-

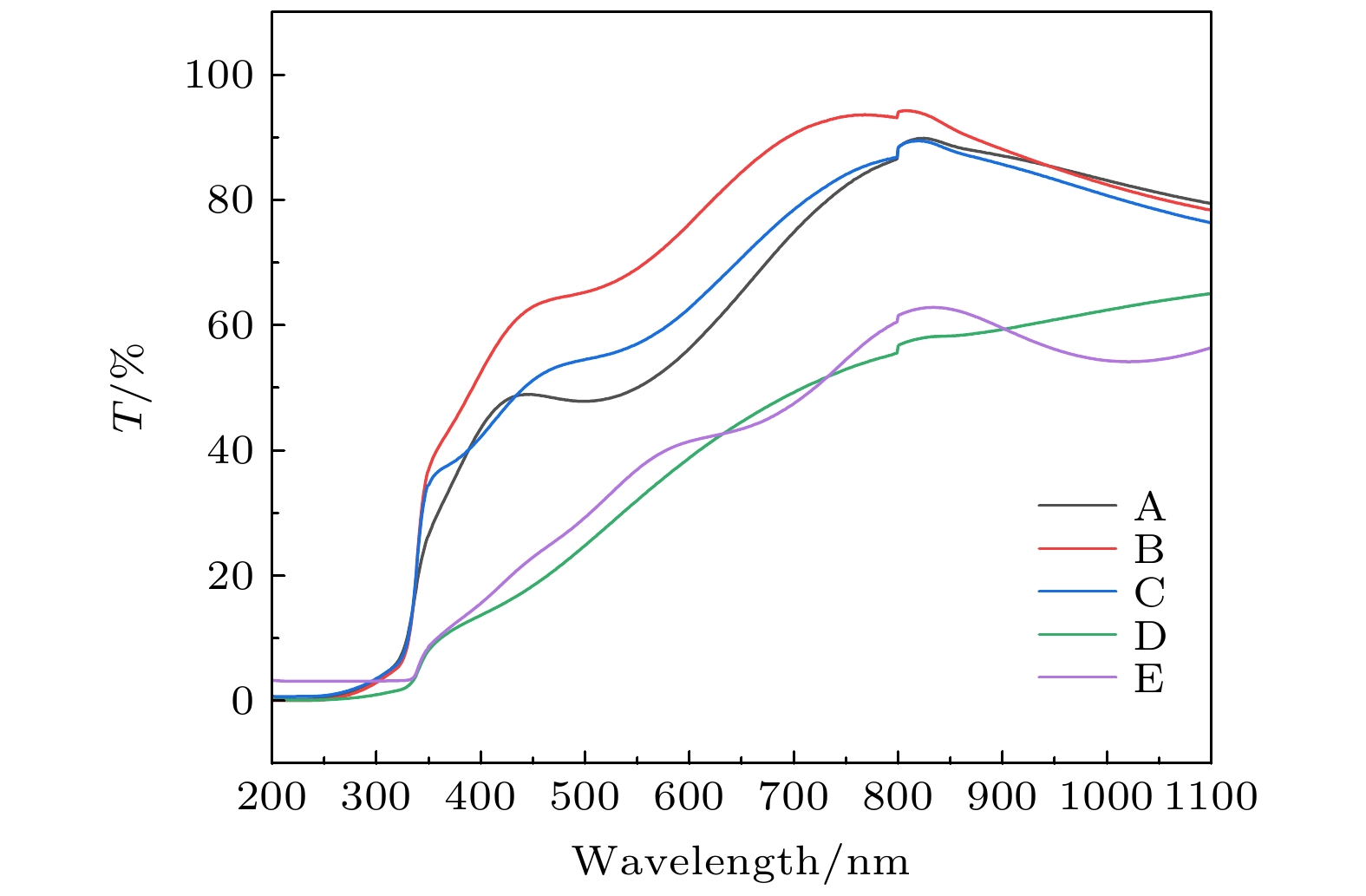

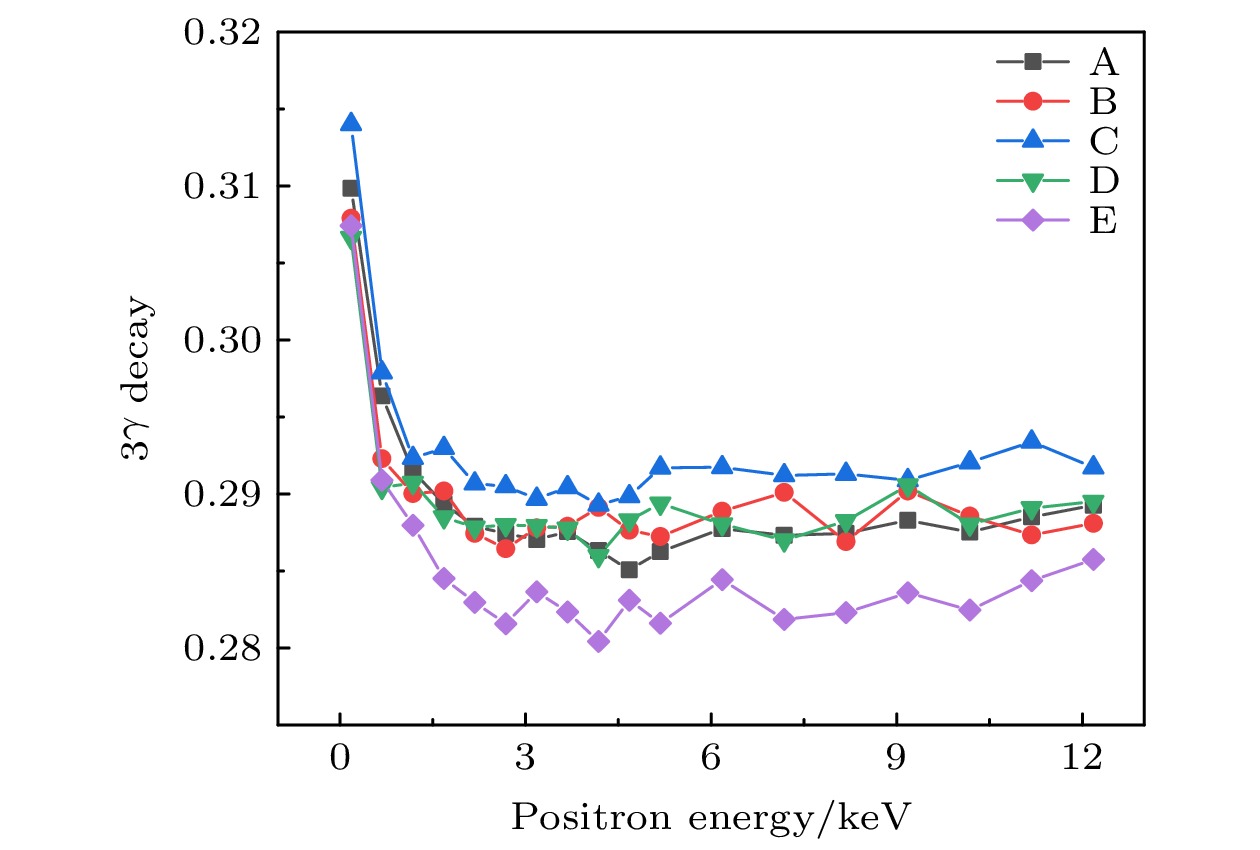

ZnS, a kind of wide-band gap semiconductor, has attracted extensive attention in recent years due to its excellent photoelectric performance, which has broad application prospects in solar cells, photocatalysts and sensors. In this work, ZnS thin films are first deposited by radio-frequency (RF) magnetron sputtering, and then annealed at 600 ℃ and different sulfur pressures. The crystal structure, surface morphology, grain size, composition, transmittance and defects of ZnS thin films are analyzed by X-ray diffraction, scanning electron microscopy, energy dispersive spectroscopy, UV-vis transmission spectra, and positron annihilation Doppler broadening spectroscopy. The results show that the crystallinities of ZnS films can be improved by being annealed in sulfur atmosphere, and the optical band gaps of ZnS films after being annealed are in a range of 3.43–3.58 eV. When the sulfur pressure is higher than 0.49 atm, the sulfur interstitial atoms in the ZnS and the elemental sulfur on the surface reduce the transmittance of the film in the visible region. The Doppler broadening spectroscopy results also show that the defect concentrations of ZnS films decrease gradually from their surface layers to the inner layers, and the defects of ZnS films decrease with the increase of sulfur pressure. Meanwhile, the 3γ annihilation also proves that the interior of the film is relatively dense, and the open porosity of the film will increase due to vulcanization. Adsorbed sulfur occupies the position of sulfur vacancy defect in the crystal through internal diffusion, which leads the defect concentration to decrease and the film quality to be improved.

-

Keywords:

- magnetron sputtering /

- sulfidation annealing /

- ZnS thin films /

- positron annihilation Doppler broadening spectroscopy

[1] Liu C, Mu L, Jia J, Zhou X, Lin Y 2013 Electrochim. Acta 111 179

Google Scholar

Google Scholar

[2] Lin Y B, Lin Y, Meng Y, Wang Y 2014 Ceram. Int. 40 8157

Google Scholar

Google Scholar

[3] Wang C, Li J, Feng W, Ye Y, Guo H 2021 Optik 242 167095

Google Scholar

Google Scholar

[4] Le Donne A, Cavalcoli D, Mereu R A, Perani M, Pagani L, Acciarri M, Binetti S 2017 Mater Sci Semicond Process 71 7

Google Scholar

Google Scholar

[5] Nayef U M 2017 Optik 130 441

Google Scholar

Google Scholar

[6] Khan T M, Zakria M, Ahmad M, Shakoor R I 2014 J. Lumin. 147 97

Google Scholar

Google Scholar

[7] Cheng Y C, Jin C Q, Gao F, Wu X L, Zhong W, Li S H, Chu P K 2009 J. Appl. Phys. 106 123101

Google Scholar

Google Scholar

[8] Fang X S, Zhai T Y, Gautam U K, Li L, Wu L M, Yoshio B, Golberg D 2011 Prog. Mater. Sci. 56 175

Google Scholar

Google Scholar

[9] Zapien J A, Jiang Y, Meng X M, Chen W, Au F C K, Lifshitz Y, Lee S T 2004 Appl. Phys. Lett. 84 1189

Google Scholar

Google Scholar

[10] Cheng G, Hu D, Chen P, Duan Y, Zhao Y, Ma Y, Liu S 2012 Thin Solid Films 520 7153

Google Scholar

Google Scholar

[11] Ummartyotin S, Infahsaeng Y 2016 Renew Sust. Energ. Rev. 55 17

Google Scholar

Google Scholar

[12] Park S, Sun G J, Kim S, Lee S, Lee C 2015 Electron. Mater. Lett. 11 572

Google Scholar

Google Scholar

[13] Thangavel S, Krishnamoorthy K, Kim S J, Venugopal G 2016 J. Alloys Compd. 683 456

Google Scholar

Google Scholar

[14] Zhang R G, Wang B Y, Zhang H, Wei L 2005 Appl. Surf. Sci. 245 340

Google Scholar

Google Scholar

[15] Lee G, Wu J J 2017 Powder Technol. 318 8

Google Scholar

Google Scholar

[16] Shin S W, Kang S R, Yun J H, Moholkar A V, Moon J H, Lee J Y, Kim J H 2011 Sol. Energy Mater Sol. Cells 95 856

Google Scholar

Google Scholar

[17] Karimi A, Sohrabi B, Vaezi M R 2018 Thin Solid Films 651 97

Google Scholar

Google Scholar

[18] Ahmed A A, Eisa M H, Abdulla M D 2022 Chalcogenide Lett. 19 591

Google Scholar

Google Scholar

[19] Amotchkina T, Trubetskov M, Hahner D, Pervak V 2020 Appl. Opt. 59 A40

Google Scholar

Google Scholar

[20] Cui A, Sun C, Wang F, Ye Z 2021 Infrared. Phys. Technol. 114 103667

Google Scholar

Google Scholar

[21] Liu W S, Huang C S, Chen S Y, Lee M Y, Kuo H C 2021 J. Alloys Compd. 884 161015

Google Scholar

Google Scholar

[22] Ghosh P K, Jana S, Nandy S, Chattopadhyay K K 2007 Mater. Res. Bull. 42 505

Google Scholar

Google Scholar

[23] Wang X, Shi J, Feng Z, Li M, Li C 2011 Phys. Chem. Chem. Phys. 13 4715

Google Scholar

Google Scholar

[24] Miller A P 1941 Lange’s Handbook of Chemistry (4th Ed.) (Washington: Amer Public Health Assoc inc) p1324

[25] 曹兴忠, 宋力刚, 靳硕学, 张仁刚, 王宝义, 魏龙 2017 66 29

Google Scholar

Google Scholar

Cao X Z, Song L G, Jin S X, Zhang R G, Wang B Y, Wei L 2017 Acta Phys. Sin. 66 29

Google Scholar

Google Scholar

[26] Imran M, Saleem A, Khan N A, Mehmood N 2018 Thin Solid Films 648 31

Google Scholar

Google Scholar

[27] Bandic Z Z, Piquette E C, McCaldin J O, McGill T C 1998 Appl. Phys. Lett. 72 2862

Google Scholar

Google Scholar

[28] Shan R, Yi J, Zhong J X, Yang S 2019 J. Mater. Sci. Mater. Electron. 30 13230

Google Scholar

Google Scholar

[29] Chen S Z, Yu R S, Song L G, Zhang R G, Cao X Z, Wang B Y, Zhang P 2019 Appl. Surf. Sci. 498 143876

Google Scholar

Google Scholar

[30] Tauc J, Grigorovici R, Vancu A 1966 Phys. Stat. Sol. 15 627

Google Scholar

Google Scholar

[31] Hasaneen M F, Ali H M, Abd El-Raheem M M, Hakeem A M A 2020 Mater Sci. Eng. B 262 114704

Google Scholar

Google Scholar

[32] Jubu P R, Yam F K, Igba V M, Beh K P 2020 J. Solid State Chem. 290 121576

Google Scholar

Google Scholar

[33] Yu R S, Ito K, Hirata K, Zheng W, Kobayashi Y 2003 Appl. Phys. 6 3340

Google Scholar

Google Scholar

[34] Wang B Y, Ma Y Y, Zhang Z, Yu R S, Wang P 2008 Appl. Surf. Sci. 255 119

Google Scholar

Google Scholar

-

表 1 不同硫压下退火的ZnS薄膜(111)晶面的晶体参数

Table 1. Crystal parameters of (111) crystal planes of ZnS films annealed under the different sulfur pressures.

样品 晶面 FWHM 晶粒尺寸/nm A (111) 0.509 40.8 B (111) 0.344 60.4 C (111) 0.291 71.4 D (111) 0.209 99.4 E (111) 0.197 105.5 表 2 不同硫压条件下退火的ZnS样品的EDS测试结果

Table 2. EDS results of ZnS samples annealed under the different sulfur pressures.

样品 Zn S Zn/S A 17.53 18.77 0.94 B 19.42 18.67 1.04 C 19.25 18.63 1.03 D 16.17 15.09 1.07 E 32.43 31.61 1.03 as-deposited ZnS 21.27 5.81 3.66 -

[1] Liu C, Mu L, Jia J, Zhou X, Lin Y 2013 Electrochim. Acta 111 179

Google Scholar

Google Scholar

[2] Lin Y B, Lin Y, Meng Y, Wang Y 2014 Ceram. Int. 40 8157

Google Scholar

Google Scholar

[3] Wang C, Li J, Feng W, Ye Y, Guo H 2021 Optik 242 167095

Google Scholar

Google Scholar

[4] Le Donne A, Cavalcoli D, Mereu R A, Perani M, Pagani L, Acciarri M, Binetti S 2017 Mater Sci Semicond Process 71 7

Google Scholar

Google Scholar

[5] Nayef U M 2017 Optik 130 441

Google Scholar

Google Scholar

[6] Khan T M, Zakria M, Ahmad M, Shakoor R I 2014 J. Lumin. 147 97

Google Scholar

Google Scholar

[7] Cheng Y C, Jin C Q, Gao F, Wu X L, Zhong W, Li S H, Chu P K 2009 J. Appl. Phys. 106 123101

Google Scholar

Google Scholar

[8] Fang X S, Zhai T Y, Gautam U K, Li L, Wu L M, Yoshio B, Golberg D 2011 Prog. Mater. Sci. 56 175

Google Scholar

Google Scholar

[9] Zapien J A, Jiang Y, Meng X M, Chen W, Au F C K, Lifshitz Y, Lee S T 2004 Appl. Phys. Lett. 84 1189

Google Scholar

Google Scholar

[10] Cheng G, Hu D, Chen P, Duan Y, Zhao Y, Ma Y, Liu S 2012 Thin Solid Films 520 7153

Google Scholar

Google Scholar

[11] Ummartyotin S, Infahsaeng Y 2016 Renew Sust. Energ. Rev. 55 17

Google Scholar

Google Scholar

[12] Park S, Sun G J, Kim S, Lee S, Lee C 2015 Electron. Mater. Lett. 11 572

Google Scholar

Google Scholar

[13] Thangavel S, Krishnamoorthy K, Kim S J, Venugopal G 2016 J. Alloys Compd. 683 456

Google Scholar

Google Scholar

[14] Zhang R G, Wang B Y, Zhang H, Wei L 2005 Appl. Surf. Sci. 245 340

Google Scholar

Google Scholar

[15] Lee G, Wu J J 2017 Powder Technol. 318 8

Google Scholar

Google Scholar

[16] Shin S W, Kang S R, Yun J H, Moholkar A V, Moon J H, Lee J Y, Kim J H 2011 Sol. Energy Mater Sol. Cells 95 856

Google Scholar

Google Scholar

[17] Karimi A, Sohrabi B, Vaezi M R 2018 Thin Solid Films 651 97

Google Scholar

Google Scholar

[18] Ahmed A A, Eisa M H, Abdulla M D 2022 Chalcogenide Lett. 19 591

Google Scholar

Google Scholar

[19] Amotchkina T, Trubetskov M, Hahner D, Pervak V 2020 Appl. Opt. 59 A40

Google Scholar

Google Scholar

[20] Cui A, Sun C, Wang F, Ye Z 2021 Infrared. Phys. Technol. 114 103667

Google Scholar

Google Scholar

[21] Liu W S, Huang C S, Chen S Y, Lee M Y, Kuo H C 2021 J. Alloys Compd. 884 161015

Google Scholar

Google Scholar

[22] Ghosh P K, Jana S, Nandy S, Chattopadhyay K K 2007 Mater. Res. Bull. 42 505

Google Scholar

Google Scholar

[23] Wang X, Shi J, Feng Z, Li M, Li C 2011 Phys. Chem. Chem. Phys. 13 4715

Google Scholar

Google Scholar

[24] Miller A P 1941 Lange’s Handbook of Chemistry (4th Ed.) (Washington: Amer Public Health Assoc inc) p1324

[25] 曹兴忠, 宋力刚, 靳硕学, 张仁刚, 王宝义, 魏龙 2017 66 29

Google Scholar

Google Scholar

Cao X Z, Song L G, Jin S X, Zhang R G, Wang B Y, Wei L 2017 Acta Phys. Sin. 66 29

Google Scholar

Google Scholar

[26] Imran M, Saleem A, Khan N A, Mehmood N 2018 Thin Solid Films 648 31

Google Scholar

Google Scholar

[27] Bandic Z Z, Piquette E C, McCaldin J O, McGill T C 1998 Appl. Phys. Lett. 72 2862

Google Scholar

Google Scholar

[28] Shan R, Yi J, Zhong J X, Yang S 2019 J. Mater. Sci. Mater. Electron. 30 13230

Google Scholar

Google Scholar

[29] Chen S Z, Yu R S, Song L G, Zhang R G, Cao X Z, Wang B Y, Zhang P 2019 Appl. Surf. Sci. 498 143876

Google Scholar

Google Scholar

[30] Tauc J, Grigorovici R, Vancu A 1966 Phys. Stat. Sol. 15 627

Google Scholar

Google Scholar

[31] Hasaneen M F, Ali H M, Abd El-Raheem M M, Hakeem A M A 2020 Mater Sci. Eng. B 262 114704

Google Scholar

Google Scholar

[32] Jubu P R, Yam F K, Igba V M, Beh K P 2020 J. Solid State Chem. 290 121576

Google Scholar

Google Scholar

[33] Yu R S, Ito K, Hirata K, Zheng W, Kobayashi Y 2003 Appl. Phys. 6 3340

Google Scholar

Google Scholar

[34] Wang B Y, Ma Y Y, Zhang Z, Yu R S, Wang P 2008 Appl. Surf. Sci. 255 119

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4223

- PDF Downloads: 80

- Cited By: 0

DownLoad:

DownLoad: