-

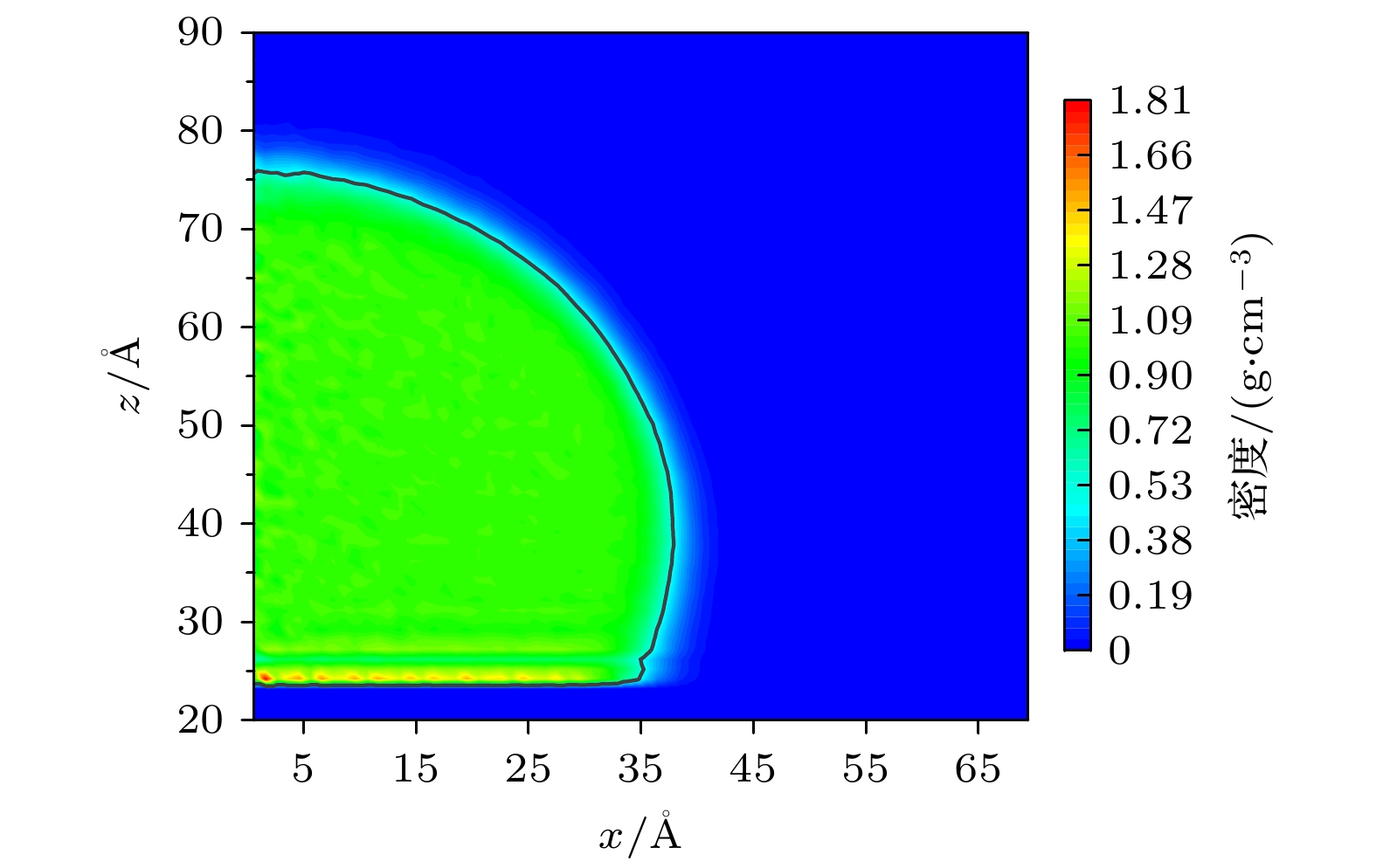

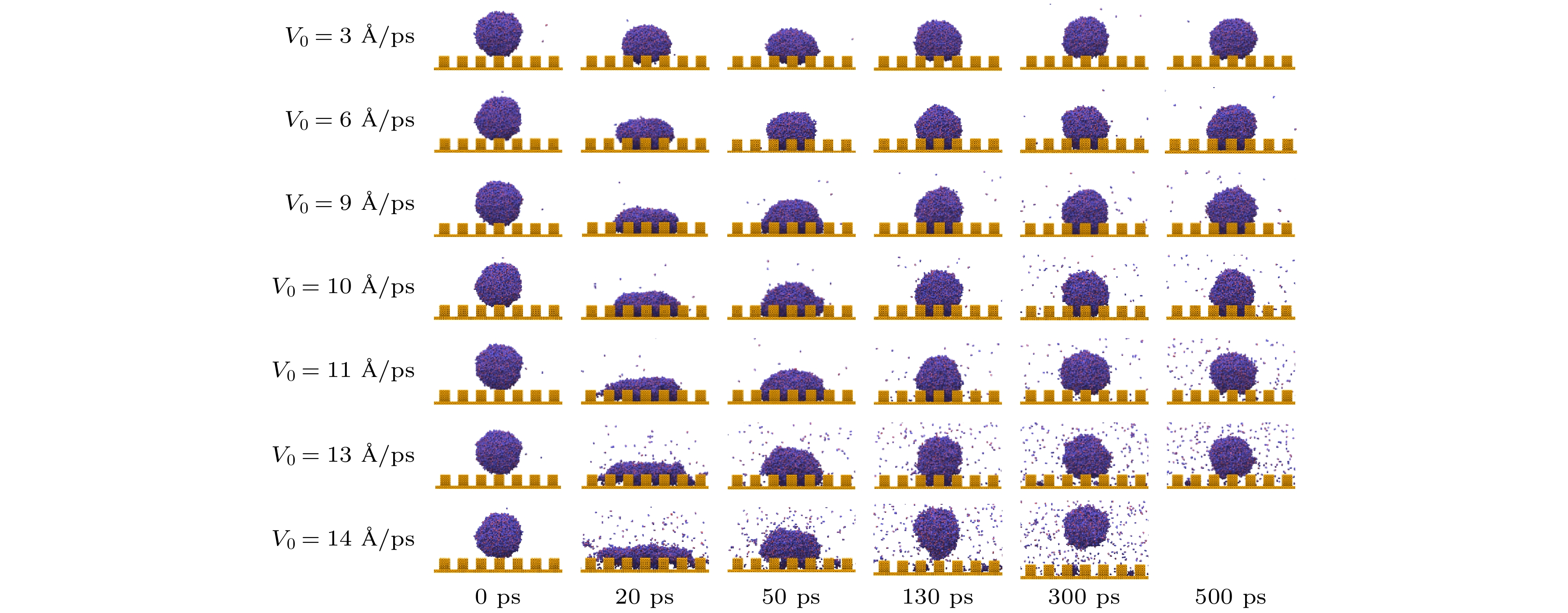

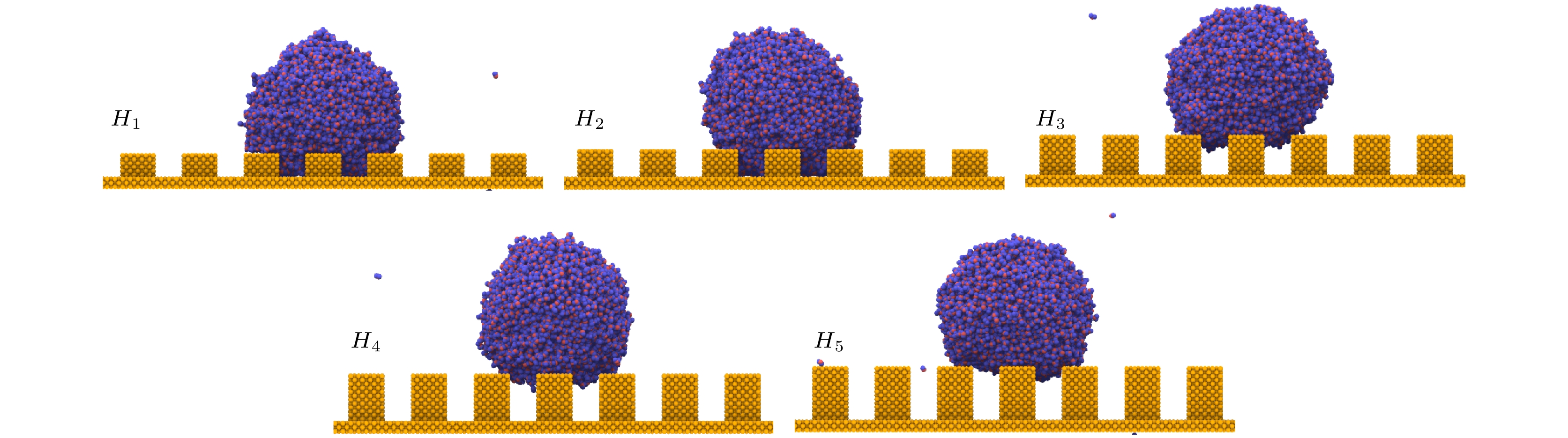

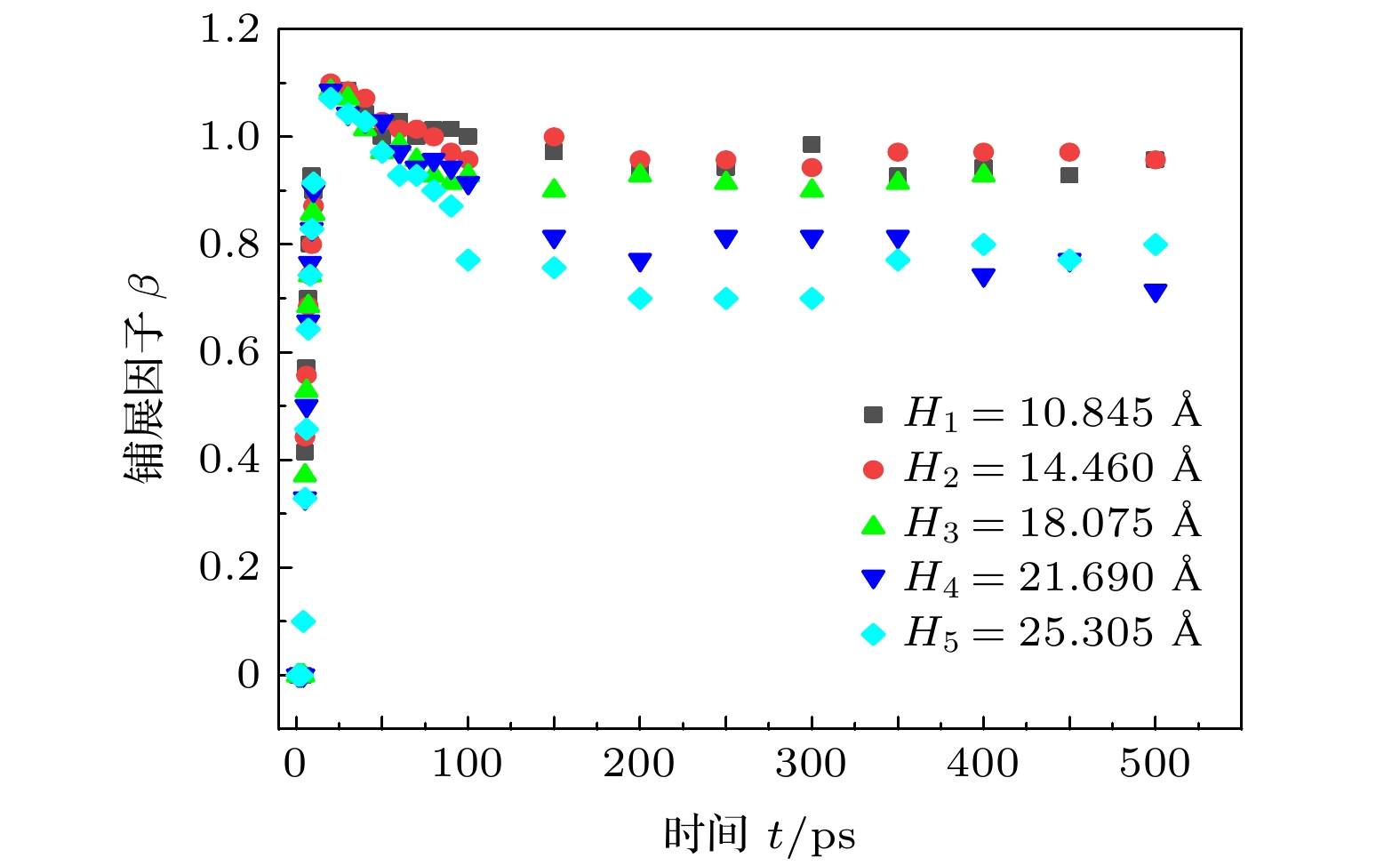

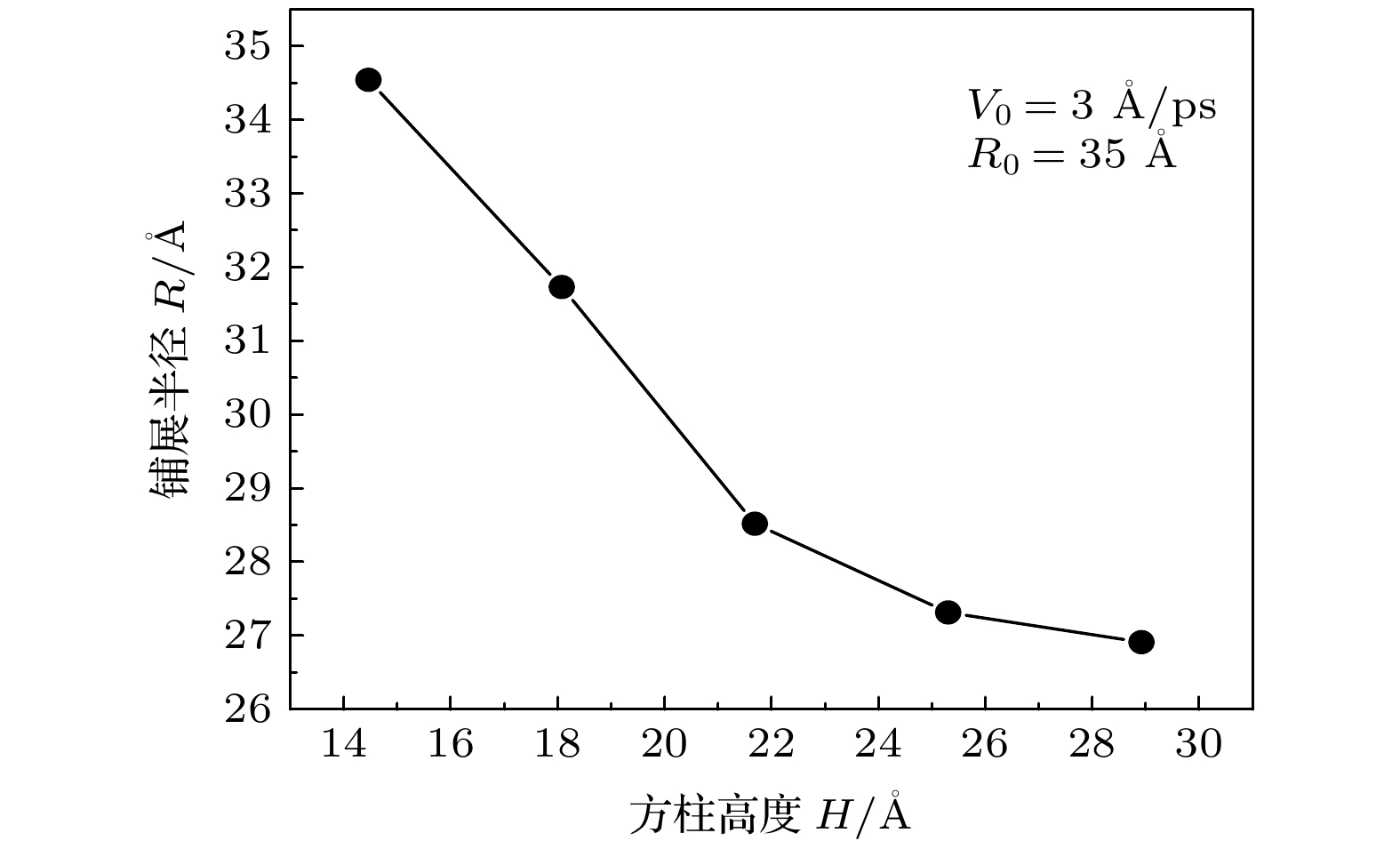

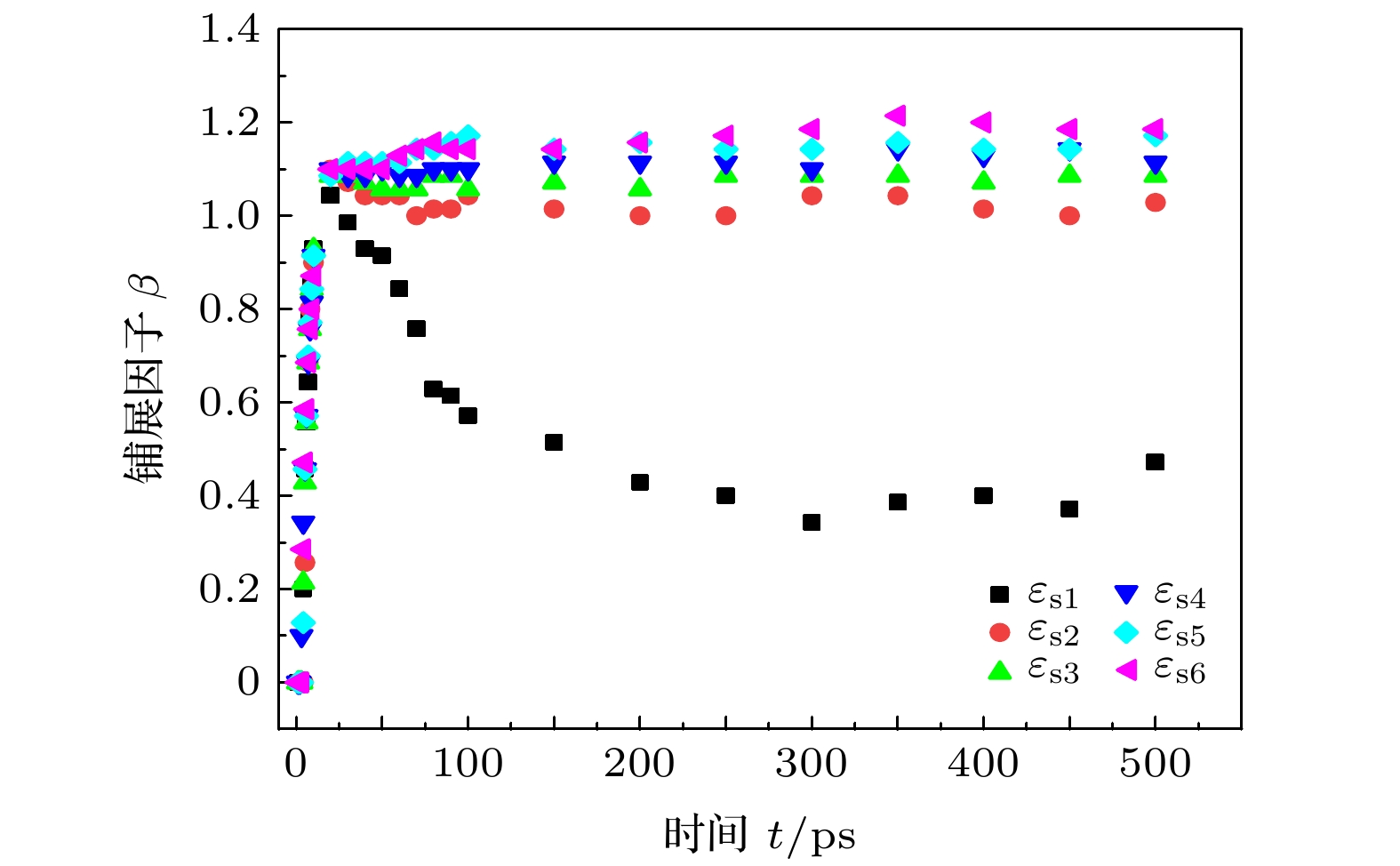

Droplets’ impinging on a solid surface is a common phenomenon in industry and agriculture. With the development of micro and nano technology, the quantitative descriptions of impinging behaviors for nanodroplets are expected to be further explored. Molecular dynamics (MD) simulation is adopted to investigate the behaviors of water nanodroplets impinging on cooper surfaces which have been decorated with square nanopillars. The dynamical characteristics of nanodroplets are analyzed at 5 different pillar heights, 6 different surface characteristic energy values, and a wide range of droplet velocities. The results show that there is no obvious difference among the dynamical behaviors for nanodroplets, whose radii are in a range from 35 to 45 Å, impinging on a solid surface. With the increase of droplet velocity, the wetting pattern of steady nanodroplets first transfers from Cassie state (V0 = 2–3 Å/ps) to Wenzel state (V0 = 4–10 Å/ps), then it returns to the Cassie state (V0 = 11–13 Å/ps) again. Nanodroplets bounce off the solid surface when V0 > 13 Å/ps. The relationship between the maximum spreading time and droplet velocity is presented. Inflection points in the curve of the relationship are discovered and their formation mechanism is studied. The spreading factors of steady states for nanodroplets with velocity lower than 9 Å/ps are nearly the same; however, they decrease gradually for nanodroplets with velocity higher than 9 Å/ps. In addition, the increasing height of square nanopillars facilitates the transition from Wenzel state to Cassie state and reduces the spreading radius of steady nanodroplets. The mechanism, which yields Wenzel state when the nanodroplets impinge on solid surface with lower height nanopillars, is investigated. In the spreading stage, spreading radii of nanodroplets impinging on surfaces with different height nanopillars are almost identical. The influence of nanopillar height mainly plays a role in the retraction stage of droplets and it fades away as the height further increases. Moreover, the higher surface characteristic energy benefits the spreading of nanodroplets and reduces the retraction time. Especially, nanodroplets do not experience retraction stage, and the spreading stage is kept until the nanodroplets reach a stable state when the surface characteristic energy is increased to 0.714 kcal/mol. Compared with the spreading factor, the centroid height of nanodroplet is very sensitive to the change of surface characteristic energy.

-

Keywords:

- nanodroplet /

- molecular dynamics simulations /

- impinge /

- dynamic behavior

[1] Galliker P, Schneider J, Eghlidi H, Kress S, Sandoghdar V, Poulikakos D 2012 Nat. Commun. 3 782

Google Scholar

Google Scholar

[2] Bergeron V, Bonn D, Martin J Y, Vovelle L 2000 Nature 405 772

Google Scholar

Google Scholar

[3] Zhou Z F, Chen B, Wang R, Wang G X 2017 Exp. Therm. Fluid Sci. 82 189

Google Scholar

Google Scholar

[4] Chen X L, Li X M, Shao J Y, An N L, Tian H M, Wang C, Han T Y, Wang L, Lu B H 2017 Small 13 1604245

Google Scholar

Google Scholar

[5] Pan K L, Chou P C, Tseng Y J 2009 Phys. Rev. E 80 036301

Google Scholar

Google Scholar

[6] Deng X, Mammen L, Butt H, Vollmer D 2012 Science 335 67

Google Scholar

Google Scholar

[7] Wang N, Xiong D S, Deng Y L, Shi Y, Wang K 2015 ACS. Appl. Mater. Interfaces 7 6260

Google Scholar

Google Scholar

[8] Peng Y, He Y X, Yang S A, Ben S, Cao M Y, Li K, Liu K, Jiang L 2015 Adv. Funct. Mater. 25 5967

Google Scholar

Google Scholar

[9] Rioboo R, Tropea C, Marengo M 2001 Atomization Spray. 11 155

Google Scholar

Google Scholar

[10] 施其明, 贾志海, 林琪焱 2016 化工进展 35 3818

Google Scholar

Google Scholar

Shi Q M, Jia Z H, Lin Q Y 2016 Chem. Ind. Eng. Prog. 35 3818

Google Scholar

Google Scholar

[11] 彭家略, 郭浩, 尤天涯, 纪献兵, 徐进良 2021 70 044701

Google Scholar

Google Scholar

Peng J L, Guo H, You T Y, Ji X B, Xu J L 2021 Acta Phys. Sin. 70 044701

Google Scholar

Google Scholar

[12] 顾秦铭, 张朝阳, 周晖, 张凯峰, 徐坤, 朱浩 2020 机械工程学报 56 223

Google Scholar

Google Scholar

Gu Q M, Zhang C Y, Zhou H, Zhang K F, Xu K, Zhu H 2020 J. Mech. Eng. 56 223

Google Scholar

Google Scholar

[13] Qi H C, Wang T Y, Che Z Z 2020 Phys. Rev. E 101 043114

Google Scholar

Google Scholar

[14] Gao S, Liao Q W, Liu W, Liu Z C 2018 J. Phys. Chem. Lett. 9 13

Google Scholar

Google Scholar

[15] Gao S, Liao Q W, Liu W, Liu Z C 2017 Langmuir 33 12379

Google Scholar

Google Scholar

[16] Xie F F, Lv S H, Yang Y R, Wang X D 2020 J. Phys. Chem. Lett. 11 2818

Google Scholar

Google Scholar

[17] 邱丰, 王猛, 周化光, 郑璇, 林鑫, 黄卫东 2013 62 120203

Google Scholar

Google Scholar

Qiu F, Wang M, Zhou H G, Zheng X, Lin X, Huang W D 2013 Acta Phys. Sin. 62 120203

Google Scholar

Google Scholar

[18] Liu H Y, Chu F Q, Zhang J, Wen D S 2020 Phys. Rev. Fluids 5 074201

Google Scholar

Google Scholar

[19] Wang Y B, Wang X D, Yang Y R, Chen M 2019 J. Phys. Chem. C. 123 12841

Google Scholar

Google Scholar

[20] Yin Z J, Ding Z L, Zhang W F, Su R, Chai F T, Yu P 2020 Comput. Mater. Sci. 183 109814

Google Scholar

Google Scholar

[21] Zhang M Y, Ma L J, Wang Q, Hao P, Zheng X 2020 Colloids Surf., A 604 125291

Google Scholar

Google Scholar

[22] Jorgensen W L, Chandrasekhar J, Madura J D, Impey R W, Klein M L 1983 J. Chem. Phys. 79 926

Google Scholar

Google Scholar

[23] Fu T, Wu N, Lu C, Wang J B, Wang Q L 2019 Mol. Simul. 45 35

Google Scholar

Google Scholar

[24] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[25] Song F H, Li B Q, Li Y 2015 Phys. Chem. Chem. Phys. 17 5543

Google Scholar

Google Scholar

[26] Gonzalez-Valle C U, Kumar S, Ramos-Alvarado B 2018 The Journal of Physical Chemistry C 122 7179

Google Scholar

Google Scholar

[27] Koishi T, Yasuoka K, Zeng X C 2017 Langmuir 33 10184

Google Scholar

Google Scholar

[28] Cordeiro J, Desai S 2017 ASME J. Micro Nano-Manuf. 5 031008

Google Scholar

Google Scholar

[29] 向恒 2008 博士学位论文 (北京: 清华大学)

Xiang H 2008 Ph. D. Dissertation (Beijing: Tsinghua University) (in Chinese)

[30] Chen L, Wang S Y, Xiang X, Tao W Q 2020 Comput. Mater. Sci. 171 109223

Google Scholar

Google Scholar

[31] 陈正隆 2007 分子模拟的实践与理论 (北京: 化学工业出版社) 第8页

Chen Z L 2007 Practice and Theory of Molecular Simulations (Beijing: Chemical Industry Press) p8 (in Chinese)

[32] Bekele S, Evans O G, Tsige M 2020 J. Phys. Chem.C. 124 20109

Google Scholar

Google Scholar

[33] Essmann U, Perera L, Berkowitz M, Darden T, Lee H, Pedersen L 1995 J. Chem. Phys. 103 8577

[34] Hoover W G 1985 Phys. Rev. A 31 1695

Google Scholar

Google Scholar

[35] Song F H, Li B Q, Liu C 2013 Langmuir 29 4266

Google Scholar

Google Scholar

[36] 章佳健 2020 博士学位论文 (合肥: 中国科学技术大学)

Zhang J J 2020 Ph. D. Dissertation (Hefei: University of Science and Technology of China) (in Chinese)

[37] 成中军, 杜明, 来华, 张乃庆, 孙克宁 2013 高等学校化学学报 34 606

Google Scholar

Google Scholar

Cheng Z J, Du M, Lai H, Zhang N Q, Sun K N 2013 Chem. J. Chin. Univ. 34 606

Google Scholar

Google Scholar

[38] Hu H B, Chen L B, Bao L Y, Huang S H 2014 Chin. Phys. B. 23 074702

Google Scholar

Google Scholar

[39] Wenzel R N 1936 Ind. Eng. Chem. 28 988

Google Scholar

Google Scholar

[40] Cassie A B D, Baxter S 1944 Trans. Farad. Soc. 40 546

Google Scholar

Google Scholar

[41] 焦云龙, 刘小君, 刘焜 2016 力学学报 48 353

Google Scholar

Google Scholar

Jiao Y L, Liu X J, Liu K 2016 Chin J. Theor. Appl. Mech. 48 353

Google Scholar

Google Scholar

-

表 1 液滴撞击柱状固体表面稳定状态时的润湿模式

Table 1. Wetting patterns of steady state of droplets impinging on nanopillared solid surfaces.

V0/(Å·ps–1) 2—3 4—10 11—13 14—15 润湿模式 Cassie Wenzel Cassie 弹跳 表 2 液滴撞击不同高度柱状表面后的稳定态润湿模式

Table 2. Wetting patterns of steady state of droplets impinging on surfaces with different height nanopillars.

方柱

高度H1 H2 H3 H4 H5 10.845 Å 14.460 Å 18.075 Å 21.690 Å 25.305 Å 润湿

模式Wenzel Wenzel Cassie Cassie Cassie 表 3 不同

${\varepsilon _{\rm{s}}}$ 固体表面对应的${\varepsilon _{{\rm{s \text- o}}}}$ 及液滴接触角$ \theta $ Table 3. Corresponding

${\varepsilon _{{\rm{s \text- o}}}}$ and contact angles of droplets for solid surfaces with different${\varepsilon _{\rm{s}}}$ .${\varepsilon _{\rm{s}}}$/(kcal·mol–1) ${\varepsilon _{\rm{s}}}$/(kcal·mol–1) 接触角$ \theta $/$ (°) $ ${\varepsilon _{{\rm{s1}}}} = 0.5{\varepsilon _{{\rm{Cu}}}} = 0.119$ 0.139 125.9 ${\varepsilon _{{\rm{s2}}}} = 1.5{\varepsilon _{{\rm{Cu}}}} = 0.357$ 0.241 97.1 ${\varepsilon _{{\rm{s3}}}} = 2.0{\varepsilon _{{\rm{Cu}}}} = 0.476$ 0.278 80 ${\varepsilon _{{\rm{s4}}}} = 3.0{\varepsilon _{{\rm{Cu}}}} = 0.714$ 0.341 63 ${\varepsilon _{{\rm{s5}}}} = 4.0{\varepsilon _{{\rm{Cu}}}} = 0.952$ 0.394 45 ${\varepsilon _{{\rm{s6}}}} = 5.0{\varepsilon _{{\rm{Cu}}}} = 1.190$ 0.440 22 -

[1] Galliker P, Schneider J, Eghlidi H, Kress S, Sandoghdar V, Poulikakos D 2012 Nat. Commun. 3 782

Google Scholar

Google Scholar

[2] Bergeron V, Bonn D, Martin J Y, Vovelle L 2000 Nature 405 772

Google Scholar

Google Scholar

[3] Zhou Z F, Chen B, Wang R, Wang G X 2017 Exp. Therm. Fluid Sci. 82 189

Google Scholar

Google Scholar

[4] Chen X L, Li X M, Shao J Y, An N L, Tian H M, Wang C, Han T Y, Wang L, Lu B H 2017 Small 13 1604245

Google Scholar

Google Scholar

[5] Pan K L, Chou P C, Tseng Y J 2009 Phys. Rev. E 80 036301

Google Scholar

Google Scholar

[6] Deng X, Mammen L, Butt H, Vollmer D 2012 Science 335 67

Google Scholar

Google Scholar

[7] Wang N, Xiong D S, Deng Y L, Shi Y, Wang K 2015 ACS. Appl. Mater. Interfaces 7 6260

Google Scholar

Google Scholar

[8] Peng Y, He Y X, Yang S A, Ben S, Cao M Y, Li K, Liu K, Jiang L 2015 Adv. Funct. Mater. 25 5967

Google Scholar

Google Scholar

[9] Rioboo R, Tropea C, Marengo M 2001 Atomization Spray. 11 155

Google Scholar

Google Scholar

[10] 施其明, 贾志海, 林琪焱 2016 化工进展 35 3818

Google Scholar

Google Scholar

Shi Q M, Jia Z H, Lin Q Y 2016 Chem. Ind. Eng. Prog. 35 3818

Google Scholar

Google Scholar

[11] 彭家略, 郭浩, 尤天涯, 纪献兵, 徐进良 2021 70 044701

Google Scholar

Google Scholar

Peng J L, Guo H, You T Y, Ji X B, Xu J L 2021 Acta Phys. Sin. 70 044701

Google Scholar

Google Scholar

[12] 顾秦铭, 张朝阳, 周晖, 张凯峰, 徐坤, 朱浩 2020 机械工程学报 56 223

Google Scholar

Google Scholar

Gu Q M, Zhang C Y, Zhou H, Zhang K F, Xu K, Zhu H 2020 J. Mech. Eng. 56 223

Google Scholar

Google Scholar

[13] Qi H C, Wang T Y, Che Z Z 2020 Phys. Rev. E 101 043114

Google Scholar

Google Scholar

[14] Gao S, Liao Q W, Liu W, Liu Z C 2018 J. Phys. Chem. Lett. 9 13

Google Scholar

Google Scholar

[15] Gao S, Liao Q W, Liu W, Liu Z C 2017 Langmuir 33 12379

Google Scholar

Google Scholar

[16] Xie F F, Lv S H, Yang Y R, Wang X D 2020 J. Phys. Chem. Lett. 11 2818

Google Scholar

Google Scholar

[17] 邱丰, 王猛, 周化光, 郑璇, 林鑫, 黄卫东 2013 62 120203

Google Scholar

Google Scholar

Qiu F, Wang M, Zhou H G, Zheng X, Lin X, Huang W D 2013 Acta Phys. Sin. 62 120203

Google Scholar

Google Scholar

[18] Liu H Y, Chu F Q, Zhang J, Wen D S 2020 Phys. Rev. Fluids 5 074201

Google Scholar

Google Scholar

[19] Wang Y B, Wang X D, Yang Y R, Chen M 2019 J. Phys. Chem. C. 123 12841

Google Scholar

Google Scholar

[20] Yin Z J, Ding Z L, Zhang W F, Su R, Chai F T, Yu P 2020 Comput. Mater. Sci. 183 109814

Google Scholar

Google Scholar

[21] Zhang M Y, Ma L J, Wang Q, Hao P, Zheng X 2020 Colloids Surf., A 604 125291

Google Scholar

Google Scholar

[22] Jorgensen W L, Chandrasekhar J, Madura J D, Impey R W, Klein M L 1983 J. Chem. Phys. 79 926

Google Scholar

Google Scholar

[23] Fu T, Wu N, Lu C, Wang J B, Wang Q L 2019 Mol. Simul. 45 35

Google Scholar

Google Scholar

[24] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[25] Song F H, Li B Q, Li Y 2015 Phys. Chem. Chem. Phys. 17 5543

Google Scholar

Google Scholar

[26] Gonzalez-Valle C U, Kumar S, Ramos-Alvarado B 2018 The Journal of Physical Chemistry C 122 7179

Google Scholar

Google Scholar

[27] Koishi T, Yasuoka K, Zeng X C 2017 Langmuir 33 10184

Google Scholar

Google Scholar

[28] Cordeiro J, Desai S 2017 ASME J. Micro Nano-Manuf. 5 031008

Google Scholar

Google Scholar

[29] 向恒 2008 博士学位论文 (北京: 清华大学)

Xiang H 2008 Ph. D. Dissertation (Beijing: Tsinghua University) (in Chinese)

[30] Chen L, Wang S Y, Xiang X, Tao W Q 2020 Comput. Mater. Sci. 171 109223

Google Scholar

Google Scholar

[31] 陈正隆 2007 分子模拟的实践与理论 (北京: 化学工业出版社) 第8页

Chen Z L 2007 Practice and Theory of Molecular Simulations (Beijing: Chemical Industry Press) p8 (in Chinese)

[32] Bekele S, Evans O G, Tsige M 2020 J. Phys. Chem.C. 124 20109

Google Scholar

Google Scholar

[33] Essmann U, Perera L, Berkowitz M, Darden T, Lee H, Pedersen L 1995 J. Chem. Phys. 103 8577

[34] Hoover W G 1985 Phys. Rev. A 31 1695

Google Scholar

Google Scholar

[35] Song F H, Li B Q, Liu C 2013 Langmuir 29 4266

Google Scholar

Google Scholar

[36] 章佳健 2020 博士学位论文 (合肥: 中国科学技术大学)

Zhang J J 2020 Ph. D. Dissertation (Hefei: University of Science and Technology of China) (in Chinese)

[37] 成中军, 杜明, 来华, 张乃庆, 孙克宁 2013 高等学校化学学报 34 606

Google Scholar

Google Scholar

Cheng Z J, Du M, Lai H, Zhang N Q, Sun K N 2013 Chem. J. Chin. Univ. 34 606

Google Scholar

Google Scholar

[38] Hu H B, Chen L B, Bao L Y, Huang S H 2014 Chin. Phys. B. 23 074702

Google Scholar

Google Scholar

[39] Wenzel R N 1936 Ind. Eng. Chem. 28 988

Google Scholar

Google Scholar

[40] Cassie A B D, Baxter S 1944 Trans. Farad. Soc. 40 546

Google Scholar

Google Scholar

[41] 焦云龙, 刘小君, 刘焜 2016 力学学报 48 353

Google Scholar

Google Scholar

Jiao Y L, Liu X J, Liu K 2016 Chin J. Theor. Appl. Mech. 48 353

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 9095

- PDF Downloads: 164

- Cited By: 0

DownLoad:

DownLoad: