-

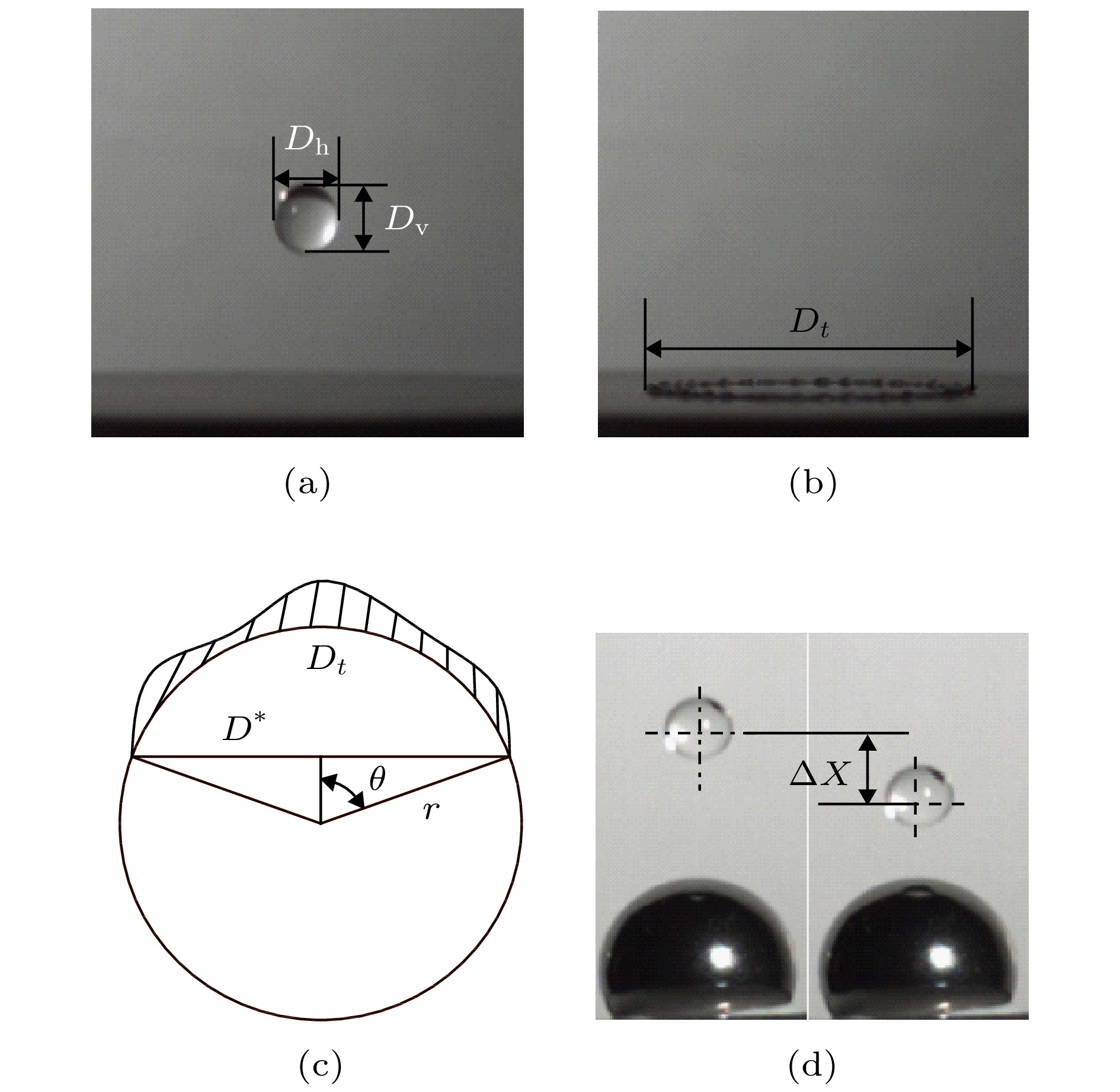

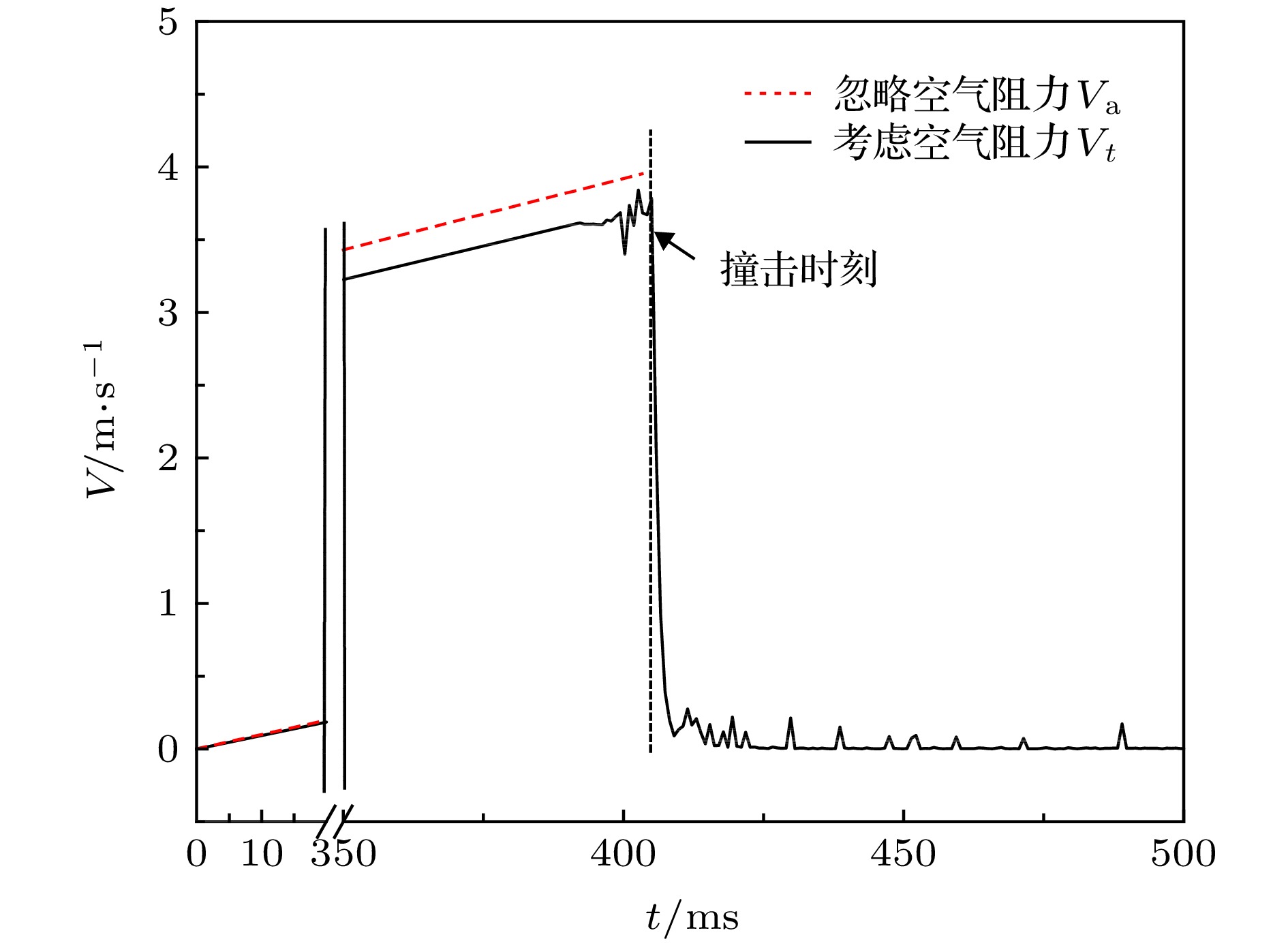

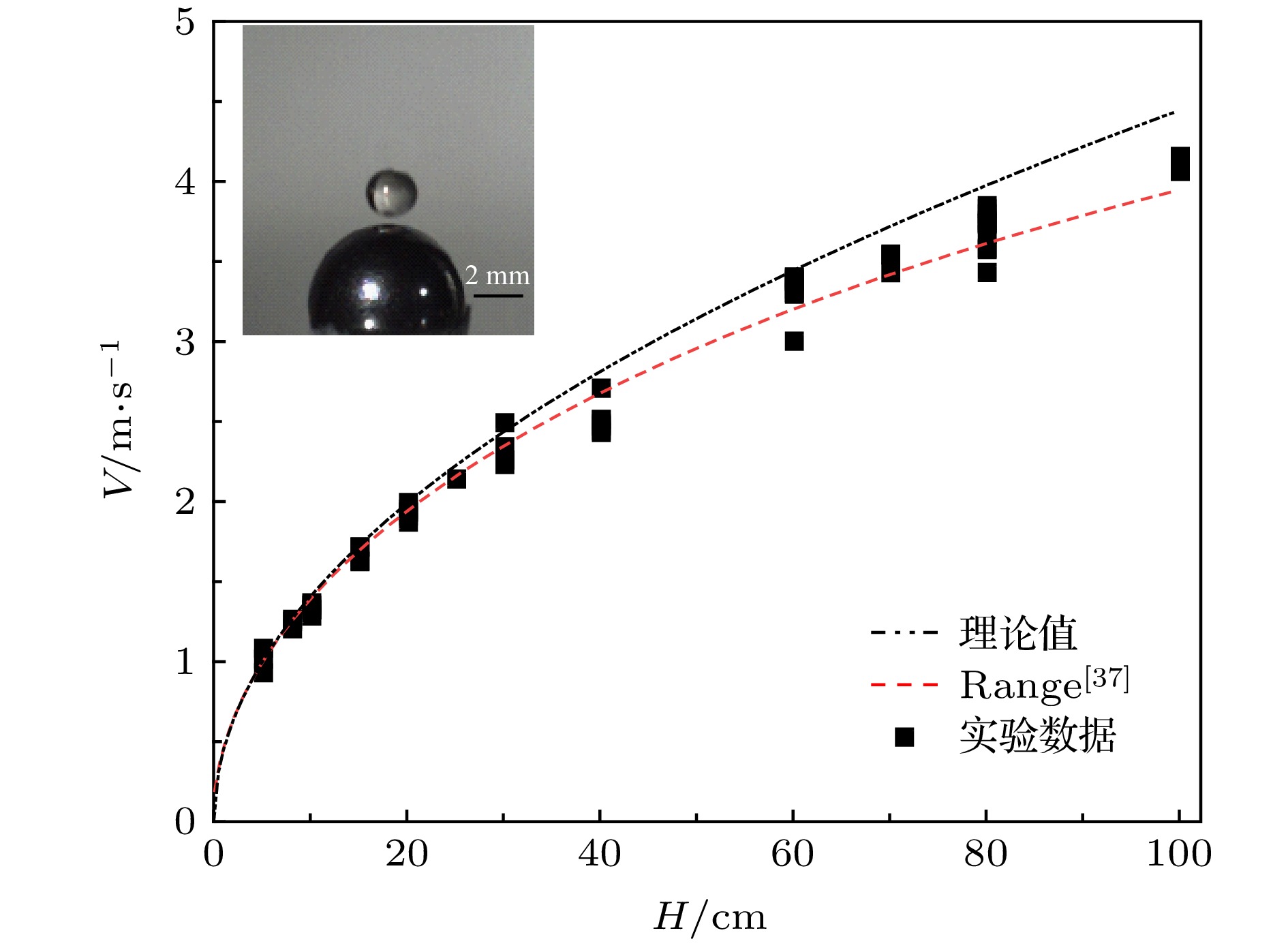

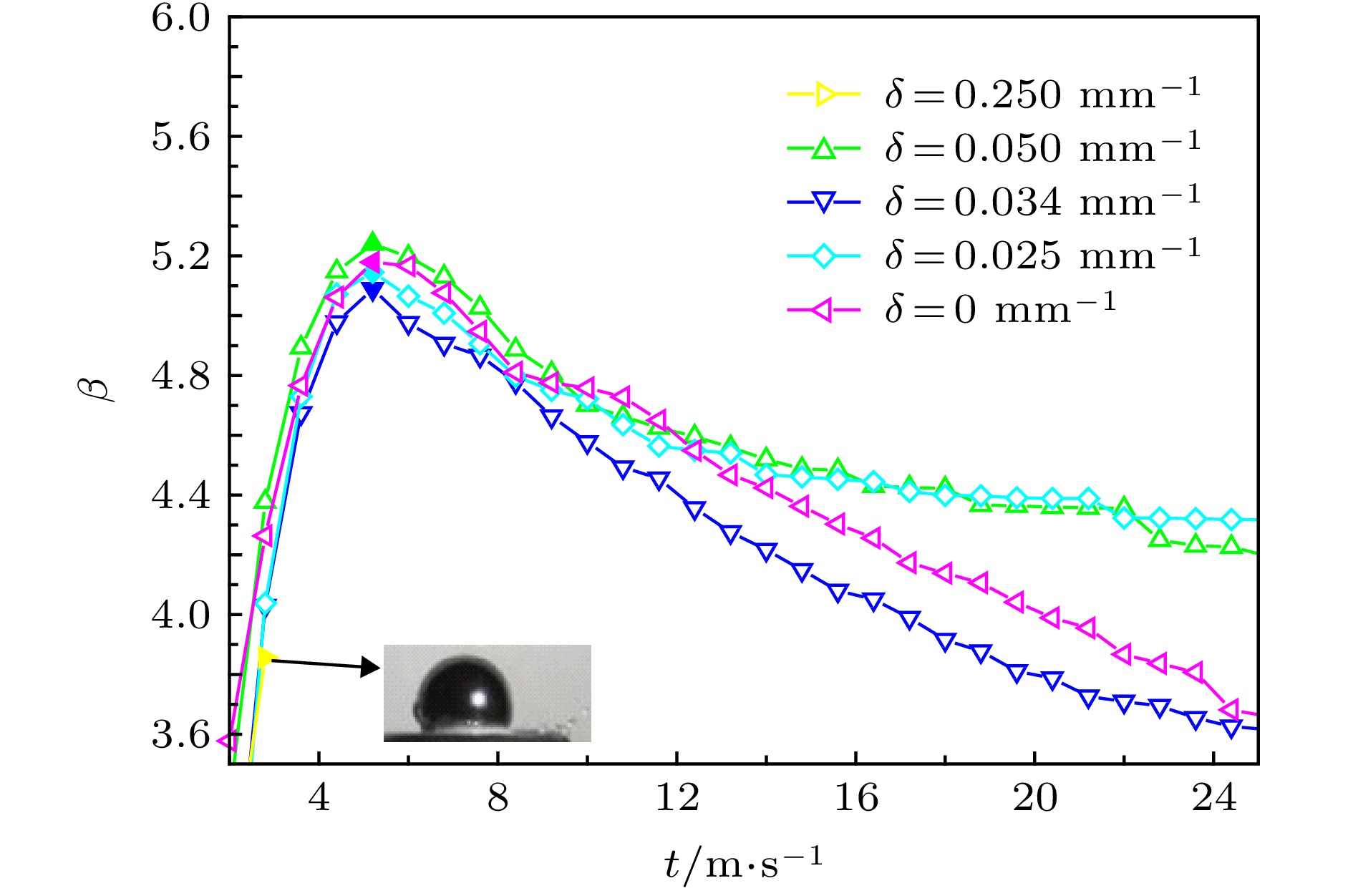

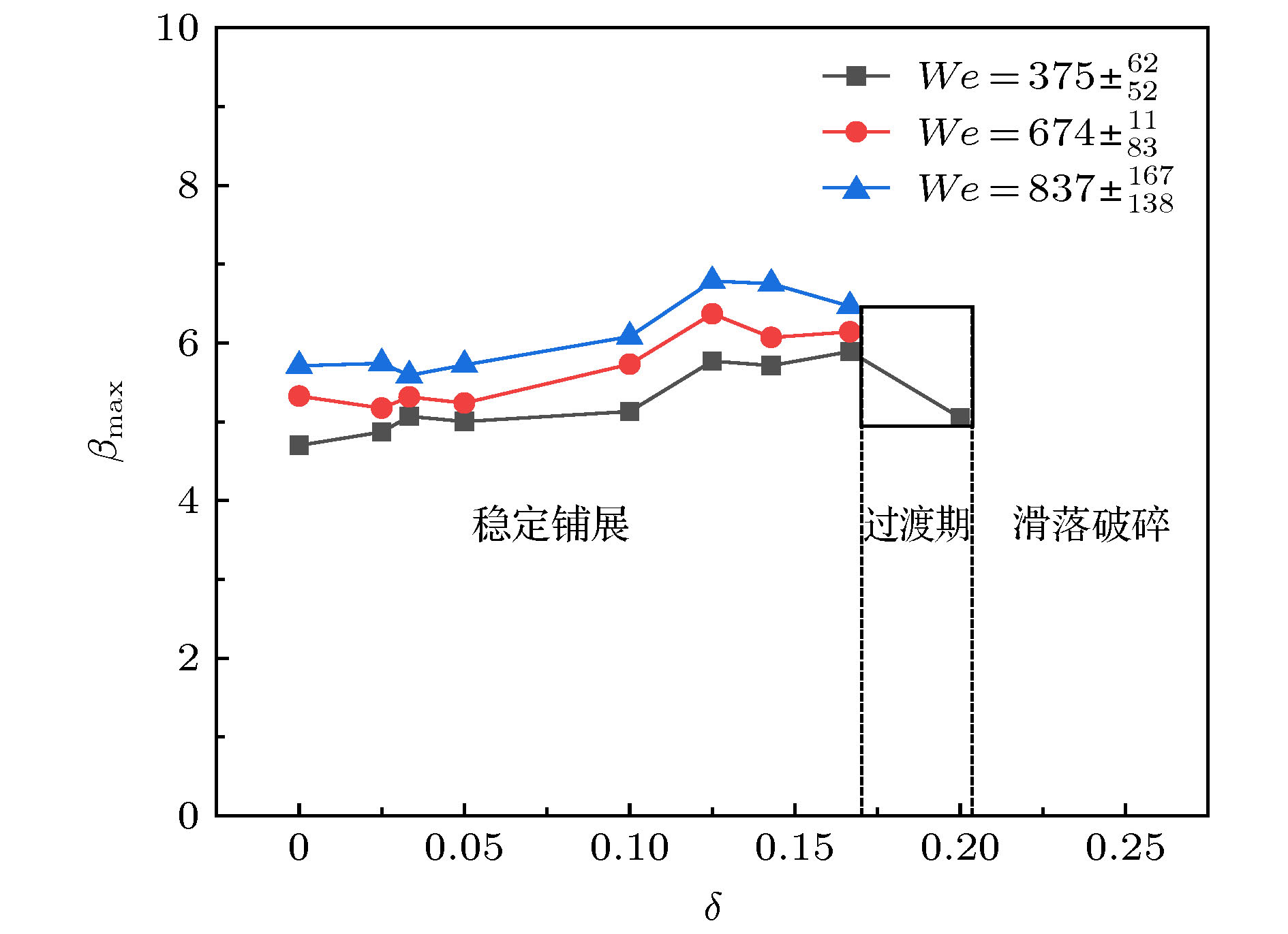

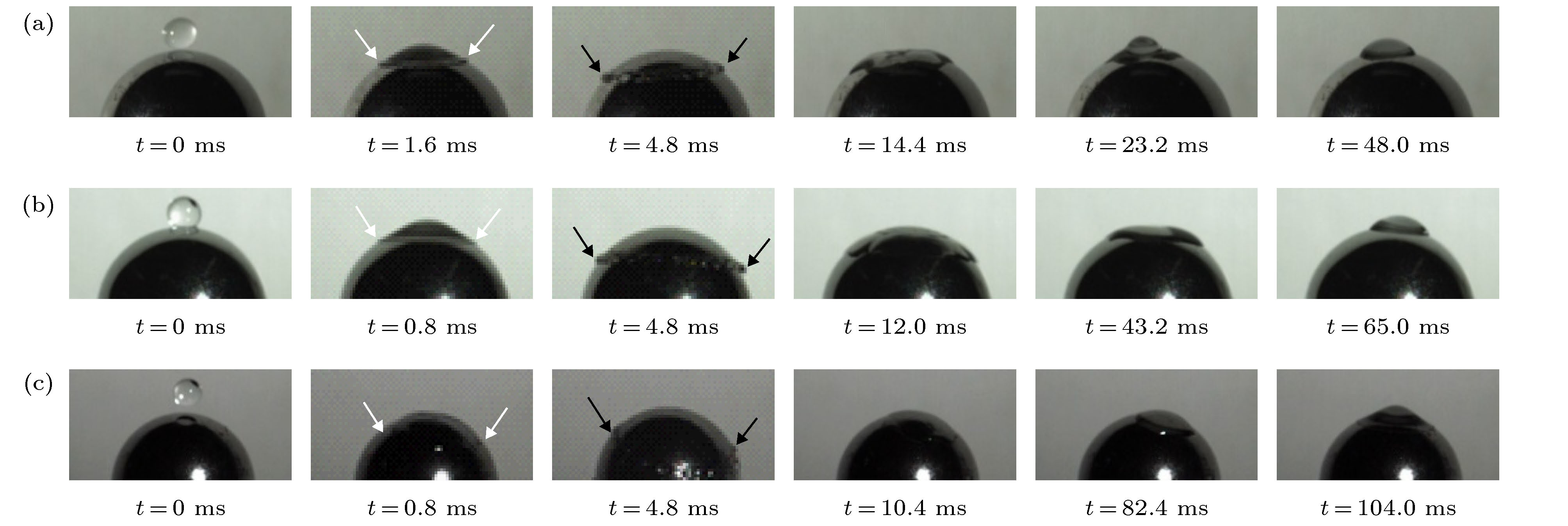

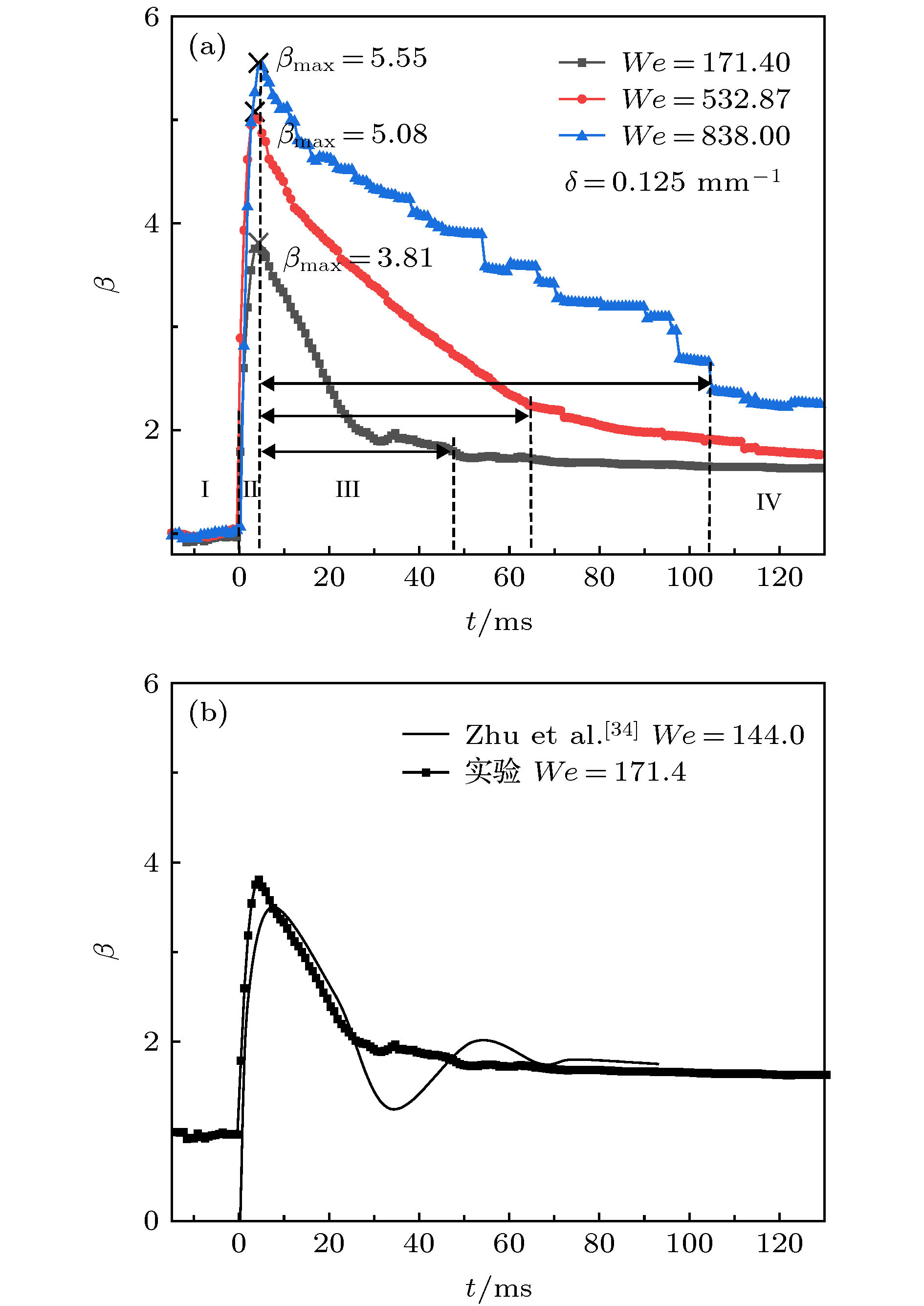

在考虑空气阻力影响, 确定液滴撞击球面速度的基础上, 对较高韦伯数液滴撞击干燥球面动态行为过程进行了实验研究, 分析了球面曲率与韦伯数对液滴撞击行为和铺展因子的影响, 并与前人撞击平面结果进行了对比. 实验表明, 靠近撞击球面时, 液滴降落速度出现明显波动; 球面曲率对液滴撞击后行为影响明显, 曲率较大时, 液滴撞击后铺展液膜会超出球面直径并滑落, 曲率较小时, 液滴撞击后在球面上呈现明显的铺展、回缩、震荡、着附动态变化行为, 此时最大铺展因子受曲率影响小, 随曲率减小, 逐渐趋向于撞击平面时的最大铺展因子; 韦伯数对液膜铺展速率影响较小, 但对液膜回缩时间影响明显, 最大铺展因子随韦伯数增加逐渐增大, 获得的关联式呈指数变化.The phenomenon that droplets impacting on the solid surface is ubiquitous in industrial applications such as spray cooling, spray painting, ink-jet printing, and fuel-air mixing internal combustion engines. The dynamic of droplet impacting on solid surface has been a hot topic in the area of fluid mechanics. Most of the existing experimental studies focused on the droplet impacting on flat or cylinder surface whereas the droplet impacting on a dry sphere surface, especially its effect from the sphere curvature, has been less investigated. Therefore, the dynamic behavior of a droplet impacting normally on a dry sphere is experimentally investigated at the relatively high Reynolds and Weber number in the present work. The impacting velocity of the droplet on the sphere is discussed with consideration of air resistance effect. The influences of spherical curvature and Weber number on the dynamic behavior and spreading factor are analyzed. The experimental results are compared with those of previous impacting flat researches. The results show that the drop velocity fluctuates significantly near the impacting sphere. The influence of the spherical curvature on the dynamic behavior of the droplet impact is obvious. The maximum spreading diameter of the liquid film will exceed that of the sphere with a curvature greater than 0.2 mm–1, and some segments of the liquid film rim even slide down directly. When the spherical curvature is less than 0.167 mm–1, the dynamic behaviors of the impacting droplet will undergo the spread, retraction, oscillation, and stable attachment after impacting. Then the maximum spreading factor of the droplet impacting sphere is little influenced by the curvature, and gradually tends to that of the droplet impacting plane with curvature decreasing. The Weber number has little influence on the spreading velocity of the liquid film, but obvious on the retraction. The maximum spreading factor gradually increases with Weber number increasing. A simple empirical correlation for the maximum spreading factor is obtained. This study conduces significantly to further investigating the dynamic characteristics of droplets impacting on the sphere.

-

Keywords:

- droplet /

- impingement /

- spherical surface /

- hydrodynamics

[1] Hsieh S, Luo S 2016 Int. J. Heat Mass Transfer 92 190

Google Scholar

Google Scholar

[2] Zama Y, Odawara Y, Furuhata T 2017 Fuel 203 757

Google Scholar

Google Scholar

[3] Lim T, Han S, Chung J, Chung J T, Ko S, Grigoropoulos C P 2009 Int. J. Heat Mass Transfer 52 431

Google Scholar

Google Scholar

[4] Gao J, Xu C, Lin S, Yang G, Guo Y 2001 Aiche J. 47 677

Google Scholar

Google Scholar

[5] Nayak S V, Joshi S L, Ranade V V 2005 Chem. Eng. Sci. 60 6049

Google Scholar

Google Scholar

[6] Rein M 1993 Fluid Dyn. Res. 12 61

Google Scholar

Google Scholar

[7] 郭加宏, 戴世强, 代钦 2010 59 2601

Google Scholar

Google Scholar

Guo J H, Dai S Q, Dai Q 2010 Acta Phys. Sin. 59 2601

Google Scholar

Google Scholar

[8] 黄虎, 洪宁, 梁宏, 施保昌, 柴振华 2016 65 084702

Google Scholar

Google Scholar

Huang H, Hong N, Liang H, Shi B C, Chai Z H 2016 Acta Phys. Sin. 65 084702

Google Scholar

Google Scholar

[9] Chandra S, Avedisian C T 1991 P Roy Soc. A-Math. Phy. 432 13

Google Scholar

Google Scholar

[10] 叶学民, 张湘珊, 李明兰, 李春曦 2018 67 184704

Google Scholar

Google Scholar

Ye X M, Zhang X S, Li M L, Li C X 2018 Acta Phys. Sin. 67 184704

Google Scholar

Google Scholar

[11] 丁思源, 王瑞祥, 徐荣吉, 张一灏, 蔡骥驰 2016 化工学报 67 2495

Google Scholar

Google Scholar

Ding S Y, Wang R X, Xu R J, Zhang Y H, Cai J C 2016 J. Chem. Ind. Eng. 67 2495

Google Scholar

Google Scholar

[12] Palacios J, Hernández J, Gómez P, Zanzi C, López J 2013 Exp. Therm. Fluid Sci. 44 571

Google Scholar

Google Scholar

[13] 张彬, 韩强, 袁小芳, 李景银 2013 西安交通大学学报 47 23

Google Scholar

Google Scholar

Zhang B, Han Q, Yuan X F, Li J Y 2013 J. Xi'an Jiaotong Univ. 47 23

Google Scholar

Google Scholar

[14] 姚一娜, 李聪, 陶振翔, 杨锐 2019 清华大学学报(自然科学版) 59 129

Google Scholar

Google Scholar

Yao Y N, Li C, Tao Z, Yang R 2019 J. Tsinghua Univ. (Sci. Technol.) 59 129

Google Scholar

Google Scholar

[15] Vaikuntanathan V, Kannan R, Sivakumar D 2010 Colloids Surf., A 369 65

Google Scholar

Google Scholar

[16] Hu H B, Huang S H, Chen L B 2013 Chin. Phys. B 22 084702

Google Scholar

Google Scholar

[17] 冯伟, 郑刚, 聂万胜 2016 推进技术 37 1136

Google Scholar

Google Scholar

Feng W, Zheng G, Nie W S 2016 J. Propul. Technol. 37 1136

Google Scholar

Google Scholar

[18] 赵宇炜, 杨龙滨, 葛坤, 李彦军 2014 燃烧科学与技术 2014 20

Google Scholar

Google Scholar

Zhao Y W, Yang L B, Ge K, Li Y J 2014 J. Combust. Sci. Technol. 2014 20

Google Scholar

Google Scholar

[19] Xie C, Zhang J, Bertola V, Wang M 2016 J. Colloid Interface Sci. 463 317

Google Scholar

Google Scholar

[20] Khoufech A, Benali M, Saleh K 2015 Powder Technol. 270 599

Google Scholar

Google Scholar

[21] Huang Q, Zhang H 2008 Pet. Sci. 5 62

Google Scholar

Google Scholar

[22] Tang C, Qin M, Weng X, Zhang X, Zhang P, Li J, Huang Z 2017 Int. J. Multiphase Flow 96 56

Google Scholar

Google Scholar

[23] Pasandideh-Fard M, Qiao Y M, Chandra S, Mostaghimi J 1996 Phys. Fluids 8 650

Google Scholar

Google Scholar

[24] Khojasteh D, Kazerooni M, Salarian S, Kamali R 2016 J. Ind. Eng. Chem. 42 1

Google Scholar

Google Scholar

[25] 刘邱祖, 寇子明, 韩振南, 高贵军 2013 62 234701

Google Scholar

Google Scholar

Liu Q Z, Kou Z M, Han Z N, Gao G J 2013 Acta Phys. Sin. 62 234701

Google Scholar

Google Scholar

[26] Sun Z H, Han R J 2008 Chin. Phys. B 17 3185

Google Scholar

Google Scholar

[27] Khojasteh D, Kazerooni N M, Marengo M 2019 J. Ind. Eng. Chem. 71 50

Google Scholar

Google Scholar

[28] 李玉杰, 黄军杰, 肖旭斌 2018 67 184701

Google Scholar

Google Scholar

Li Y J, Huang J J, Xiao X B 2018 Acta Phys. Sin. 67 184701

Google Scholar

Google Scholar

[29] Liu Y, Andrew M, Li J, Yeomans J M, Wang Z 2015 Nat. Commun. 6 1

Google Scholar

Google Scholar

[30] Shamit B, Ilia V R, Cam T 2007 Phys. Fluids 19 032102

Google Scholar

Google Scholar

[31] Liang G, Guo Y, Mu X, Shen S 2014 Exp. Therm. Fluid Sci. 55 150

Google Scholar

Google Scholar

[32] 梁刚涛, 郭亚丽, 沈胜强 2013 62 184703

Google Scholar

Google Scholar

Liang G T, Guo Y L, Shen S Q 2013 Acta Phys. Sin. 62 184703

Google Scholar

Google Scholar

[33] Hardalupas Y, Taylor A M K P, Wilkins J H 1999 Int. J. Heat Fluid Fl. 20 477

Google Scholar

Google Scholar

[34] Zhu Y, Liu H, Mu K, Gao P, Ding H, Lu X 2017 J. Fluid Mech. 82 4

Google Scholar

Google Scholar

[35] Tabakova S, Feuillebois F 2004 J. Colloid Interface Sci. 272 225

Google Scholar

Google Scholar

[36] Rioboo R, Marengo M, Tropea C 2002 Exp. Fluids 33 112

Google Scholar

Google Scholar

[37] Range K, Feuillebois F 1998 J. Colloid Interface Sci. 203 16

Google Scholar

Google Scholar

[38] Huang Y C, Hammitt F G, Yang W J 1973 J. Fluids Eng. 95 276

Google Scholar

Google Scholar

[39] Clanet C, Béguin C, Richard D, Quéré D 1999 J. Fluid Mech. 517 199

Google Scholar

Google Scholar

-

图 6 不同撞击曲率下的动态铺展因子实时分布

$\left( {We = 674 \pm _{83}^{11}, \;Re = 14257 \pm _{1654}^{1025}, \;{V_{{\rm{im}}}} = 3.8{\rm{ m}}/{\rm{s}}} \right)$ Fig. 6. Dynamic spreading factor of droplet impacting on different curvatures

$\left( {We = 674 \pm _{83}^{11},\;Re = 14257 \pm _{1654}^{1025},} \right.$ $\left. {{V_{{\rm{im}}}} = 3.8{\rm{m}}/{\rm{s}}} \right)$ 表 1 撞击壁面结构参数

Table 1. Structure parameters of impacting surface

壁面结构 平面 球形 球形 球形 球形 球形 球形 撞击小球

直径 d/mm∞ 8 16 20 40 60 80 曲率 δ/mm–1 0 0.250 0.125 0.100 0.050 0.034 0.025 -

[1] Hsieh S, Luo S 2016 Int. J. Heat Mass Transfer 92 190

Google Scholar

Google Scholar

[2] Zama Y, Odawara Y, Furuhata T 2017 Fuel 203 757

Google Scholar

Google Scholar

[3] Lim T, Han S, Chung J, Chung J T, Ko S, Grigoropoulos C P 2009 Int. J. Heat Mass Transfer 52 431

Google Scholar

Google Scholar

[4] Gao J, Xu C, Lin S, Yang G, Guo Y 2001 Aiche J. 47 677

Google Scholar

Google Scholar

[5] Nayak S V, Joshi S L, Ranade V V 2005 Chem. Eng. Sci. 60 6049

Google Scholar

Google Scholar

[6] Rein M 1993 Fluid Dyn. Res. 12 61

Google Scholar

Google Scholar

[7] 郭加宏, 戴世强, 代钦 2010 59 2601

Google Scholar

Google Scholar

Guo J H, Dai S Q, Dai Q 2010 Acta Phys. Sin. 59 2601

Google Scholar

Google Scholar

[8] 黄虎, 洪宁, 梁宏, 施保昌, 柴振华 2016 65 084702

Google Scholar

Google Scholar

Huang H, Hong N, Liang H, Shi B C, Chai Z H 2016 Acta Phys. Sin. 65 084702

Google Scholar

Google Scholar

[9] Chandra S, Avedisian C T 1991 P Roy Soc. A-Math. Phy. 432 13

Google Scholar

Google Scholar

[10] 叶学民, 张湘珊, 李明兰, 李春曦 2018 67 184704

Google Scholar

Google Scholar

Ye X M, Zhang X S, Li M L, Li C X 2018 Acta Phys. Sin. 67 184704

Google Scholar

Google Scholar

[11] 丁思源, 王瑞祥, 徐荣吉, 张一灏, 蔡骥驰 2016 化工学报 67 2495

Google Scholar

Google Scholar

Ding S Y, Wang R X, Xu R J, Zhang Y H, Cai J C 2016 J. Chem. Ind. Eng. 67 2495

Google Scholar

Google Scholar

[12] Palacios J, Hernández J, Gómez P, Zanzi C, López J 2013 Exp. Therm. Fluid Sci. 44 571

Google Scholar

Google Scholar

[13] 张彬, 韩强, 袁小芳, 李景银 2013 西安交通大学学报 47 23

Google Scholar

Google Scholar

Zhang B, Han Q, Yuan X F, Li J Y 2013 J. Xi'an Jiaotong Univ. 47 23

Google Scholar

Google Scholar

[14] 姚一娜, 李聪, 陶振翔, 杨锐 2019 清华大学学报(自然科学版) 59 129

Google Scholar

Google Scholar

Yao Y N, Li C, Tao Z, Yang R 2019 J. Tsinghua Univ. (Sci. Technol.) 59 129

Google Scholar

Google Scholar

[15] Vaikuntanathan V, Kannan R, Sivakumar D 2010 Colloids Surf., A 369 65

Google Scholar

Google Scholar

[16] Hu H B, Huang S H, Chen L B 2013 Chin. Phys. B 22 084702

Google Scholar

Google Scholar

[17] 冯伟, 郑刚, 聂万胜 2016 推进技术 37 1136

Google Scholar

Google Scholar

Feng W, Zheng G, Nie W S 2016 J. Propul. Technol. 37 1136

Google Scholar

Google Scholar

[18] 赵宇炜, 杨龙滨, 葛坤, 李彦军 2014 燃烧科学与技术 2014 20

Google Scholar

Google Scholar

Zhao Y W, Yang L B, Ge K, Li Y J 2014 J. Combust. Sci. Technol. 2014 20

Google Scholar

Google Scholar

[19] Xie C, Zhang J, Bertola V, Wang M 2016 J. Colloid Interface Sci. 463 317

Google Scholar

Google Scholar

[20] Khoufech A, Benali M, Saleh K 2015 Powder Technol. 270 599

Google Scholar

Google Scholar

[21] Huang Q, Zhang H 2008 Pet. Sci. 5 62

Google Scholar

Google Scholar

[22] Tang C, Qin M, Weng X, Zhang X, Zhang P, Li J, Huang Z 2017 Int. J. Multiphase Flow 96 56

Google Scholar

Google Scholar

[23] Pasandideh-Fard M, Qiao Y M, Chandra S, Mostaghimi J 1996 Phys. Fluids 8 650

Google Scholar

Google Scholar

[24] Khojasteh D, Kazerooni M, Salarian S, Kamali R 2016 J. Ind. Eng. Chem. 42 1

Google Scholar

Google Scholar

[25] 刘邱祖, 寇子明, 韩振南, 高贵军 2013 62 234701

Google Scholar

Google Scholar

Liu Q Z, Kou Z M, Han Z N, Gao G J 2013 Acta Phys. Sin. 62 234701

Google Scholar

Google Scholar

[26] Sun Z H, Han R J 2008 Chin. Phys. B 17 3185

Google Scholar

Google Scholar

[27] Khojasteh D, Kazerooni N M, Marengo M 2019 J. Ind. Eng. Chem. 71 50

Google Scholar

Google Scholar

[28] 李玉杰, 黄军杰, 肖旭斌 2018 67 184701

Google Scholar

Google Scholar

Li Y J, Huang J J, Xiao X B 2018 Acta Phys. Sin. 67 184701

Google Scholar

Google Scholar

[29] Liu Y, Andrew M, Li J, Yeomans J M, Wang Z 2015 Nat. Commun. 6 1

Google Scholar

Google Scholar

[30] Shamit B, Ilia V R, Cam T 2007 Phys. Fluids 19 032102

Google Scholar

Google Scholar

[31] Liang G, Guo Y, Mu X, Shen S 2014 Exp. Therm. Fluid Sci. 55 150

Google Scholar

Google Scholar

[32] 梁刚涛, 郭亚丽, 沈胜强 2013 62 184703

Google Scholar

Google Scholar

Liang G T, Guo Y L, Shen S Q 2013 Acta Phys. Sin. 62 184703

Google Scholar

Google Scholar

[33] Hardalupas Y, Taylor A M K P, Wilkins J H 1999 Int. J. Heat Fluid Fl. 20 477

Google Scholar

Google Scholar

[34] Zhu Y, Liu H, Mu K, Gao P, Ding H, Lu X 2017 J. Fluid Mech. 82 4

Google Scholar

Google Scholar

[35] Tabakova S, Feuillebois F 2004 J. Colloid Interface Sci. 272 225

Google Scholar

Google Scholar

[36] Rioboo R, Marengo M, Tropea C 2002 Exp. Fluids 33 112

Google Scholar

Google Scholar

[37] Range K, Feuillebois F 1998 J. Colloid Interface Sci. 203 16

Google Scholar

Google Scholar

[38] Huang Y C, Hammitt F G, Yang W J 1973 J. Fluids Eng. 95 276

Google Scholar

Google Scholar

[39] Clanet C, Béguin C, Richard D, Quéré D 1999 J. Fluid Mech. 517 199

Google Scholar

Google Scholar

计量

- 文章访问数: 15921

- PDF下载量: 207

- 被引次数: 0

下载:

下载: