-

高熵合金纤维因其优异的力学性能和稳定性, 在高科技领域具有广阔的应用前景. 然而, 该类材料强塑性不匹配的问题制约了其进一步应用, 虽然热处理可以进一步优化其力学性能, 但传统热处理方法对时间和能源的消耗较高, 且难以精准调控材料的组织, 易导致晶粒粗化. 本文采用电流处理技术调制微米级(直径~70 μm)冷拔态CoCrFeNi高熵合金纤维的性能, 采用电子背散射衍射、透射电子显微镜以及同步辐射等技术探讨了电流处理过程中的热效应与非热效应对材料组织结构和力学性能的影响, 建立了CoCrFeNi纤维再结晶形核和长大模型. 相比于传统热处理, 电流处理过程中电子风力和焦耳热效应的协同作用显著加快再结晶过程, 获得更细小且均匀的晶粒, 并有效降低位错密度, 进而获得更优异的力学性能. 电流处理可获得屈服强度为400—2033 MPa的纤维, 延伸率最高可达53%. 本文证实, 电流处理可作为优化高熵合金纤维组织结构及性能的有效手段, 为高性能金属纤维的制备及工程化应用提供理论支撑和工艺指导.High-entropy alloy (HEA) microfibers exhibit promising prospects in microscale high-tech applications due to their exceptional mechanical properties and stability. However, the strength-plasticity tradeoff largely hinders their further industrial applications. Heat treatment can optimize the mechanical properties of HEA microfibers. However,the traditional heat treatment (CHT) faces challenges in accurately adjusting the microstructures in a short period of time, while also being prone to grain coarsening, which can affect performance. In this study, an electric current treatment (ECT) technique is used to finely modulate the properties of cold-drawn CoCrFeNi high-entropy alloy microfibers on a microscale (~70 μm in diameter), the effects of thermal and athermal effects during ECT on microstructure and mechanical properties are systematically investigated through electron back scatter diffraction, transmission electron microscopy, and synchrotron radiation. A model of recrystallization, nucleation and growth of HEA microfibers is established. Compared with CHT, the synergistic effects of electron wind force and Joule heating during ECT significantly accelerate recrystallization kinetics, yielding finer and more homogeneous grains with a great decrease in dislocation density, and finally lead to better mechanical properties. The ECT-processed HEA microfibers achieve a yield strength in a range from 400 to 2033 MPa and a tensile elongation reaching 53%, which are much higher than those of CHT samples. These results demonstrate that the ECT is effective for optimizing the microstructure and properties of HEA microfibers, and can also provide both a theoretical foundation and technical guidance for fabricating high-performance metallic microfibers.

-

Keywords:

- high-entropy alloy /

- microfibers /

- electric current treatment /

- microstructure /

- mechanical properties

-

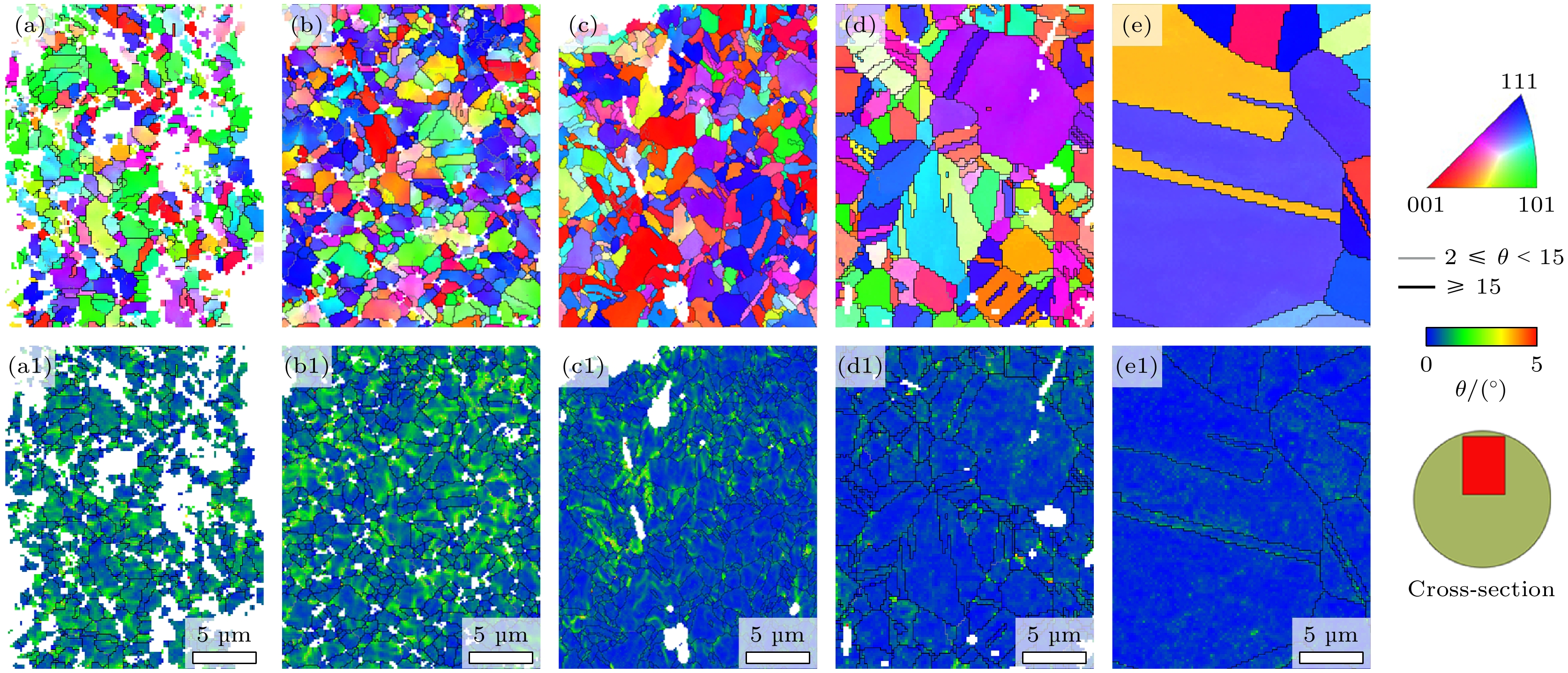

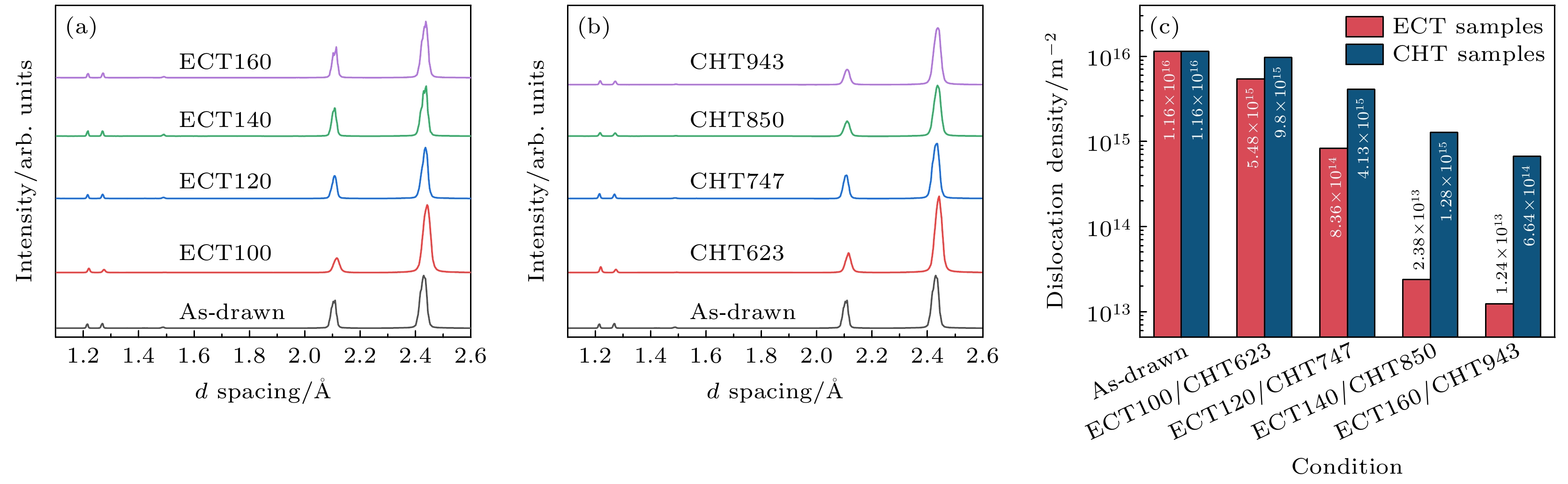

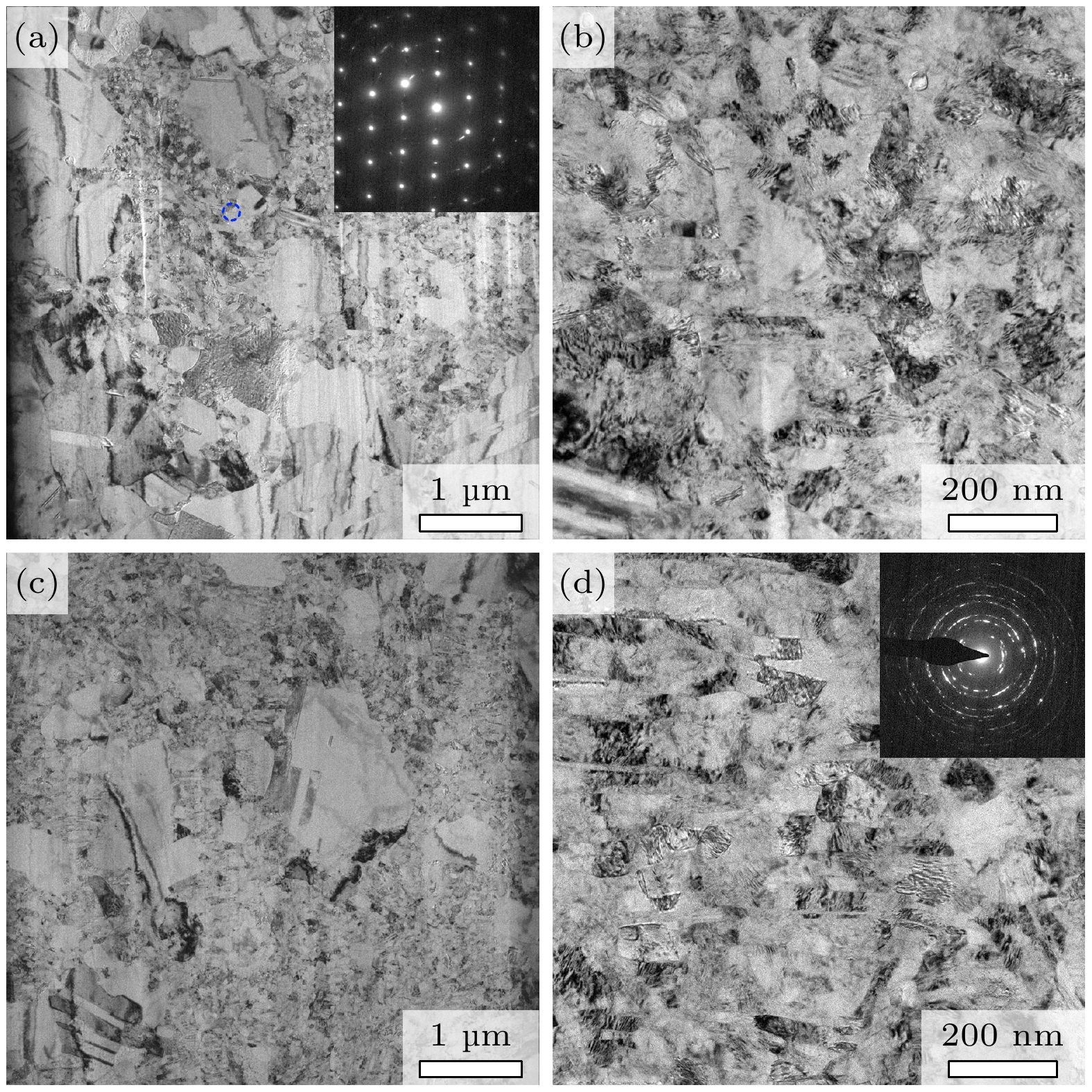

图 1 不同电流密度电流处理CoCrFeNi高熵合金纤维的的IPF图和KAM图 (a), (a1) ECT120; (b), (b1) ECT140; (c), (c1) ECT160; (d), (d1) ECT180; (e), (e1) ECT200

Fig. 1. EBSD images of electric current treated CoCrFeNi HEA microfibers with various current densities: (a), (a1) ECT120; (b), (b1) ECT140; (c), (c1) ECT160; (d), (d1) ECT180; (e), (e1) ECT200.

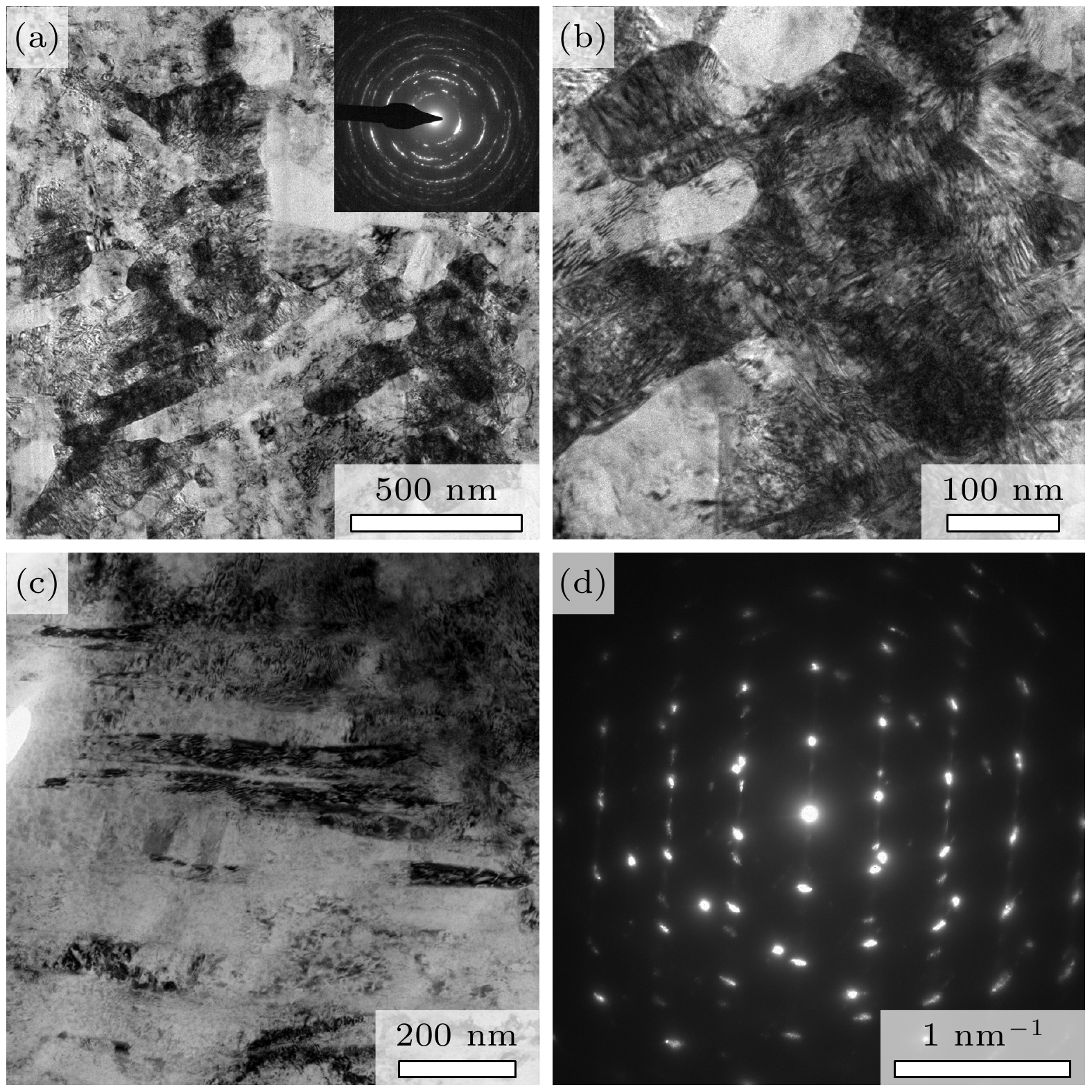

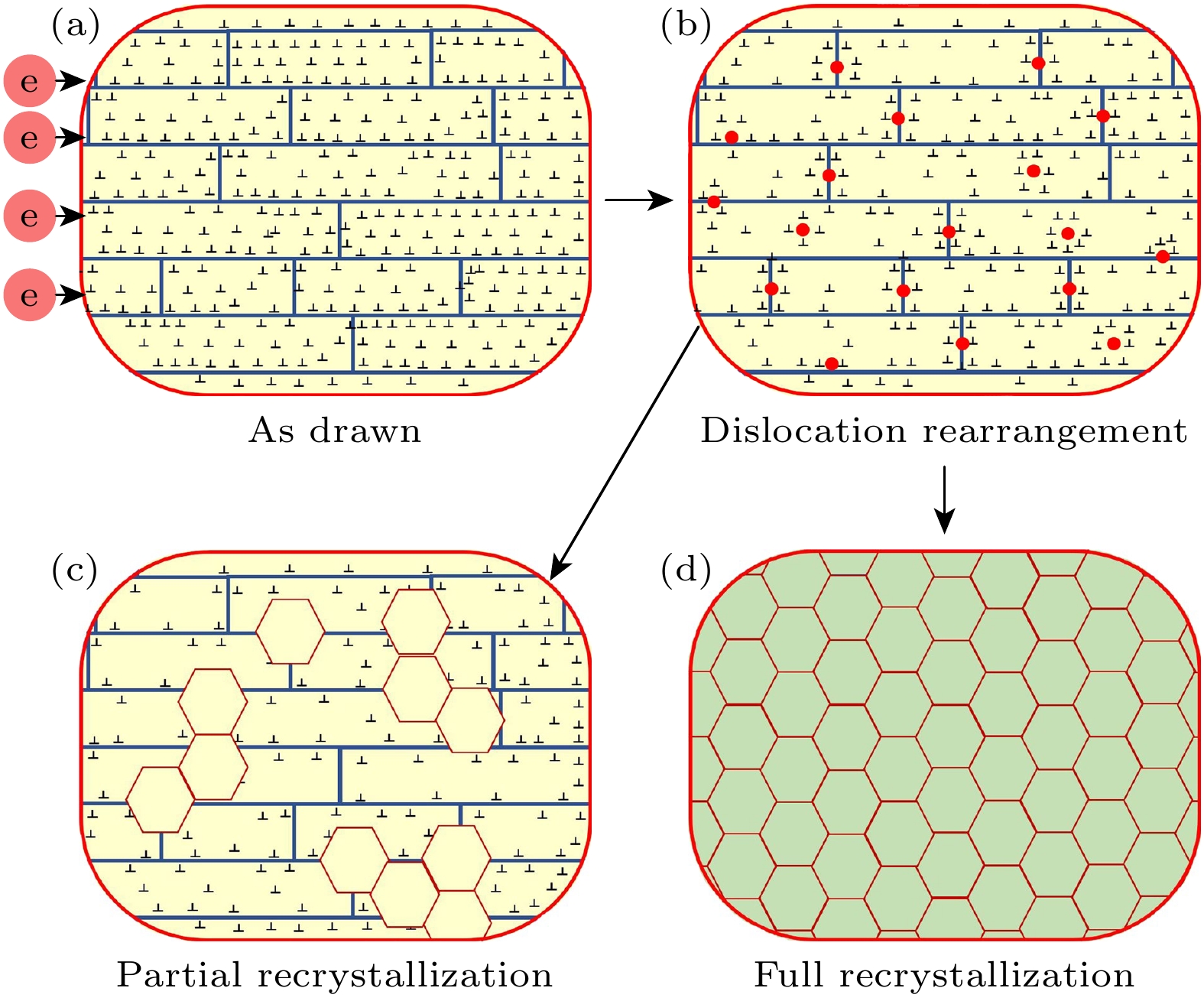

图 5 ECT100和CHT623高熵合金纤维TEM图像(a), (b) ECT100纤维的TEM明场像; (c), (d) CHT623纤维的TEM明场像及对应的选区电子衍射斑点

Fig. 5. TEM images of ECT100 and CHT623 HEA microfibers: (a), (b) TEM bright field images of ECT100 microfibers; (c), (d) TEM bright field images and corresponding selected area electron diffraction pattern of CHT623 microfibers.

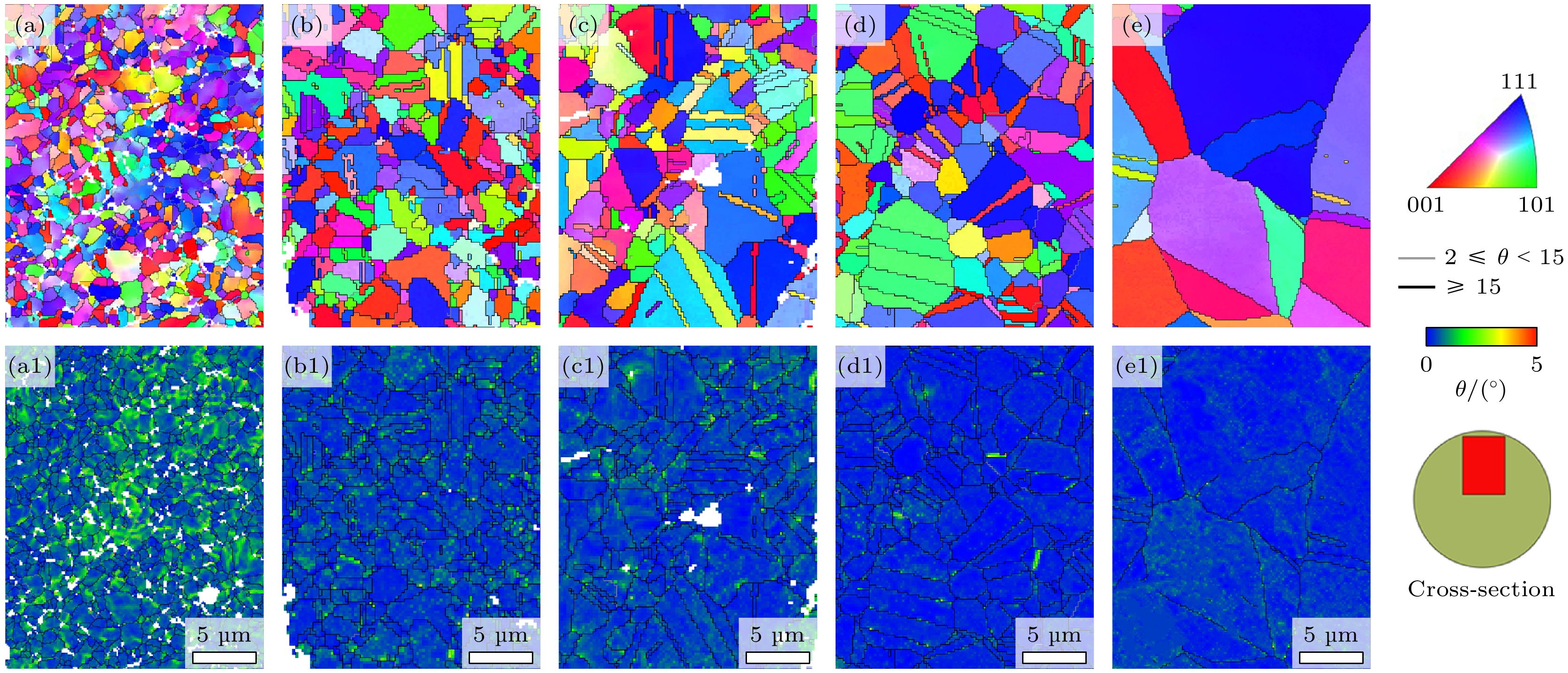

图 7 电流处理对CoCrFeNi高熵合金纤维再结晶的作用机制示意图 (a)冷拔态; (b)再结晶形核(位错重排); (c)部分再结晶; (d)完全再结晶

Fig. 7. Schematic diagram of the mechanism of electric current treatment on CoCrFeNi HEA microfiber recrystallization: (a) Cold drawn; (b) recrystallized nucleation (dislocation rearrangement); (c) partial recrystallization; (d) complete recrystallization.

表 1 实验设计方案

Table 1. Experimental design scheme.

电流密度

/(A·mm–2)标记 稳定温度/K 传统热处理

温度/K标记 100 ECT100 623 623 CHT623 120 ECT120 747 747 CHT747 140 ECT140 850 850 CHT850 160 ECT160 943 943 CHT943 180 ECT180 1013 1013 CHT1013 200 ECT200 1075 1075 CHT1075 表 2 电流处理和热处理样品的平均晶粒尺寸

Table 2. Average grain size of samples subjected to ECT and CHT.

样品 晶粒尺寸/μm 样品 晶粒尺寸/μm ECT100 — CHT623 — ECT120 1.5±0.2 CHT747 1.3±0.1 ECT140 1.9±0.2 CHT850 1.7±0.2 ECT160 2.5±0.7 CHT943 3.1±0.6 ECT180 4.6±1.1 CHT1013 5.8±1.3 ECT200 15.0±3.1 CHT1075 16.8±4.0 表 3 不同电流处理和退火处理工艺得到的高熵合金纤维的屈服强度和均匀延伸率

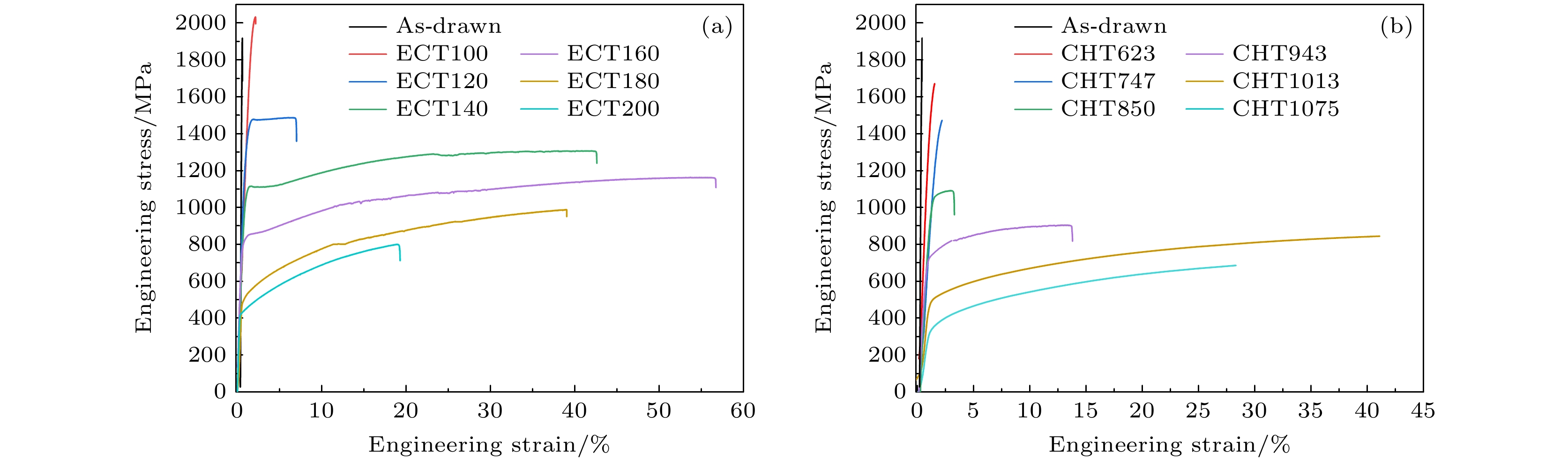

Table 3. Yield strength and uniform elongation of electric current treated microfibers with various current densities and heat treated microfibers with various temperatures.

样品 屈服强度/

MPa均匀延伸率/

%样品 屈服强度/

MPa均匀延伸率/

%As drawn 1930 0 — — — ECT100 2033 0 CHT623 1680 0 ECT120 1480 7 CHT747 1490 0 ECT140 1130 43 CHT850 1050 3 ECT160 800 52 CHT943 715 13.5 ECT180 550 39 CHT1013 500 41 ECT200 400 19 CHT1075 360 28 -

[1] 陈金玺, 徐彬, 戴兰宏, 陈艳 2024 科学通报 69 3154

Google Scholar

Google Scholar

Chen J X, Xu B, Dai L H, Chen Y 2024 Chin. Sci. Bull. 69 3154

Google Scholar

Google Scholar

[2] 高裕昆, 赵洁, 周晶晶, 周静 2025 74 057701

Google Scholar

Google Scholar

Gao Y K, Zhao J, Zhou J J, Zhou J 2025 Acta Phys. Sinica 74 057701

Google Scholar

Google Scholar

[3] Zhang Y F, Wu K K, Shen S N, Zhang Q Y, Cao W, Liu S 2023 J. Micromech. Microeng. 33 025002

Google Scholar

Google Scholar

[4] You J M, Kim H, Kim J, Kwon D S 2021 IEEE Rob. Autom. Lett. 6 7357

Google Scholar

Google Scholar

[5] Abbas M, Eom H S, Byun J Y, Shin D, Kim S H 2023 J. Cleaner Prod. 418 138044

Google Scholar

Google Scholar

[6] Hsu W L, Tsai C W, Yeh A C, Yeh J W 2024 Nat. Rev. Chem. 8 471

Google Scholar

Google Scholar

[7] Sohrabi M J, Kalhor A, Mirzadeh H, Rodak K, Kim H S 2024 Prog. Mater Sci. 144 101295

Google Scholar

Google Scholar

[8] Tong Y, Chen D, Han B, Wang J, Feng R, Yang T, Zhao C, Zhao Y L, Guo W, Shimizu Y, Liu C T, Liaw P K, Inoue K, Nagai Y, Hu A, Kai J J 2019 Acta Mater. 165 228

Google Scholar

Google Scholar

[9] Wang K Y, Cheng Z J, Liu C Y, Yu H P, Ning Z L, Ramasamy P, Eckert J, Sun J F, Huang Y J, Zhang Y M, Ngan A H W 2025 Int. J. Plast. 189 104321

Google Scholar

Google Scholar

[10] Wang K Y, Cheng Z J, Ning Z L, Yu H P, Ramasamy P, Eckert J, Sun J F, Ngan A H W, Huang Y J. 2025 Rare Metals 44 1332

Google Scholar

Google Scholar

[11] Li D Y, Li C X, Feng T, Zhang Y D, Sha G, Lewandowski J J, Liaw P K, Zhang Y 2017 Acta Mater. 123 285

Google Scholar

Google Scholar

[12] Ma X G, Chen J, Wang X H, Xu Y J, Xue Y J 2019 J. Alloys Compd. 795 45

Google Scholar

Google Scholar

[13] Liu J P, Chen J X, Liu T W, Li C, Chen Y, Dai L H 2020 Scr. Mater. 181 19

Google Scholar

Google Scholar

[14] Chen J X, Chen Y, Liu J P, Liu T W, Dai L H 2021 Scr. Mater. 199 113897

Google Scholar

Google Scholar

[15] Gao X Y, Liu J, Fu W J, Huang Y J, Ning Z L, Zhang Z, Sun J F, Chen W 2023 Mater. Des. 233 112250

Google Scholar

Google Scholar

[16] Zhou S C, Dai C D, Hou H X, Lu Y P, Liaw P K, Zhang Y 2023 Scr. Mater 226 115234

Google Scholar

Google Scholar

[17] Deng L, Li R X, Luo J R, Li S L, Xie X F, Wu S S, Zhang W R, Liaw P K, Korznikova E A, Zhang Y 2024 Int. J. Plast. 175 103929

Google Scholar

Google Scholar

[18] Liu X L, Wu Y D, Zheng B Y, Bai R, Gao L, Dong Z, Song C Q, Yu Y, Gao P, Hui X D 2024 Small 20 2403371

Google Scholar

Google Scholar

[19] Yan K, Sun J P, Bai J, Liu H, Huang X, Jin Z Y, Wu Y N 2019 Mater. Sci. Eng. , A 739 513

Google Scholar

Google Scholar

[20] Bo L, Gao X Y, Song W J, Ning Z L, Sun J F, Ngan A H W, Huang Y J 2025 Int. J. Plast. 188 104307

Google Scholar

Google Scholar

[21] Kustra P, Milenin A, Byrska-Wójcik D, Grydin O, Schaper M 2017 J. Mater. Process. Technol. 247 234

Google Scholar

Google Scholar

[22] 陆子川, 姜风春, 侯红亮, 刘郢, 程玉洁, 果春焕 2015 塑性工程学报 22 117

Google Scholar

Google Scholar

Lu Z C, Jiang F C, Hou H L, Liu Y, Cheng Y J, Guo C H 2015 J. Plast. Eng. 22 117

Google Scholar

Google Scholar

[23] Jeong K, Jin S W, Kang S G, Park J W, Jeong H J, Hong S T, Cho S H, Kim M J, Han H N 2022 Acta Mater. 232 117925

Google Scholar

Google Scholar

[24] Wu Z C, Xu X F, Zhao Y, Yan X D, Zhou Y C, Wei L, Yu Y Q 2023 Mater. Sci. Eng. , A 863 144536

Google Scholar

Google Scholar

[25] Li M Q, Shen Y D, Luo K, An Q, Gao P, Xiao P H, Zou Y 2023 Nat. Mater. 22 958

Google Scholar

Google Scholar

[26] Gao X Y, Liu J, Bo L, Chen W, Sun J F, Ning Z L, Ngan W, Huang Y J 2024 Acta Mater. 277 120203

Google Scholar

Google Scholar

[27] Liu Y F, Ren J, Guan S, Li C Y, Zhang Y, Muskeri S, Liu Z Y, Yu D J, Chen Y, An K, Cao Y, Liu W, Zhu Y T, Chen W, Mukherjee S, Zhu T, Chen W 2023 Acta Mater. 250 118884

Google Scholar

Google Scholar

[28] HajyAkbary F, Sietsma J, Bottger A J, Santofimia M J 2015 Mater. Sci. Eng. A 639 208

Google Scholar

Google Scholar

[29] 李亦庄, 黄明欣 2020 金属学报 56 487

Google Scholar

Google Scholar

Li Y Z, Huang M X 2020 Acta Metall. Sin. 56 487

Google Scholar

Google Scholar

[30] Yang B, Motz C, Rester M, Dehm G 2012 Philos. Mag. 92 3243

Google Scholar

Google Scholar

[31] Peng S Y, Tian Y Z, Ni Z Y, Lu S, Li S 2024 Int. J. Plast. 182 104129

Google Scholar

Google Scholar

[32] Liu M W, Gong W, Zheng R X, Li J, Zhang Z, Gao S, Ma C L, Tsuji N 2022 Acta Mater. 226 117629

Google Scholar

Google Scholar

[33] Ben D D, Yang H J, Dong Y A, Tian Y Z, Sun S J, Meng L X, Duan Q Q, Zhang P, Zhang Z F 2023 Mater. Charact. 195 112557

Google Scholar

Google Scholar

[34] 秦荣山, 周本濂 1997 材料研究学报 69

Qin R S, Zhou B L 1997 Chin. J. Mater. Res. 69

[35] Zhang W, Sui M L, Zhou Y Z, Zhong Y, Li D X 2002 Adv. Eng. Mater. 4 697

Google Scholar

Google Scholar

[36] Liu Y, Fan J F, Zhang H, Jin W, Dong H B, Xu B S 2015 J. Alloys Compd. 622 229

Google Scholar

Google Scholar

[37] Zhang X, Li H W, Shao G D, Gao J, Zhan M 2022 J. Alloys Compd. 898 162762

Google Scholar

Google Scholar

[38] Li X, Zhu Q, Hong Y R, Zheng H, Wang J, Wang J W, Zhang Z 2022 Nat. Commun. 13 6503

Google Scholar

Google Scholar

[39] Cao W D, Sprecher A F, Conrad H 1989 J. Phys. Sci. Instrum. E 22 1026

Google Scholar

Google Scholar

计量

- 文章访问数: 252

- PDF下载量: 6

- 被引次数: 0

下载:

下载: