-

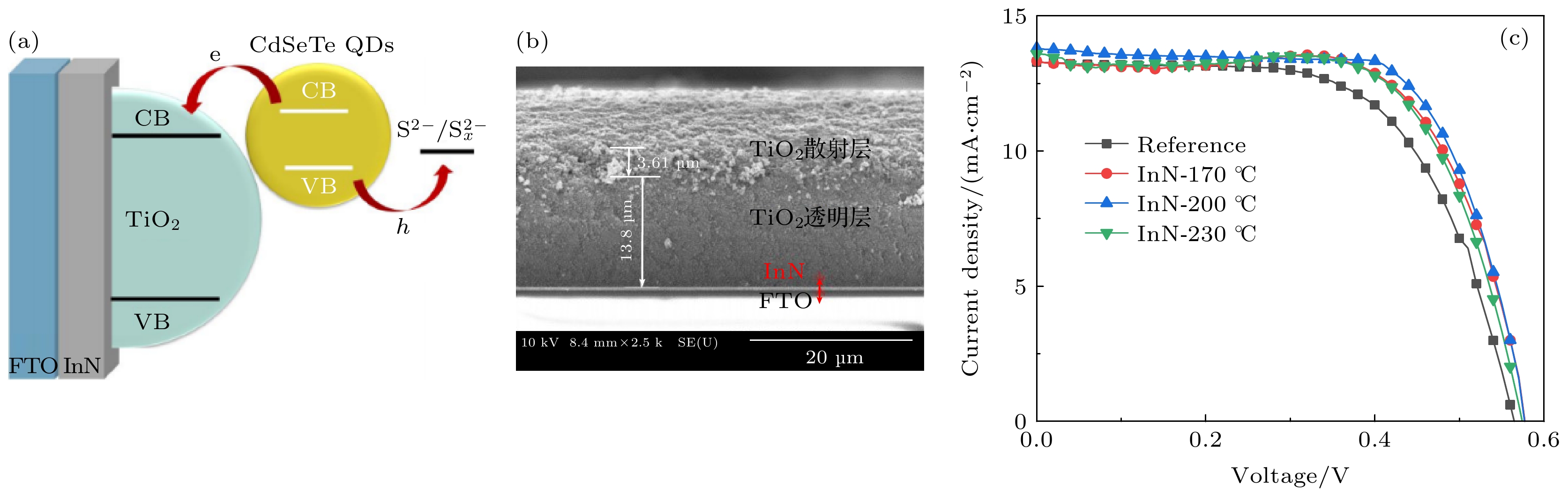

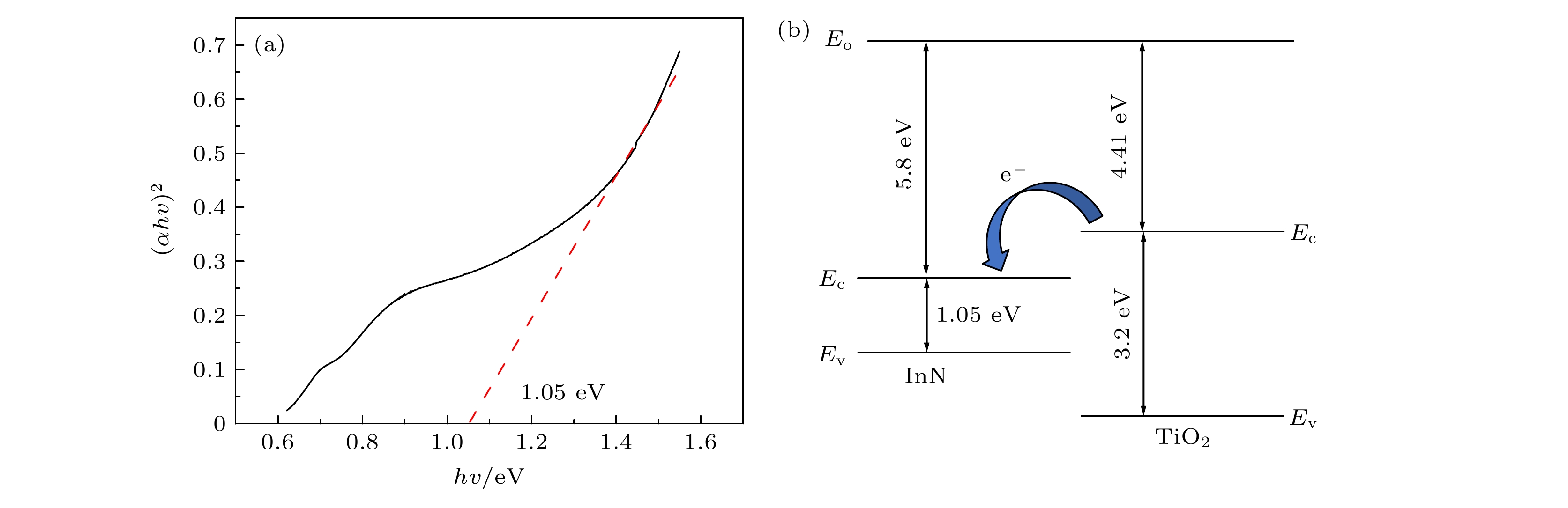

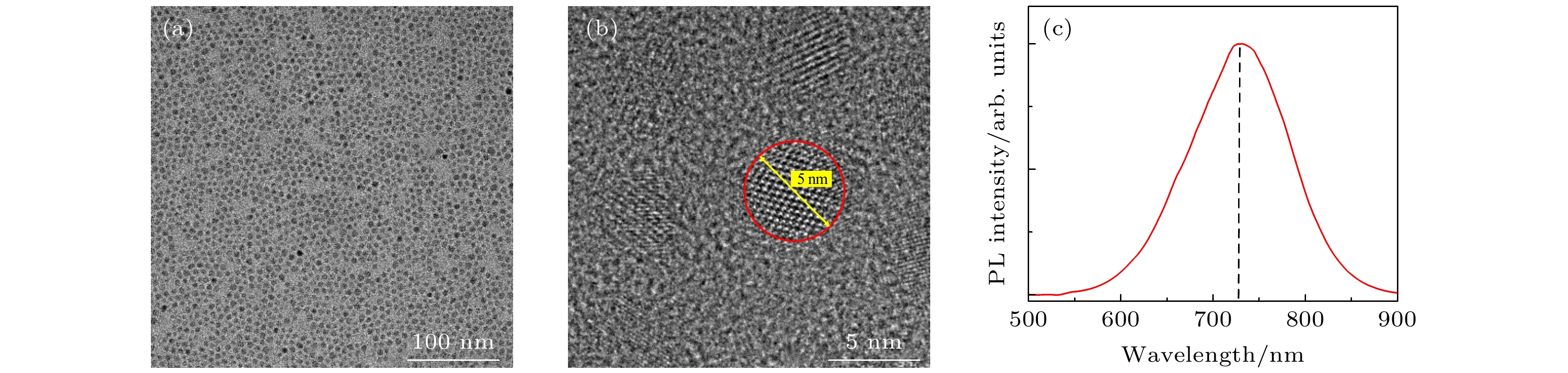

量子点敏化太阳能电池具有重要的潜在应用, 但仍存在界面输运、稳定性和效率改善的挑战. 本文采用等离子增强原子层沉积技术在低温下(170—230 ℃)制备了InN, 并将其插入至CdSeTe基量子点太阳能电池光阳极的FTO/TiO2界面处, 进行了原子层沉积窗口和电池性能改善的物理机理研究. 结果表明, 引入InN 超薄层后的电池效率整体有明显提升, 并且促进了电子的输运, 填充因子明显增加. 同时, 加速了电子抽取、转移和分离, 降低了电荷复合的可能性. 对插入的InN沉积温度和厚度对电池性能的影响进行了深入分析, 并对背后的物理机理进行了讨论.Quantum dot-sensitized solar cells have gained rapid development which could produce potential applications. Although they have a theoretical photoelectric conversion efficiency of 44%, there is still a considerable gap in comparison with corresponding practical solar cells, which is mainly due to the fact that the interface transfer, stability and efficiency improvement are still facing some problems. In particular, the carrier recombination loss at the cell interface seriously hinders the quantum dot-sensitized solar cells from developing. In this work, an ultra-thin layer of InN prepared by plasma-enhanced atomic layer deposition is inserted into the FTO/TiO2 interface of the photoanode of CdSeTe based quantum dot-sensitized solar cells to improve the performance of the photoanode structure, and physical mechanism behind the device is discussed. We first investigate the effects of different deposition temperatures (170, 200 and 230 ℃) on the cell performance of InN films. While the InN ultra-thin layer is deposited at 200 ℃, an enhancement of 16.9% in conversion efficiency is achieved as compared with the reference group. Then, the effects of different thickness (5, 10, and 15 cycles) on the cell are investigated at a fixed deposition temperature of 200 ℃. Additionally, an improvement of fill factor for the device after an introduction of InN layer is observed. This enhancement is further convinced by an apparent reduction of series resistance extracted by the Nyquist curve. The significant increase in fill factor indicates that the introduction of InN accelerates the extraction, transfer and separation of electrons, and reduces the possibility of photon-generated carriers recombination. However, the insertion of InN deposition temperature and thickness have a certain range of enhancement in the cell performance, and further investigation of the mechanism will be carried out.

-

Keywords:

- InN /

- atomic layer deposition /

- fill factor /

- interface transport

[1] Tian J, Cao G 2013 Nano Rev. 4 22578

Google Scholar

Google Scholar

[2] Beard M C, Luther J M, Semonin O E, Nozik A J 2013 Acc. Chem. Res. 46 1252

Google Scholar

Google Scholar

[3] Gopi C V V M, Singh S, Reddy A E, Kim H J 2018 ACS Appl. Mater. Interfaces 10 10036

Google Scholar

Google Scholar

[4] Wei H, Wang G, Wu H, Luo Y, Li D, Meng Q 2016 Acta Phys. Chim. Sin. 32 201

Google Scholar

Google Scholar

[5] Jalali-Moghadam E, Shariatinia Z 2018 Appl. Surf. Sci. 441 1

Google Scholar

Google Scholar

[6] Pan Z, Rao H, Mora-Seró I, Bisquert J, Zhong X 2018 Chem. Soc. Rev. 47 7659

Google Scholar

Google Scholar

[7] Jo I, Lee Y, Kim H, Ahn K 2021 J. Alloys Compd. 870 159527

Google Scholar

Google Scholar

[8] Salant A, Shalom M, Hod I, Faust A, Zaban A, Banin U 2010 ACS Nano 4 5962

Google Scholar

Google Scholar

[9] Wang G, Wei H, Shi J, Xu Y, Wu H, Luo Y, Li D, Meng Q 2017 Nano Energy 35 17

Google Scholar

Google Scholar

[10] Wang W, Feng W, Du J, Xue W, Zhang L, Zhao L, Li Y, Zhong X 2018 Adv. Mater. 30 1705746

Google Scholar

Google Scholar

[11] Wei H, Li D, Zheng X, Meng Q 2018 Chin. Phys. B 27 018808

Google Scholar

Google Scholar

[12] Wei H, Wang G, Shi J, Wu H, Luo Y, Li D, Meng Q 2016 J. Mater. Chem. A 4 14194

Google Scholar

Google Scholar

[13] Song H, Lin Y, Zhang Z, Rao H, Wang W, Fang Y, Pan Z, Zhong X 2021 J. Am. Chem. Soc. 143 4790

Google Scholar

Google Scholar

[14] Liu Z, Miyauchi M, Uemura Y, Cui Y, Hara K, Zhao Z, Sunahara K, Furube A 2010 Appl. Phys. Lett. 96 233107

Google Scholar

Google Scholar

[15] Ito S, Murakami T N, Comte P, Liska P, Grätzel C, Nazeeruddin M K, Grätzel M 2008 Thin Solid Films 516 4613

Google Scholar

Google Scholar

[16] Hart J N, Menzies D, Cheng Y B, Simon G P, Spiccia L 2006 C.R. Chim. 9 622

Google Scholar

Google Scholar

[17] Martinson A B F, Elam J W, Hupp J T, Pellin M J 2007 Nano Lett. 7 2183

Google Scholar

Google Scholar

[18] Wu Y, Yang X, Chen H, Zhang K, Qin C, Liu J, Peng W, Islam A, Bi E, Ye F, Yin M, Zhang P, Han L 2014 Appl. Phys. Express 7 052301

Google Scholar

Google Scholar

[19] Brennan T P, Tanskanen J T, Roelofs K E, To J W F, Nguyen W H, Bakke J R, Ding I K, Hardin B E, Sellinger A, McGehee M D, Bent S F 2013 J. Phys. Chem. B 117 24138

Google Scholar

Google Scholar

[20] Flack T J, Pushpakaran B N, Bayne S B 2016 J. Electron. Mater. 45 2673

Google Scholar

Google Scholar

[21] Florian C, Cignani R, Santarelli A, Filicori F, Longo F, Ieee 2013 IEEE Mtt-S International Microwave Symposium Digest Seattle, WA, USA, June 2–7, 2013 p14021954

[22] Wei H, Qiu P, Peng M, Wu Q, Liu S, An Y, He Y, Song Y, Zheng X 2019 Appl. Surf. Sci. 476 608

Google Scholar

Google Scholar

[23] Liu H, Wang X, Chen Z, Zheng X, Wang P, Sheng B, Wang T, Rong X, Li M, Zhang J, Yang X, Xu F, Ge W, Shen B 2018 Appl. Phys. Lett. 112 162102

Google Scholar

Google Scholar

[24] Polyakov V M, Schwierz F 2006 Appl. Phys. Lett. 88 032101

Google Scholar

Google Scholar

[25] Haider A, Kizir S, Biyikli N 2016 AIP Adv. 6 045203

Google Scholar

Google Scholar

[26] 白一鸣, 陈诺夫, 戴松元, 姚建曦. 2014 太阳电池物理基础 (北京: 机械工业出版社) 第108页

Bai Y M, Chen N F, Dai S Y, Yao J X 2014 Physical Fundamentals of Solar Cells (Beijing: Mechanical Industry Press) p108 (in Chinese)

[27] Adachi M, Sakamoto M, Jiu J, Ogata Y, Isoda S 2006 J. Phys. Chem. B 110 13872

Google Scholar

Google Scholar

[28] Bard A, Faulkner L 2000 Electrochemical Methods: Fundamentals and Applications (2nd Ed.) (New York: John Wiley & Sons) pp580−650

[29] Pan Z, Zhao K, Wang J, Zhang H, Feng Y, Zhong X 2013 ACS Nano 7 5215

Google Scholar

Google Scholar

[30] An Y, He Y, Wei H, Liu S, Li M, Song Y, Qiu P, Rehman A, Zheng X, Peng M 2019 Results Phys. 12 804

Google Scholar

Google Scholar

[31] Singh T, Lehnen T, Leuning T, Sahu D, Mathur S 2014 Appl. Surf. Sci. 289 27

Google Scholar

Google Scholar

[32] Chang Y, Lu Y, Hong Y, Kuo C, Gwo S, Yeh J 2010 J. Appl. Phys. 107 043710

Google Scholar

Google Scholar

-

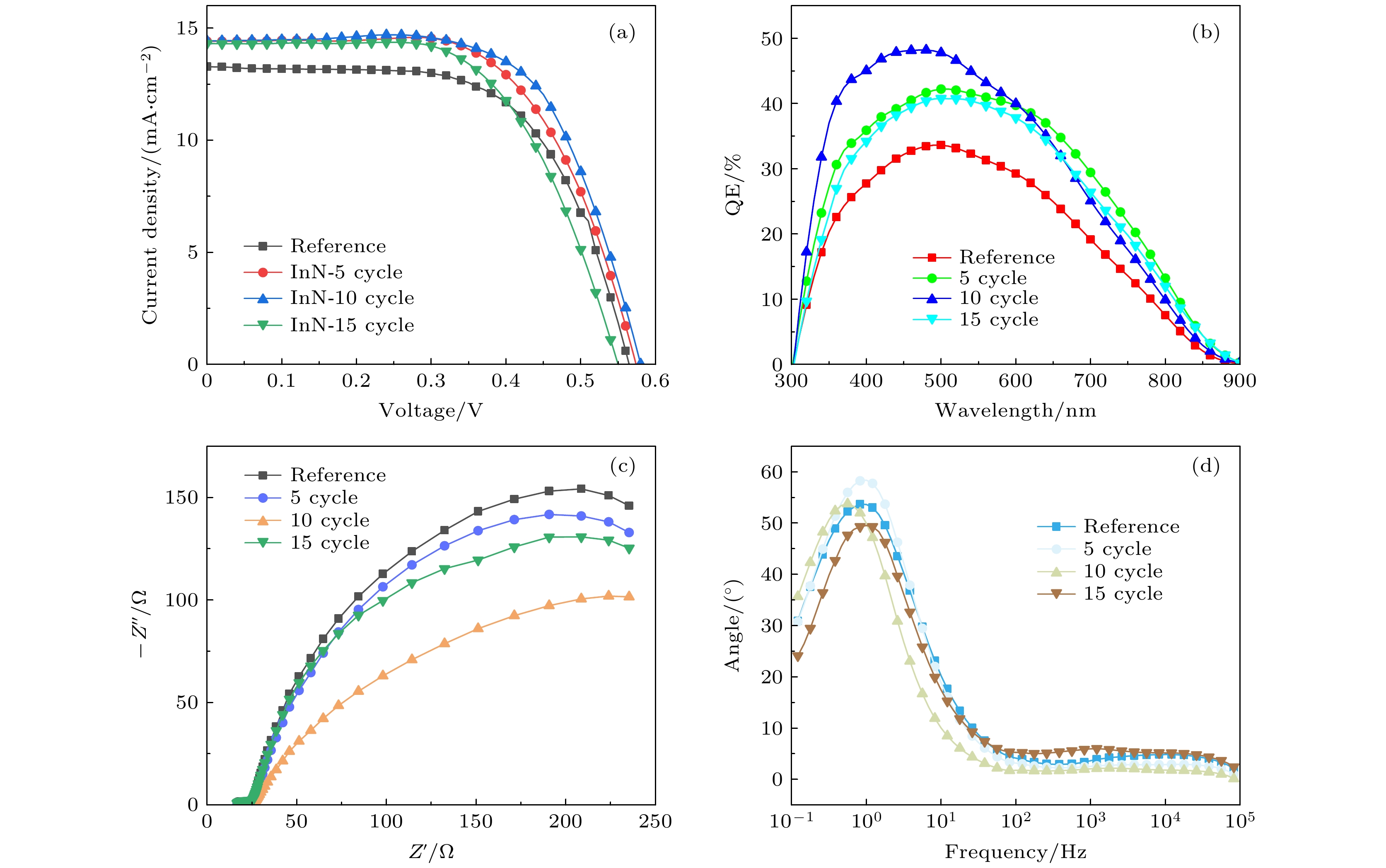

图 3 (a) 基于不同InN厚度的QDSCs的J -V曲线; (b) 基于不同厚度InN的QDSCs的量子效率; (c) 基于不同厚度InN的QDSCs的暗态Nyquist曲线; (d)基于不同厚度InN的QDSCs的Bode曲线

Fig. 3. (a) J -V curves of QDSCs based on different InN thickness; (b) quantum efficiency of QDSCs based on different thickness of InN; (c) Nyquist curves of QDSCs based on different thicknesses of InN; (d) Bode curves of QDSCs based on different thicknesses of InN.

表 1 不同温度下生长的InN超薄层的电池的J -V测试参数

Table 1. J -V test parameters of InN ultra-thin layer batteries grown at different temperatures.

Samples Jsc/(mA·cm–2) Voc/V FF/% η/% Reference 13.28 0.56 62.37 4.68 InN-170 ℃ 13.33 0.58 67.98 5.23 InN-200 ℃ 14.43 0.58 69.98 5.47 InN-230 ℃ 13.59 0.57 66.55 4.68 表 2 不同厚度的InN太阳能电池的J -V 测试参数

Table 2. J -V test parameters of InN solar cells with different thicknesses.

Samples Jsc/(mA·cm–2) Voc/V FF/% η/% Reference 13.28 0.56 62.37 4.68 5 cycles 14.41 0.58 62.48 5.18 10 cycles 14.43 0.58 69.98 5.47 15 cycles 14.29 0.55 60.85 4.77 表 3 不同厚度的InN太阳能电池的QE测试参数

Table 3. QE test parameters of InN solar cells with different thicknesses.

Samples QE/% Reference 33.61 5 cycles 42.20 10 cycles 47.78 15 cycles 40.76 表 4 EIS 拟合结果和载流子寿命

Table 4. EIS fitting results and carrier lifetime.

Samples Rs/Ω Rct-TiO2/Ω·cm–2 τn/% Reference 18.29 283.5 159.2 5 cycles 16.92 274 193.0 10 cycles 17.68 188.2 283.3 15 cycles 18.82 221 163.6 -

[1] Tian J, Cao G 2013 Nano Rev. 4 22578

Google Scholar

Google Scholar

[2] Beard M C, Luther J M, Semonin O E, Nozik A J 2013 Acc. Chem. Res. 46 1252

Google Scholar

Google Scholar

[3] Gopi C V V M, Singh S, Reddy A E, Kim H J 2018 ACS Appl. Mater. Interfaces 10 10036

Google Scholar

Google Scholar

[4] Wei H, Wang G, Wu H, Luo Y, Li D, Meng Q 2016 Acta Phys. Chim. Sin. 32 201

Google Scholar

Google Scholar

[5] Jalali-Moghadam E, Shariatinia Z 2018 Appl. Surf. Sci. 441 1

Google Scholar

Google Scholar

[6] Pan Z, Rao H, Mora-Seró I, Bisquert J, Zhong X 2018 Chem. Soc. Rev. 47 7659

Google Scholar

Google Scholar

[7] Jo I, Lee Y, Kim H, Ahn K 2021 J. Alloys Compd. 870 159527

Google Scholar

Google Scholar

[8] Salant A, Shalom M, Hod I, Faust A, Zaban A, Banin U 2010 ACS Nano 4 5962

Google Scholar

Google Scholar

[9] Wang G, Wei H, Shi J, Xu Y, Wu H, Luo Y, Li D, Meng Q 2017 Nano Energy 35 17

Google Scholar

Google Scholar

[10] Wang W, Feng W, Du J, Xue W, Zhang L, Zhao L, Li Y, Zhong X 2018 Adv. Mater. 30 1705746

Google Scholar

Google Scholar

[11] Wei H, Li D, Zheng X, Meng Q 2018 Chin. Phys. B 27 018808

Google Scholar

Google Scholar

[12] Wei H, Wang G, Shi J, Wu H, Luo Y, Li D, Meng Q 2016 J. Mater. Chem. A 4 14194

Google Scholar

Google Scholar

[13] Song H, Lin Y, Zhang Z, Rao H, Wang W, Fang Y, Pan Z, Zhong X 2021 J. Am. Chem. Soc. 143 4790

Google Scholar

Google Scholar

[14] Liu Z, Miyauchi M, Uemura Y, Cui Y, Hara K, Zhao Z, Sunahara K, Furube A 2010 Appl. Phys. Lett. 96 233107

Google Scholar

Google Scholar

[15] Ito S, Murakami T N, Comte P, Liska P, Grätzel C, Nazeeruddin M K, Grätzel M 2008 Thin Solid Films 516 4613

Google Scholar

Google Scholar

[16] Hart J N, Menzies D, Cheng Y B, Simon G P, Spiccia L 2006 C.R. Chim. 9 622

Google Scholar

Google Scholar

[17] Martinson A B F, Elam J W, Hupp J T, Pellin M J 2007 Nano Lett. 7 2183

Google Scholar

Google Scholar

[18] Wu Y, Yang X, Chen H, Zhang K, Qin C, Liu J, Peng W, Islam A, Bi E, Ye F, Yin M, Zhang P, Han L 2014 Appl. Phys. Express 7 052301

Google Scholar

Google Scholar

[19] Brennan T P, Tanskanen J T, Roelofs K E, To J W F, Nguyen W H, Bakke J R, Ding I K, Hardin B E, Sellinger A, McGehee M D, Bent S F 2013 J. Phys. Chem. B 117 24138

Google Scholar

Google Scholar

[20] Flack T J, Pushpakaran B N, Bayne S B 2016 J. Electron. Mater. 45 2673

Google Scholar

Google Scholar

[21] Florian C, Cignani R, Santarelli A, Filicori F, Longo F, Ieee 2013 IEEE Mtt-S International Microwave Symposium Digest Seattle, WA, USA, June 2–7, 2013 p14021954

[22] Wei H, Qiu P, Peng M, Wu Q, Liu S, An Y, He Y, Song Y, Zheng X 2019 Appl. Surf. Sci. 476 608

Google Scholar

Google Scholar

[23] Liu H, Wang X, Chen Z, Zheng X, Wang P, Sheng B, Wang T, Rong X, Li M, Zhang J, Yang X, Xu F, Ge W, Shen B 2018 Appl. Phys. Lett. 112 162102

Google Scholar

Google Scholar

[24] Polyakov V M, Schwierz F 2006 Appl. Phys. Lett. 88 032101

Google Scholar

Google Scholar

[25] Haider A, Kizir S, Biyikli N 2016 AIP Adv. 6 045203

Google Scholar

Google Scholar

[26] 白一鸣, 陈诺夫, 戴松元, 姚建曦. 2014 太阳电池物理基础 (北京: 机械工业出版社) 第108页

Bai Y M, Chen N F, Dai S Y, Yao J X 2014 Physical Fundamentals of Solar Cells (Beijing: Mechanical Industry Press) p108 (in Chinese)

[27] Adachi M, Sakamoto M, Jiu J, Ogata Y, Isoda S 2006 J. Phys. Chem. B 110 13872

Google Scholar

Google Scholar

[28] Bard A, Faulkner L 2000 Electrochemical Methods: Fundamentals and Applications (2nd Ed.) (New York: John Wiley & Sons) pp580−650

[29] Pan Z, Zhao K, Wang J, Zhang H, Feng Y, Zhong X 2013 ACS Nano 7 5215

Google Scholar

Google Scholar

[30] An Y, He Y, Wei H, Liu S, Li M, Song Y, Qiu P, Rehman A, Zheng X, Peng M 2019 Results Phys. 12 804

Google Scholar

Google Scholar

[31] Singh T, Lehnen T, Leuning T, Sahu D, Mathur S 2014 Appl. Surf. Sci. 289 27

Google Scholar

Google Scholar

[32] Chang Y, Lu Y, Hong Y, Kuo C, Gwo S, Yeh J 2010 J. Appl. Phys. 107 043710

Google Scholar

Google Scholar

计量

- 文章访问数: 7334

- PDF下载量: 87

- 被引次数: 0

下载:

下载: