-

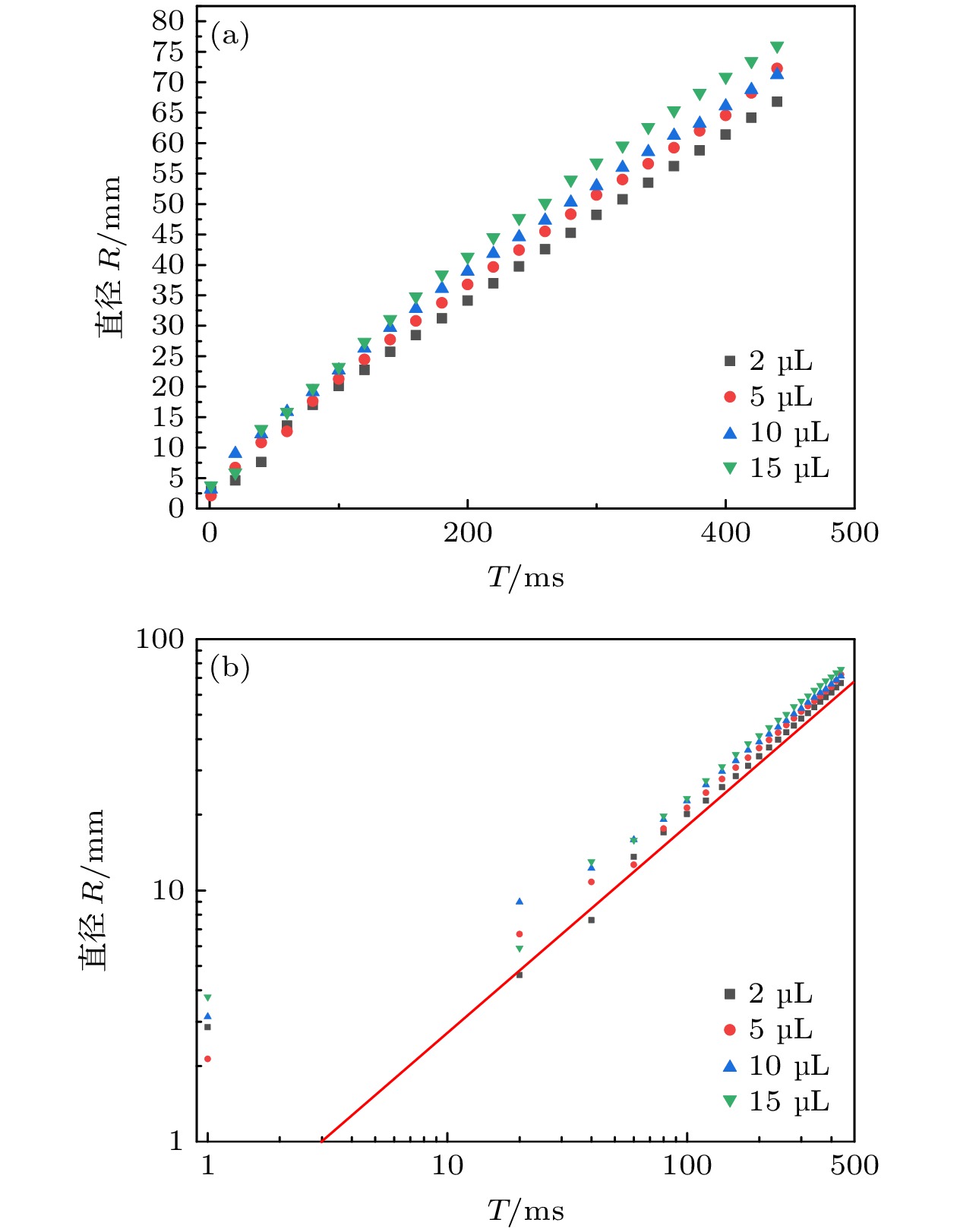

Surface tension gradient due to concentration difference and temperature difference induces liquid convection, known as Marangoni effect. The Marangoni effect has been extensively studied to understand its fundamental physics and its industrial applications. In this paper we study Marangoni effect of droplet in a three-phase liquid system. In this system, silicone oil is chosen as a driving liquid, and n-hexadecane is used as a driven liquid. A high-speed camera is used to capture the spreading process of n-hexadecane driven by silicon oil on the sodium dodecyl sulfate (SDS) solution. The experiment shows that n-hexadecane driven by silicone oil spreads from inside out, forming a ring structure. According to spreading dynamic behavior of internal boundary and external boundary of n-hexadecane ring, we study the spreading pattern of internal boundary and external boundary of n-hexadecane ring, and the influence of silicone oil volume on the spreading process. Analysis shows that the spreading law of internal silicone oil conforms to single droplet spreading at the liquid interface. In the initial spreading stage, the spreading of four-phase contact line (internal boundary) among silicone oil, air, n-hexadecane and water are dominated by gravity, The scale law of spreading distance R of four-phase contact line and t is in a range of

$ R \sim {t}^{1/4} $ -$ R \sim {t}^{1/2} $ . Owing to the gravity influence, the larger the volume of silicone oil, the faster the four-phase contact line spreads. The volume of silicone oil has no effect on the scaling law of the whole spreading process. The next spreading stage, the spreading of the contact line is dominated by the interfacial tension gradient. The scale law of spreading distance R and t conforms to$ R \sim {t}^{3/4} $ . Under silicone oil driven, the liquid thickness of n-hexadecane at the four-phase contact line (internal boundary) among air, silicone oil, N-hexadecane and water increases, thus changing the contact angle at three-phase contact line (external boundary) among air, n-hexadecane and water. The change of contact angle leads the interfacial tension gradient to produce. The interfacial tension gradient drives external boundary to spread. Because the spreading of the three-phase contact line is dominated by interfacial tension gradient, the scale law of spreading distance R of three-phase contact line and time t conforms to$ \sim {t}^{3/4} $ .-

Keywords:

- three-phase liquid system /

- droplet /

- Marangoni effect /

- interfacial tension gradient

[1] Gennes P D, Brochard-Wyart F, Quéré D 2004 Capillarity and Wetting Phenomena-Drops, Bubbles, Pearls, Waves (New York: Springer-Verlag)

[2] Sanatkaran N, Kulichikhin V G, Malkin A Y, Foudazi R 2018 Langmuir 34 10974

Google Scholar

Google Scholar

[3] Wodlei F, Sebilleau J, Magnaudet J, Pimienta V 2018 Nat. Commun. 9 820

Google Scholar

Google Scholar

[4] Motaghian M, Shirsavar R, Erfanifam M, Sabouhi M, Stone H A, van der Linden E, Bonn D, Habibi M 2019 Langmuir 35 14855

Google Scholar

Google Scholar

[5] Dugas V, Broutin J, Souteyrand E 2005 Langmuir 21 9130

Google Scholar

Google Scholar

[6] Brutin D, Sobac B, Loquet B, Sampol J 2011 J. Fluid Mech. 667 85

Google Scholar

Google Scholar

[7] Kim Y K, Na H K, Ham S, Min D H 2014 RSC Adv. 4 50091

Google Scholar

Google Scholar

[8] Sellier M, Nock V, Gaubert C, Verdier C 2013 Eur. Phys. J. Spec. Top. 219 131

Google Scholar

Google Scholar

[9] Jones A R, Kim C B, Zhou S X, Ha H, Katsumata R, Blachut G, Bonnecaze R T, Ellison C J 2017 Macromolecules 50 4588

Google Scholar

Google Scholar

[10] Harkins W D 1941 J. Chem. Phys. 9 552

Google Scholar

Google Scholar

[11] Fay J A 1969 Oil on the Sea (Boston: Springer) pp53–63

[12] Huh C, Inoue M, Mason S G 1975 Can. J. Chem. Eng. 53 367

Google Scholar

Google Scholar

[13] Foda M, Cox R G 1980 J. Fluid Mech. 101 33

[14] Borgas M S, Grotberg J B 1988 J. Fluid Mech. 193 151

[15] Kita Y, Askounis A, Kohno M, Takata Y, Kim J, Sefiane K 2016 Appl. Phys. Lett. 109 171602

Google Scholar

Google Scholar

[16] Malyuk A Y, Ivanova N A 2018 Appl. Phys. Lett. 112 103701

Google Scholar

Google Scholar

[17] Izri Z, Linden M, Michelin S, Dauchot O 2014 Phys. Rev. Lett. 113 248302

Google Scholar

Google Scholar

[18] Vernay C, Ramos L, Ligoure C 2015 Phys. Rev. Lett. 115 198302

Google Scholar

Google Scholar

[19] Venerus D C, Simavilla D N 2015 Sci. Rep. 5 16162

Google Scholar

Google Scholar

[20] Tan H, Diddens C, Lv P, Kuerten J, Zhang X, Lohse D 2019 Nat. Commun. 10 478

Google Scholar

Google Scholar

[21] Keiser L, Bense H, Colinet P, Bico J, Reyssat E 2017 Phys. Rev. Lett 118 074504

Google Scholar

Google Scholar

[22] Kim H, Muller K, Shardt O, Afkhami S, Stone H A 2017 Nat. Phys. 13 1105

Google Scholar

Google Scholar

[23] Hasegawa K, Manzaki Y 2021 Phys. Fluids 33 034124

[24] Hernández-Sánchez J F, Eddi A, Snoeijer J H 2015 Phys. Fluids 27 032003

Google Scholar

Google Scholar

[25] 赵文景, 王进, 秦威广, 纪文杰, 蓝鼎, 王育人 2021 70 184701

Google Scholar

Google Scholar

Zhao W J, Wang J, Qin W G, Ji W J, Lan D, Wang Y R 2021 Acta Phys. Sin. 70 184701

Google Scholar

Google Scholar

[26] Joos P, Pintens J 1977 J. Colloid Interface Sci. 60 507

Google Scholar

Google Scholar

-

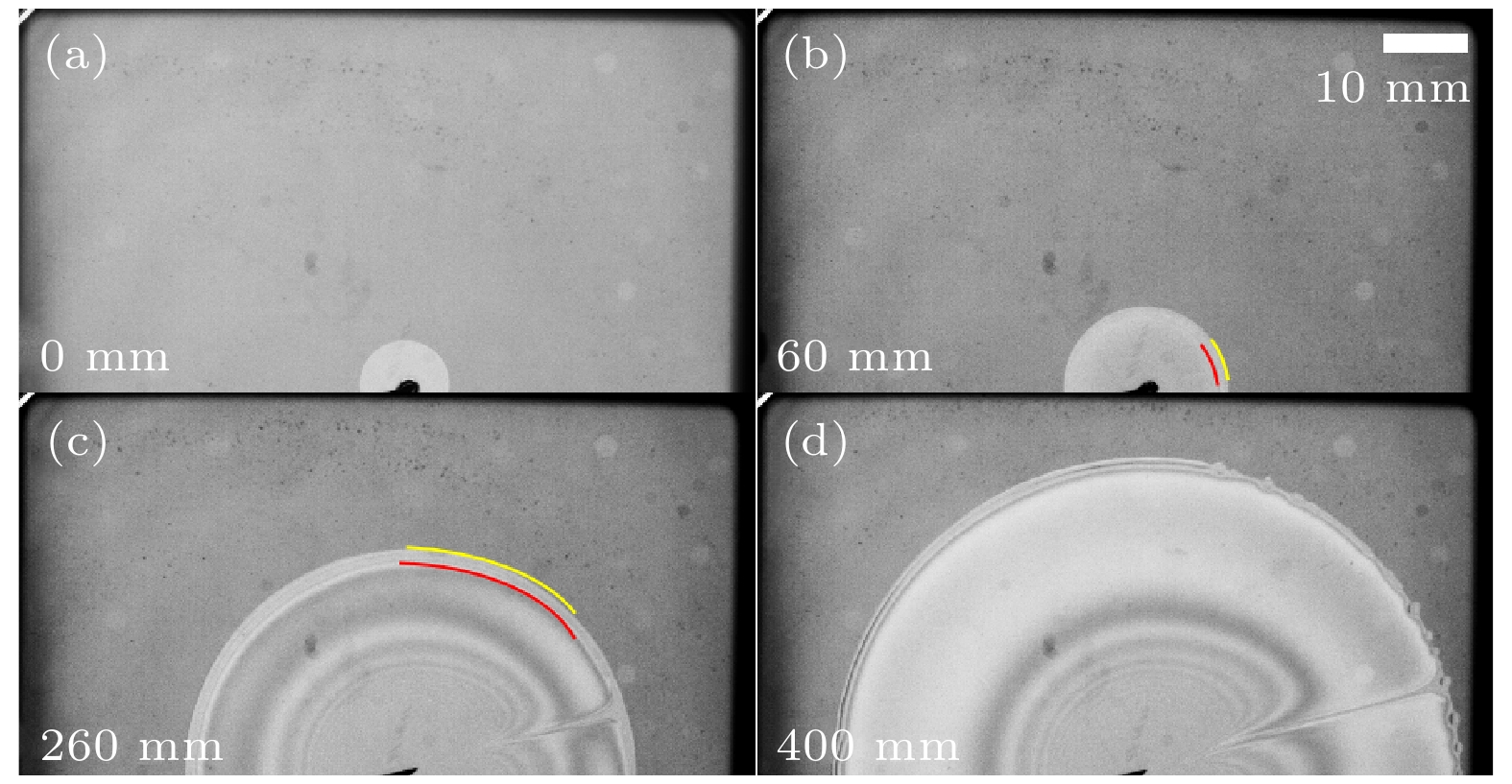

图 2 2 μL硅油驱动正十六烷实验图像, 其中黄线为正十六烷/SDS基底接触线, 红线为硅油/正十六烷接触线(比例尺为10 mm)

Figure 2. Schematic of spreading process of n-hexadecane driven by 2 μL silicon oil, where the yellow line is the contact line between n-hexadecane and SDS solution, the red line is the contact line between n-hexadecane and silicon oil (scale bar: 10 mm).

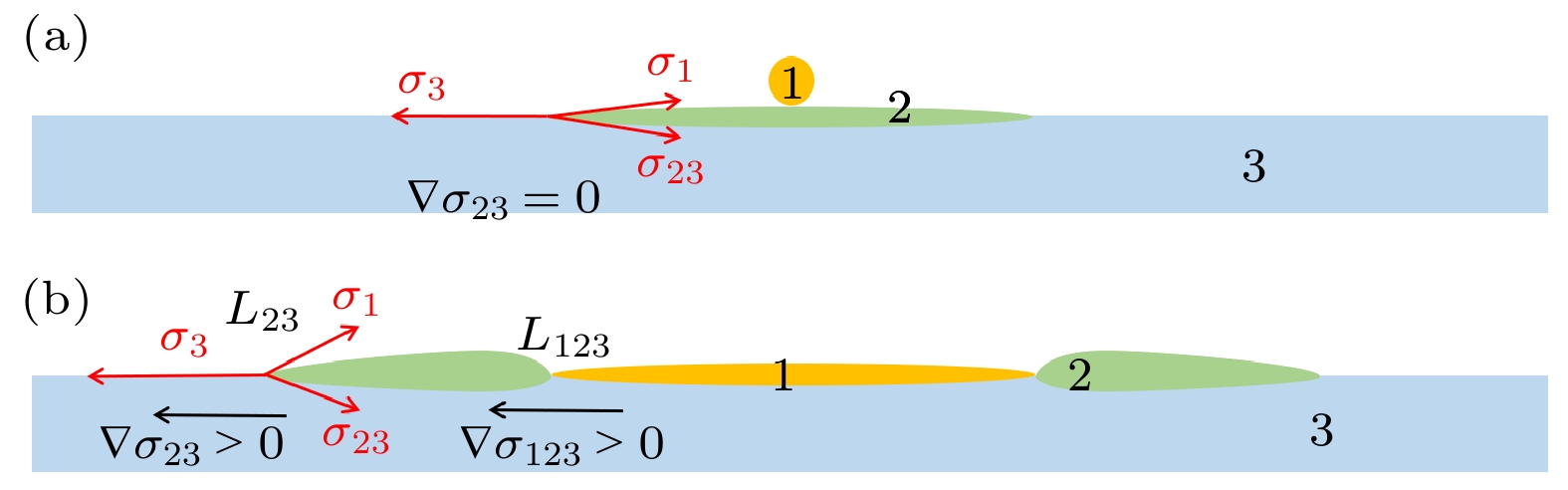

图 3 实验原理图, 其中液体1, 2, 3分别为硅油、正十六烷、SDS溶液; L123 为四相接触线, L23三相接触线,

${\nabla \sigma }_{123}{\rm{和}} $ $ {\nabla \sigma }_{23}{\rm{分}}{\rm{别}}{\rm{为}}$ 接触线处L123和L23处的界面张力梯度; σi 为第i相液体表面张力, σij为第i, j相之间的界面张力Figure 3. Experimental schematic diagram, where liquids 1, 2 and 3 are silicone oil, n-hexadecane and SDS solution respectively, L123 is four phase contact line and L23 is three phase contact line.

${\nabla \sigma }_{123},\; {\nabla \sigma }_{23}$ are Interfacial tension gradient in L123, L23 respectively. σi is the tension of i liquid, σij is the tension of the i, j interface.图 5 正十六烷外边界直径R随时间变化图 (a)线性坐标轴; (b)双对数坐标轴, 其中红线斜率为3/4, T0为初始时刻, T1是斜率向3/4靠近的拐点

Figure 5. Diagram of the diameter of n-hexadecane outer boundary over time: (a) Linear axis; (b) dual logarithmic axis, where the slope of the red line is 3/4, T0 is the initial moment, T1 is the inflection point where the slope approaches 3/4.

-

[1] Gennes P D, Brochard-Wyart F, Quéré D 2004 Capillarity and Wetting Phenomena-Drops, Bubbles, Pearls, Waves (New York: Springer-Verlag)

[2] Sanatkaran N, Kulichikhin V G, Malkin A Y, Foudazi R 2018 Langmuir 34 10974

Google Scholar

Google Scholar

[3] Wodlei F, Sebilleau J, Magnaudet J, Pimienta V 2018 Nat. Commun. 9 820

Google Scholar

Google Scholar

[4] Motaghian M, Shirsavar R, Erfanifam M, Sabouhi M, Stone H A, van der Linden E, Bonn D, Habibi M 2019 Langmuir 35 14855

Google Scholar

Google Scholar

[5] Dugas V, Broutin J, Souteyrand E 2005 Langmuir 21 9130

Google Scholar

Google Scholar

[6] Brutin D, Sobac B, Loquet B, Sampol J 2011 J. Fluid Mech. 667 85

Google Scholar

Google Scholar

[7] Kim Y K, Na H K, Ham S, Min D H 2014 RSC Adv. 4 50091

Google Scholar

Google Scholar

[8] Sellier M, Nock V, Gaubert C, Verdier C 2013 Eur. Phys. J. Spec. Top. 219 131

Google Scholar

Google Scholar

[9] Jones A R, Kim C B, Zhou S X, Ha H, Katsumata R, Blachut G, Bonnecaze R T, Ellison C J 2017 Macromolecules 50 4588

Google Scholar

Google Scholar

[10] Harkins W D 1941 J. Chem. Phys. 9 552

Google Scholar

Google Scholar

[11] Fay J A 1969 Oil on the Sea (Boston: Springer) pp53–63

[12] Huh C, Inoue M, Mason S G 1975 Can. J. Chem. Eng. 53 367

Google Scholar

Google Scholar

[13] Foda M, Cox R G 1980 J. Fluid Mech. 101 33

[14] Borgas M S, Grotberg J B 1988 J. Fluid Mech. 193 151

[15] Kita Y, Askounis A, Kohno M, Takata Y, Kim J, Sefiane K 2016 Appl. Phys. Lett. 109 171602

Google Scholar

Google Scholar

[16] Malyuk A Y, Ivanova N A 2018 Appl. Phys. Lett. 112 103701

Google Scholar

Google Scholar

[17] Izri Z, Linden M, Michelin S, Dauchot O 2014 Phys. Rev. Lett. 113 248302

Google Scholar

Google Scholar

[18] Vernay C, Ramos L, Ligoure C 2015 Phys. Rev. Lett. 115 198302

Google Scholar

Google Scholar

[19] Venerus D C, Simavilla D N 2015 Sci. Rep. 5 16162

Google Scholar

Google Scholar

[20] Tan H, Diddens C, Lv P, Kuerten J, Zhang X, Lohse D 2019 Nat. Commun. 10 478

Google Scholar

Google Scholar

[21] Keiser L, Bense H, Colinet P, Bico J, Reyssat E 2017 Phys. Rev. Lett 118 074504

Google Scholar

Google Scholar

[22] Kim H, Muller K, Shardt O, Afkhami S, Stone H A 2017 Nat. Phys. 13 1105

Google Scholar

Google Scholar

[23] Hasegawa K, Manzaki Y 2021 Phys. Fluids 33 034124

[24] Hernández-Sánchez J F, Eddi A, Snoeijer J H 2015 Phys. Fluids 27 032003

Google Scholar

Google Scholar

[25] 赵文景, 王进, 秦威广, 纪文杰, 蓝鼎, 王育人 2021 70 184701

Google Scholar

Google Scholar

Zhao W J, Wang J, Qin W G, Ji W J, Lan D, Wang Y R 2021 Acta Phys. Sin. 70 184701

Google Scholar

Google Scholar

[26] Joos P, Pintens J 1977 J. Colloid Interface Sci. 60 507

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6188

- PDF Downloads: 107

- Cited By: 0

DownLoad:

DownLoad: