-

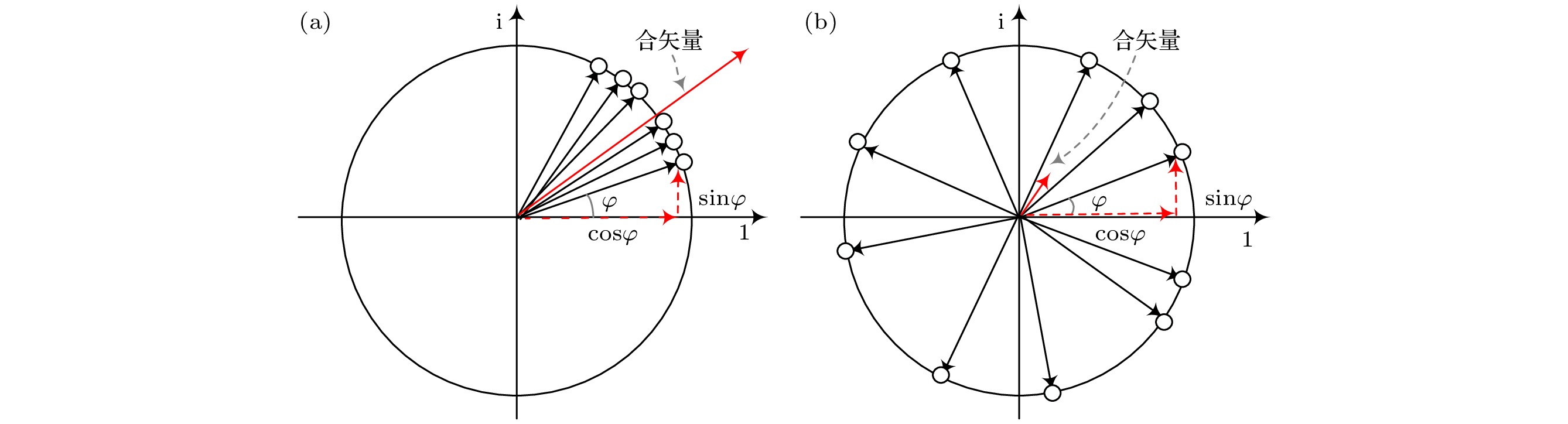

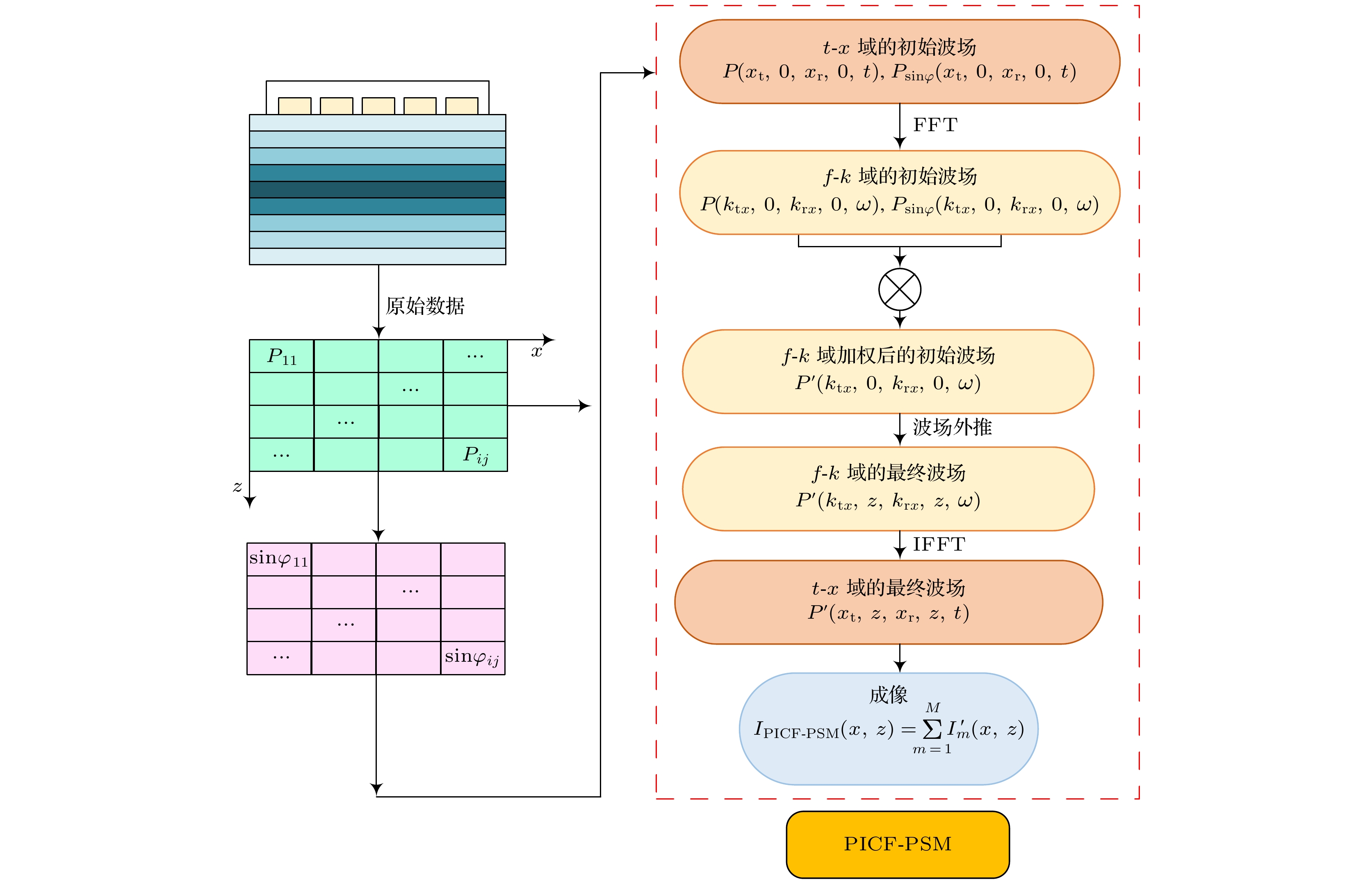

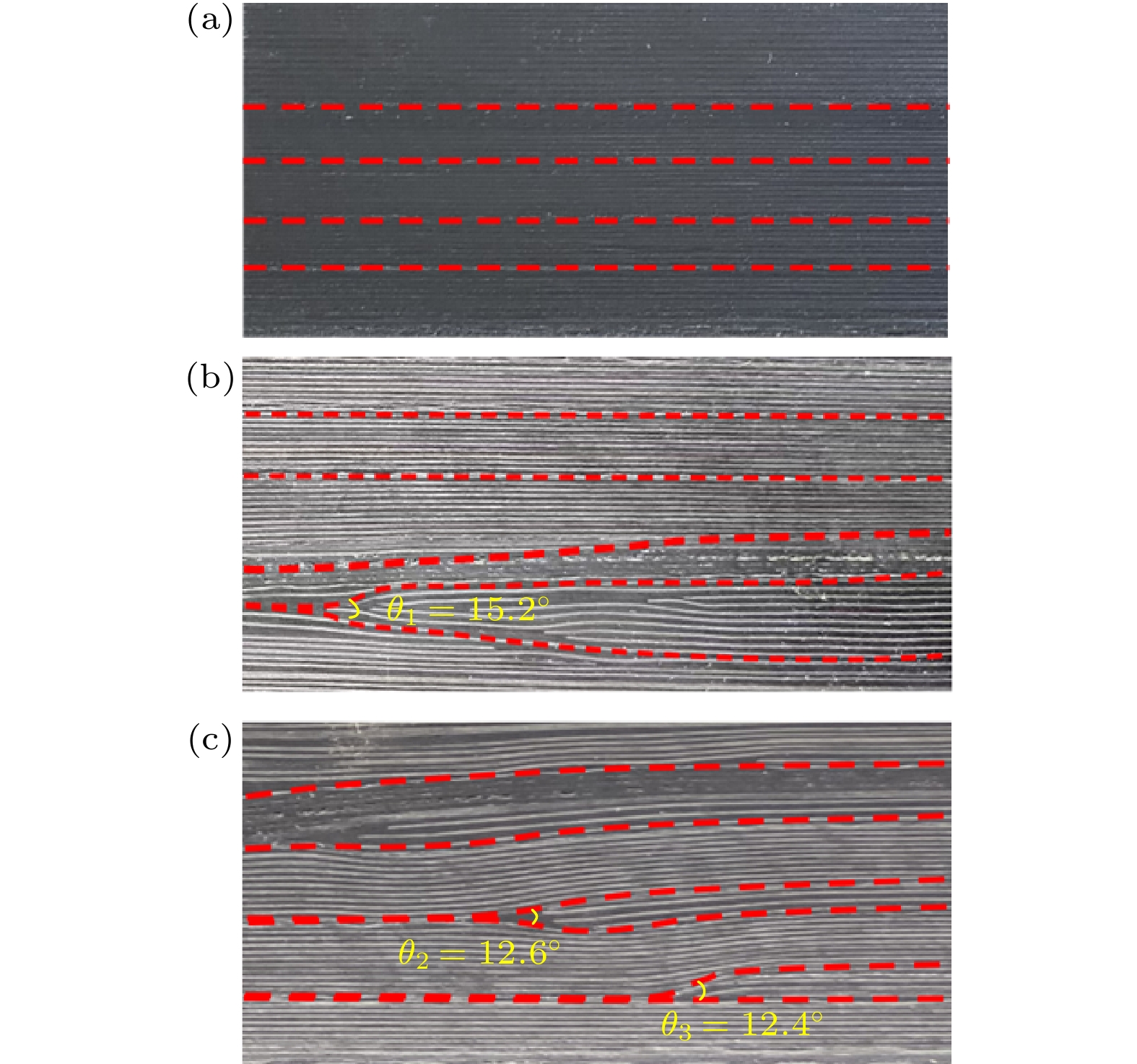

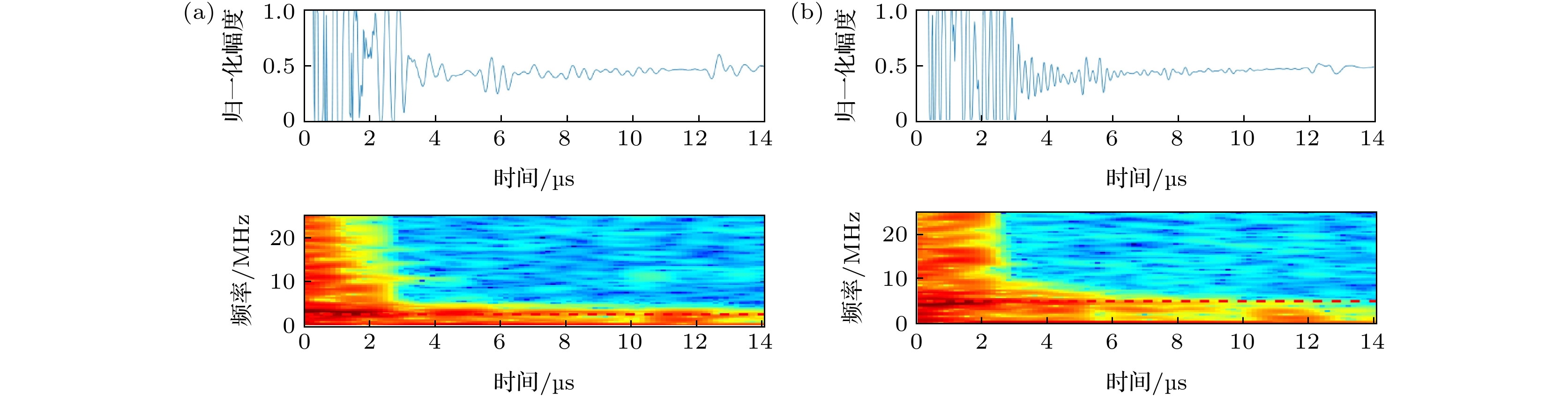

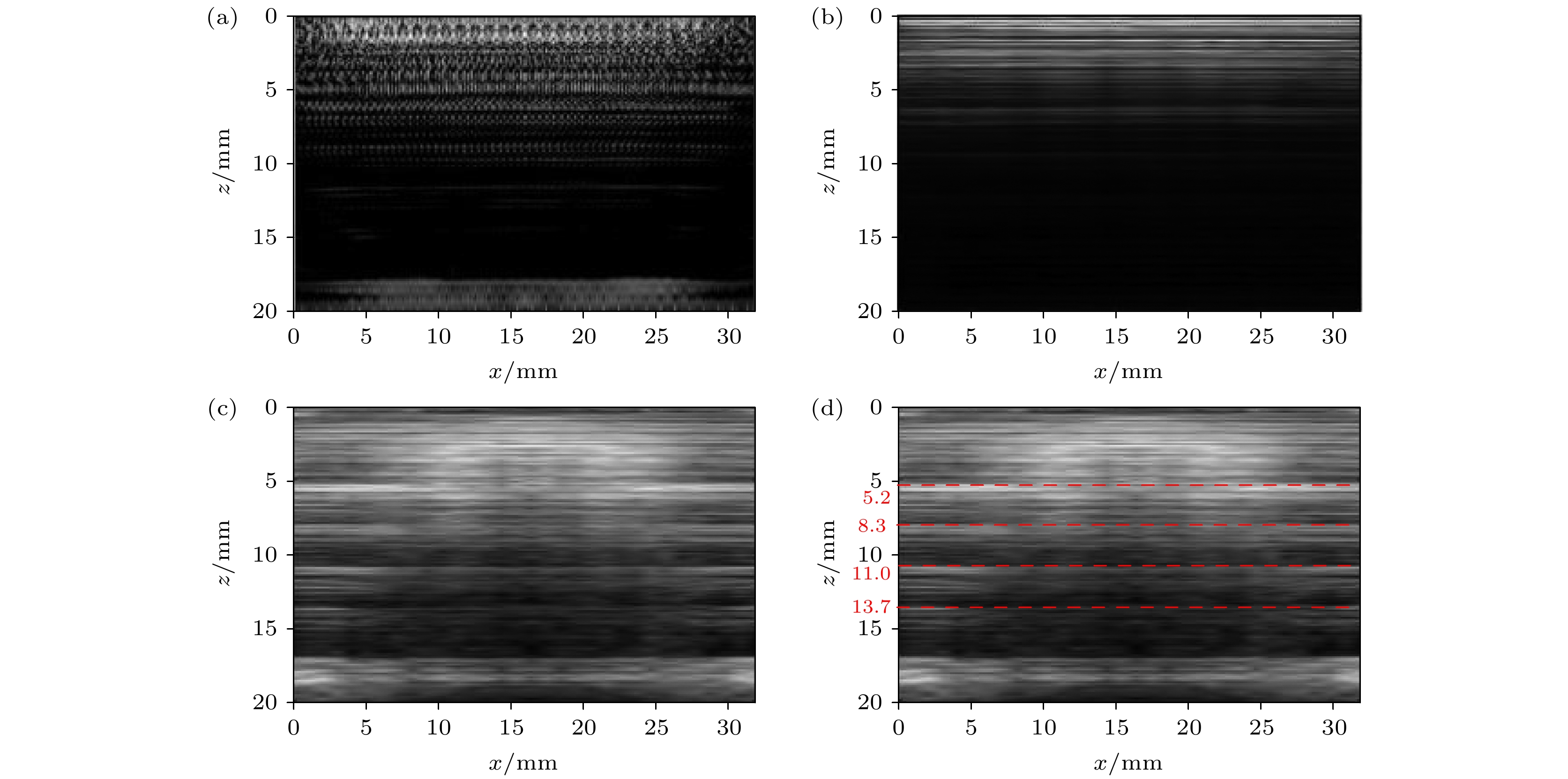

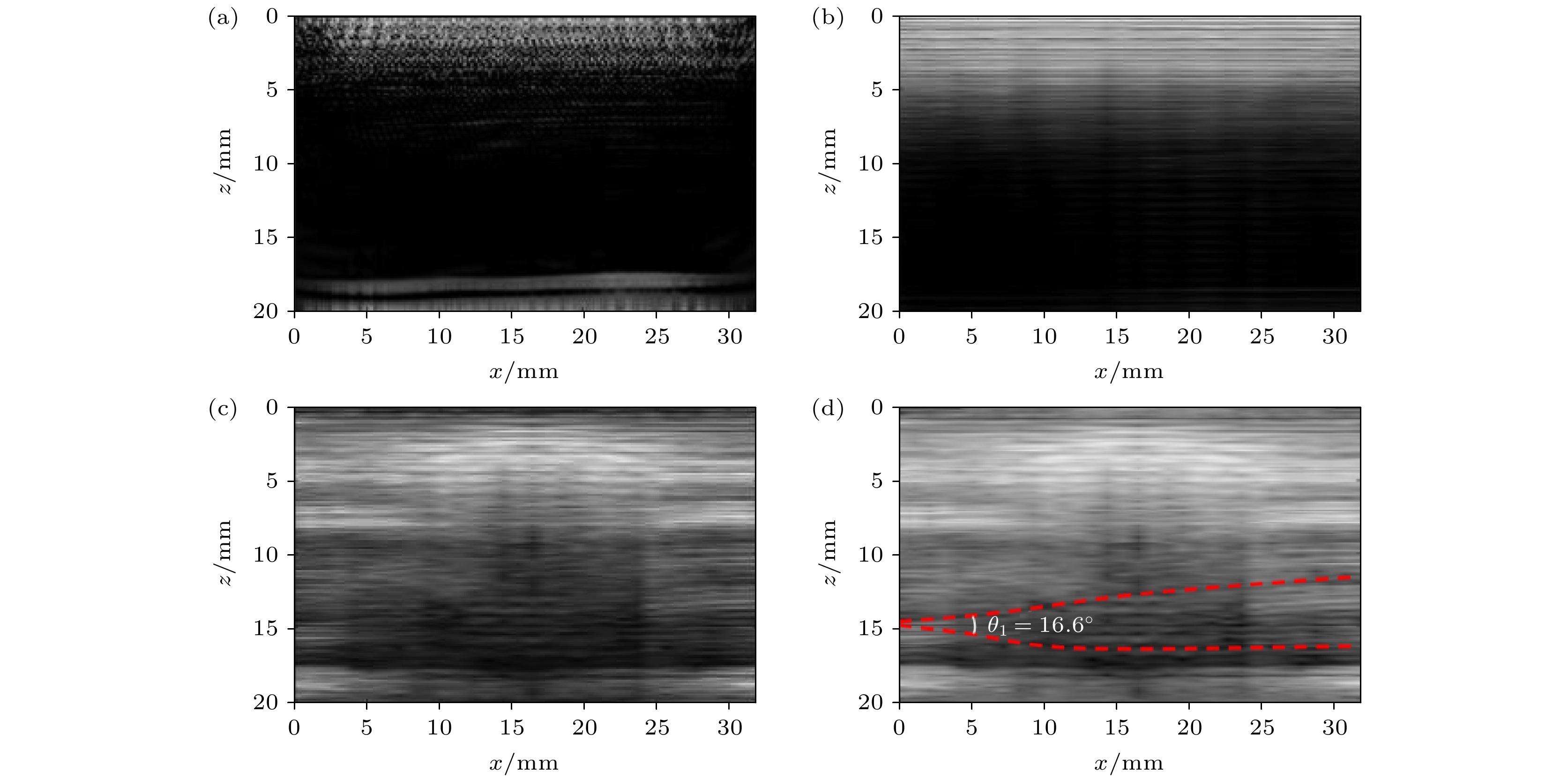

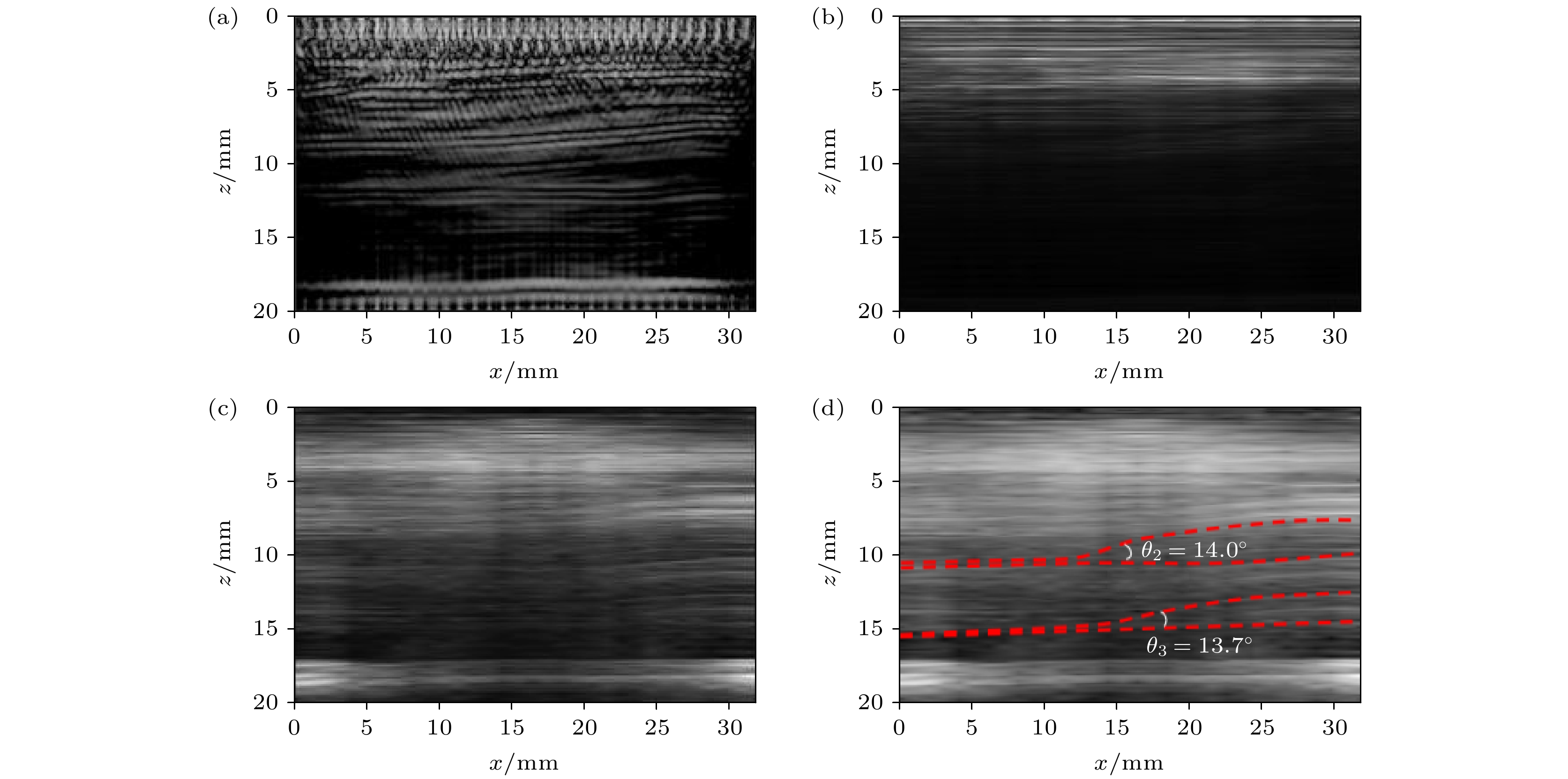

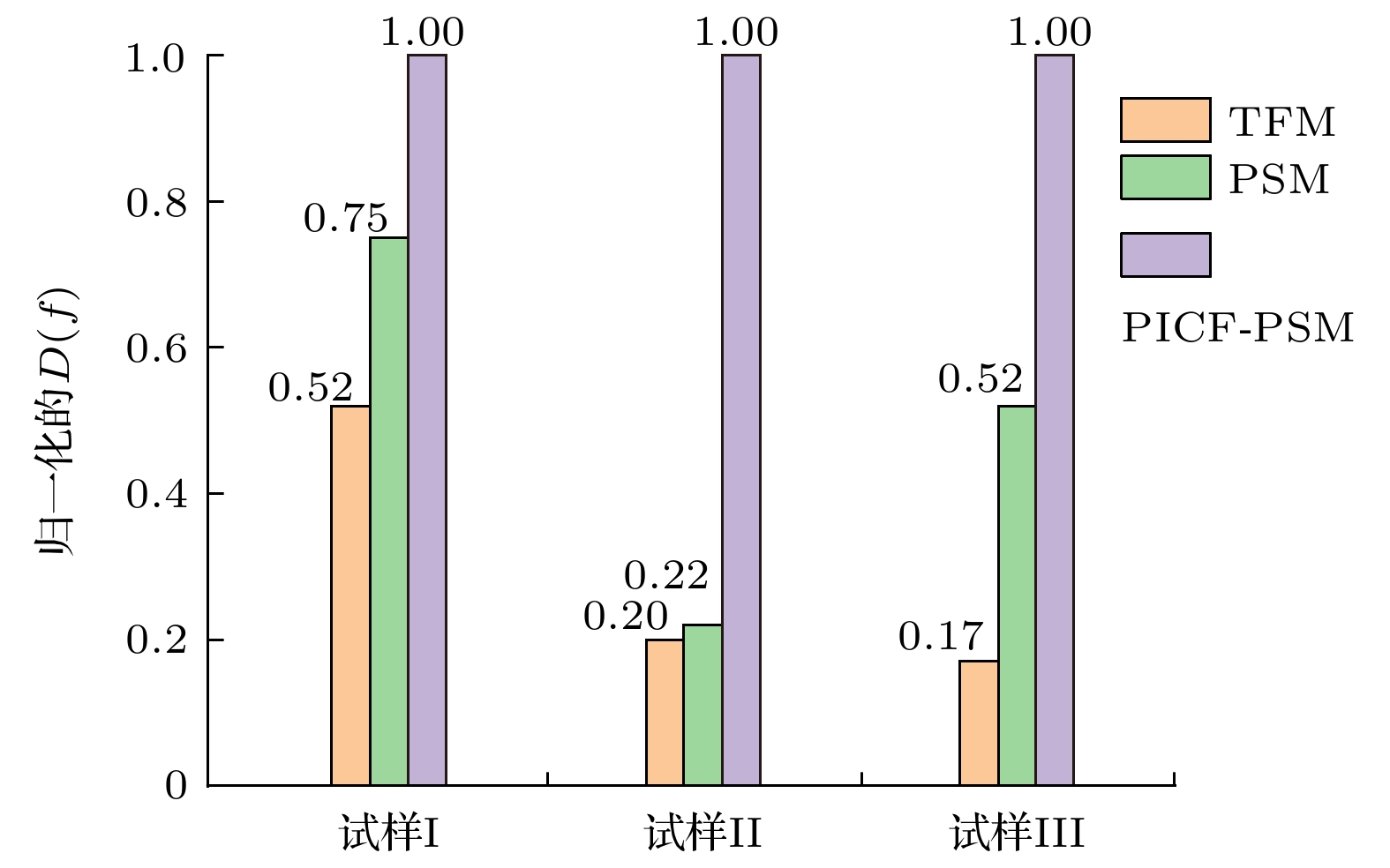

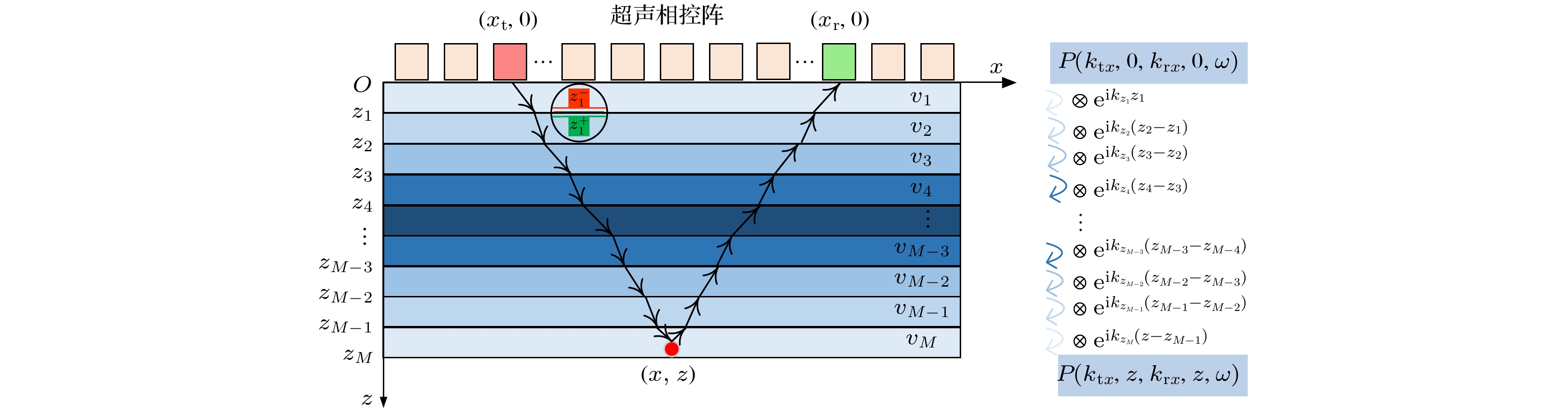

Ultrasonic phase changes carry critical information about tissue structures, and phase weighting can enhance the sharpness of ultrasonic images. Addressed here are challenges, such as the faint scattering echoes from folds, substantial noise interference, and the lengthy processing time involved in time-domain corrected imaging. Processed in this work is a frequency-domain coherent imaging method based on the coherence factor of the phase imaginary part. Firstly, the phase information in the wavefield signal is extracted, and then the phase imaginary part matrix is extracted by using circular statistics. Subsequent construction of the phase imaginary coherence factor (PICF) involves multiplying this matrix with the original frequency-domain matrix used in phase shift migration (PSM) imaging. By incorporating the PICF into phase migration imaging and adjusting the PICF of the migrating wavefield at each layer, fibre texture information can be efficiently recovered by frequency domain signal multiplication. In this paper, this technique is applied to the 18-mm-thick carbon-glass fiber composite boards. The experimental outcomes indicate that without PICF weighting, phase shift imaging loses the fiber layout information at depths exceeding 10 mm and cannot detect defects in deeper areas. The PICF-weighted PSM imaging identifies three fibre folds with depths of 11 mm, 15 mm and 16 mm, respectively. This method improves the imaging clarity and textural detail of folding defects, while maintaining a detection error of about 10% for folding angles. The imaging time is only 1.5 s, and its computational efficiency is at least 8.67 times that of time-domain TFM imaging.

[1] Teng G Y, Zhou X J, Yang C L, Zeng X 2018 Opt. Prec. Eng. 26 3108

Google Scholar

Google Scholar

[2] Mukhopadhyay S, Jones M I, Hallett S R 2015 Compos. Pt. A-Appl. Sci. Manuf. 73 132

Google Scholar

Google Scholar

[3] Gigante V, Aliotta L, Phuong V T, Coltelli M B, Cinelli P, Lazzeri A 2017 Compos. Sci. Technol. 152 129

Google Scholar

Google Scholar

[4] Kulkarni P, Mali K D, Singh S 2020 Compos. Pt. A-Appl. Sci. Manuf. 137 106013

Google Scholar

Google Scholar

[5] Xie N B, Smith R A, Mukhopadhyay S, Hallett S R 2018 Mater. Des. 140 7

Google Scholar

Google Scholar

[6] Liu D, Fleck N A, Sutcliffe M F 2004 J. Mech. Phys. Solids 52 1481

Google Scholar

Google Scholar

[7] Wang Z, Yang C L, Zhou X J, Teng Y H 2019 Russ. J. Nondestr. Test. 55 192

Google Scholar

Google Scholar

[8] 陈越超, 周晓军, 杨辰龙, 李钊, 郑慧峰 2015 农业机械学报 46 372

Google Scholar

Google Scholar

Chen Y C, Zhou X J, Yang C L, Li Z, Zheng H F 2015 Trans. Chin. Soc. Agricult. Machin. 46 372

Google Scholar

Google Scholar

[9] Cruza J F, Camacho J 2016 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 63 1581

Google Scholar

Google Scholar

[10] 张海燕, 宋佳昕, 任燕, 朱琦, 马雪芬 2021 70 114301

Google Scholar

Google Scholar

Zhang H Y, Song J X, Ren Y, Zhu Q, Ma X F 2021 Acta Phys. Sin. 70 114301

Google Scholar

Google Scholar

[11] Zhang H Y, Ren Y, Song J X, Zhu Q, Ma X F 2021 J. Compos. Mater. 55 4633

Google Scholar

Google Scholar

[12] Liu Z H, Chen L, Zhu Y P, Liu X Y, Lu Z J, He C F 2024 Ultrasonics 141 107321

Google Scholar

Google Scholar

[13] Olofsson T 2010 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 57 2522

Google Scholar

Google Scholar

[14] Skjelvareid M H, Olofsson T, Birkelund Y, Larsen Y 2011 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 58 1037

Google Scholar

Google Scholar

[15] Wang Y D, Zheng C C, Peng H 2019 Comput. Biol. Med. 108 249

Google Scholar

Google Scholar

[16] Yang C, Jiao Y, Jiang T Y, Xu Y W, Cui Y Y 2020 Appl. Sci. Basel 10 2250

[17] Camacho J, Parrilla M, Fritsch C 2009 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 56 958

Google Scholar

Google Scholar

[18] Cruza J F, Camacho J, Fritsch C 2017 NDT E. Int. 87 31

Google Scholar

Google Scholar

[19] Prado V T, Higuti R T, Kitano C, Martínez-Graullera O 2014 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 61 1204

Google Scholar

Google Scholar

[20] Chen Y, Xiong Z H, Kong Q R, Ma X X, Chen M, Lu C 2023 Ultrasonics 128 106856

Google Scholar

Google Scholar

[21] Nelson L J, Smith R A, Mienczakowski M 2018 Compos. Pt. A-Appl. Sci. Manuf. 104 108

Google Scholar

Google Scholar

[22] Smith R A 2007 Mater. Eval. 65 697

[23] Garcia D, Le Tarnec L, Muth S, Montagnon E, Porée J, Cloutier G 2013 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 60 1853

Google Scholar

Google Scholar

[24] Ji K P, Zhao P, Zhuo C J, Jin H R, Chen M, Chen J, Ye S, Fu J Z 2022 Mech. Syst. Signal Proc. 174 109114

Google Scholar

Google Scholar

[25] Lukomski T 2016 Ultrasonics 70 241

Google Scholar

Google Scholar

[26] Schleicher J, Costa J C, Novais A 2008 Geophysics 73 S219

Google Scholar

Google Scholar

[27] Pain D, Drinkwater B W 2013 J. Nondestruct. Eval. 32 215

Google Scholar

Google Scholar

[28] Smith R A, Nelson L J, Mienczakowski M J, Wilcox P D 2018 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 65 231

Google Scholar

Google Scholar

-

表 1 材料参数

Table 1. Parameters of materials.

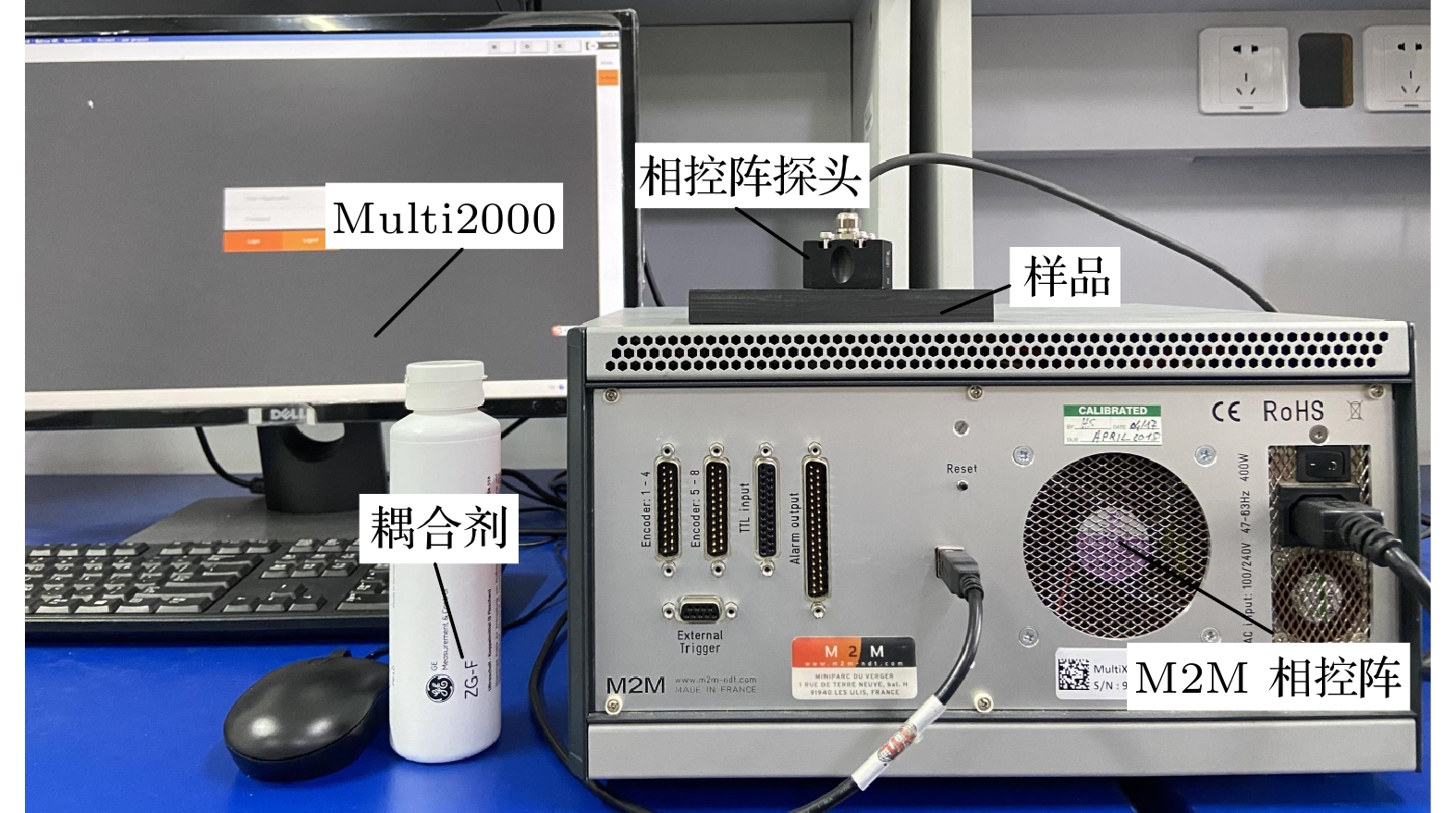

试样 褶皱深度/mm 褶皱角度/(°) 健康试样I 无褶皱 褶皱试样II 16 15.2 褶皱试样III 11 12.6 15 12.4 表 2 相控阵探头参数

Table 2. Parameters of phased array probes.

参数 探头A 探头B 阵元个数 32 32 阵元间隔/mm 1 1 阵元宽度/mm 0.9 0.9 中心频率/MHz 5 2.5 激励电源/V 70 70 采样频率/MHz 50 50 激励信号 5个周期的高斯正弦波 5个周期的高斯正弦波 激励方式 纵波 纵波 表 3 PICF-PSM成像的褶皱角误差

Table 3. Errors of samples with wrinkles in PICF-PSM imaging.

褶皱试样 实际褶皱

角度/(°)PICF-PSM检测

角度/(°)误差/% 试样II 15.2 16.6 9.22 试样III 12.6 14.0 11.1 12.4 13.7 10.48 表 4 不同成像算法计算耗时

Table 4. Calculation time of different imaging algorithms.

成像方法 计算时间/s 时域 TFM 13.0 频域 PSM 1.3 PICF-PSM 1.5 -

[1] Teng G Y, Zhou X J, Yang C L, Zeng X 2018 Opt. Prec. Eng. 26 3108

Google Scholar

Google Scholar

[2] Mukhopadhyay S, Jones M I, Hallett S R 2015 Compos. Pt. A-Appl. Sci. Manuf. 73 132

Google Scholar

Google Scholar

[3] Gigante V, Aliotta L, Phuong V T, Coltelli M B, Cinelli P, Lazzeri A 2017 Compos. Sci. Technol. 152 129

Google Scholar

Google Scholar

[4] Kulkarni P, Mali K D, Singh S 2020 Compos. Pt. A-Appl. Sci. Manuf. 137 106013

Google Scholar

Google Scholar

[5] Xie N B, Smith R A, Mukhopadhyay S, Hallett S R 2018 Mater. Des. 140 7

Google Scholar

Google Scholar

[6] Liu D, Fleck N A, Sutcliffe M F 2004 J. Mech. Phys. Solids 52 1481

Google Scholar

Google Scholar

[7] Wang Z, Yang C L, Zhou X J, Teng Y H 2019 Russ. J. Nondestr. Test. 55 192

Google Scholar

Google Scholar

[8] 陈越超, 周晓军, 杨辰龙, 李钊, 郑慧峰 2015 农业机械学报 46 372

Google Scholar

Google Scholar

Chen Y C, Zhou X J, Yang C L, Li Z, Zheng H F 2015 Trans. Chin. Soc. Agricult. Machin. 46 372

Google Scholar

Google Scholar

[9] Cruza J F, Camacho J 2016 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 63 1581

Google Scholar

Google Scholar

[10] 张海燕, 宋佳昕, 任燕, 朱琦, 马雪芬 2021 70 114301

Google Scholar

Google Scholar

Zhang H Y, Song J X, Ren Y, Zhu Q, Ma X F 2021 Acta Phys. Sin. 70 114301

Google Scholar

Google Scholar

[11] Zhang H Y, Ren Y, Song J X, Zhu Q, Ma X F 2021 J. Compos. Mater. 55 4633

Google Scholar

Google Scholar

[12] Liu Z H, Chen L, Zhu Y P, Liu X Y, Lu Z J, He C F 2024 Ultrasonics 141 107321

Google Scholar

Google Scholar

[13] Olofsson T 2010 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 57 2522

Google Scholar

Google Scholar

[14] Skjelvareid M H, Olofsson T, Birkelund Y, Larsen Y 2011 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 58 1037

Google Scholar

Google Scholar

[15] Wang Y D, Zheng C C, Peng H 2019 Comput. Biol. Med. 108 249

Google Scholar

Google Scholar

[16] Yang C, Jiao Y, Jiang T Y, Xu Y W, Cui Y Y 2020 Appl. Sci. Basel 10 2250

[17] Camacho J, Parrilla M, Fritsch C 2009 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 56 958

Google Scholar

Google Scholar

[18] Cruza J F, Camacho J, Fritsch C 2017 NDT E. Int. 87 31

Google Scholar

Google Scholar

[19] Prado V T, Higuti R T, Kitano C, Martínez-Graullera O 2014 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 61 1204

Google Scholar

Google Scholar

[20] Chen Y, Xiong Z H, Kong Q R, Ma X X, Chen M, Lu C 2023 Ultrasonics 128 106856

Google Scholar

Google Scholar

[21] Nelson L J, Smith R A, Mienczakowski M 2018 Compos. Pt. A-Appl. Sci. Manuf. 104 108

Google Scholar

Google Scholar

[22] Smith R A 2007 Mater. Eval. 65 697

[23] Garcia D, Le Tarnec L, Muth S, Montagnon E, Porée J, Cloutier G 2013 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 60 1853

Google Scholar

Google Scholar

[24] Ji K P, Zhao P, Zhuo C J, Jin H R, Chen M, Chen J, Ye S, Fu J Z 2022 Mech. Syst. Signal Proc. 174 109114

Google Scholar

Google Scholar

[25] Lukomski T 2016 Ultrasonics 70 241

Google Scholar

Google Scholar

[26] Schleicher J, Costa J C, Novais A 2008 Geophysics 73 S219

Google Scholar

Google Scholar

[27] Pain D, Drinkwater B W 2013 J. Nondestruct. Eval. 32 215

Google Scholar

Google Scholar

[28] Smith R A, Nelson L J, Mienczakowski M J, Wilcox P D 2018 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 65 231

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 2795

- PDF Downloads: 52

- Cited By: 0

DownLoad:

DownLoad: