-

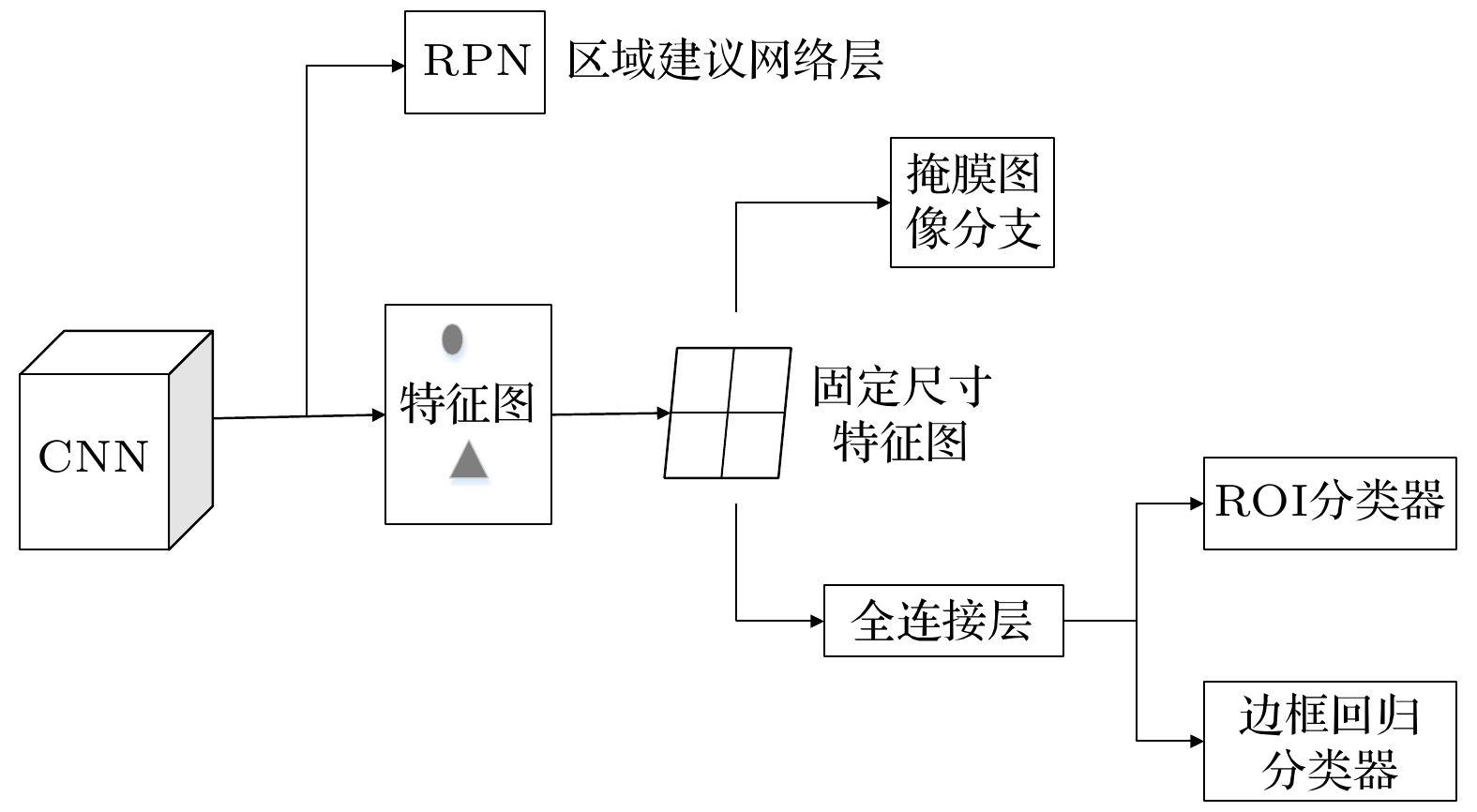

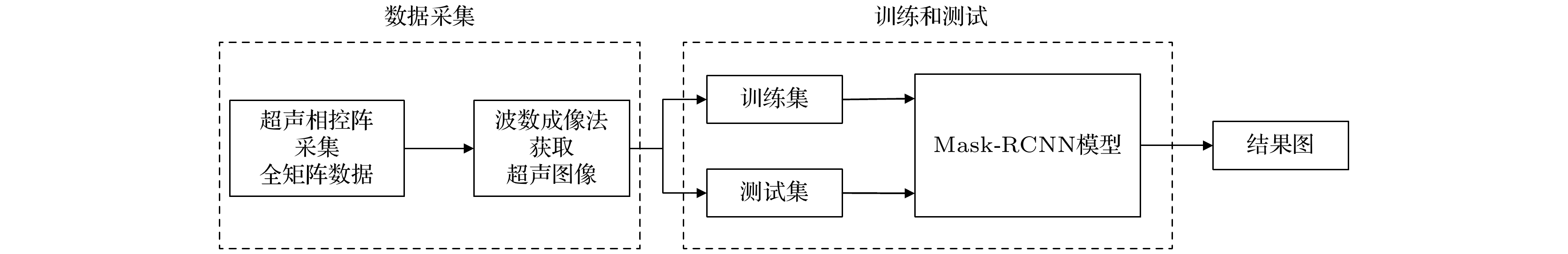

Wrinkle defects will be inevitably produced during composite manufacturing and the in-service life of composite structures. Because of their diverse morphological changes and small deformation, it is difficult to manually identify the wrinkle with important errors. In order to improve the inspection efficiency, a Mask-RCNN algorithm is proposed to detect and classify different forms of wrinkle defects in composites based on phased array images. Carbon fiber composite laminates are prepared first in different forms of wrinkle defects. Secondly, the ultrasonic phased array is used to collect full matrix data. The longitudinal scanning image of the composite laminate is then obtained through the wavenumber imaging algorithm. According to the geometric characteristics of the folds in the geological layer, the wrinkles in the composite laminate are divided into three categories, and the relationship between the wrinkle shape and the material damage degree is established. The Mask-RCNN algorithm is finally proposed for automaticaly detecting and classifying the wrinkle defects. The introduction of semantic segmentation in this algorithm can help to reveal the positions and shapes of wrinkle defects. The experimental results show that the accuracies of Mask-RCNN in the recognition of different forms of wrinkles reach 92.1%, 90.9%, and 93.3%, respectively, and the classification and recognition of wrinkles are accurate and effective. It provides theoretical support for the integration and automation of data acquisition-imaging-defect recognition in composite industries.

-

Keywords:

- wrinkle /

- wavenumber imaging /

- Mask-RCNN /

- target detection

[1] 赵伟, 刘立武, 孙健, 冷劲松, 刘彦菊 2021 宇航材料工艺 51 73

Google Scholar

Google Scholar

Zhao W, Liu L W, Sun J, Leng J S 2021 Aerosp. Mater. Technol. 51 73

Google Scholar

Google Scholar

[2] 黎盛寓 2020 塑料科技 48 81

Google Scholar

Google Scholar

Li S Y 2020 Plast. Sci. Technol. 48 81

Google Scholar

Google Scholar

[3] 陈珍, 李锐 2021 农机使用与维修 06 33

Google Scholar

Google Scholar

Chen Z, Li R 2021 Agric. Machinery Using Maintenance 06 33

Google Scholar

Google Scholar

[4] 张梦杰, 周春鹏, 陈华辉, 张刚利 2019 中国临床神经外科杂志 24 356

Google Scholar

Google Scholar

Zhang M G, Zhou C P, Chen H H, Zhang G L 2019 Chin. J. Clin. Neurosurg. 24 356

Google Scholar

Google Scholar

[5] 于晓东, 胡海晓, 贾欲明, 王敏, 曹东风 2020 复合材料学报 37 1932

Google Scholar

Google Scholar

Yu X D, Hu H X, Jia Y M, Wang M, Cao D F 2020 Acta Mater. Compos. Sin. 37 1932

Google Scholar

Google Scholar

[6] Pandey R K, Sun C T 1999 Compos. Sci. Technol. 59 405

Google Scholar

Google Scholar

[7] Hsiao H M, Daniel I M 1996 Compos. Sci. Technol. 56 581

Google Scholar

Google Scholar

[8] Hsiao H M, Daniel I M 1996 Composites Part A 27 931

Google Scholar

Google Scholar

[9] Alexander C, Kulkarni S 2008 Int. Pipeline Conf. 7 61

[10] 李韦清, 杨涛, 杨冠侠, 刘思南, 杜宇, 刘畅 2018 固体火箭技术 41 621

Google Scholar

Google Scholar

Li W Q, Yang T, Yang G X, Liu S N, Du Y, Liu C 2018 J. Solid Rocket Technol. 41 621

Google Scholar

Google Scholar

[11] 张婷, 黄爱华, 李向前 2021 航空制造技术 64 78

Google Scholar

Google Scholar

Zhang T, Huang A H, Li X Q 2021 Aeronaut. Manuf. Technol. 64 78

Google Scholar

Google Scholar

[12] Sandhu A, Reinarz A, Dodwell T J 2018 Composites Part B 205 58

Google Scholar

Google Scholar

[13] Koichi M, Yoshihiro M, Akira T, Yoshiro S 2016 Composites Part B 86 84

Google Scholar

Google Scholar

[14] 张海燕, 宋佳昕, 任燕, 朱琦, 马雪芬 2021 70 060501

Google Scholar

Google Scholar

Zhang H Y, Song J X, Ren Y, Zhu Q, Ma X F 2021 Acta Phys. Sin. 70 060501

Google Scholar

Google Scholar

[15] 周正干, 李洋, 周文彬 2016 机械工程学报 52 1

Google Scholar

Google Scholar

Zhou Z G, Li Y, Zhou W B 2016 Chin. J. Mech. Eng. 52 1

Google Scholar

Google Scholar

[16] Zhang H Y, Song J X, Ren Y, Zhu Q, Ma X F 2021 J. Compos. Mater. 56 1

Google Scholar

Google Scholar

[17] Callow H J, Hayes M P, Gough P T 2022 Electron. Lett. 38 336

Google Scholar

Google Scholar

[18] 于爱暄 2020 硕士学位论文 (大庆: 东北石油大学)

Yu A X 2020 M. S. Thesis (Daqing: Northeast Petroleum University) (in Chinese)

[19] Xie Z K, He F X, Fu S P, Sato I, Tao D C, Sugiyama M 2021 Neural Comput. 33 2163

Google Scholar

Google Scholar

[20] Zhang W P, Chen Y G, Yang W M, Wang G J, Xue J H 2021 IEEE Trans. Neural. Networks. Learn. Syst. 32 4742

Google Scholar

Google Scholar

[21] Abdulhamit S 2013 Comput. Biol. Med. 43 576

Google Scholar

Google Scholar

-

图 7 测试图像及其分类结果 (a) 含有一个褶皱的原始图片; (b) 图(a)的测试结果图; (c)含有同一种类多个褶皱的原始图片; (d) 图(c)的测试结果图; (e) 含有多种类多个褶皱的原始图片; (f) 图(e)的测试结果

Figure 7. Test image and its results: (a) The original picture containing one wrinkle; (b) the test result picture of Figure (a); (c) the original picture containing multiple wrinkles of the same type; (d) the test result picture of Figure (c); (e) the original picture containing multiple types of wrinkles; (f) the test result picture of Figure (e).

表 1 超声相控阵参数设置

Table 1. Parameter settings of ultrasonic phased array.

参数 阵元数 阵元宽度 /mm 阵元

中心距/mm中心频率/MHz 采样频率/MHz 值 32 0.9 1.0 5 50 表 2 分类结果的混淆矩阵

Table 2. Classification results confusion matrix.

真实标签 预测标签 类别A 类别B 类别A TP FN 类别B FP TN 表 3 form-Ⅰ混淆矩阵数据

Table 3. The form-Ⅰ confusion matrix data.

真实标签 预测标签 form-Ⅰ 其他 form-Ⅰ 35 4 其他 3 26 表 4 form-Ⅱ混淆矩阵数据

Table 4. The form-Ⅱ confusion matrix data.

真实标签 预测标签 form-Ⅱ 其他 form-Ⅱ 10 0 其他 1 23 表 5 form-Ⅲ混淆矩阵数据

Table 5. The form-Ⅲ confusion matrix data.

真实标签 预测标签 form-Ⅲ 其他 form-Ⅲ 28 3 其他 2 31 -

[1] 赵伟, 刘立武, 孙健, 冷劲松, 刘彦菊 2021 宇航材料工艺 51 73

Google Scholar

Google Scholar

Zhao W, Liu L W, Sun J, Leng J S 2021 Aerosp. Mater. Technol. 51 73

Google Scholar

Google Scholar

[2] 黎盛寓 2020 塑料科技 48 81

Google Scholar

Google Scholar

Li S Y 2020 Plast. Sci. Technol. 48 81

Google Scholar

Google Scholar

[3] 陈珍, 李锐 2021 农机使用与维修 06 33

Google Scholar

Google Scholar

Chen Z, Li R 2021 Agric. Machinery Using Maintenance 06 33

Google Scholar

Google Scholar

[4] 张梦杰, 周春鹏, 陈华辉, 张刚利 2019 中国临床神经外科杂志 24 356

Google Scholar

Google Scholar

Zhang M G, Zhou C P, Chen H H, Zhang G L 2019 Chin. J. Clin. Neurosurg. 24 356

Google Scholar

Google Scholar

[5] 于晓东, 胡海晓, 贾欲明, 王敏, 曹东风 2020 复合材料学报 37 1932

Google Scholar

Google Scholar

Yu X D, Hu H X, Jia Y M, Wang M, Cao D F 2020 Acta Mater. Compos. Sin. 37 1932

Google Scholar

Google Scholar

[6] Pandey R K, Sun C T 1999 Compos. Sci. Technol. 59 405

Google Scholar

Google Scholar

[7] Hsiao H M, Daniel I M 1996 Compos. Sci. Technol. 56 581

Google Scholar

Google Scholar

[8] Hsiao H M, Daniel I M 1996 Composites Part A 27 931

Google Scholar

Google Scholar

[9] Alexander C, Kulkarni S 2008 Int. Pipeline Conf. 7 61

[10] 李韦清, 杨涛, 杨冠侠, 刘思南, 杜宇, 刘畅 2018 固体火箭技术 41 621

Google Scholar

Google Scholar

Li W Q, Yang T, Yang G X, Liu S N, Du Y, Liu C 2018 J. Solid Rocket Technol. 41 621

Google Scholar

Google Scholar

[11] 张婷, 黄爱华, 李向前 2021 航空制造技术 64 78

Google Scholar

Google Scholar

Zhang T, Huang A H, Li X Q 2021 Aeronaut. Manuf. Technol. 64 78

Google Scholar

Google Scholar

[12] Sandhu A, Reinarz A, Dodwell T J 2018 Composites Part B 205 58

Google Scholar

Google Scholar

[13] Koichi M, Yoshihiro M, Akira T, Yoshiro S 2016 Composites Part B 86 84

Google Scholar

Google Scholar

[14] 张海燕, 宋佳昕, 任燕, 朱琦, 马雪芬 2021 70 060501

Google Scholar

Google Scholar

Zhang H Y, Song J X, Ren Y, Zhu Q, Ma X F 2021 Acta Phys. Sin. 70 060501

Google Scholar

Google Scholar

[15] 周正干, 李洋, 周文彬 2016 机械工程学报 52 1

Google Scholar

Google Scholar

Zhou Z G, Li Y, Zhou W B 2016 Chin. J. Mech. Eng. 52 1

Google Scholar

Google Scholar

[16] Zhang H Y, Song J X, Ren Y, Zhu Q, Ma X F 2021 J. Compos. Mater. 56 1

Google Scholar

Google Scholar

[17] Callow H J, Hayes M P, Gough P T 2022 Electron. Lett. 38 336

Google Scholar

Google Scholar

[18] 于爱暄 2020 硕士学位论文 (大庆: 东北石油大学)

Yu A X 2020 M. S. Thesis (Daqing: Northeast Petroleum University) (in Chinese)

[19] Xie Z K, He F X, Fu S P, Sato I, Tao D C, Sugiyama M 2021 Neural Comput. 33 2163

Google Scholar

Google Scholar

[20] Zhang W P, Chen Y G, Yang W M, Wang G J, Xue J H 2021 IEEE Trans. Neural. Networks. Learn. Syst. 32 4742

Google Scholar

Google Scholar

[21] Abdulhamit S 2013 Comput. Biol. Med. 43 576

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6795

- PDF Downloads: 118

- Cited By: 0

DownLoad:

DownLoad: