-

利用密度泛函理论结合玻尔兹曼输运方程, 预测了二维层状热电材料XTe2 (X = Pd, Pt)的热电性质. 两种材料都具有较低的热导率, 材料的晶格热导率随温度的升高而降低, 且表现出各向异性. 而电子热导率随温度的升高而升高. 在较低温时, 晶格热导率对总热导率的贡献占据主导地位. 较高的载流子迁移率、电导率及塞贝克系数也对材料的热电转换效率产生极大的影响, 展现出较为优异的电输运性能. 对比分析PdTe2和PtTe2两种材料的ZT值, 发现两种材料的热电性能以p型掺杂为主. PtTe2单层的ZT值高于PdTe2单层, 并且PtTe2单层在常温下的ZT峰值可达到2.75, 是一种极具潜力的热电材料.

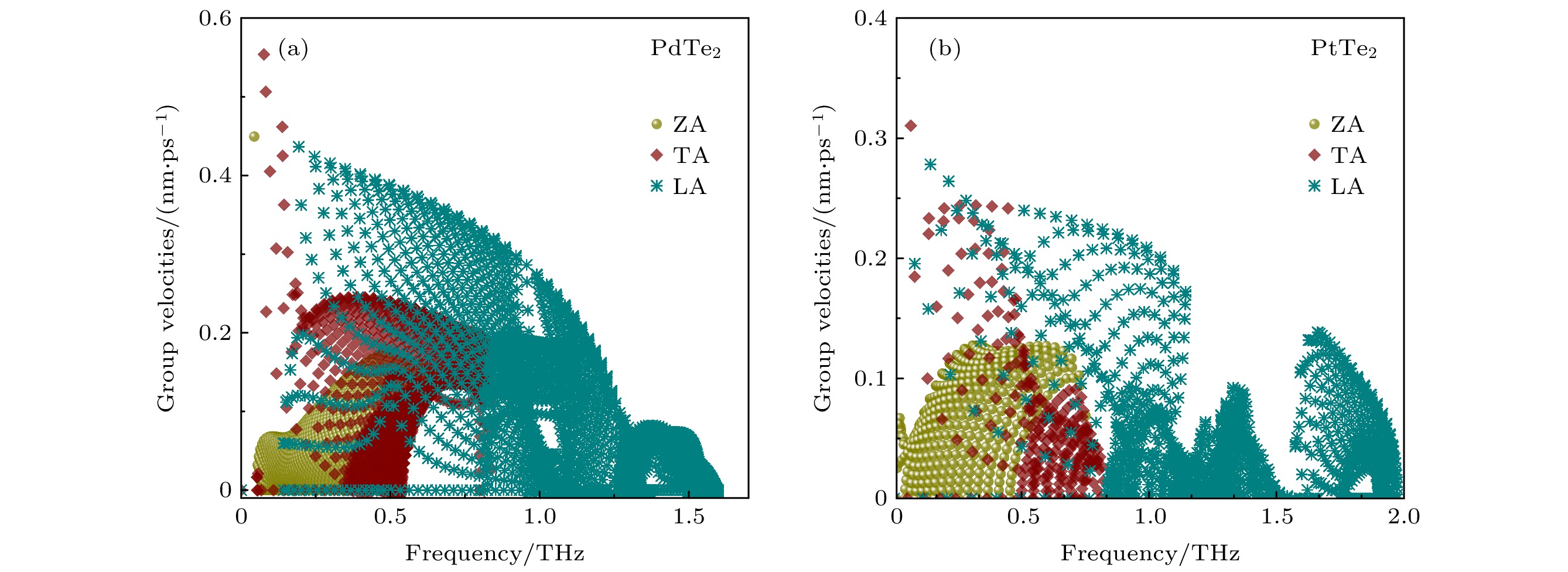

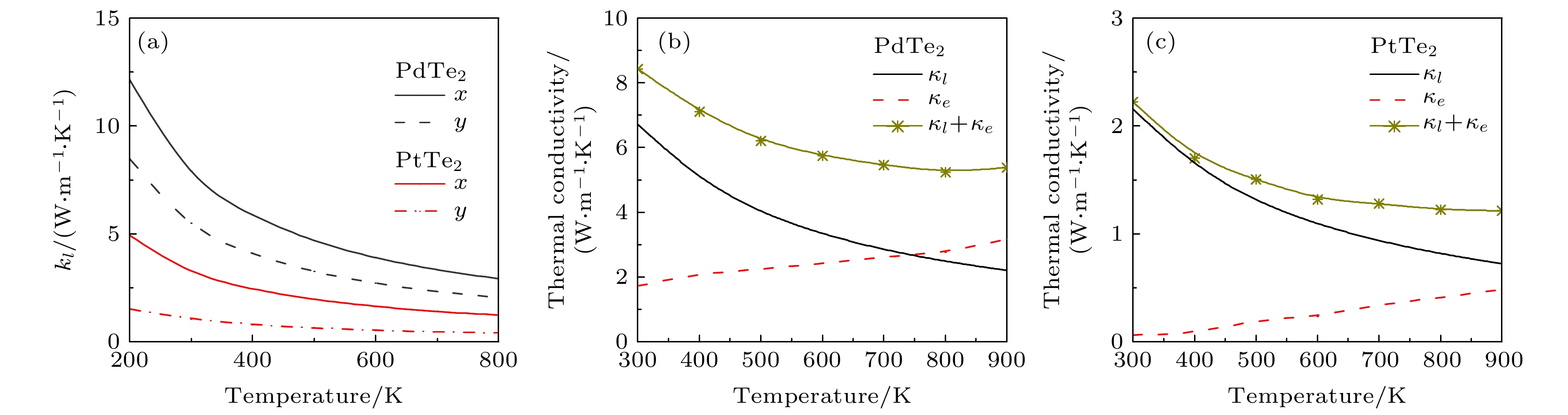

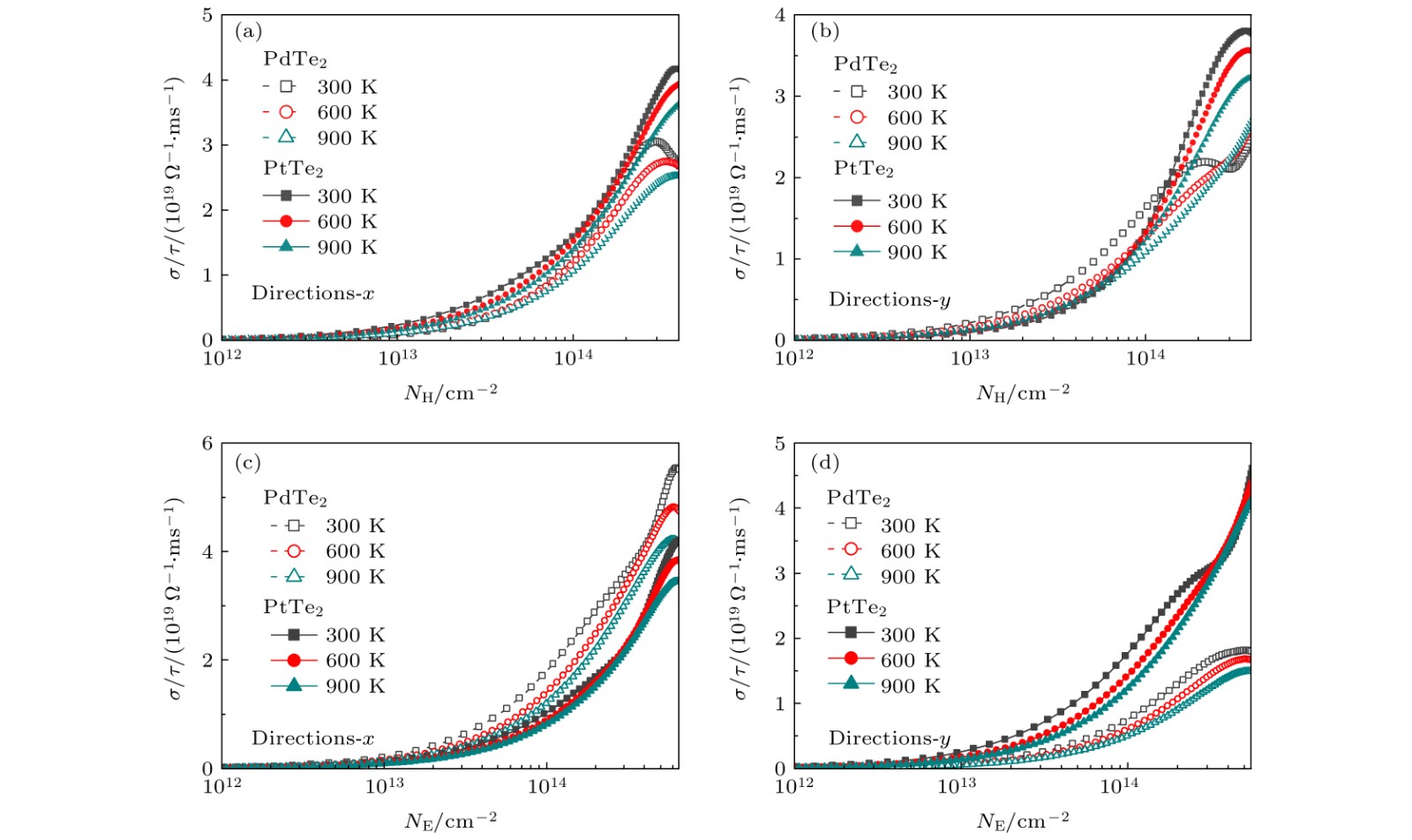

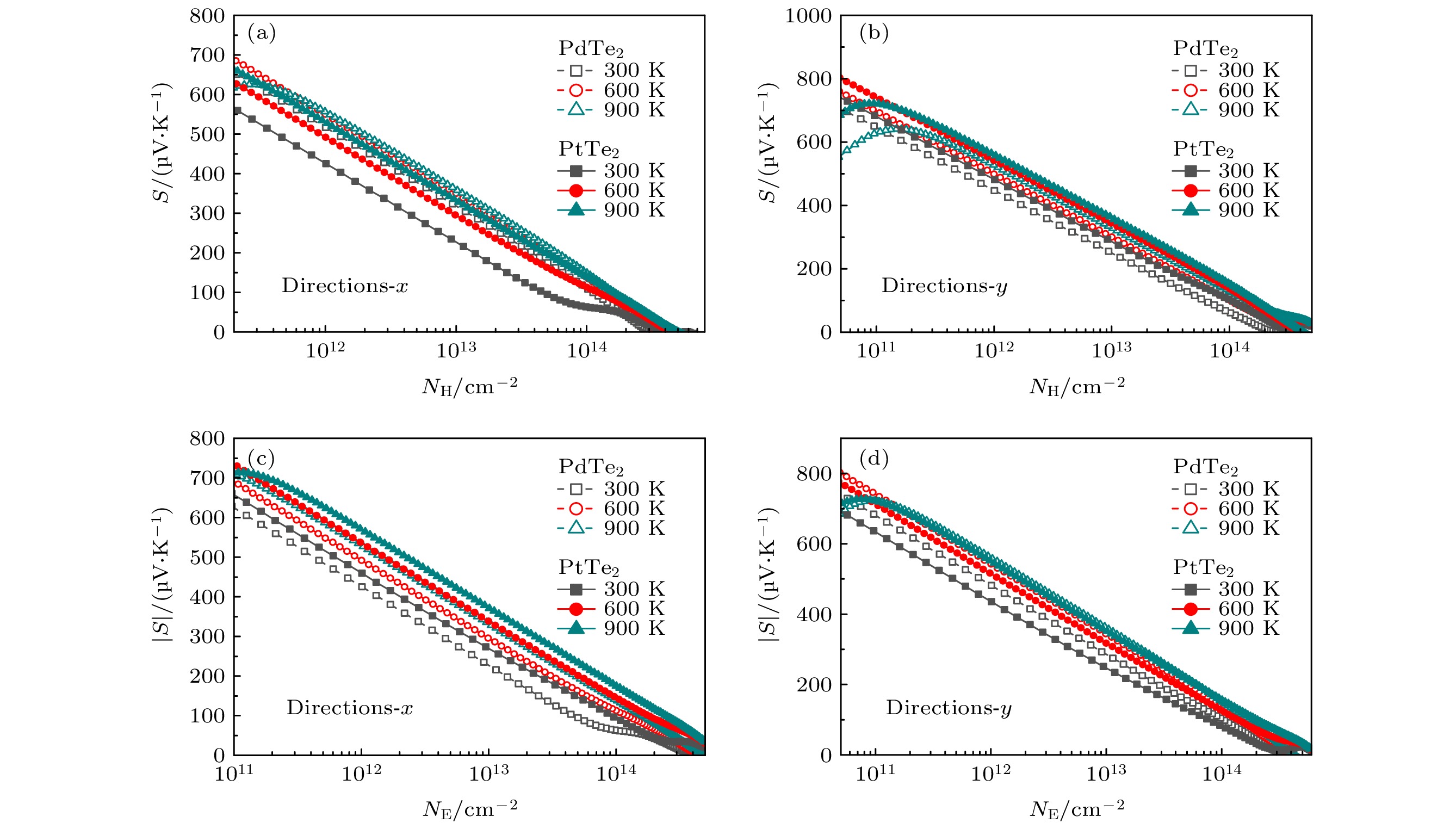

Developing efficient thermoelectric materials has never lost the attraction due to their promising performances in the energy conversion. The different mechanisms of phonon scattering lead to the various outstanding performances of layered materials in thermoelectric properties. So we investigate the structure, electronic and thermoelectric transport properties of Penta-XTe2 (X = Pd, Pt) layers based on the density functional theory and Boltzmann transport theory. Those monolayers have a beautiful penta-graphene-like buckled structure with a space group of P2_1/c (No.14). The values of optimized lattice constant a (b) are 6.437 Å (6.145 Å) and 6.423 Å (6.12 Å) for PdTe2 and PtTe2 monolayers, respectively. In order to assess the stability, we calculate the phonon dispersion along the high symmetry lines in the Brillouin zone. The second-order harmonic and third-order anharmonic interatomic force constants (IFCs) are calculated by using 5 × 5 × 1 supercell and 4 × 4 × 1 supercell based on the relaxed unit cell. All these results indicate that those monolayers are thermodynamically stable. Energy band structure is essential in obtaining reliable transport properties. So we calculate the band structures of penta-XTe2. Both PdTe2 and PtTe2 are semiconductors with indirect band gaps of 1.24 eV and 1.38 eV, respectively, which are in good agreement with previous experimental and theoretical results. The lattice thermal conductivity of XTe2 decreases with temperature increasing, but the electronic thermal conductivity varies with temperature in the opposite way exactly. It is found that the thermal conductivity comes from the contribution of the lattice thermal conductivity at low temperature. The room-temperature total thermal conductivities in the x (y) direction of the PdTe2 and PtTe2 monolayers are 3.95 W/(m·K) (2.7 W/(m·K)) and 3.27 W/(m·K)(1.04 W/(m·K)), respectively. The contribution of low thermal conductivity indicates that the thermoelectric properties of PtTe2 monolayer may be better than those of PdTe2 monolayer. The relaxation time (τ) and carrier mobility (μ) are obtained based on the Bardeen-Shockley deformation potential (DP) theory in two-dimensional materials. Remarkably, they have the higher hole mobility than the electron mobility. The anisotropic electronic transport properties of XTe2 are obtained by solving Boltzmann transport equation. The electrical conductivity over relaxation time (σ/τ) and Seebeck coefficient (S) contribute to the figure of merit ZT. High Seebeck coefficient (S) with the value larger than 400 μV/K can be found in both p-type and n-type cases, suggesting that the TE performance of XTe2 may be considerable. The room-temperature largest ZT values of penta-XTe2 (X = Pd, Pt) at p-type are 0.83 and 2.75 respectively. The monolayer PtTe2 is a potential thermoelectric material. -

Keywords:

- first-principles theory /

- transport properties /

- thermoelectric effects /

- electric and thermal conductivity

[1] Jaziri N, Boughamoura A, Müller J, Mezghani B, Tounsi F, Ismail M 2019 Energy Rep. 6 7

Google Scholar

Google Scholar

[2] Zhu T, Liu Y, Fu C, Heremans J P, Snyder J G, Zhao X 2017 Adv. Mater. 29 1605884

Google Scholar

Google Scholar

[3] Zhou W W, Zhu J X, Li D, Hng H H, Boey F Y C, Ma J Zhang H, Yan Q Y 2009 Adv. Mater. 21 3196

Google Scholar

Google Scholar

[4] Zhao L D, Lo S H, Zhang Y S, Sun H, Tan G J, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2014 Nature 508 7496

[5] Novoselov K S, Jiang D, Schedin F, Booth T J, Khotkevich V V, Morozov S V, Geim A K 2005 Proc. Natl. Acad. Sci. USA 102 10451

Google Scholar

Google Scholar

[6] Balandin A, Wang K L 1998 J. Appl. Phys. 84 6149

Google Scholar

Google Scholar

[7] Zhou Y, Zhao L D 2017 Adv. Mater. 29 1702676

Google Scholar

Google Scholar

[8] Lan Y S, Chen X R, Hu C E, Cheng Y, Chen Q F 2019 J. Mater. Chem. A 7 11134

Google Scholar

Google Scholar

[9] Ghosh K, Singisetti U 2015 J. Appl. Phys. 118 135711

Google Scholar

Google Scholar

[10] Jin Z L, Liao Q W, Fang H S, Liu Z C, Liu W, Ding Z D, Luo T F, Yang N 2015 Sci Rep 5 18342

Google Scholar

Google Scholar

[11] Kumar S, Schwingenschlogl U 2015 Chem. Mat. 27 1278

Google Scholar

Google Scholar

[12] Roldán R, Silva-Guillén J A, López-Sancho M P, Guinea F, Cappelluti E, Ordejón P 2014 Ann. Phys. 526 347

Google Scholar

Google Scholar

[13] Chow W L, Yu P, Liu F C, Hong J H, Wang X L, Zeng Q S, Hsu C H, Zhu C, Zhou J D, Wang X W, Xia J, Yan J X, Chen Yu, Wu D, Yu T, Shen Z X, Lin H, Jin C H, Tay B K, Liu Z 2017 Adv. Mater. 29 1602969

Google Scholar

Google Scholar

[14] 张贺, 骆军, 朱航天, 刘泉林, 梁敬魁, 饶光辉 2005 8 313

Google Scholar

Google Scholar

Zhang H, Luo J, Zhu H T, Liu Q L, Liang J K, Rao G H 2005 Acta Phys. Sin. 8 313

Google Scholar

Google Scholar

[15] Ahmad S 2017 Mater. Chem. Phys. 198 162

Google Scholar

Google Scholar

[16] Qin D, Yan P, Ding G Q, Ge X J, Song H Y, Gao G 2018 Sci Rep 8 1

[17] Lan Y S, Lu Q, Hu C E, Chen X R, Chen Q F 2018 Appl. Phys. A-Mater. Sci. Process. 125 33

[18] Su T Y, Medina H, Chen Y Z, Wang S W, Lee S S, Shih Y C, Chen C W, Kuo H C, Chuang F C, Chueh Y L 2018 Small 14 1800032

Google Scholar

Google Scholar

[19] Wang M J, Ko T J, Shawkat M S, Han S S, Okogbue E, Chung H S, Bae T S, Sattar S, Gil J, Noh C, Oh K H, Jung Y J, Larsson J A, Jung Y 2020 ACS Appl. Mater. Interfaces 12 10839

Google Scholar

Google Scholar

[20] Sun G, Kürti J, Rajczy P, Kertesz M, Hafner J, Kresse G 2003 J. Mol. Struct. 624 37

Google Scholar

Google Scholar

[21] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[22] Blöchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[23] Kresse G, Furthmüller J 1996 Comput. Mater. Sci. 6 15

Google Scholar

Google Scholar

[24] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[25] Soulard C, Rocquefelte X, Petit P E, Evain M, Jobic S, Itié J P, Munson P, Koo H J, Whangbo M H 2004 Inorg. Chem. 43 1943

Google Scholar

Google Scholar

[26] Oyedele A D, Yang S, Liang L, Puretzky A, Wang K, Zhang J, Yu P, Pudasaini P R, Ghosh A W, Liu Z, Rouleau C M, Sumpter B G, Chisholm M F, Zhou W, Rack P D, Geohegan D B, Xiao K 2017 J. Am. Chem. Soc. 139 1490

Google Scholar

Google Scholar

[27] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[28] Georg K H M, David J S 2006 Comput. Phys. Commun. 175 67

Google Scholar

Google Scholar

[29] Li W, Carrete J, Katcho N A, Mingo N 2014 Comput. Phys. Commun. 185 1747

Google Scholar

Google Scholar

[30] Togo A, Oba F, Tanaka I 2008 Phys. Rev. B 78 134106

Google Scholar

Google Scholar

[31] Bardeen J, Shockley W 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[32] Xi J, Long M, Tang L, Wang D, Shuai Z 2012 Nanoscale 4 4348

Google Scholar

Google Scholar

[33] Huang S, Liu H J, Fan D D, Jiang P H, Liang J H, Cao G H, Shi J 2018 J. Phys. Chem. C 122 4217

Google Scholar

Google Scholar

[34] Guo H H, Yang T, Tao P, Zhang Z D. 2014 Chin. Phys. B 23 017201

Google Scholar

Google Scholar

[35] Marfoua B, Hong J 2019 ACS Appl. Mater. Interfaces 11 38819

Google Scholar

Google Scholar

[36] Wu P. 2019 IOP Conf. Ser.: Mater. Sci. Eng. 631 042010

Google Scholar

Google Scholar

[37] Carrete J, Li W, Lindsay L, Broido D A, Gallego L J, Mingo N 2016 Mater. Res. Lett. 4 204

Google Scholar

Google Scholar

[38] Peng B, Zhang D, Zhang H, Shao H, Ni G, Zhu Y, Zhu H 2017 Nanoscale 9 7397

Google Scholar

Google Scholar

-

图 6 (a) PdTe2和PtTe2层状材料的晶格热导率沿x, y方向随温度的变化率; PdTe2 (b)和PtTe2 (c) 晶格热导率, 电子热导率及总热导率随温度变化的关系

Fig. 6. (a) Calculated lattice thermal conductivity of monolayer PdTe2 and PtTe2 along the x (dark dashed line) and the y (red dashed line) directions and from 200 K to 800 K with the interval of 100 K; thermal conductivity of PdTe2 (b) and PtTe2 (c) at different temperatures, where ke is electron thermal conductivity, kl is lattice thermal conductivity, and ke + kl is total thermal conductivity.

图 7 p型掺杂时, PdTe2 (a)和PtTe2 (b)两种材料在不同温度下沿x, y两个方向σ/τ 随载流子浓度的变化. n型掺杂时, PdTe2 (c)和PtTe2 (d)两种材料在不同温度下沿x, y两个方向σ/τ 随载流子浓度的变化

Fig. 7. Calculated electrical conductivity of p-type (a), (b) and n-type (c), (b) monolayer PdTe2 and PtTe2 along the x and the y directions from 300 K to 900 K with the interval of 300 K.

图 8 p型掺杂时, PdTe2 (a)和PtTe2 (b)两种材料在不同温度下沿x, y两个方向的塞贝克系数S随载流子浓度的变化. n型掺杂时, PdTe2 (c)和PtTe2 (d)两种材料在不同温度下沿x, y两个方向的塞贝克系数S随载流子浓度的变化

Fig. 8. Calculated Seebeck coefficient S of p-type (a), (b) and n-type (c), (d) monolayer PdTe2 and PtTe2 along the x and the y directions from 300 to 900 K with the interval of 300 K.

表 1 XTe2 (X = Pd, Pt) 单层的晶格常数(a, b)

Table 1. The optimized lattice parameters (a, b) of XTe2 (X = Pd, Pt) monolayers.

表 2 温度为300 K时, PdTe2和PtTe2的有效弹性模量C2D、形变势常量El、有效质量m*、载流子迁移率μ及弛豫时间τ

Table 2. Calculated elastic modulus C2 D, DP constant El, effective mass (m*), carrier mobility (μ), and relaxation time (τ) at 300 K of PdTe2 and PtTe2 monolayers.

PdTe2 x y PtTe2 x y p n p n p n p n C2D/(eV·Å–2) 4.86 3.90 4.75 5.84 El/eV 3.6 5.5 3.2 4.6 2.65 3.83 3.9 6.4 m*/me 0.88 0.58 0.88 0.58 0.44 0.33 0.46 0.29 μ/(cm2·V–1·s–1) 162 157 168 183 1150 1071 630 546 τ/(10–14 s) 8.2 5.3 8.5 6.1 28.9 20.3 16.6 8.9 -

[1] Jaziri N, Boughamoura A, Müller J, Mezghani B, Tounsi F, Ismail M 2019 Energy Rep. 6 7

Google Scholar

Google Scholar

[2] Zhu T, Liu Y, Fu C, Heremans J P, Snyder J G, Zhao X 2017 Adv. Mater. 29 1605884

Google Scholar

Google Scholar

[3] Zhou W W, Zhu J X, Li D, Hng H H, Boey F Y C, Ma J Zhang H, Yan Q Y 2009 Adv. Mater. 21 3196

Google Scholar

Google Scholar

[4] Zhao L D, Lo S H, Zhang Y S, Sun H, Tan G J, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2014 Nature 508 7496

[5] Novoselov K S, Jiang D, Schedin F, Booth T J, Khotkevich V V, Morozov S V, Geim A K 2005 Proc. Natl. Acad. Sci. USA 102 10451

Google Scholar

Google Scholar

[6] Balandin A, Wang K L 1998 J. Appl. Phys. 84 6149

Google Scholar

Google Scholar

[7] Zhou Y, Zhao L D 2017 Adv. Mater. 29 1702676

Google Scholar

Google Scholar

[8] Lan Y S, Chen X R, Hu C E, Cheng Y, Chen Q F 2019 J. Mater. Chem. A 7 11134

Google Scholar

Google Scholar

[9] Ghosh K, Singisetti U 2015 J. Appl. Phys. 118 135711

Google Scholar

Google Scholar

[10] Jin Z L, Liao Q W, Fang H S, Liu Z C, Liu W, Ding Z D, Luo T F, Yang N 2015 Sci Rep 5 18342

Google Scholar

Google Scholar

[11] Kumar S, Schwingenschlogl U 2015 Chem. Mat. 27 1278

Google Scholar

Google Scholar

[12] Roldán R, Silva-Guillén J A, López-Sancho M P, Guinea F, Cappelluti E, Ordejón P 2014 Ann. Phys. 526 347

Google Scholar

Google Scholar

[13] Chow W L, Yu P, Liu F C, Hong J H, Wang X L, Zeng Q S, Hsu C H, Zhu C, Zhou J D, Wang X W, Xia J, Yan J X, Chen Yu, Wu D, Yu T, Shen Z X, Lin H, Jin C H, Tay B K, Liu Z 2017 Adv. Mater. 29 1602969

Google Scholar

Google Scholar

[14] 张贺, 骆军, 朱航天, 刘泉林, 梁敬魁, 饶光辉 2005 8 313

Google Scholar

Google Scholar

Zhang H, Luo J, Zhu H T, Liu Q L, Liang J K, Rao G H 2005 Acta Phys. Sin. 8 313

Google Scholar

Google Scholar

[15] Ahmad S 2017 Mater. Chem. Phys. 198 162

Google Scholar

Google Scholar

[16] Qin D, Yan P, Ding G Q, Ge X J, Song H Y, Gao G 2018 Sci Rep 8 1

[17] Lan Y S, Lu Q, Hu C E, Chen X R, Chen Q F 2018 Appl. Phys. A-Mater. Sci. Process. 125 33

[18] Su T Y, Medina H, Chen Y Z, Wang S W, Lee S S, Shih Y C, Chen C W, Kuo H C, Chuang F C, Chueh Y L 2018 Small 14 1800032

Google Scholar

Google Scholar

[19] Wang M J, Ko T J, Shawkat M S, Han S S, Okogbue E, Chung H S, Bae T S, Sattar S, Gil J, Noh C, Oh K H, Jung Y J, Larsson J A, Jung Y 2020 ACS Appl. Mater. Interfaces 12 10839

Google Scholar

Google Scholar

[20] Sun G, Kürti J, Rajczy P, Kertesz M, Hafner J, Kresse G 2003 J. Mol. Struct. 624 37

Google Scholar

Google Scholar

[21] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[22] Blöchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[23] Kresse G, Furthmüller J 1996 Comput. Mater. Sci. 6 15

Google Scholar

Google Scholar

[24] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[25] Soulard C, Rocquefelte X, Petit P E, Evain M, Jobic S, Itié J P, Munson P, Koo H J, Whangbo M H 2004 Inorg. Chem. 43 1943

Google Scholar

Google Scholar

[26] Oyedele A D, Yang S, Liang L, Puretzky A, Wang K, Zhang J, Yu P, Pudasaini P R, Ghosh A W, Liu Z, Rouleau C M, Sumpter B G, Chisholm M F, Zhou W, Rack P D, Geohegan D B, Xiao K 2017 J. Am. Chem. Soc. 139 1490

Google Scholar

Google Scholar

[27] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[28] Georg K H M, David J S 2006 Comput. Phys. Commun. 175 67

Google Scholar

Google Scholar

[29] Li W, Carrete J, Katcho N A, Mingo N 2014 Comput. Phys. Commun. 185 1747

Google Scholar

Google Scholar

[30] Togo A, Oba F, Tanaka I 2008 Phys. Rev. B 78 134106

Google Scholar

Google Scholar

[31] Bardeen J, Shockley W 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[32] Xi J, Long M, Tang L, Wang D, Shuai Z 2012 Nanoscale 4 4348

Google Scholar

Google Scholar

[33] Huang S, Liu H J, Fan D D, Jiang P H, Liang J H, Cao G H, Shi J 2018 J. Phys. Chem. C 122 4217

Google Scholar

Google Scholar

[34] Guo H H, Yang T, Tao P, Zhang Z D. 2014 Chin. Phys. B 23 017201

Google Scholar

Google Scholar

[35] Marfoua B, Hong J 2019 ACS Appl. Mater. Interfaces 11 38819

Google Scholar

Google Scholar

[36] Wu P. 2019 IOP Conf. Ser.: Mater. Sci. Eng. 631 042010

Google Scholar

Google Scholar

[37] Carrete J, Li W, Lindsay L, Broido D A, Gallego L J, Mingo N 2016 Mater. Res. Lett. 4 204

Google Scholar

Google Scholar

[38] Peng B, Zhang D, Zhang H, Shao H, Ni G, Zhu Y, Zhu H 2017 Nanoscale 9 7397

Google Scholar

Google Scholar

计量

- 文章访问数: 16047

- PDF下载量: 704

- 被引次数: 0

下载:

下载: