-

Perovskite solar cells have been widely recognized as the most promising new-type photovoltaic device due to its power conversion efficiency rapidly increasing from 3.8% to over 26% in merely fifteen years. However, the high performances are achieved mainly on small area cells with an active area lower than 0.1 cm2. When enlarging the active area of perovskite solar cells, the efficiency falls dramatically. So, how to reduce the gap between performances of small area cells and large area cells gradually becomes a critical point in the path towards the commercialization of perovskite photovoltaic technology. Herein, a strategy of pre-growing thin layer of TiO2 on a rough FTO substrate by atomic layer deposition method before spin-coating SnO2 nanoparticles is proposed. Due to the inherent conformal film growth mode of atomic layer deposition, the FTO substrate can be completely covered by TiO2, thus preventing the direct contact between local protrusions of FTO and perovskite layer and impeding the current leakage phenomenon, which can be verified by the measurements from X-ray photoelectron spectroscopy, scanning electron microscopy, and atomic force microscopy, and further proved by the dark current measurement. By using this method, the repeatability and consistency of the small area cell fabrication technology on the same substrate are improved obviously. The improved electron transport process revealed by photoluminescence results and incident light management process revealed by external quantum efficiency results also brings about better solar cell performances. More importantly, highly efficient 0.5 cm2 large area perovskite solar cells are fabricated through optimization of TiO2 thickness. When growing 200 cycles TiO2 (~9 nm in thickness) by using atomic layer deposition technology, the champion large area perovskite solar cell possesses a power conversion efficiency as high as 24.8% (certified 24.65%). The device performances also show excellent repeatability between different fabrication batches. The perovskite solar cell with TiO2 buffer layer grown by the atomic layer deposition method can still retain over 95% of its initial efficiency after having been stored in a nitrogen atmosphere for 1500 h. The technique proposed in this paper can be helpful in manufacturing perovskite solar cell modules in the realistic photovoltaic market and can be extended to the large area fabrication of other perovskite optoelectronic devices such as light emitting diode, laser and detector.

-

Keywords:

- atomic layer deposition /

- metal oxide /

- large area /

- perovskite solar cell

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Lee M M, Teuscher J, Miyasaka T, Murakami T N, Snaith H J 2012 Science 338 643

Google Scholar

Google Scholar

[3] Yang W S, Noh J H, Jeon N J, Kim Y C, Ryu S, Seo J, Seok S I 2015 Science 348 1234

Google Scholar

Google Scholar

[4] Jiang Q, Zhao Y, Zhang X W, Yang X L, Chen Y, Chu Z M, Ye Q F, Li X X, Yin Z G, You J B 2019 Nat. Photonics 13 460

Google Scholar

Google Scholar

[5] Zhao Y, Ma F, Qu Z H, Yu S Q, Shen T, Deng H X, Chu X B, Peng X X, Yuan Y B, Zhang X W, You J B 2022 Science 377 531

Google Scholar

Google Scholar

[6] Park J, Kim J, Yun H S, Paik M J, Noh E, Mun H J, Kim M G, Shin T J, Seok S I 2023 Nature 616 724

Google Scholar

Google Scholar

[7] https://www.nrel.gov/pv/interactive-cell-efficiency.html [2024-2-1]

[8] Lin H, Yang M, Ru X N, et al. 2023 Nat. Energy 8 789

Google Scholar

Google Scholar

[9] Yin W J, Shi T, Yan Y 2014 Adv. Mater. 26 4653

Google Scholar

Google Scholar

[10] Stranks S D, Eperon G E, Grancini G, et al. 2013 Science 342 341

Google Scholar

Google Scholar

[11] Yin W J, Shi T T, Yan Y F 2014 Appl. Phys. Lett. 104 063903

Google Scholar

Google Scholar

[12] Cheng Y, Peng Y, Jen A K Y, Yip H L 2021 Sol. RRL 6 2100545

Google Scholar

Google Scholar

[13] Kim G H, Kim D S 2021 Joule 5 1033

Google Scholar

Google Scholar

[14] Plutnar J, Pumera M 2021 Small 17 2102088

Google Scholar

Google Scholar

[15] Ahvenniemi E, Akbashev A R, Ali S, et al. 2017 J. Vac. Sci. Technol. A 35 010801

Google Scholar

Google Scholar

[16] Cho Y J, Jeong M J, Park J H, Hu W, Lim J, Chang H S 2021 Energies 14 1156

Google Scholar

Google Scholar

[17] Correa Baena J P, Steier L, Tress W, et al. 2015 Energy Environ. Sci. 8 2928

Google Scholar

Google Scholar

[18] Li C, Xu H, Zhi C, Wan Z, Li Z 2022 Chin. Phys. B 31 111004

Google Scholar

Google Scholar

[19] Kim M, Jeong J, Lu H Z, et al. 2022 Science 375 302

Google Scholar

Google Scholar

[20] You Y, Tian W, Min L, Cao F, Deng K, Li L 2019 Adv. Mater. Interfaces 7 1901406

Google Scholar

Google Scholar

[21] Jiang Q, Zhang L Q, Wang H L, et al. 2017 Nat. Energy 2 16177

Google Scholar

Google Scholar

[22] Lin R X, Wang Y R, Lu Q W, et al. 2023 Nature 620 994

Google Scholar

Google Scholar

[23] 周玚, 任信钢, 闫业强, 任昊, 杜红梅, 蔡雪原, 黄志祥 2022 71 208802

Google Scholar

Google Scholar

Zhou Y, Ren X G, Yan Y Q, Ren H, Du H M, Cai X Y, Huang Z X 2022 Acta Phys. Sin. 71 208802

Google Scholar

Google Scholar

[24] Peng J, Walter D, Ren Y H, et al. 2021 Science 371 390

Google Scholar

Google Scholar

[25] Chiappim W, Testoni G E, Moraes R S, et al. 2016 Vacuum 123 91

Google Scholar

Google Scholar

[26] Sadollahkhani A, Liu P, Leandri V, Safdari M, Zhang W, Gardner J M 2017 Chemphyschem 18 3047

Google Scholar

Google Scholar

[27] Chu S L, Zhang Y H, Xiao P, et al. 2022 Adv. Mater. 34 2108939

Google Scholar

Google Scholar

[28] Zhao J J, Zhao L, Deng Y H, Xiao X, Ni Z Y, Xu S, Huang J S 2020 Nat. Photonics 14 612

Google Scholar

Google Scholar

-

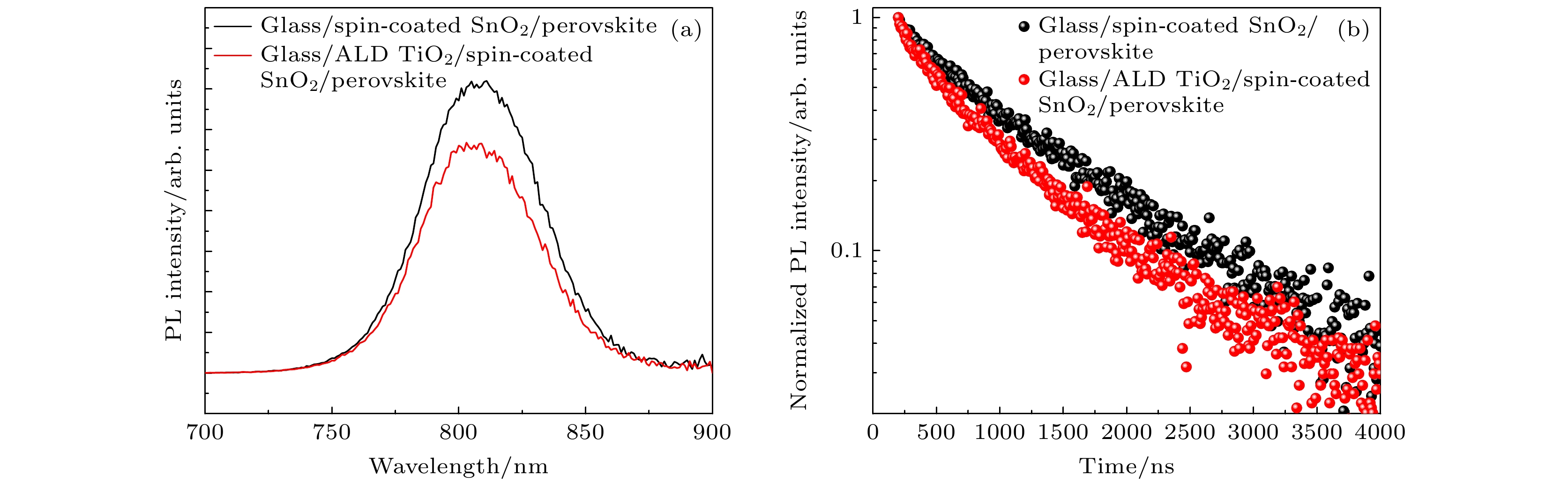

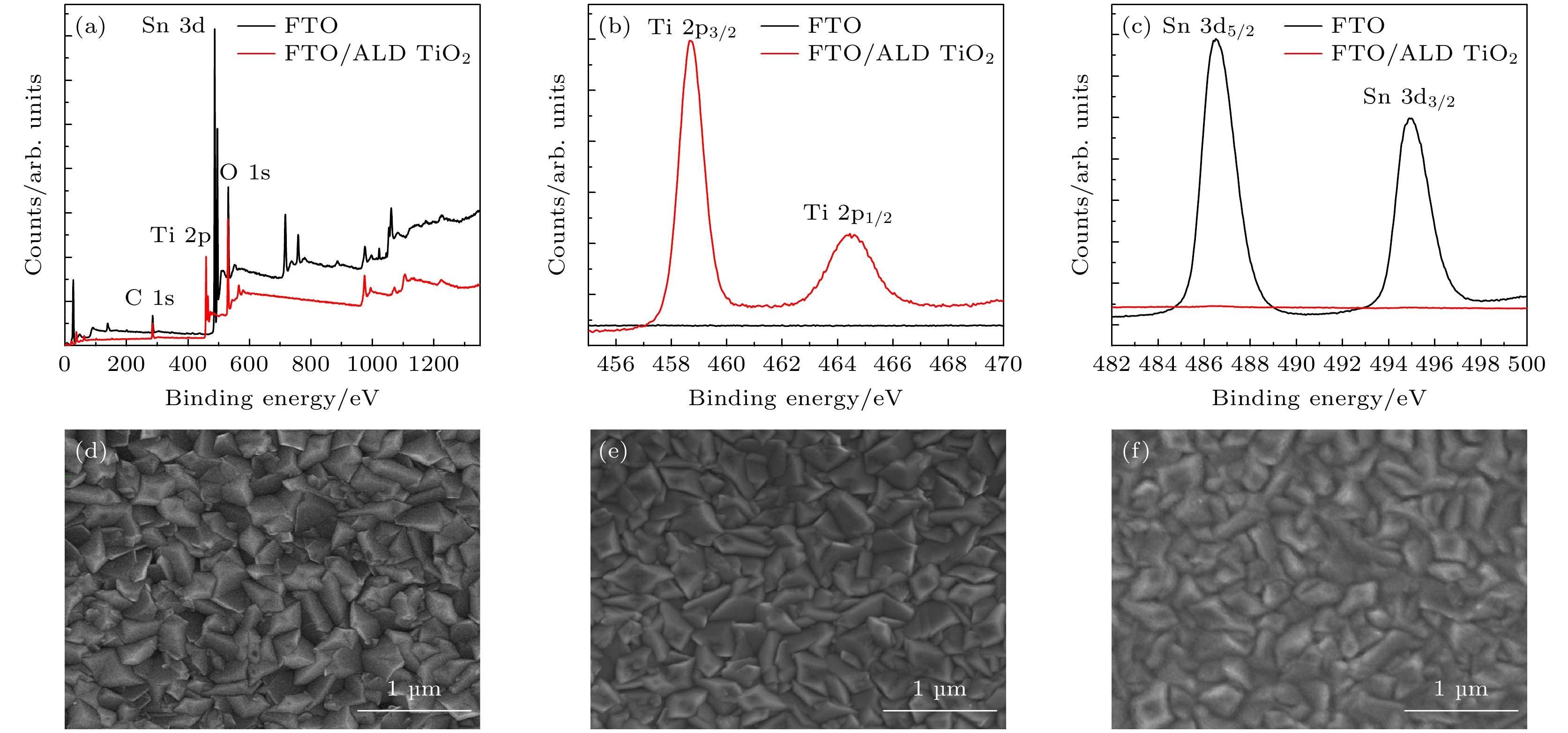

图 1 FTO衬底上有无ALD生长TiO2样品的XPS结果, 其中(a) 扫描全谱, (b) Ti的2p轨道, (c) Sn的3d轨道; 样品表面SEM结果, 其中 (d) FTO衬底, (e) FTO/TiO2, (f) FTO/TiO2/SnO2

Figure 1. XPS results of FTO substrate with and without ALD grown TiO2: (a) Full spectrum; (b) Ti 2p orbit; (c) Sn 3d orbit. Surface SEM results: (d) FTO substrate; (e) FTO/TiO2; (f) FTO/TiO2/SnO2

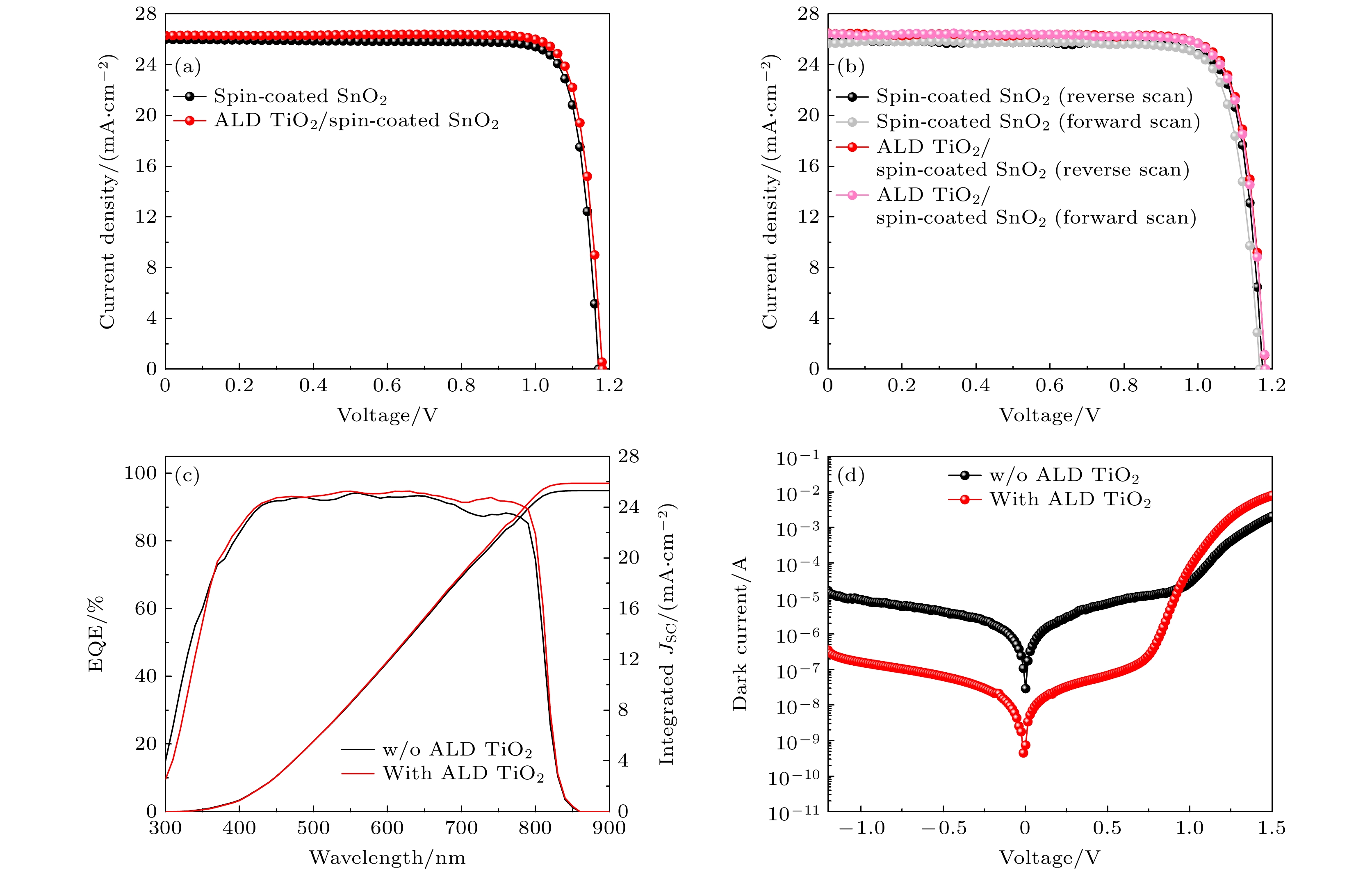

图 4 有无TiO2层的小面积钙钛矿太阳电池测试结果 (a) 快速单次J-V扫描曲线; (b) 慢速正向和反向扫描J-V曲线; (c) 外量子效率随波长变化和积分电流密度随波长累加曲线; (d) 暗态电流-电压曲线

Figure 4. Measurement results of small area perovskite solar cells with or without TiO2 layer: (a) Single J-V sweep curve under fast scan mode; (b) reverse and forward J-V sweep curves under slow scan mode; (c) EQE and accumulated integrated current density versus wavelength curves; (d) current-voltage curves under dark environment.

图 5 0.5 cm2大面积钙钛矿太阳电池测试结果 (a) 不同TiO2厚度电池性能对比; (b) 电池制备工艺重复性; (c) 冠军电池快速单次J-V扫描曲线(内插图为第三方认证结果); (d) 冠军电池慢速正向和反向扫描J-V曲线

Figure 5. Measurement results for 0.5 cm2 large area perovskite solar cells: (a) Solar cell performances comparison of different TiO2 thicknesses; (b) repeatability of solar cell fabrication technology; (c) single J-V sweep curve under fast scan mode for champion cell (inset graph: certified result); (d) reverse and forward J-V sweep curves under slow scan mode for champion cell.

表 1 有无ALD生长的金属氧化物缓冲层制备的整块器件分割出的子电池效率

Table 1. Power conversion efficiency of the sub-cells from the whole device with or without ALD grown metal oxide buffer layer.

电子传输层 F1-PCE /% F2-PCE

/%F3-PCE

/%F4-PCE

/%旋涂SnO2 25.40 24.95 25.76 8.72 ALD SnO2/旋涂SnO2 24.27 25.74 25.16 25.29 ALD TiO2/旋涂SnO2 25.92 26.46 26.21 25.92 表 2 有无ALD生长的TiO2整块器件上性能最佳子电池的各项参数

Table 2. Performance parameters of the best sub-cell on the whole device with or without ALD grown TiO2.

电子传输层 VOC/V JSC/(mA·cm–2) FF/% PCE/% Reverse PCE, forward PCE/% SnO2 1.17 26.00 84.65 25.76 25.25/24.87 TiO2/SnO2 1.18 26.30 85.19 26.46 25.99/25.81 表 3 不同TiO2生长循环数制备的大面积钙钛矿太阳电池性能参数

Table 3. Performance parameters of large area perovskite solar cells fabricated based on TiO2 grown by different cycles.

TiO2生长循

环数/cycleVOC/V JSC/(mA·cm–2) FF/% PCE/% 0 1.17 24.44 74.36 21.33 100 1.17 25.39 76.11 22.65 200 1.18 25.45 79.86 24.07 400 1.17 25.39 61.57 18.23 -

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Lee M M, Teuscher J, Miyasaka T, Murakami T N, Snaith H J 2012 Science 338 643

Google Scholar

Google Scholar

[3] Yang W S, Noh J H, Jeon N J, Kim Y C, Ryu S, Seo J, Seok S I 2015 Science 348 1234

Google Scholar

Google Scholar

[4] Jiang Q, Zhao Y, Zhang X W, Yang X L, Chen Y, Chu Z M, Ye Q F, Li X X, Yin Z G, You J B 2019 Nat. Photonics 13 460

Google Scholar

Google Scholar

[5] Zhao Y, Ma F, Qu Z H, Yu S Q, Shen T, Deng H X, Chu X B, Peng X X, Yuan Y B, Zhang X W, You J B 2022 Science 377 531

Google Scholar

Google Scholar

[6] Park J, Kim J, Yun H S, Paik M J, Noh E, Mun H J, Kim M G, Shin T J, Seok S I 2023 Nature 616 724

Google Scholar

Google Scholar

[7] https://www.nrel.gov/pv/interactive-cell-efficiency.html [2024-2-1]

[8] Lin H, Yang M, Ru X N, et al. 2023 Nat. Energy 8 789

Google Scholar

Google Scholar

[9] Yin W J, Shi T, Yan Y 2014 Adv. Mater. 26 4653

Google Scholar

Google Scholar

[10] Stranks S D, Eperon G E, Grancini G, et al. 2013 Science 342 341

Google Scholar

Google Scholar

[11] Yin W J, Shi T T, Yan Y F 2014 Appl. Phys. Lett. 104 063903

Google Scholar

Google Scholar

[12] Cheng Y, Peng Y, Jen A K Y, Yip H L 2021 Sol. RRL 6 2100545

Google Scholar

Google Scholar

[13] Kim G H, Kim D S 2021 Joule 5 1033

Google Scholar

Google Scholar

[14] Plutnar J, Pumera M 2021 Small 17 2102088

Google Scholar

Google Scholar

[15] Ahvenniemi E, Akbashev A R, Ali S, et al. 2017 J. Vac. Sci. Technol. A 35 010801

Google Scholar

Google Scholar

[16] Cho Y J, Jeong M J, Park J H, Hu W, Lim J, Chang H S 2021 Energies 14 1156

Google Scholar

Google Scholar

[17] Correa Baena J P, Steier L, Tress W, et al. 2015 Energy Environ. Sci. 8 2928

Google Scholar

Google Scholar

[18] Li C, Xu H, Zhi C, Wan Z, Li Z 2022 Chin. Phys. B 31 111004

Google Scholar

Google Scholar

[19] Kim M, Jeong J, Lu H Z, et al. 2022 Science 375 302

Google Scholar

Google Scholar

[20] You Y, Tian W, Min L, Cao F, Deng K, Li L 2019 Adv. Mater. Interfaces 7 1901406

Google Scholar

Google Scholar

[21] Jiang Q, Zhang L Q, Wang H L, et al. 2017 Nat. Energy 2 16177

Google Scholar

Google Scholar

[22] Lin R X, Wang Y R, Lu Q W, et al. 2023 Nature 620 994

Google Scholar

Google Scholar

[23] 周玚, 任信钢, 闫业强, 任昊, 杜红梅, 蔡雪原, 黄志祥 2022 71 208802

Google Scholar

Google Scholar

Zhou Y, Ren X G, Yan Y Q, Ren H, Du H M, Cai X Y, Huang Z X 2022 Acta Phys. Sin. 71 208802

Google Scholar

Google Scholar

[24] Peng J, Walter D, Ren Y H, et al. 2021 Science 371 390

Google Scholar

Google Scholar

[25] Chiappim W, Testoni G E, Moraes R S, et al. 2016 Vacuum 123 91

Google Scholar

Google Scholar

[26] Sadollahkhani A, Liu P, Leandri V, Safdari M, Zhang W, Gardner J M 2017 Chemphyschem 18 3047

Google Scholar

Google Scholar

[27] Chu S L, Zhang Y H, Xiao P, et al. 2022 Adv. Mater. 34 2108939

Google Scholar

Google Scholar

[28] Zhao J J, Zhao L, Deng Y H, Xiao X, Ni Z Y, Xu S, Huang J S 2020 Nat. Photonics 14 612

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5546

- PDF Downloads: 276

- Cited By: 0

DownLoad:

DownLoad: