-

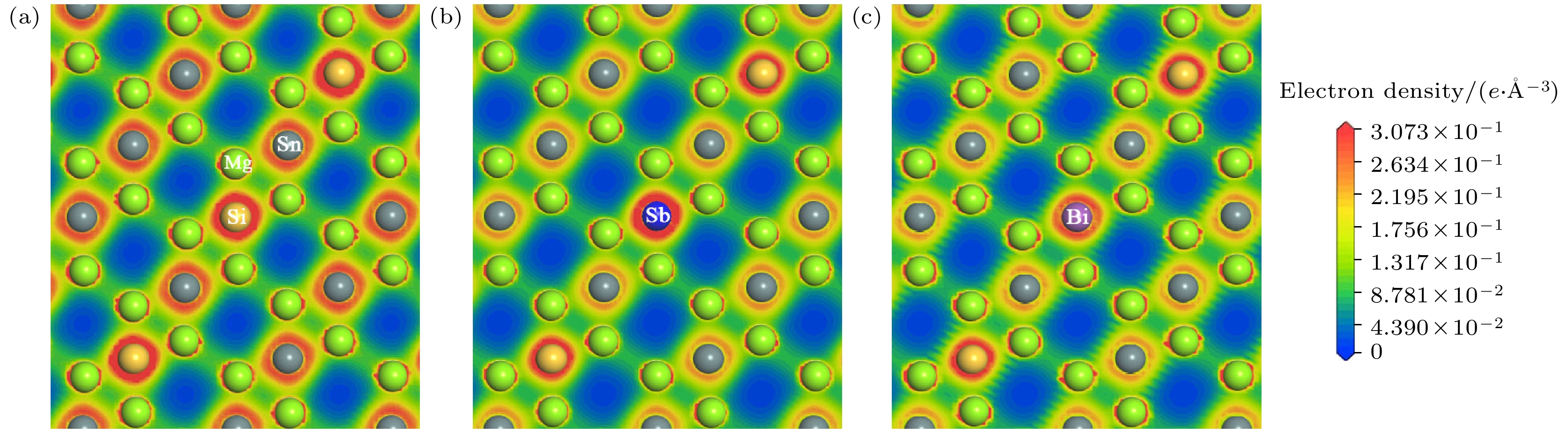

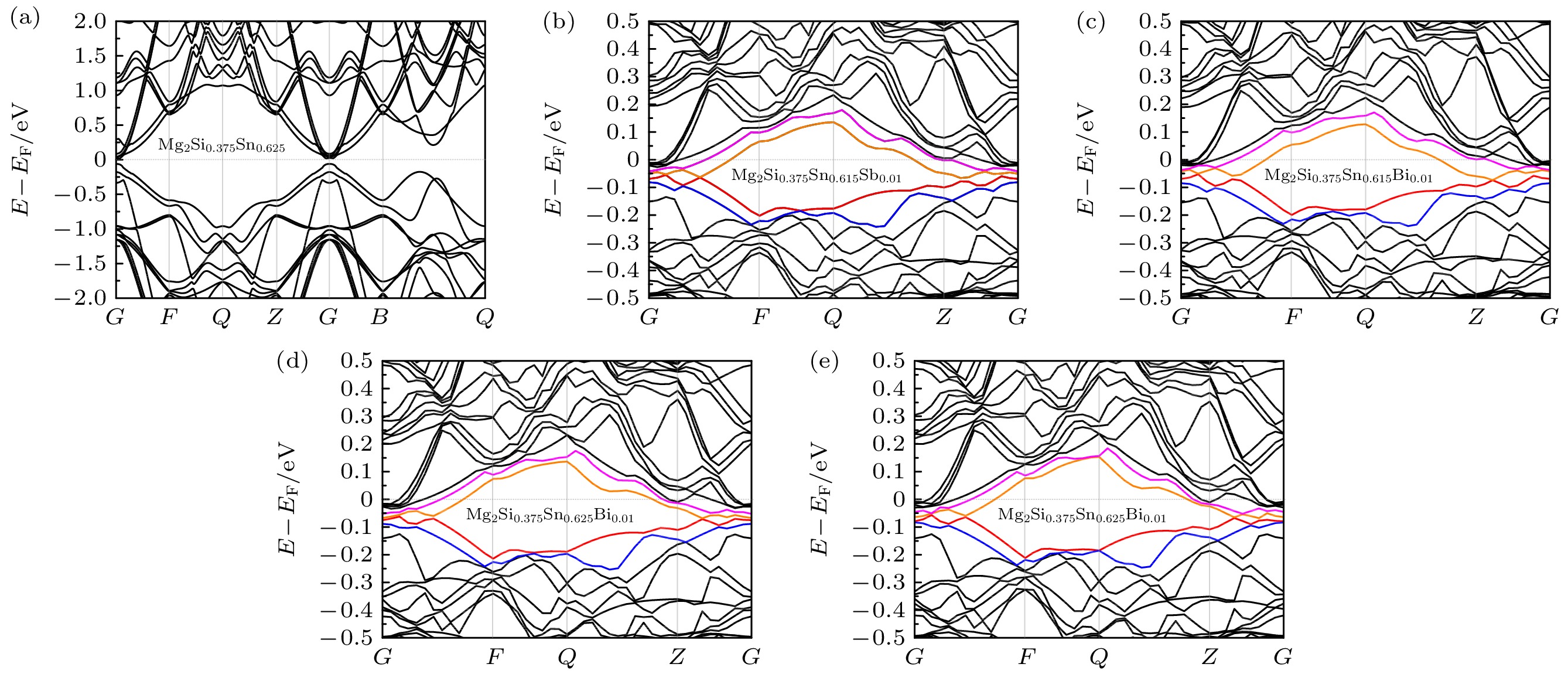

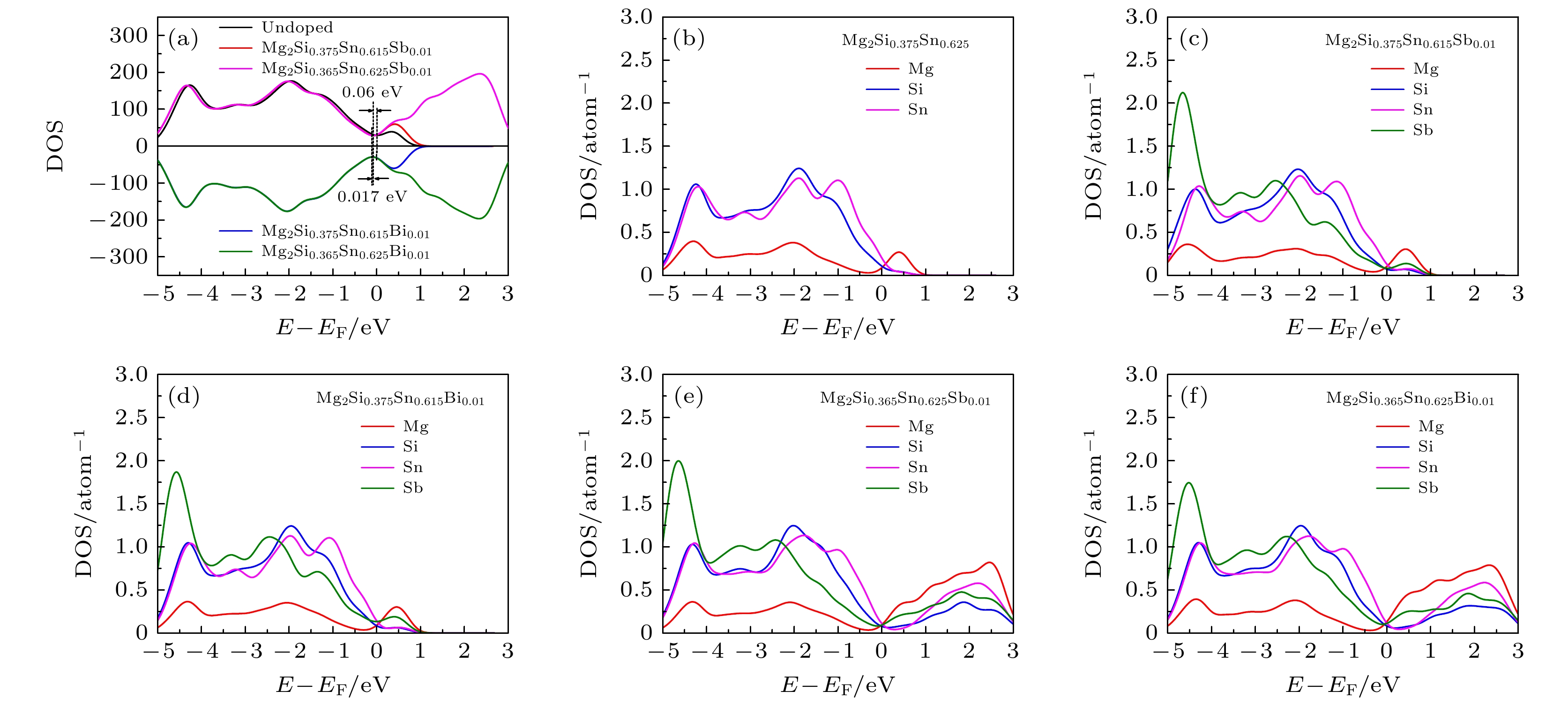

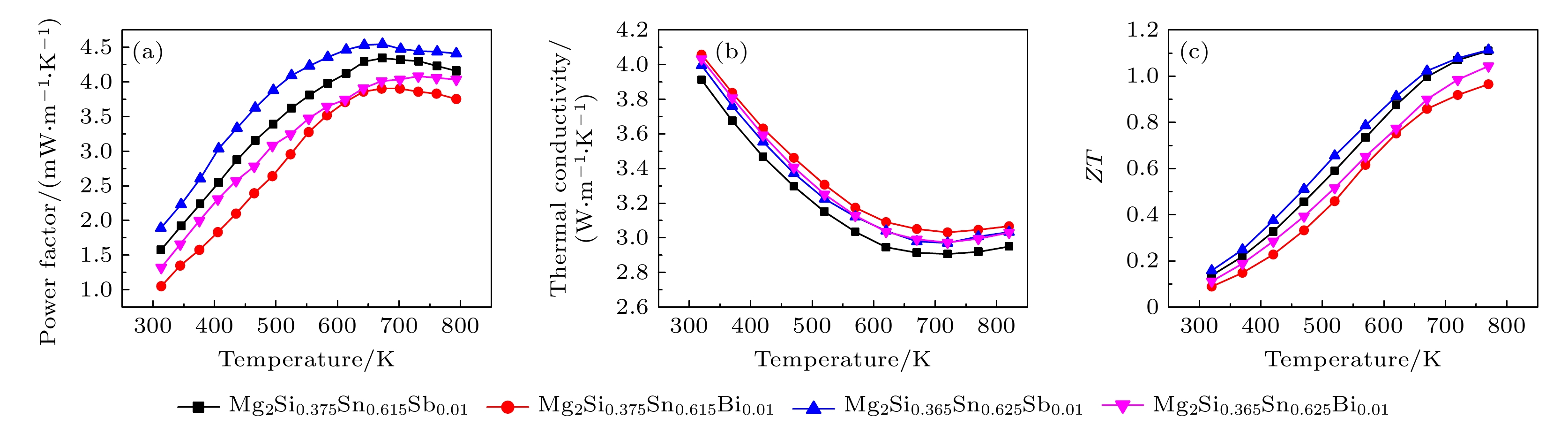

Mg2(Si,Sn)-based thermoelectric materials, which are environmentally friendly and low-cost, have great development potential in a moderate temperature range. Electronic transport properties of Mg2Si1-xSnx alloys can be optimized by doping elements. Doping is still one of the most effective methods of optimizing electronic transport performance, such as carrier concentration, mobility, and effective mass. The most effective doping elements are Sb and Bi. Much attention has been paid to the influence of element type and doping content. Different substitution sites will also greatly affect the electronic transport parameters. In this work, the defect formation energy value of Mg2Si0.375Sn0.625 alloy for substituting Sb atoms and Bi atoms for Sn sties and Si sites, respectively, are calculated by first-principles calculations. The influence on electronic transport parameters is systematically analyzed by combining the calculated results of band structures and density of states. Corresponding component Sb and Bi atoms doped Mg2Si0.375Sn0.625 alloys are prepared by rapid solidification method, and microstructures, Seebeck coefficients, and electrical conductivities of the alloys are measured. Combined with the predicted results by solving the Boltzmann transport equation, electronic transport performances are compared and analyzed. The results indicate that both Sn and Si sites are equally susceptible to Sb and Bi doping, but the Si sites are preferentially substituted due to their lower ∆Ef values. Doped Bi atoms provide a higher electron concentration, and Sb atoms offer higher carrier effective mass. Thus, the maximum σ value of the Mg2Si0.375Sn0.615Bi0.01 alloy is 1620 S/cm. The maximum S value of the Mg2Si0.365Sn0.625Sb0.01 alloy is –228 μV/K. Correspondingly, the highest PF value for this alloy is 4.49 mW/(m·K) at T = 800 K because of the dominant role of S values. Although its power factor is slightly lower, the Mg2Si0.375Sn0.615Sb0.01 alloy is expected to exhibit lower lattice thermal conductivity due to the lattice shrinkage caused by substituting Sb sites for Sn sites. The optimal doping concentration of the Bi-doped alloy is lower than that of the Sb-doped alloy. These results are expected to provide a significant reference for optimizing the experimental performance of Mg2(Si, Sn)-based alloys.

-

Keywords:

- first-principles calculation /

- atomic substituted sites /

- electronic transport performance /

- rapid solidification

[1] Bahrami A, Schierning G, Nielsch K 2020 Adv. Energy Mater. 10 1904159

Google Scholar

Google Scholar

[2] Mao J, Chen G, Ren Z F 2021 Nat. Mater. 20 454

Google Scholar

Google Scholar

[3] 赵英浩, 张瑞, 张波萍, 尹阳, 王明军, 梁豆豆 2021 70 128401

Google Scholar

Google Scholar

Zhao Y H, Zhang R, Zhang B P, Yin Y, Wang M J, Liang D D 2021 Acta Phys. Sin. 70 128401

Google Scholar

Google Scholar

[4] 程立东, 刘瑞恒, 史迅 2018 热电材料与器件 (北京: 科学出版社) 第8—13页

Cheng L D, Liu R H, Shi X 2018 Thermoelectric Materials and Devices (Beijing: Science Press) pp8–13 (in Chinese)

[5] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[6] Chen L C, Chen P Q, Li W J, Zhang Q, Struzhkin V V, Goncharov A F, Ren Z F, Chen X J 2019 Nat. Mater. 18 1321

Google Scholar

Google Scholar

[7] 李彩云, 何文科, 王东洋, 张潇, 赵立东 2021 70 208401

Google Scholar

Google Scholar

Li C Y, He W K, Wang D Y, Zhang X, Zhao L D 2021 Acta Phys. Sin. 70 208401

Google Scholar

Google Scholar

[8] 黄青松, 段波, 陈刚, 叶泽昌, 李江, 李国栋, 翟鹏程 2021 70 157401

Google Scholar

Google Scholar

Huang Q S, Duan B, Chen G, Ye Z C, Li J, Li G D, Zhai P C 2021 Acta Phys. Sin. 70 157401

Google Scholar

Google Scholar

[9] 陈赟斐, 魏锋, 王赫, 赵未昀, 邓元 2021 70 207303

Google Scholar

Google Scholar

Chen Y F, Wei F, Wang H, Zhao W Y, Deng Y 2021 Acta Phys. Sin. 70 207303

Google Scholar

Google Scholar

[10] Kim M S, Lee W J, Cho K H, Ahn J P, Sung Y M 2016 ACS Nano 10 7197

Google Scholar

Google Scholar

[11] Zhao Y W, Liu Y, Ma H Y, Deng S P, Wang H Y, Xiong R, Huang S 2021 Ceram. Int. 47 28268

Google Scholar

Google Scholar

[12] Cahana M, Gelbstein Y 2020 Intermetallics 120 106767

Google Scholar

Google Scholar

[13] Sankhla A, Kamila H, Kelm K, Mueller E, de Boor J 2020 Acta Mater. 199 85

Google Scholar

Google Scholar

[14] Gao P, Lu X, Berkun I, Schmidt R D, Case E D, Hogan T P 2014 Appl. Phys. Lett. 105 202104

Google Scholar

Google Scholar

[15] Mao J, Kim H S, Shuai J, Liu Z, He R, Saparamadu U, Tian F, Liu W, Ren Z F 2016 Acta Mater. 103 633

Google Scholar

Google Scholar

[16] Tan X J, Liu W, Shi H J, Tang X F, Uher C 2012 Phys. Rev. B 85 205212

Google Scholar

Google Scholar

[17] Li X, Li S M, Feng S K, Zhong H 2018 J. Electron. Mater. 47 1022

Google Scholar

Google Scholar

[18] Li X, Li S M, Yang B, Feng S K, Zhong H 2018 J. Mater. Sci. Mater. Electron. 29 6245

Google Scholar

Google Scholar

[19] Li X, Li S M, Feng S K, Zhong H 2018 J. Alloy Compd. 739 705

Google Scholar

Google Scholar

[20] Fan W H, Chen S P, Zeng B, Zhang Q, Meng Q S, Wang W X, Munir Z A 2017 ACS Appl. Mater. Inter 34 28635

Google Scholar

Google Scholar

[21] Jiang G Y, He J, Zhu T J, Fu C G, Liu X H, Hu L P, Zhao X B 2014 Adv. Func. Mate. 24 1

Google Scholar

Google Scholar

[22] Liu W, Tang X F, Li H, Sharp J, Zhou X Y, Uher C 2011 Chem. Mate. 23 5256

Google Scholar

Google Scholar

[23] Du Z L, Zhu T J, Zhao X B 2012 Mater. Lett. 66 76

Google Scholar

Google Scholar

[24] Khan A U, Vlachos N, Kyratsi T 2013 Scripta Mater. 69 606

Google Scholar

Google Scholar

[25] Howlader S, Gupta S, Vasudevan R, Banerjee M K, Sachdev K 2020 Mater. Today Proc. 30 100

Google Scholar

Google Scholar

[26] Chen X X, Wu H J, Cui J, Xiao Y, Zhang Y, He J Q, Chen Y, Cao J, Cai W, Pennycook S J, Liu Z H, Zhao L D, Sui J H 2018 Nano Energy 52 246

Google Scholar

Google Scholar

[27] Imasato K, Kang S D, Ohno S, Snyder G J 2018 Mater. Horiz. 5 59

Google Scholar

Google Scholar

[28] Mao J, Wu Y X, Song S W, Shuai J, Liu Z H, Pei Y Z, Ren Z F 2017 Mater. Today Phys. 3 1

Google Scholar

Google Scholar

[29] Liu Y, Hu W C, Li D J, Zeng X Q, Xu C S 2013 Phys. Scripta 88 45302

Google Scholar

Google Scholar

[30] Feng S K, Li S M, Fu H Z 2014 Comp. Mater. Sci. 82 45

Google Scholar

Google Scholar

[31] Vanderbilt D 1990 Phys. Rev. B Condens. Matter. 41 7892

Google Scholar

Google Scholar

[32] Scheidemantel T J, Ambrosch-Draxl C, Thonhauser T, Badding J V, Sofo J O 2003 Phys. Rev. B 68 125210

Google Scholar

Google Scholar

[33] Madsen G K H, Singh D J 2006 Comp. Phys. Commun. 175 67

Google Scholar

Google Scholar

[34] Chou T L, Mustonen O, Tripathi T S, Karppinen M 2015 J. Phys. Condens. Matter. 28 35802

Google Scholar

Google Scholar

[35] Chong X Y, Guan P W, Wang Y, Shang S L, Palma J P S, Drymiotis F, Ravi V A, Star K E, Fleurial J, Liu Z K 2018 ACS Appl. Energy Mater. 1 6600

Google Scholar

Google Scholar

[36] Snyder G J, Toberer E S 2008 Nature Mater. 7 105

Google Scholar

Google Scholar

[37] Zhang Q, Zheng Y, Su X L, Yin K, Tang X F, Uher C 2015 Scripta Mater. 96 1

Google Scholar

Google Scholar

[38] Liu W, Zhang Q, Yin K, Chi H, Zhou X Y, Tang X F, Uher C 2013 J. Solid State Chem. 203 333

Google Scholar

Google Scholar

-

图 7 不同掺杂条件下Mg2Si0.375Sn0.625合金Seebeck系数(a)和电导率(b)随温度的变化曲线; T = 800 K时Seebeck系数随载流子浓度的变化曲线(c)和框选部分的局部放大图(d)

Figure 7. Temperature dependence of Seebeck coefficient (a) and electrical conductivity (b) of Mg2Si0.375Sn0.625 crystals under different doping conditions. Calculated Seebeck coefficient as a function of carrier concentration (c) and magnified view (d) of the outlined area at T = 800 K.

表 1 Bi/Sb掺杂Mg192Si36Sn60晶体晶格常数、键长度和Mulliken布居数的计算结果

Table 1. Calculated results of lattice constant, bond length and Mulliken population for Bi/Sb doped Mg192Si36Sn60 crystals.

超晶胞结构 晶格常数/Å 键类型 Mulliken

布居数键长

度/Å形成

能/eVMg192Si36Sn60 18.436 Mg—Sn 0.26 2.846 — Mg—Si 0.19 2.748 Mg192Si36Sn59Sb 18.422 Mg—Sb 0.10 2.896 –1.102 Mg—Sn 0.33 2.814 Mg—Si 0.22 2.708 Mg192Si36Sn59Bi 18.442 Mg—Bi 0.22 2.963 –0.674 Mg—Sn 0.27 2.849 Mg—Si 0.20 2.763 Mg192Si35Sn60Sb 18.438 Mg—Sb 0.14 2.935 –1.337 Mg—Sn 0.30 2.831 Mg—Si 0.21 2.727 Mg19Si35Sn60Bi 18.440 Mg—Bi 0.17 2.989 –0.945 Mg—Sn 0.20 2.855 Mg—Si 0.20 2.766 表 2 不同掺杂条件下Mg2Si0.375Sn0.625合金的理论成分和实验所得样品的EDS成分测试结果

Table 2. Nominal and measured results of elementary composition of Mg2Si0.375Sn0.625 alloys under different doping conditions

理论成分 元素含量/% 实际成分 Mg Si Sn Sb/Bi Mg2Si0.375Sn0.625 66.91 12.51 20.58 — Mg2.007Si0.375Sn0.618 Mg2Si0.375Sn0.615Sb0.01 66.82 12.43 20.36 0.39 Mg2.004Si0.373Sn0.611Sb0.012 Mg2Si0.375Sn0.615Bi0.01 66.88 12.41 20.30 0.41 Mg2.006Si0.372Sn0.609Bi0.013 Mg2Si0.365Sn0.625Sb0.01 66.93 12.01 20.74 0.32 Mg2.008Si0.360Sn0.623Sb0.009 Mg2Si0.365Sn0.625Bi0.01 66.77 12.07 20.71 0.45 Mg2.003Si0.362Sn0.621Bi0.014 -

[1] Bahrami A, Schierning G, Nielsch K 2020 Adv. Energy Mater. 10 1904159

Google Scholar

Google Scholar

[2] Mao J, Chen G, Ren Z F 2021 Nat. Mater. 20 454

Google Scholar

Google Scholar

[3] 赵英浩, 张瑞, 张波萍, 尹阳, 王明军, 梁豆豆 2021 70 128401

Google Scholar

Google Scholar

Zhao Y H, Zhang R, Zhang B P, Yin Y, Wang M J, Liang D D 2021 Acta Phys. Sin. 70 128401

Google Scholar

Google Scholar

[4] 程立东, 刘瑞恒, 史迅 2018 热电材料与器件 (北京: 科学出版社) 第8—13页

Cheng L D, Liu R H, Shi X 2018 Thermoelectric Materials and Devices (Beijing: Science Press) pp8–13 (in Chinese)

[5] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[6] Chen L C, Chen P Q, Li W J, Zhang Q, Struzhkin V V, Goncharov A F, Ren Z F, Chen X J 2019 Nat. Mater. 18 1321

Google Scholar

Google Scholar

[7] 李彩云, 何文科, 王东洋, 张潇, 赵立东 2021 70 208401

Google Scholar

Google Scholar

Li C Y, He W K, Wang D Y, Zhang X, Zhao L D 2021 Acta Phys. Sin. 70 208401

Google Scholar

Google Scholar

[8] 黄青松, 段波, 陈刚, 叶泽昌, 李江, 李国栋, 翟鹏程 2021 70 157401

Google Scholar

Google Scholar

Huang Q S, Duan B, Chen G, Ye Z C, Li J, Li G D, Zhai P C 2021 Acta Phys. Sin. 70 157401

Google Scholar

Google Scholar

[9] 陈赟斐, 魏锋, 王赫, 赵未昀, 邓元 2021 70 207303

Google Scholar

Google Scholar

Chen Y F, Wei F, Wang H, Zhao W Y, Deng Y 2021 Acta Phys. Sin. 70 207303

Google Scholar

Google Scholar

[10] Kim M S, Lee W J, Cho K H, Ahn J P, Sung Y M 2016 ACS Nano 10 7197

Google Scholar

Google Scholar

[11] Zhao Y W, Liu Y, Ma H Y, Deng S P, Wang H Y, Xiong R, Huang S 2021 Ceram. Int. 47 28268

Google Scholar

Google Scholar

[12] Cahana M, Gelbstein Y 2020 Intermetallics 120 106767

Google Scholar

Google Scholar

[13] Sankhla A, Kamila H, Kelm K, Mueller E, de Boor J 2020 Acta Mater. 199 85

Google Scholar

Google Scholar

[14] Gao P, Lu X, Berkun I, Schmidt R D, Case E D, Hogan T P 2014 Appl. Phys. Lett. 105 202104

Google Scholar

Google Scholar

[15] Mao J, Kim H S, Shuai J, Liu Z, He R, Saparamadu U, Tian F, Liu W, Ren Z F 2016 Acta Mater. 103 633

Google Scholar

Google Scholar

[16] Tan X J, Liu W, Shi H J, Tang X F, Uher C 2012 Phys. Rev. B 85 205212

Google Scholar

Google Scholar

[17] Li X, Li S M, Feng S K, Zhong H 2018 J. Electron. Mater. 47 1022

Google Scholar

Google Scholar

[18] Li X, Li S M, Yang B, Feng S K, Zhong H 2018 J. Mater. Sci. Mater. Electron. 29 6245

Google Scholar

Google Scholar

[19] Li X, Li S M, Feng S K, Zhong H 2018 J. Alloy Compd. 739 705

Google Scholar

Google Scholar

[20] Fan W H, Chen S P, Zeng B, Zhang Q, Meng Q S, Wang W X, Munir Z A 2017 ACS Appl. Mater. Inter 34 28635

Google Scholar

Google Scholar

[21] Jiang G Y, He J, Zhu T J, Fu C G, Liu X H, Hu L P, Zhao X B 2014 Adv. Func. Mate. 24 1

Google Scholar

Google Scholar

[22] Liu W, Tang X F, Li H, Sharp J, Zhou X Y, Uher C 2011 Chem. Mate. 23 5256

Google Scholar

Google Scholar

[23] Du Z L, Zhu T J, Zhao X B 2012 Mater. Lett. 66 76

Google Scholar

Google Scholar

[24] Khan A U, Vlachos N, Kyratsi T 2013 Scripta Mater. 69 606

Google Scholar

Google Scholar

[25] Howlader S, Gupta S, Vasudevan R, Banerjee M K, Sachdev K 2020 Mater. Today Proc. 30 100

Google Scholar

Google Scholar

[26] Chen X X, Wu H J, Cui J, Xiao Y, Zhang Y, He J Q, Chen Y, Cao J, Cai W, Pennycook S J, Liu Z H, Zhao L D, Sui J H 2018 Nano Energy 52 246

Google Scholar

Google Scholar

[27] Imasato K, Kang S D, Ohno S, Snyder G J 2018 Mater. Horiz. 5 59

Google Scholar

Google Scholar

[28] Mao J, Wu Y X, Song S W, Shuai J, Liu Z H, Pei Y Z, Ren Z F 2017 Mater. Today Phys. 3 1

Google Scholar

Google Scholar

[29] Liu Y, Hu W C, Li D J, Zeng X Q, Xu C S 2013 Phys. Scripta 88 45302

Google Scholar

Google Scholar

[30] Feng S K, Li S M, Fu H Z 2014 Comp. Mater. Sci. 82 45

Google Scholar

Google Scholar

[31] Vanderbilt D 1990 Phys. Rev. B Condens. Matter. 41 7892

Google Scholar

Google Scholar

[32] Scheidemantel T J, Ambrosch-Draxl C, Thonhauser T, Badding J V, Sofo J O 2003 Phys. Rev. B 68 125210

Google Scholar

Google Scholar

[33] Madsen G K H, Singh D J 2006 Comp. Phys. Commun. 175 67

Google Scholar

Google Scholar

[34] Chou T L, Mustonen O, Tripathi T S, Karppinen M 2015 J. Phys. Condens. Matter. 28 35802

Google Scholar

Google Scholar

[35] Chong X Y, Guan P W, Wang Y, Shang S L, Palma J P S, Drymiotis F, Ravi V A, Star K E, Fleurial J, Liu Z K 2018 ACS Appl. Energy Mater. 1 6600

Google Scholar

Google Scholar

[36] Snyder G J, Toberer E S 2008 Nature Mater. 7 105

Google Scholar

Google Scholar

[37] Zhang Q, Zheng Y, Su X L, Yin K, Tang X F, Uher C 2015 Scripta Mater. 96 1

Google Scholar

Google Scholar

[38] Liu W, Zhang Q, Yin K, Chi H, Zhou X Y, Tang X F, Uher C 2013 J. Solid State Chem. 203 333

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6228

- PDF Downloads: 63

- Cited By: 0

DownLoad:

DownLoad: