-

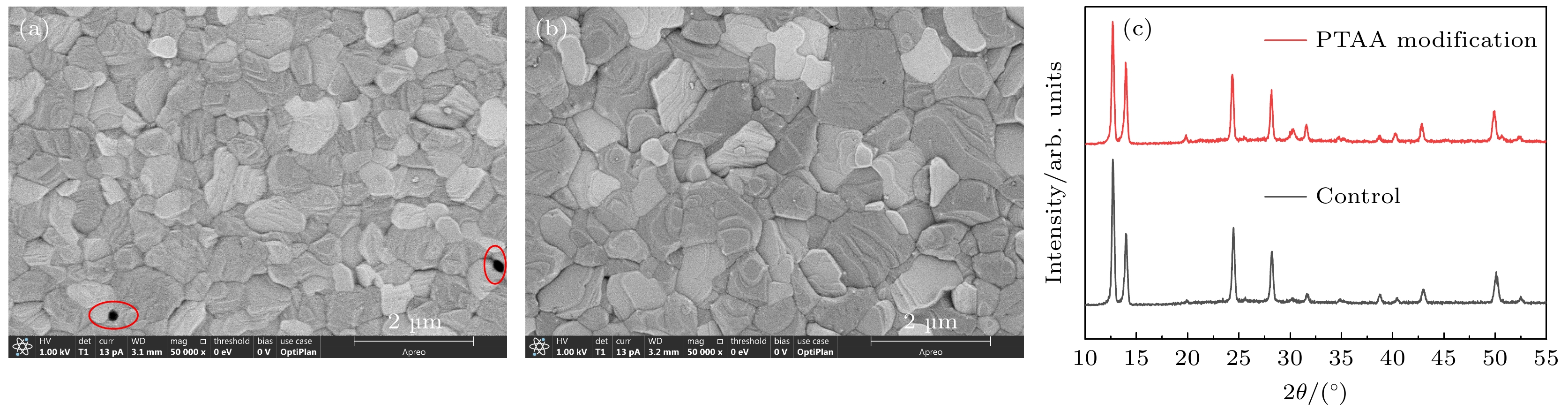

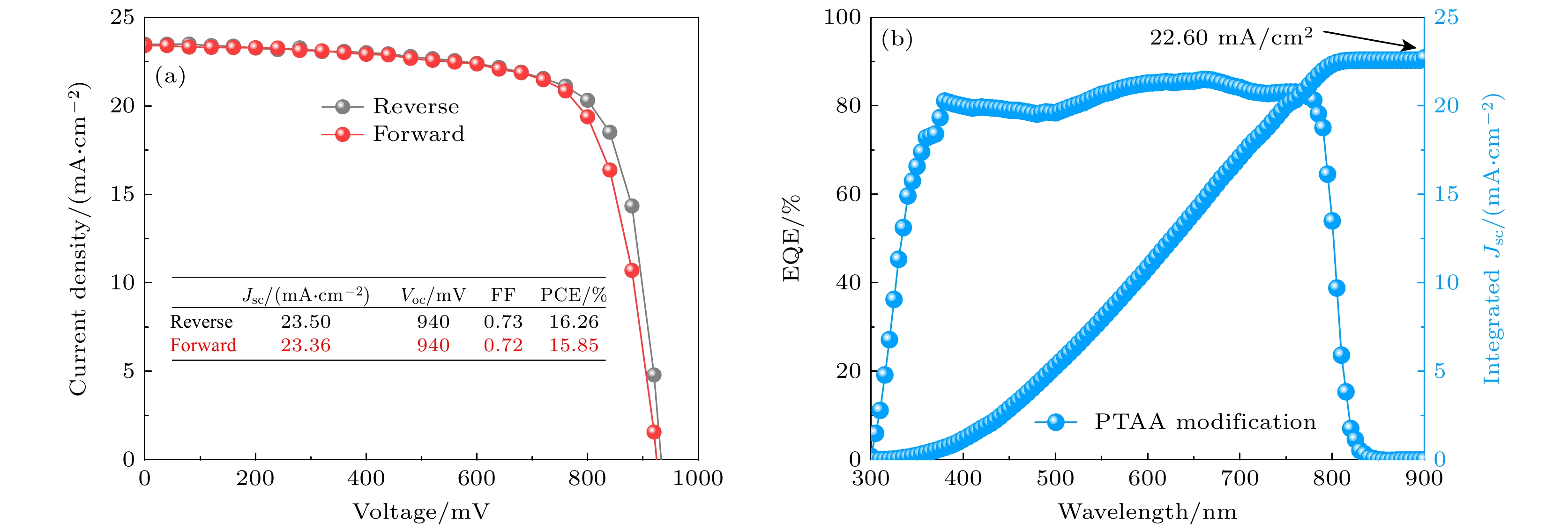

高效钙钛矿太阳电池中通常采用有机p型半导体材料作为空穴传输层. 有机材料在湿度、温度、紫外照射等环境因素下会出现严重的性能衰退, 加速钙钛矿太阳电池的老化, 成为实现其实际应用的主要障碍之一. 本文提出采用无机硫氢酸亚铜(CuSCN)作为空穴传输材料, 并通过锂掺杂提高其空穴传输特性; 在此基础上采用聚[双(4苯基)(2,4,6-三甲基苯基)胺]修饰CuSCN表面, 避免CuSCN和碘化铅(PbI2)间的相互作用, 实现了大晶粒、致密钙钛矿薄膜的制备, 最终实现了钙钛矿太阳电池性能的有效提升. 本工作为稳定、高效钙钛矿太阳电池的制备提供了可借鉴的策略.Perovskite solar cells have attracted extensive attention because of their photoelectric characteristics. Since 2009, the photoelectric conversion rate of the solar cells has soared from 3.8% to 25.7%. Perovskite material has become a focus of extensive academic research due to its advantages of high carrier mobility, low exciton binding energy, wide absorption spectrum and high optical absorption coefficient. However, organic P-type semiconductor material is usually used as a hole transport layer in high efficiency perovskite solar cells, for example, Spiro-OMeTAD, PEDOT:PSS, and PTAA. Because Spiro-OMeTAD is difficult to purify, many hole transport materials containing triphenylamine like Spiro-OMeTAD have been synthesized, such as triphenylamine polymer PTAA. As the conjugate parts of these triphenylamine transport materials are not coplanar and the space is distorted, they cannot form ordered stacks by spin-coating method, so their charge properties are weak, and li-TFSI and tBP are often added to improve the hole transport, so as to achieve better device effects. Moreover, the PTAA has the problem of infiltration, and it is difficult to form a completely covered perovskite film on it, which seriously affects the quality and surface morphology of perovskite film. The PEDOT:PSS itself has an acidic and corrosive electrode, and is easy to absorb moisture, which will affect the stability of the solar cell. The performance of organic material will deteriorate seriously under environmental factors such as humidity, temperature and UV irradiation, which will accelerate the aging of perovskite solar cells and become one of the main obstacles to their practical applications. In this work, the inorganic cuprous thiocyanate (CuSCN) is used as a hole transport material, the CuSCN is a rich and stable P-type semiconductor material, which has the characteristics of abundance, low cost, high carrier mobility, appropriate energy level, low defect density, good thermal stability, and excellent light transmittance. The CuSCN is one of the few known compounds with both high optical transparency (its wide band gap is 3.7–3.9 eV) and significant P-type electrical conductivity. Most importantly, CuSCN is inexpensive and can be prepared by solution method at room temperature. And its hole transport properties are improved by lithium doping. On this basis, the surface of CuSCN is modified with PTAA to avoid the interaction between CuSCN and lead iodide (PbI2), and the large-grained and dense perovskite films are prepared. Finally, the performance of perovskite solar cells is effectively improved. This work provides a reference for the preparation of the stable and efficient perovskite solar cells.

-

Keywords:

- perovskite solar cells /

- hole transport layer /

- cuprous thiocyanate /

- Li-doping

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Stranks S D, Eperon G E, Grancini G, Menelaou C, Alcocer M J P, Leijtens T, Herz L M, Petrozza A, Snaith H J 2013 Science 342 341

Google Scholar

Google Scholar

[3] Zhang J, Zhang T, Jiang L, Bach U, Cheng Y B 2018 ACS Energy Lett. 3 1677

Google Scholar

Google Scholar

[4] Petrus M L, Bein T, Dingemans T J, Docampo P 2015 J. Mater. Chem. A. 3 12159

Google Scholar

Google Scholar

[5] Kim J Y, Jung J H, Lee D E, Joo J 2002 Synth. Met. 126 311

Google Scholar

Google Scholar

[6] Li W, Liu C, Li Y, Kong W, Wang X, Chen H, Xu B, Cheng C 2018 Sol. RRL. 2 1800173

Google Scholar

Google Scholar

[7] Jaffe J E, Kaspar T C, Droubay T C, Varga T, Bowden M E, Exarhos G J 2010 J. Phys. Chem. C 114 9111

Google Scholar

Google Scholar

[8] Arora N, Dar M I, Hinderhofer A, Pellet N, Schreiber F, Zakeeruddin S M, Grätzel M 2017 Science 358 768

Google Scholar

Google Scholar

[9] Ren X, Wang Z, Sha W E I, Choy W C H 2017 ACS Photonics 4 934

Google Scholar

Google Scholar

[10] 周玚, 任信钢, 闫业强, 任昊, 杜红梅, 蔡雪原, 黄志祥 2022 71 208802

Google Scholar

Google Scholar

Zhou Y, Ren X G, Yan Y Q, Ren H, Du H M, Cai X Y, Huang Z X 2022 Acta Phys. Sin. 71 208802

Google Scholar

Google Scholar

[11] Zaumseil J, Sirringhaus H 2007 Chem. Rev. 107 1296

Google Scholar

Google Scholar

[12] Zhang C, Chen P, Hu W 2016 Small 12 1252

Google Scholar

Google Scholar

[13] Guo N, Li J, Yang S, Zhang J, Ni J, Cai H 2021 Nanotechnology 32 395704

Google Scholar

Google Scholar

[14] Zhou H, Chen Q, Li G, Luo S, Song T B, Duan H S, Hong Z, You J, Liu Y, Yang Y 2014 Science 345 542

Google Scholar

Google Scholar

[15] Yang J, Liu C, Cai C, Hu X, Huang Z, Duan X, Meng X, Yuan Z, Tan L, Chen Y 2019 Adv. Energy Mater. 9 1900198

Google Scholar

Google Scholar

[16] Luo J, Xia J, Yang H, Malik H A, Han F, Shu H, Yao X, Wan Z, Jia C 2020 Nano Energy 70 104509

Google Scholar

Google Scholar

[17] Son D Y, Kim S G, Seo J Y, Lee S H, Shin H, Lee D, Park N G 2018 J. Am. Chem. Soc. 140 1358

Google Scholar

Google Scholar

[18] Wang S, Sakurai T, Wen W, Qi Y 2018 Adv. Mater. Interfaces 5 1800260

Google Scholar

Google Scholar

[19] Sherkar T S, Momblona C, Gil-Escrig L, Bolink H J, Koster L J A 2017 Adv. Energy Mater. 7 1602432

Google Scholar

Google Scholar

[20] Saliba M, Matsui T, Domanski K, Seo J Y, Ummadisingu A, Zakeeruddin S M, Correa-Baena J P, Tress W R, Abate A, Hagfeldt A, Grätzel M 2016 Science 354 206

Google Scholar

Google Scholar

[21] Hou F, Shi B, Li T, Xin C, Ding Y, Wei C, Wang G, Li Y, Zhao Y, Zhang X 2019 ACS Appl. Mater. Interfaces 11 25218

Google Scholar

Google Scholar

[22] Wang P, Li R, Chen B, Hou F, Zhang J, Zhao Y, Zhang X 2020 Adv. Mater. 32 1905766

Google Scholar

Google Scholar

-

图 4 (a)无修饰和(b) PTAA修饰后CuSCN薄膜上的钙钛矿薄膜表面SEM图; (c)无修饰和PTAA修饰后CuSCN薄膜上的钙钛矿薄膜XRD图

Fig. 4. (a), (b) SEM images of perovskite film surface on CuSCN film (a) without modification and (b) with PTAA modification; (c) XRD patterns of perovskite films on CuSCN films without modification and after PTAA modification.

表 1 掺锂前后CuSCN薄膜的μFE和Vth (Vd是漏电压)

Table 1. μFE and Vth of CuSCN films doped with or without Li.

Vd/V μFE/(cm2·(V·s)–1) Vth/V Control +1 0.031 –4.93 0.1%LiSCN+CuSCN +1 0.88 –1.72 0.5%LiSCN+CuSCN +1 1.13 4.35 1%LiSCN+CuSCN +1 2.28 –0.71 表 2 不掺杂和CuSCN中掺杂不同体积比LiSCN所得薄膜上的钙钛矿薄膜的TRPL拟合结果

Table 2. TRPL fitting results of perovskite films fabricated on CuSCN with different LiSCN doping ratio.

τ1/ns

A1/(A1+A2)/%

τ2/ns

A2/(A1+A2)/%

τave/nsControl 20.02 0.80 295.88 99.20 293.67 0.1%LiSCN+CuSCN 16.44 1.58 179.74 98.42 177.16 0.5%LiSCN+CuSCN 21.98 2.29 159.29 97.71 156.15 1%LiSCN+CuSCN 19.21 2.29 170.87 97.71 167.51 -

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Stranks S D, Eperon G E, Grancini G, Menelaou C, Alcocer M J P, Leijtens T, Herz L M, Petrozza A, Snaith H J 2013 Science 342 341

Google Scholar

Google Scholar

[3] Zhang J, Zhang T, Jiang L, Bach U, Cheng Y B 2018 ACS Energy Lett. 3 1677

Google Scholar

Google Scholar

[4] Petrus M L, Bein T, Dingemans T J, Docampo P 2015 J. Mater. Chem. A. 3 12159

Google Scholar

Google Scholar

[5] Kim J Y, Jung J H, Lee D E, Joo J 2002 Synth. Met. 126 311

Google Scholar

Google Scholar

[6] Li W, Liu C, Li Y, Kong W, Wang X, Chen H, Xu B, Cheng C 2018 Sol. RRL. 2 1800173

Google Scholar

Google Scholar

[7] Jaffe J E, Kaspar T C, Droubay T C, Varga T, Bowden M E, Exarhos G J 2010 J. Phys. Chem. C 114 9111

Google Scholar

Google Scholar

[8] Arora N, Dar M I, Hinderhofer A, Pellet N, Schreiber F, Zakeeruddin S M, Grätzel M 2017 Science 358 768

Google Scholar

Google Scholar

[9] Ren X, Wang Z, Sha W E I, Choy W C H 2017 ACS Photonics 4 934

Google Scholar

Google Scholar

[10] 周玚, 任信钢, 闫业强, 任昊, 杜红梅, 蔡雪原, 黄志祥 2022 71 208802

Google Scholar

Google Scholar

Zhou Y, Ren X G, Yan Y Q, Ren H, Du H M, Cai X Y, Huang Z X 2022 Acta Phys. Sin. 71 208802

Google Scholar

Google Scholar

[11] Zaumseil J, Sirringhaus H 2007 Chem. Rev. 107 1296

Google Scholar

Google Scholar

[12] Zhang C, Chen P, Hu W 2016 Small 12 1252

Google Scholar

Google Scholar

[13] Guo N, Li J, Yang S, Zhang J, Ni J, Cai H 2021 Nanotechnology 32 395704

Google Scholar

Google Scholar

[14] Zhou H, Chen Q, Li G, Luo S, Song T B, Duan H S, Hong Z, You J, Liu Y, Yang Y 2014 Science 345 542

Google Scholar

Google Scholar

[15] Yang J, Liu C, Cai C, Hu X, Huang Z, Duan X, Meng X, Yuan Z, Tan L, Chen Y 2019 Adv. Energy Mater. 9 1900198

Google Scholar

Google Scholar

[16] Luo J, Xia J, Yang H, Malik H A, Han F, Shu H, Yao X, Wan Z, Jia C 2020 Nano Energy 70 104509

Google Scholar

Google Scholar

[17] Son D Y, Kim S G, Seo J Y, Lee S H, Shin H, Lee D, Park N G 2018 J. Am. Chem. Soc. 140 1358

Google Scholar

Google Scholar

[18] Wang S, Sakurai T, Wen W, Qi Y 2018 Adv. Mater. Interfaces 5 1800260

Google Scholar

Google Scholar

[19] Sherkar T S, Momblona C, Gil-Escrig L, Bolink H J, Koster L J A 2017 Adv. Energy Mater. 7 1602432

Google Scholar

Google Scholar

[20] Saliba M, Matsui T, Domanski K, Seo J Y, Ummadisingu A, Zakeeruddin S M, Correa-Baena J P, Tress W R, Abate A, Hagfeldt A, Grätzel M 2016 Science 354 206

Google Scholar

Google Scholar

[21] Hou F, Shi B, Li T, Xin C, Ding Y, Wei C, Wang G, Li Y, Zhao Y, Zhang X 2019 ACS Appl. Mater. Interfaces 11 25218

Google Scholar

Google Scholar

[22] Wang P, Li R, Chen B, Hou F, Zhang J, Zhao Y, Zhang X 2020 Adv. Mater. 32 1905766

Google Scholar

Google Scholar

计量

- 文章访问数: 5814

- PDF下载量: 130

- 被引次数: 0

下载:

下载: