mn后, 其性能变化却显著不同, 陶瓷的铁电畴尺寸无明显变化、居里温度未发生变化、拉曼光谱中的振动峰未发生宽化, 呈现出饱和的矩形电滞回线和不可回复的双极场致应变曲线. 这可能是因为, (K0.5Na0.5)NbO3陶瓷相比KNbO3陶瓷具有更大的离子无序度和晶格畸变, 从而使得Mn掺杂所产生的影响相对减小.Potassium sodium niobate ((K0.5Na0.5)NbO3)-based lead-free piezoelectric ceramics are excellent ferroelectric materials and have been demonstrated to have many practical applications. Recent studies have revealed that chemical doping plays a crucial role in optimizing the electromechanical coupling properties of (K0.5Na0.5)NbO3-based piezoelectric ceramics. In this paper, MnO2 is doped into potassium niobate (KNbO3) and (K0.5Na0.5)NbO3 piezoelectric ceramics prepared by the conventional solid-state reaction method. The influences of doped Mn cation on KNbO3 and (K0.5Na0.5)NbO3 piezoelectric ceramics including microstructure and macroscopic electrical properties are systematically investigated. The doping effects of Mn cation on the KNbO3 and (K0.5Na0.5)NbO3 piezoelectric ceramics are significantly different from each other. For the Mn-doped KNbO3 piezoelectric ceramics, the sizes of ferroelectric domains are reduced. Meanwhile, the diffused orthorhombic-tetragonal phase transition is observed, which is accompanied by reducing dielectric loss and Curie temperature, and broadening vibration peaks in Raman spectrum. It is known that the oxygen vacancy can be formed to compensate for the charges created by the acceptor doping of Mn into the B site of perovskite, and thus forming a defect dipole with the acceptor center. From the ferroelectric measurement, a double hysteresis loop (P-E curve) and a recoverable electric-field-induced strain due to the formation of defect dipole are observed. On the contrary, for the Mn-doped (K0.5Na0.5)NbO3 piezoelectric ceramics, the sizes of ferroelectric domains are not reduced. Meanwhile, the Curie temperature and vibration peaks in Raman spectrum are not changed. A rectangular hysteresis loop (P-E curve) and an unrecoverable electric-field-induced strain are observed in the ferroelectric measurement. The difference between these systems might originate from the greater ionic disorder and lattice distortion in (K0.5Na0.5)NbO3 piezoelectric ceramics. The difference in ionic radius between Na+ and K+ can affect the migration and distribution of oxygen vacancies, which makes it difficult to form stable defect dipoles in the Mn-doped (K0.5Na0.5)NbO3 piezoelectric ceramics. The results will serve as an important reference for preparing high-performance (K0.5Na0.5)NbO3-based piezoelectric ceramics via chemical doping.

-

Keywords:

- potassium niobate /

- potassium-sodium niobate /

- defect dipoles /

- Mn-doping

[1] Wang K, Malič B, Wu J 2018 MRS Bull. 43 607

Google Scholar

Google Scholar

[2] Thong H C, Zhao C, Zhou Z, Wu C F, Liu Y X, Du Z Z, Li J F, Gong W, Wang K 2019 Mater. Today 29 37

Google Scholar

Google Scholar

[3] 吴金根, 高翔宇, 陈建国, 王春明, 张树君, 董蜀湘 2018 67 207701

Google Scholar

Google Scholar

Wu J G, Gao X Y, Chen J G, Wang C M, Zhang S J, Dong S X 2018 Acta Phys. Sin. 67 207701

Google Scholar

Google Scholar

[4] 刘涛, 丁爱丽, 何夕云, 郑鑫森, 仇萍荪, 程文秀 2007 无机材料学报 22 469

Google Scholar

Google Scholar

Liu T, Ding A L, He X Y, Zheng X S, Qiu P S, Cheng W X 2007 J. Inorg. Mater. 22 469

Google Scholar

Google Scholar

[5] Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, Homma T, Nagaya T, Nakamura M 2004 Nature 432 84

Google Scholar

Google Scholar

[6] Koruza J, Bell A J, Frömling T, Webber K G, Wang K, Rödel J 2018 J. Materiomics 4 13

Google Scholar

Google Scholar

[7] Liu Q, Zhang Y, Gao J, Zhou Z, Yang D, Lee K Y, Studer A, Hinterstein M, Wang K, Zhang X, Li L, Li J F 2020 Natl. Sci. Rev. 7 355

Google Scholar

Google Scholar

[8] Zhang J, Pan Z, Guo F F, Liu W C, Ning H, Chen Y B, Lu M H, Yang B, Chen J, Zhang S T, Xing X, Rödel J, Cao W, Chen Y F 2015 Nat. Commun. 6 1

Google Scholar

Google Scholar

[9] Wang Y, Luo C, Wang S, Chen C, Yuan G, Luo H, Viehland D 2020 Adv. Electron. Mater. 6 1900949

Google Scholar

Google Scholar

[10] Wu J, Xiao D, Zhu J 2015 Chem. Rev. 115 2559

Google Scholar

Google Scholar

[11] Mgbemere H E, Herber R P, Schneider G A 2009 J. Eur. Ceram. Soc. 29 1729

Google Scholar

Google Scholar

[12] Cheng X, Wu J, Lou X, Wang X, Wang X, Xiao D, Zhu J 2014 ACS Appl. Mater. Inter. 6 750

Google Scholar

Google Scholar

[13] Hao J, Li W, Zhai J, Chen H 2019 Mat. Sci. Eng. R 135 1

Google Scholar

Google Scholar

[14] Wang K, Yao F Z, Jo W, Gobeljic D, Shvartsman V V, Lupascu D C, Li J F, Rödel J 2013 Adv. Funct. Mater. 23 4079

Google Scholar

Google Scholar

[15] Yao F Z, Wang K, Jo W, Webber K G, Comyn T P, Ding J X, Xu B, Cheng L Q, Zheng M P, Hou Y D, Li J F 2016 Adv. Funct. Mater. 26 1217

Google Scholar

Google Scholar

[16] Zheng T, Wu J, Xiao D, Zhu J 2018 Prog. Mater. Sci. 98 552

Google Scholar

Google Scholar

[17] Tao H, Wu H, Liu Y, Zhang Y, Wu J, Li F, Lü X, Zhao C, Xiao D, Zhu J, Pennycook S J 2019 J. Am. Chem. Soc. 141 13987

Google Scholar

Google Scholar

[18] Zhang M H, Wang K, Du Y J, Dai G, Sun W, Li G, Hu D, Thong H C, Zhao C, Xi X Q, Yue Z X, Li J F 2017 J. Am. Chem. Soc. 139 3889

Google Scholar

Google Scholar

[19] 王轲, 沈宗洋, 张波萍, 李敬锋 2014 无机材料学报 29 13

Google Scholar

Google Scholar

Wang K, Shen Z Y, Zhang B P, Li J F 2014 J. Inorg. Mater. 29 13

Google Scholar

Google Scholar

[20] Hollenstein E, Davis M, Damjanovic D, Setter N 2005 Appl. Phys. Lett. 87 182905

Google Scholar

Google Scholar

[21] Birol H, Damjanovic D, Setter N 2005 J. Am. Ceram. Soc. 88 1754

Google Scholar

Google Scholar

[22] Kim D H, Joung M R, Seo I T, Hur J, Kim J H, Kim B Y, Lee H J, Nahm S 2014 J. Eur. Ceram. Soc. 34 4193

Google Scholar

Google Scholar

[23] Du H, Li Z, Tang F, Qu S, Pei Z, Zhou W 2006 Mat. Sci. Eng. B 131 83

Google Scholar

Google Scholar

[24] Lin D, Kwok K W, Chan H L W 2008 J. Alloys Compd. 461 273

Google Scholar

Google Scholar

[25] Wu L, Zhang J L, Wang C L, Li J C 2008 J. Appl. Phys. 103 084116

Google Scholar

Google Scholar

[26] Standards Committee of the IEEE Ultrasonics, Ferroelectrics, and Frequency Control Society 1988 IEEE Standard on Piezoelectricity (New York: IEEE) ANSI/IEEE Std. 176-1987

[27] Thong H C, Xu Z, Zhao C, Lou L Y, Chen S, Zuo S Q, Li J F, Wang K 2019 J. Am. Ceram. Soc. 102 836

Google Scholar

Google Scholar

[28] Camargo J, Espinosa P A, Zabotto F, Ramajo L, Castro M 2020 J. Alloys Compd. 826 154129

Google Scholar

Google Scholar

[29] 李睿 2015 64 167303

Google Scholar

Google Scholar

Li R 2015 Acta Phys. Sin. 64 167303

Google Scholar

Google Scholar

[30] 贺连星, 李承恩 2000 无机材料学报 15 293

Google Scholar

Google Scholar

He L X, Li C E 2000 J. Inorg. Mater. 15 293

Google Scholar

Google Scholar

[31] Kamiya T, Suzuki T, Tsurumi T, Daimon M 1992 Jpn. J. Appl. Phys. 31 3058

Google Scholar

Google Scholar

[32] Yao F Z, Zhang M H, Wang K, Zhou J J, Chen F, Xu B, Li F, Shen Y, Zhang Q H, Gu L, Zhang X W, Li J F 2018 ACS Appl. Mater. Inter. 10 37298

Google Scholar

Google Scholar

[33] Cheng L Q, Wang K, Yu Q, Li J F 2014 J. Mater. Chem. C 2 1519

Google Scholar

Google Scholar

[34] Shen Z X, Hu Z P, Chong T C, Beh C Y, Tang S H, Kuok M H 1995 Phys. Rev. B 52 3976

[35] Sundarakannan B, Kakimoto K, Ohsato H 2004 Ferroelectrics 302 175

Google Scholar

Google Scholar

[36] 路朋献, 许德合, 马秋花, 王改民, 侯永改, 周文俊, 栗政新 2007 红外与毫米波学报 26 69

Google Scholar

Google Scholar

Lu P X, Xu D H, Ma Q H, Wang G M, Hou Y G, Zhou W J, Li Z X 2007 J. Infrared Millm. W. 26 69

Google Scholar

Google Scholar

[37] Wang Z, Gu H, Hu Y, Yang K, Hu M, Zhou D, Guan J 2010 Cryst. Eng. Comm. 12 3157

Google Scholar

Google Scholar

[38] Li J F, Wang K, Zhu F Y, Cheng L Q, Yao F Z 2013 J. Am. Ceram. Soc. 96 3677

Google Scholar

Google Scholar

[39] 刘霄, 徐小敏, 杜慧玲 2018 无机材料学报 33 683

Google Scholar

Google Scholar

Liu X, Xu X M, Du H L 2018 J. Inorg. Mater. 33 683

Google Scholar

Google Scholar

[40] Lee D, Jeon B C, Baek S H, Yang J S, Kim T H, Kim Y S, Yoon J G, Eom C B, Noh T W 2012 Adv. Mater. 24 6490

Google Scholar

Google Scholar

[41] Ren X 2004 Nat. Mater. 3 91

Google Scholar

Google Scholar

[42] Feng Z, Ren X 2007 Appl. Phys. Lett. 91 032904

Google Scholar

Google Scholar

[43] Voas B K, Usher T M, Liu X, Li S, Jones J L, Tan X, Cooper V R, Beckman S P 2014 Phys. Rev. B 90 024105

Google Scholar

Google Scholar

[44] Steiner S, Seo I T, Ren P, Li M, Keeble D J, Frömling T 2019 J. Am. Ceram. Soc. 102 5295

Google Scholar

Google Scholar

[45] Herber R P, Schneider G A, Wagner S, Hoffmann M J 2007 Appl. Phys. Lett. 90 252905

Google Scholar

Google Scholar

[46] Nakamura K, Tokiwa T, Kawamura Y 2002 J. Appl. Phys. 91 9272

Google Scholar

Google Scholar

[47] Qin Y, Zhang J, Yao W, Wang C, Zhang S 2015 J. Am. Ceram. Soc. 98 1027

Google Scholar

Google Scholar

-

表 1 KN, KN-Mn, KNN和KNN-Mn陶瓷的相对密度、压电性能和介电性能

Table 1. Relative density, piezoelectric and dielectric properties of KN, KN-Mn, KNN, and KNN-Mn ceramics.

d33/pC·N–1 Relative density/% kp Qm θmax/(°) tanδ εr (1 kHz) KN 90 92.0 0.26 177 66 0.042 576 KN-Mn 83 95.1 0.27 185 77 0.015 526 KNN 115 94.9 0.29 85 64 0.060 393 KNN-Mn 109 94.3 0.32 330 83 0.024 355 -

[1] Wang K, Malič B, Wu J 2018 MRS Bull. 43 607

Google Scholar

Google Scholar

[2] Thong H C, Zhao C, Zhou Z, Wu C F, Liu Y X, Du Z Z, Li J F, Gong W, Wang K 2019 Mater. Today 29 37

Google Scholar

Google Scholar

[3] 吴金根, 高翔宇, 陈建国, 王春明, 张树君, 董蜀湘 2018 67 207701

Google Scholar

Google Scholar

Wu J G, Gao X Y, Chen J G, Wang C M, Zhang S J, Dong S X 2018 Acta Phys. Sin. 67 207701

Google Scholar

Google Scholar

[4] 刘涛, 丁爱丽, 何夕云, 郑鑫森, 仇萍荪, 程文秀 2007 无机材料学报 22 469

Google Scholar

Google Scholar

Liu T, Ding A L, He X Y, Zheng X S, Qiu P S, Cheng W X 2007 J. Inorg. Mater. 22 469

Google Scholar

Google Scholar

[5] Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, Homma T, Nagaya T, Nakamura M 2004 Nature 432 84

Google Scholar

Google Scholar

[6] Koruza J, Bell A J, Frömling T, Webber K G, Wang K, Rödel J 2018 J. Materiomics 4 13

Google Scholar

Google Scholar

[7] Liu Q, Zhang Y, Gao J, Zhou Z, Yang D, Lee K Y, Studer A, Hinterstein M, Wang K, Zhang X, Li L, Li J F 2020 Natl. Sci. Rev. 7 355

Google Scholar

Google Scholar

[8] Zhang J, Pan Z, Guo F F, Liu W C, Ning H, Chen Y B, Lu M H, Yang B, Chen J, Zhang S T, Xing X, Rödel J, Cao W, Chen Y F 2015 Nat. Commun. 6 1

Google Scholar

Google Scholar

[9] Wang Y, Luo C, Wang S, Chen C, Yuan G, Luo H, Viehland D 2020 Adv. Electron. Mater. 6 1900949

Google Scholar

Google Scholar

[10] Wu J, Xiao D, Zhu J 2015 Chem. Rev. 115 2559

Google Scholar

Google Scholar

[11] Mgbemere H E, Herber R P, Schneider G A 2009 J. Eur. Ceram. Soc. 29 1729

Google Scholar

Google Scholar

[12] Cheng X, Wu J, Lou X, Wang X, Wang X, Xiao D, Zhu J 2014 ACS Appl. Mater. Inter. 6 750

Google Scholar

Google Scholar

[13] Hao J, Li W, Zhai J, Chen H 2019 Mat. Sci. Eng. R 135 1

Google Scholar

Google Scholar

[14] Wang K, Yao F Z, Jo W, Gobeljic D, Shvartsman V V, Lupascu D C, Li J F, Rödel J 2013 Adv. Funct. Mater. 23 4079

Google Scholar

Google Scholar

[15] Yao F Z, Wang K, Jo W, Webber K G, Comyn T P, Ding J X, Xu B, Cheng L Q, Zheng M P, Hou Y D, Li J F 2016 Adv. Funct. Mater. 26 1217

Google Scholar

Google Scholar

[16] Zheng T, Wu J, Xiao D, Zhu J 2018 Prog. Mater. Sci. 98 552

Google Scholar

Google Scholar

[17] Tao H, Wu H, Liu Y, Zhang Y, Wu J, Li F, Lü X, Zhao C, Xiao D, Zhu J, Pennycook S J 2019 J. Am. Chem. Soc. 141 13987

Google Scholar

Google Scholar

[18] Zhang M H, Wang K, Du Y J, Dai G, Sun W, Li G, Hu D, Thong H C, Zhao C, Xi X Q, Yue Z X, Li J F 2017 J. Am. Chem. Soc. 139 3889

Google Scholar

Google Scholar

[19] 王轲, 沈宗洋, 张波萍, 李敬锋 2014 无机材料学报 29 13

Google Scholar

Google Scholar

Wang K, Shen Z Y, Zhang B P, Li J F 2014 J. Inorg. Mater. 29 13

Google Scholar

Google Scholar

[20] Hollenstein E, Davis M, Damjanovic D, Setter N 2005 Appl. Phys. Lett. 87 182905

Google Scholar

Google Scholar

[21] Birol H, Damjanovic D, Setter N 2005 J. Am. Ceram. Soc. 88 1754

Google Scholar

Google Scholar

[22] Kim D H, Joung M R, Seo I T, Hur J, Kim J H, Kim B Y, Lee H J, Nahm S 2014 J. Eur. Ceram. Soc. 34 4193

Google Scholar

Google Scholar

[23] Du H, Li Z, Tang F, Qu S, Pei Z, Zhou W 2006 Mat. Sci. Eng. B 131 83

Google Scholar

Google Scholar

[24] Lin D, Kwok K W, Chan H L W 2008 J. Alloys Compd. 461 273

Google Scholar

Google Scholar

[25] Wu L, Zhang J L, Wang C L, Li J C 2008 J. Appl. Phys. 103 084116

Google Scholar

Google Scholar

[26] Standards Committee of the IEEE Ultrasonics, Ferroelectrics, and Frequency Control Society 1988 IEEE Standard on Piezoelectricity (New York: IEEE) ANSI/IEEE Std. 176-1987

[27] Thong H C, Xu Z, Zhao C, Lou L Y, Chen S, Zuo S Q, Li J F, Wang K 2019 J. Am. Ceram. Soc. 102 836

Google Scholar

Google Scholar

[28] Camargo J, Espinosa P A, Zabotto F, Ramajo L, Castro M 2020 J. Alloys Compd. 826 154129

Google Scholar

Google Scholar

[29] 李睿 2015 64 167303

Google Scholar

Google Scholar

Li R 2015 Acta Phys. Sin. 64 167303

Google Scholar

Google Scholar

[30] 贺连星, 李承恩 2000 无机材料学报 15 293

Google Scholar

Google Scholar

He L X, Li C E 2000 J. Inorg. Mater. 15 293

Google Scholar

Google Scholar

[31] Kamiya T, Suzuki T, Tsurumi T, Daimon M 1992 Jpn. J. Appl. Phys. 31 3058

Google Scholar

Google Scholar

[32] Yao F Z, Zhang M H, Wang K, Zhou J J, Chen F, Xu B, Li F, Shen Y, Zhang Q H, Gu L, Zhang X W, Li J F 2018 ACS Appl. Mater. Inter. 10 37298

Google Scholar

Google Scholar

[33] Cheng L Q, Wang K, Yu Q, Li J F 2014 J. Mater. Chem. C 2 1519

Google Scholar

Google Scholar

[34] Shen Z X, Hu Z P, Chong T C, Beh C Y, Tang S H, Kuok M H 1995 Phys. Rev. B 52 3976

[35] Sundarakannan B, Kakimoto K, Ohsato H 2004 Ferroelectrics 302 175

Google Scholar

Google Scholar

[36] 路朋献, 许德合, 马秋花, 王改民, 侯永改, 周文俊, 栗政新 2007 红外与毫米波学报 26 69

Google Scholar

Google Scholar

Lu P X, Xu D H, Ma Q H, Wang G M, Hou Y G, Zhou W J, Li Z X 2007 J. Infrared Millm. W. 26 69

Google Scholar

Google Scholar

[37] Wang Z, Gu H, Hu Y, Yang K, Hu M, Zhou D, Guan J 2010 Cryst. Eng. Comm. 12 3157

Google Scholar

Google Scholar

[38] Li J F, Wang K, Zhu F Y, Cheng L Q, Yao F Z 2013 J. Am. Ceram. Soc. 96 3677

Google Scholar

Google Scholar

[39] 刘霄, 徐小敏, 杜慧玲 2018 无机材料学报 33 683

Google Scholar

Google Scholar

Liu X, Xu X M, Du H L 2018 J. Inorg. Mater. 33 683

Google Scholar

Google Scholar

[40] Lee D, Jeon B C, Baek S H, Yang J S, Kim T H, Kim Y S, Yoon J G, Eom C B, Noh T W 2012 Adv. Mater. 24 6490

Google Scholar

Google Scholar

[41] Ren X 2004 Nat. Mater. 3 91

Google Scholar

Google Scholar

[42] Feng Z, Ren X 2007 Appl. Phys. Lett. 91 032904

Google Scholar

Google Scholar

[43] Voas B K, Usher T M, Liu X, Li S, Jones J L, Tan X, Cooper V R, Beckman S P 2014 Phys. Rev. B 90 024105

Google Scholar

Google Scholar

[44] Steiner S, Seo I T, Ren P, Li M, Keeble D J, Frömling T 2019 J. Am. Ceram. Soc. 102 5295

Google Scholar

Google Scholar

[45] Herber R P, Schneider G A, Wagner S, Hoffmann M J 2007 Appl. Phys. Lett. 90 252905

Google Scholar

Google Scholar

[46] Nakamura K, Tokiwa T, Kawamura Y 2002 J. Appl. Phys. 91 9272

Google Scholar

Google Scholar

[47] Qin Y, Zhang J, Yao W, Wang C, Zhang S 2015 J. Am. Ceram. Soc. 98 1027

Google Scholar

Google Scholar

计量

- 文章访问数: 15529

- PDF下载量: 715

- 被引次数: 0

下载:

下载: