-

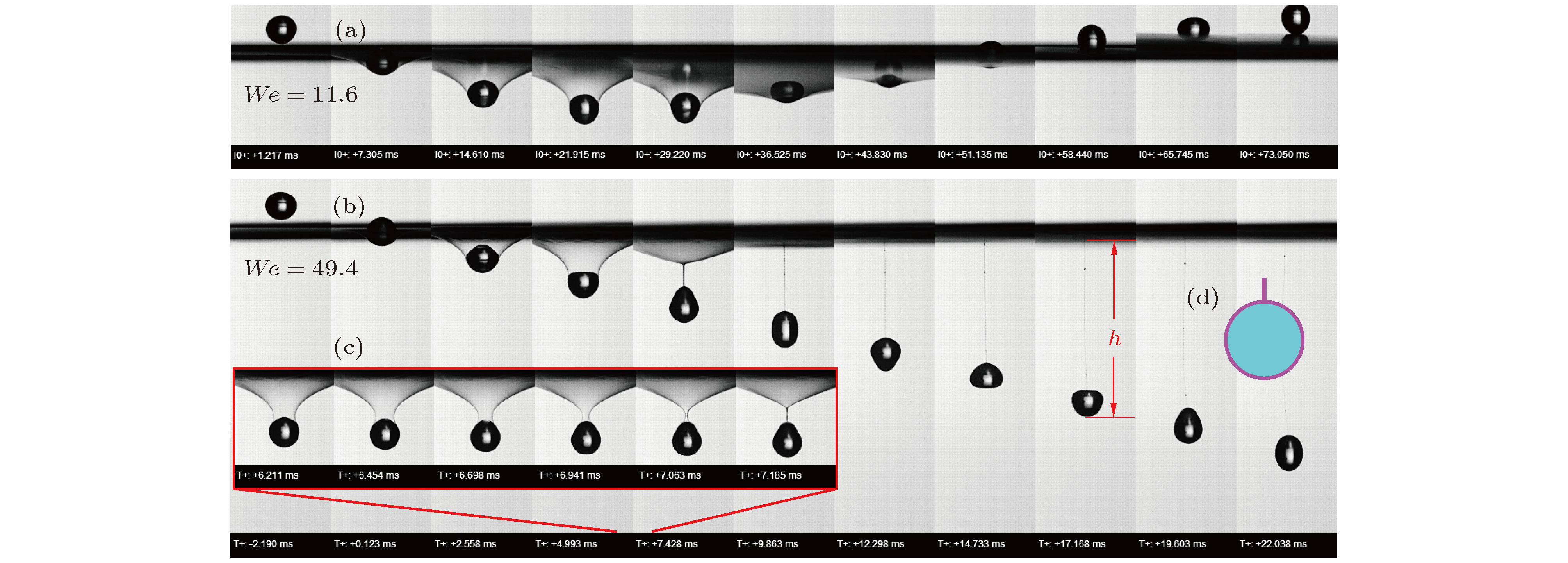

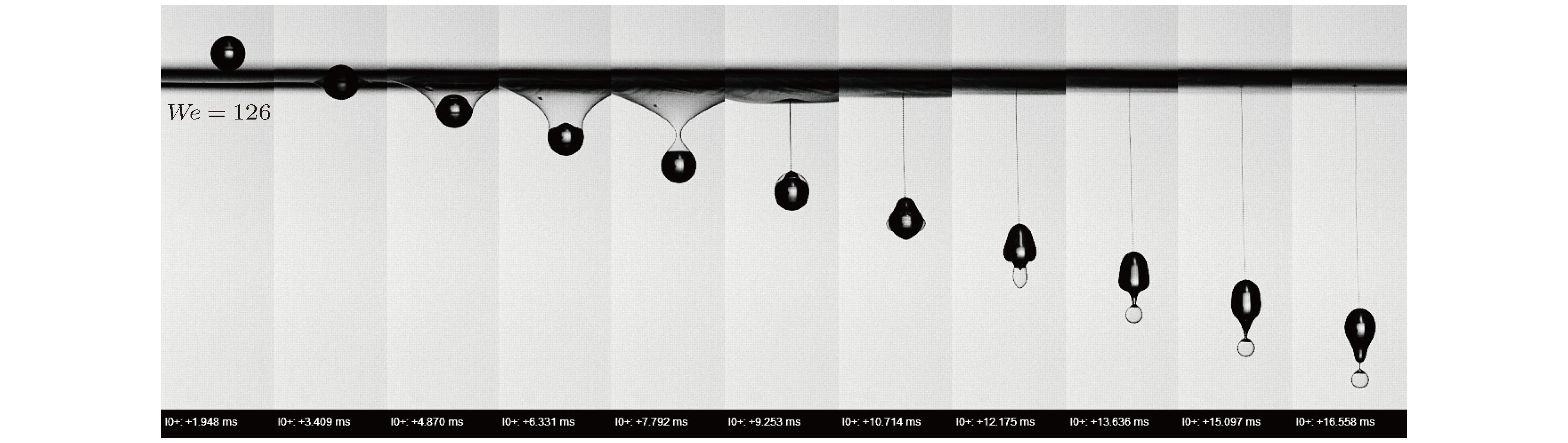

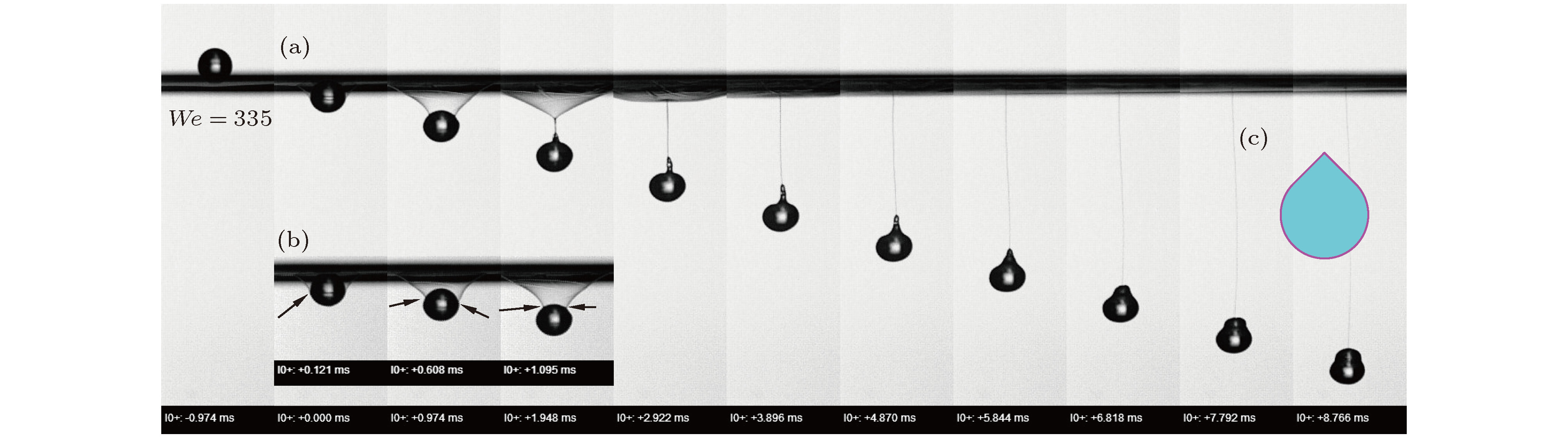

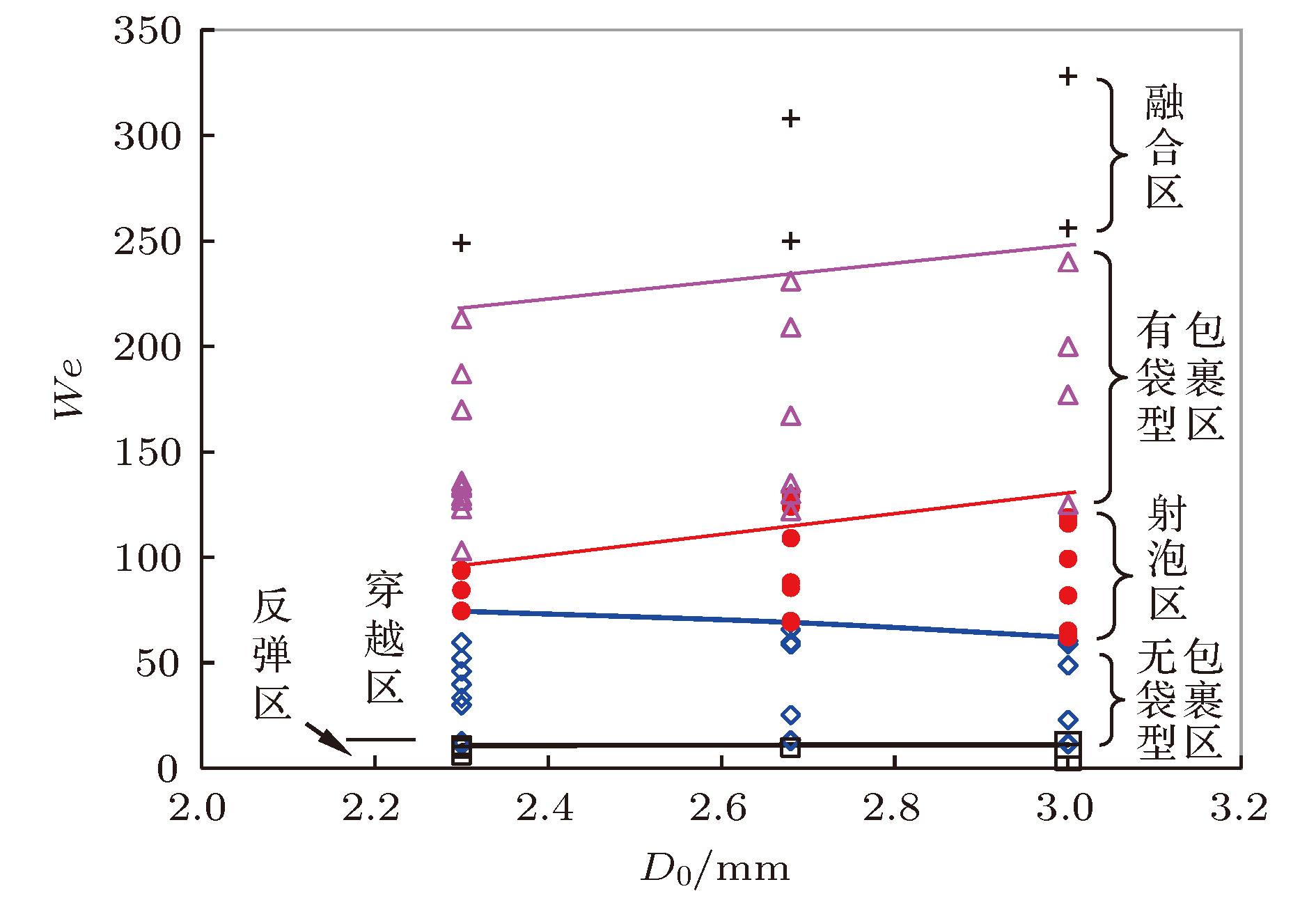

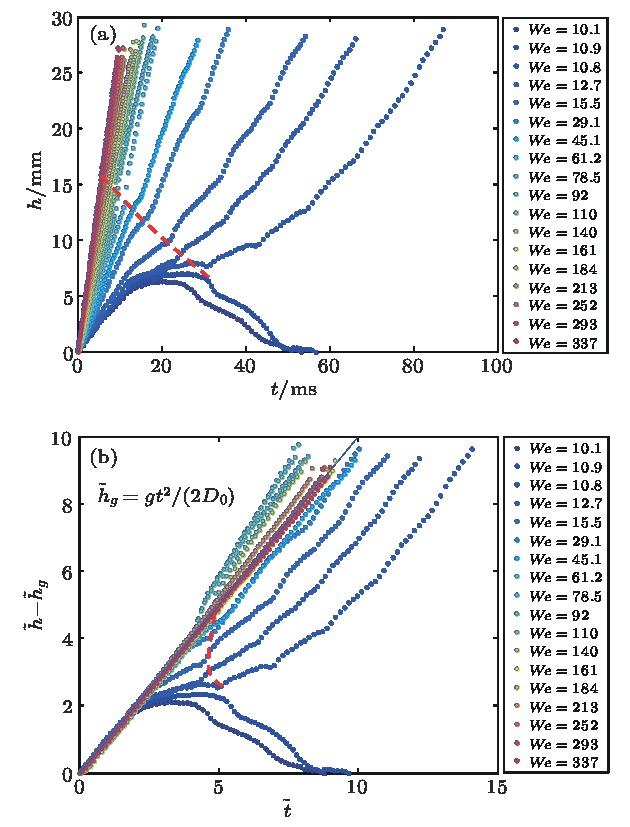

Droplet passing through a film is a ubiquitous phenomenon in nature, such as a rain drop impacting on a rain bubble in paddle and pouring beer onto the beer foam, etc. This phenomenon has not been sufficiently investigated and many interfacial interaction mechanisms are still unknown. In this paper, the passing modes and the kinematics of a droplet impacting on a soap film are studied with the help of a high-speed cameral. The impacting Weber number of the droplet varies from 10 to more than 350. The droplet position and velocity are extracted from the video by a self-designed Matlab codes. Experimental results show that the droplet may pass through the soap film in five modes, i.e., bouncing, bagless packaging, package peeling, bag packaging, and instaneous coalescence. A " drop-cushion-shell”-type compound droplet can be formatted in bag-[We ∈ (10.8, 60)] and bagless [We ∈ (120, 240)] packaging mode, while in the package peeling [We ∈ (60, 120)] and coalescence [We ∈ (240, 350)] mode it will form single phase droplets, however, with the surface coated with a soap solution layer (original soap film). Although compound droplets have three surfaces, i.e., the droplet’s original surface and the inner and outer surface of the soap film, the apparent surface tension for the bagless-packed droplet is just that of the soap solution, while for the bag-packed droplet it is the sum of the three surface tensions. The outer shell of the compound droplet may peel off and eject a bubble when the Weber number is in the certain range (We ∈ (60, 120) for droplet with D0 = 3.0 mm), the lower limit decreases and the upper limit increases with the increase of the initial diameter of the droplets and thus expands the bubble-shooting range. The droplet performs a free fall motion, however, it is interfered by the soap film. The droplet can be stopped and rebounded when We < 10.8, and penetrate the film and start another free fall when We > 10.8. The velocity loss before and after the penetration decrease with impact velocity increasing, hence the motion of the higher We droplet is less retarded by the soap film, the motion curve approaches to the free fall curve. The approaching is not a linear but an accelerating behavior. -

Keywords:

- droplet /

- soap film /

- impact /

- passing modes /

- bubble shooting

[1] Bartolo D, Jossereand C, Bonn D 2006 Phys. Rev. Lett. 96 124501

Google Scholar

Google Scholar

[2] Xu W, Leeladhar R, Kang Y T, Choi C H 2013 Langmuir 29 6032

[3] Pan K L, Hung C Y 2010 Colloid Interface Sci. 352 186

[4] Thoraval M J, Takehara K, Etoh T G, Thoroddsen S 2013 J. Fluid Mech. 724 234

[5] Hu H B, Huang S H, Chen L B 2013 Chin. Phys. B 22 84702

Google Scholar

Google Scholar

[6] Pearson T, Maynes D, Webb B W 2012 Exp. Fluids 53 603

[7] Aziz D S, Chandra S 2000 Int. J. Heat Mass Tran. 43 2841

[8] Tran T, de Maleprade H, Sun C, Lohse D 2013 J. Fluid Mech. 726 R3

Google Scholar

Google Scholar

[9] Josserand C, Zaleski S 2003 Phys. Fluids 15 1650

Google Scholar

Google Scholar

[10] Eggers J, Fontelos M A, Josserand C, Zaleski S 2010 Phys. Fluids 22 062101

Google Scholar

Google Scholar

[11] Kim I, Wu X L 2010 Phys. Rev. E 82 026313

Google Scholar

Google Scholar

[12] Yarin A L 2006 Annu. Rev. Fluid Mech. 38 159

[13] Fell D, Sokuler M, Lembach A, Eibach T F, Liu C J, Bonaccurso E, Auernhammer G K, Butt H J 2013 Colloid Polym. Sci. 291 1963

Google Scholar

Google Scholar

[14] Gilet T, Bush J W M 2009 J. Fluid Mech. 625 167

Google Scholar

Google Scholar

[15] Courbin L, Stone H A 2006 Phys. Fluids 18 91105

Google Scholar

Google Scholar

[16] Bai L, Xu W, Wu P F, Lin W J, Li C, Xu D L 2016 Colloids Surf. A 509 334

Google Scholar

Google Scholar

[17] Kim P G, Stone H A 2008 Europhys. Lett. 83 54001

Google Scholar

Google Scholar

[18] Dorbolo S, Caps H, Vandewalle N 2003 New J. Phys. 5 161

Google Scholar

Google Scholar

[19] Dorbolo S, Reyssat E, Vandewalle N 2005 Europhys. Lett. 69 966

Google Scholar

Google Scholar

[20] Thoroddsen S T, Takehara K, Etoh T G 2005 J. Fluid Mech. 530 295

Google Scholar

Google Scholar

[21] Hicks P D, Purvis R 2011 Phys. Fluids 23 062104

Google Scholar

Google Scholar

[22] Tang X Y, Saha A, Law C K, Sun C 2019 Phys. Fluids 31 013304

Google Scholar

Google Scholar

-

-

[1] Bartolo D, Jossereand C, Bonn D 2006 Phys. Rev. Lett. 96 124501

Google Scholar

Google Scholar

[2] Xu W, Leeladhar R, Kang Y T, Choi C H 2013 Langmuir 29 6032

[3] Pan K L, Hung C Y 2010 Colloid Interface Sci. 352 186

[4] Thoraval M J, Takehara K, Etoh T G, Thoroddsen S 2013 J. Fluid Mech. 724 234

[5] Hu H B, Huang S H, Chen L B 2013 Chin. Phys. B 22 84702

Google Scholar

Google Scholar

[6] Pearson T, Maynes D, Webb B W 2012 Exp. Fluids 53 603

[7] Aziz D S, Chandra S 2000 Int. J. Heat Mass Tran. 43 2841

[8] Tran T, de Maleprade H, Sun C, Lohse D 2013 J. Fluid Mech. 726 R3

Google Scholar

Google Scholar

[9] Josserand C, Zaleski S 2003 Phys. Fluids 15 1650

Google Scholar

Google Scholar

[10] Eggers J, Fontelos M A, Josserand C, Zaleski S 2010 Phys. Fluids 22 062101

Google Scholar

Google Scholar

[11] Kim I, Wu X L 2010 Phys. Rev. E 82 026313

Google Scholar

Google Scholar

[12] Yarin A L 2006 Annu. Rev. Fluid Mech. 38 159

[13] Fell D, Sokuler M, Lembach A, Eibach T F, Liu C J, Bonaccurso E, Auernhammer G K, Butt H J 2013 Colloid Polym. Sci. 291 1963

Google Scholar

Google Scholar

[14] Gilet T, Bush J W M 2009 J. Fluid Mech. 625 167

Google Scholar

Google Scholar

[15] Courbin L, Stone H A 2006 Phys. Fluids 18 91105

Google Scholar

Google Scholar

[16] Bai L, Xu W, Wu P F, Lin W J, Li C, Xu D L 2016 Colloids Surf. A 509 334

Google Scholar

Google Scholar

[17] Kim P G, Stone H A 2008 Europhys. Lett. 83 54001

Google Scholar

Google Scholar

[18] Dorbolo S, Caps H, Vandewalle N 2003 New J. Phys. 5 161

Google Scholar

Google Scholar

[19] Dorbolo S, Reyssat E, Vandewalle N 2005 Europhys. Lett. 69 966

Google Scholar

Google Scholar

[20] Thoroddsen S T, Takehara K, Etoh T G 2005 J. Fluid Mech. 530 295

Google Scholar

Google Scholar

[21] Hicks P D, Purvis R 2011 Phys. Fluids 23 062104

Google Scholar

Google Scholar

[22] Tang X Y, Saha A, Law C K, Sun C 2019 Phys. Fluids 31 013304

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 13994

- PDF Downloads: 189

- Cited By: 0

DownLoad:

DownLoad: