-

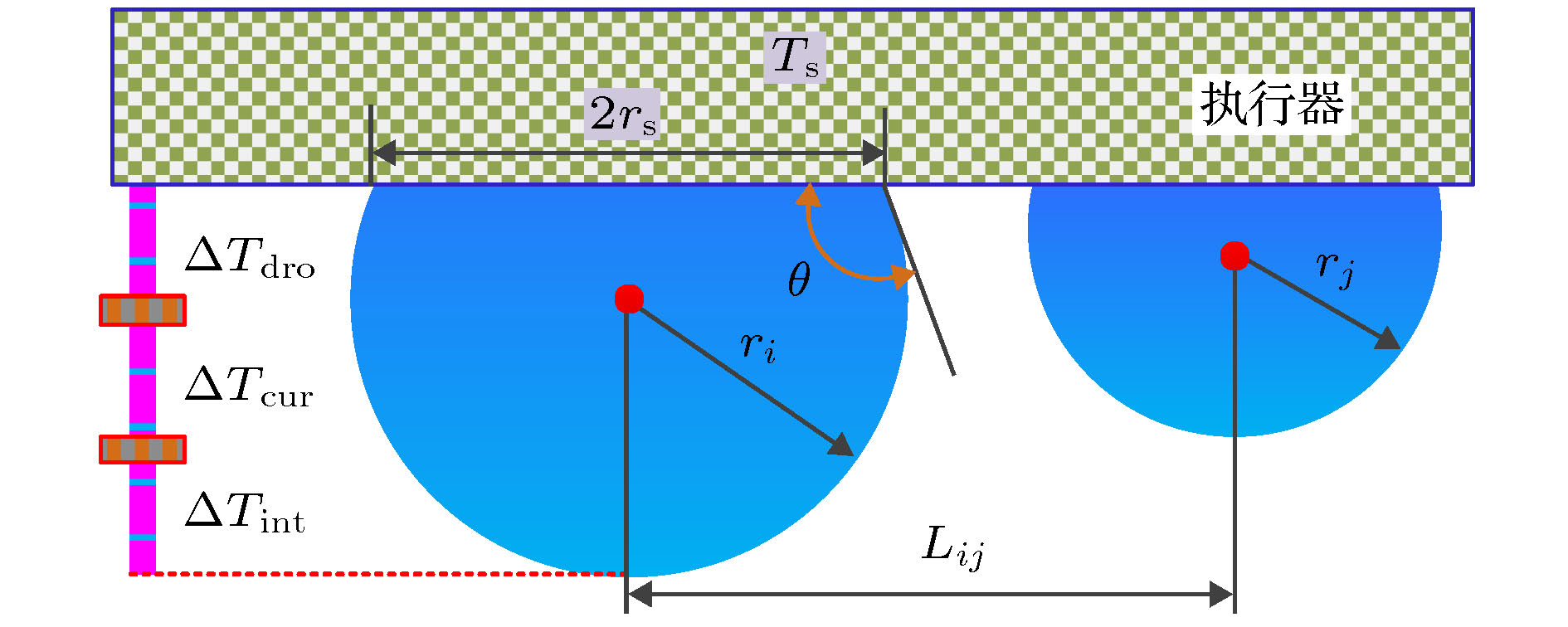

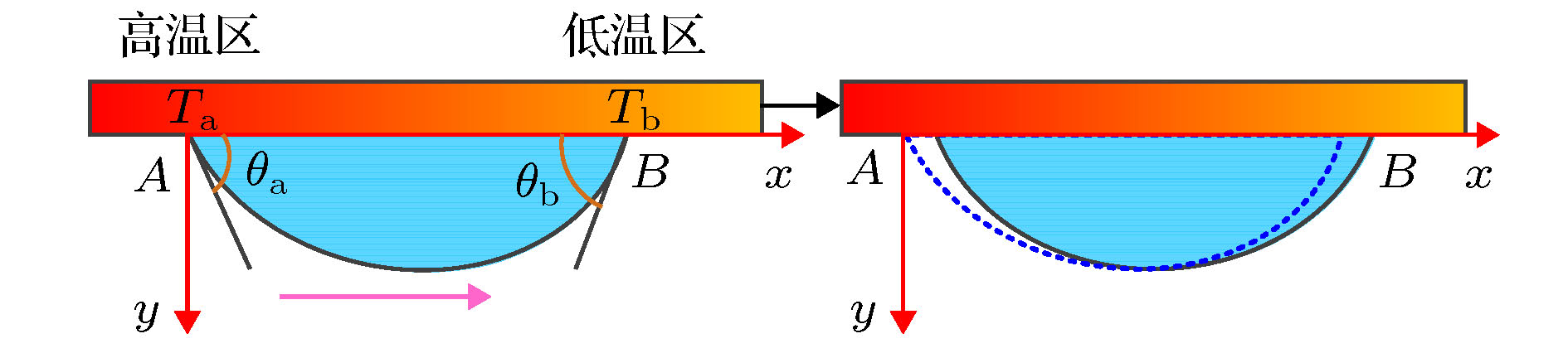

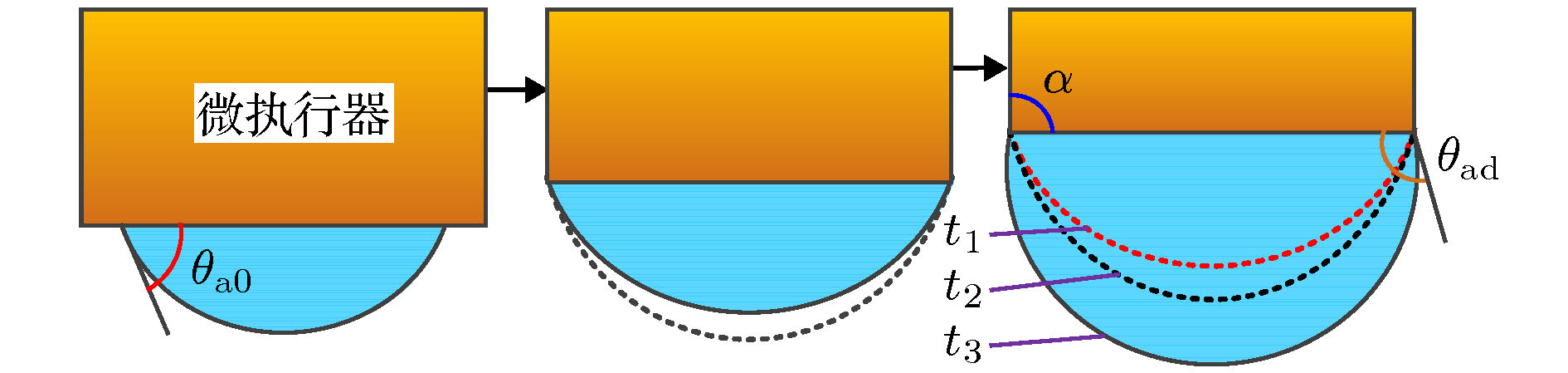

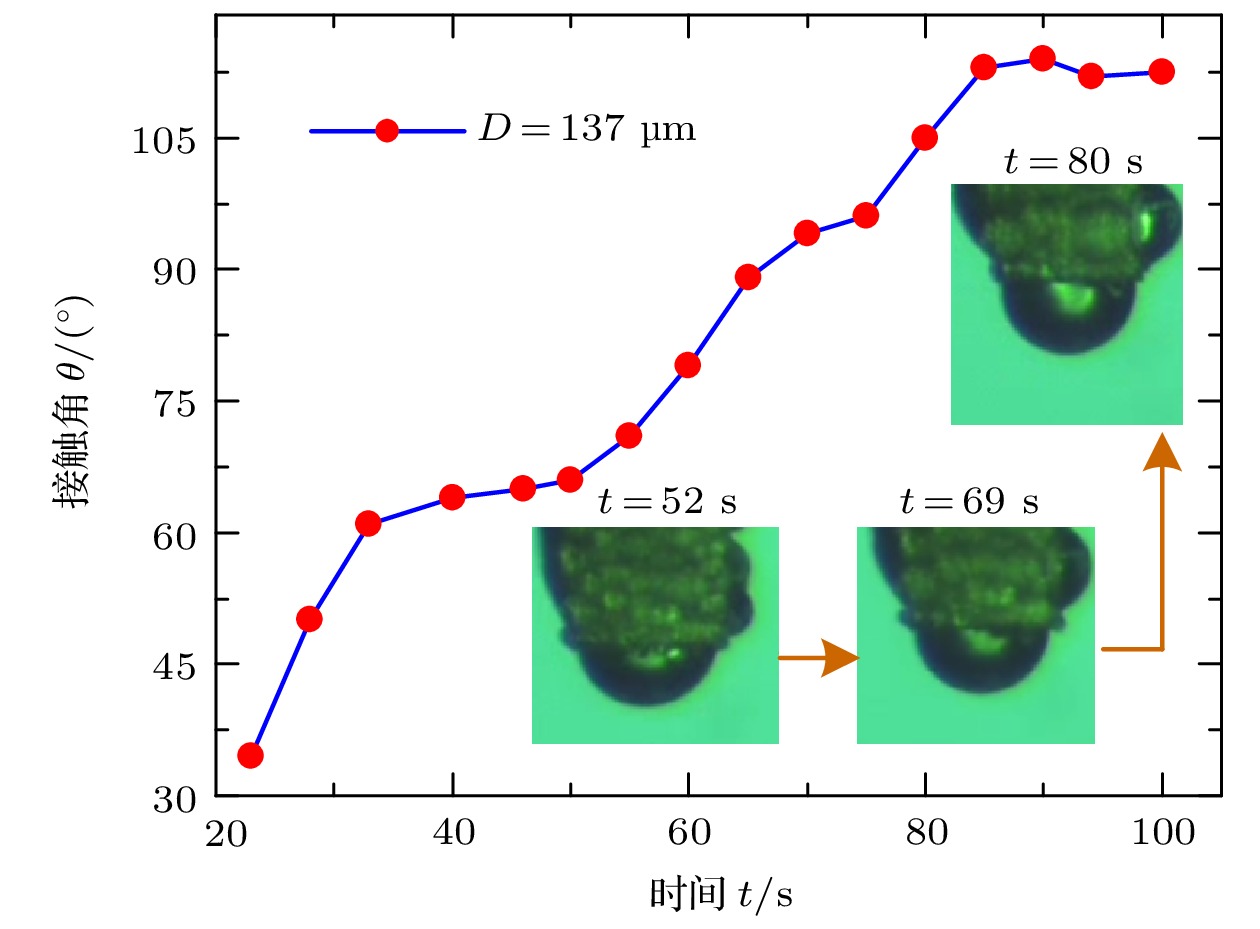

操作液滴是液体介质微操作机器人的先决条件, 研究单指微执行器端面冷凝液滴的迁移特性, 对操作液滴的稳定获取具有重要指导意义. 首先分析基于冷凝液滴的微构件柔顺操作原理, 推导作用于微球上的液桥力方程. 建立单指微执行器端面的冷凝液滴生长模型, 包括单液滴生长、液滴合并、温度诱导和边缘滞后, 分析影响端面冷凝液滴迁移的因素. 直径130—400 μm单指微执行器的端面冷凝实验表明, 冷凝液滴经过生长合并后, 在端面形成单个液滴, 温度梯度和边缘效应会影响所形成液滴的稳定性. 在制冷片表面温度–5 ℃, 环境温度24 ℃, 湿度37%的条件下, 直径400 μm的疏水执行器末端最终获取5.5 nL的液滴, 且固着在端面. 相对于未处理执行器, 疏水处理后的微执行器末端的冷凝液滴更稳定. 实验结果验证了理论分析的有效性.Liquid droplet is a prerequisite for micro-robot based on liquid medium. The investigation of the migration characteristics of condensed droplets on the end surface of a single-finger microgripper is of significance for obtaining stable droplets. The principle of flexible operation for micro-components using droplet condensation is analyzed first. The liquid bridge force acting on a microsphere is derived. A growth model of condensed droplet on the tip of a single-finger microgripper is established, including single-droplet growth, droplet coalesce, droplet movement, and pining effect. Condensation process on the tip of single-finger microgripper with a diameter of 130-400 μm is observed experimentally. Small droplets are formed by directly growing with a big growth rate in the initial stage, then the droplet growth is determined by droplet coalesce. The experimental results show that a single droplet is formed on the end surface after direct growth and droplets coalesce. The maximum droplet volume of 5.5 nL appears on the tip of a single-finger actuator with a diameter of 400 μm under the conditions of surface temperature of –5 °C, room temperature of 24 °C and humidity of 37%. The stability of the formed droplets is dominated by temperature gradients and edge effects during growth process. The distribution of condensed droplets is asymmetric while the microgripper is placed on a cooling surface with temperature gradient. A big growth rate is shown in a low temperature range. A single asymmetric droplet with an offset of 13 μm with respect to the axis of the actuator is formed, which is caused by the temperature gradient. A stable contact angle of 112° is obtained on the end surface of a single-finger microgripper with a diameter of 137 μm because of edge effect using the ambient temperature of 24 °C and humidity of 42%. Condensed droplets located on the end surface of hydrophobic microgripper are more stable than the untreated microgripper. Compared with the droplet formation (0.3 nL) on an untreated microgripper with a diameter of 150 μm, a lager stable droplet of 0.4 nL is obtained on the end face of a small microgripper with a diameter of 130 μm because of the hydrophobic action. The validity of theoretical analysis is verified by experimental results. The experimental investigation of the migration characteristics of condensed droplets on the end surface of a single-finger microgripper shows that the droplet shape can be changed by adjusting the temperature gradient and hydrophilic/hydrophobic performance, which plays an important role in achieving a stable droplet on the end surface.

-

Keywords:

- droplet /

- migration characteristics /

- condensation /

- single-finger microgripper

[1] Yao T, Chisholm N G, Steager E B, Stebe K J 2020 Appl. Phys. Lett. 116 043702

Google Scholar

Google Scholar

[2] Wang K, Gu Z, Liu S, Li J, Xiao S, Song Q 2016 Opt. Lett. 41 555

Google Scholar

Google Scholar

[3] Vasudev A, Zhe J 2008 Appl. Phys. Lett. 93 103503

Google Scholar

Google Scholar

[4] Fantoni G, Hansen H N, Santochi M 2013 CIRP Ann. Manuf. Technol. 62 17

Google Scholar

Google Scholar

[5] Bhushan B, Ling X 2009 J. Colloid Interface Sci. 329 196

Google Scholar

Google Scholar

[6] Wang L F, Chu Z Q, Fan Z H, Rong, W B 2014 Adv. Mater. Res. 971 915

Google Scholar

Google Scholar

[7] Fuchiwaki O, Kumagai K 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems Tokyo, Japan, November 3−7, 2013 p1003

[8] Obata K J, Motokado T, Saito S, Takahashi K 2004 J. Fluid Mech. 498 113

Google Scholar

Google Scholar

[9] Chang B, Zhu Z, Koverola M, Zhou Q 2017 Micromachines 8 361

Google Scholar

Google Scholar

[10] Chang B, Shah A, Routa I, Lipsanen H, Zhou Q 2012 Appl. Phys. Lett. 101 114105

Google Scholar

Google Scholar

[11] Shah A, Chang B, Suihkonen S, Zhou Q, Lipsanen H 2013 J. Microelectromech. Syst. 22 739

Google Scholar

Google Scholar

[12] 张勤, 甘裕明, 黄维军, 青山尚之 2014 机器人 36 430

Google Scholar

Google Scholar

Zhang Q, Gan Y M, Huang W J, Aoyama H 2014 Robot 36 430

Google Scholar

Google Scholar

[13] Ji X, Zhou D, Dai C, Xu J 2019 Int. J. Heat Mass Transfer 132 52

Google Scholar

Google Scholar

[14] 兰忠, 朱霞, 彭本利, 林勐, 马学虎 2012 61 150508

Google Scholar

Google Scholar

Lan Z, Zhu X, Peng B L, Lin M, Ma X H 2012 Acta Phys. Sin. 61 150508

Google Scholar

Google Scholar

[15] 刘天庆, 孙玮, 李香琴, 孙相彧, 艾宏儒 2014 63 086801

Google Scholar

Google Scholar

Liu T Q, Sun W, Li X Q, Sun X Y, Ai H R 2014 Acta Phys. Sin. 63 086801

Google Scholar

Google Scholar

[16] 吴兵兵, 吴化平, 张征, 董晨晨, 柴国钟 2015 64 176801

Google Scholar

Google Scholar

Wu B B, Wu H P, Zhang Z, Dong C C, Chai G Z 2015 Acta Phys. Sin. 64 176801

Google Scholar

Google Scholar

[17] 周建臣, 耿兴国, 林可君, 张永建, 臧渡洋 2014 63 216801

Google Scholar

Google Scholar

Zhou J C, Geng X G, Lin K J, Zhang Y J, Zang D Y 2014 Acta Phys. Sin. 63 216801

Google Scholar

Google Scholar

[18] Fan Z, Rong W, Tian Y, Wei X, Gao J 2019 Appl. Phys. Lett. 114 013703

Google Scholar

Google Scholar

[19] Wang L, Su F, Xu H, Rong W, Xie H 2016 Particuology 27 122

Google Scholar

Google Scholar

[20] Miljkovic N, Enright R, Wang E N 2013 J. Heat Transfer 135 111004

Google Scholar

Google Scholar

[21] Fan Z, Wang L, Rong W, Sun L 2015 Appl. Phys. Lett. 106 084105

Google Scholar

Google Scholar

-

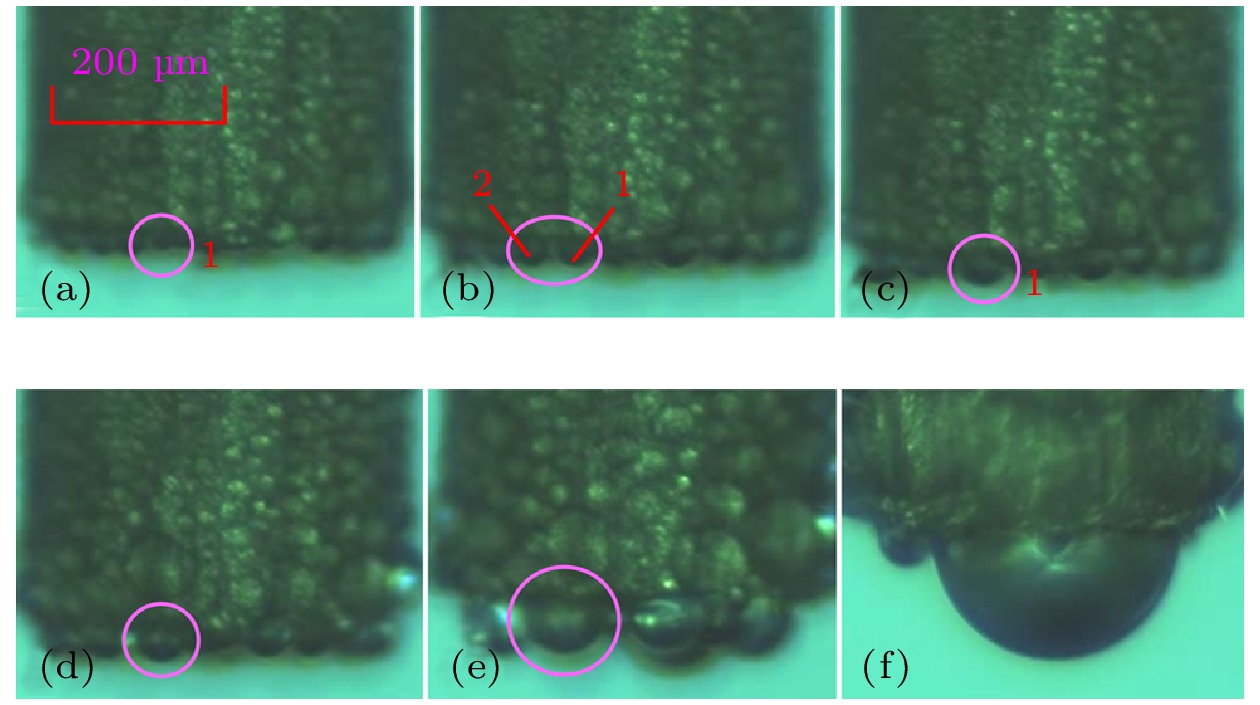

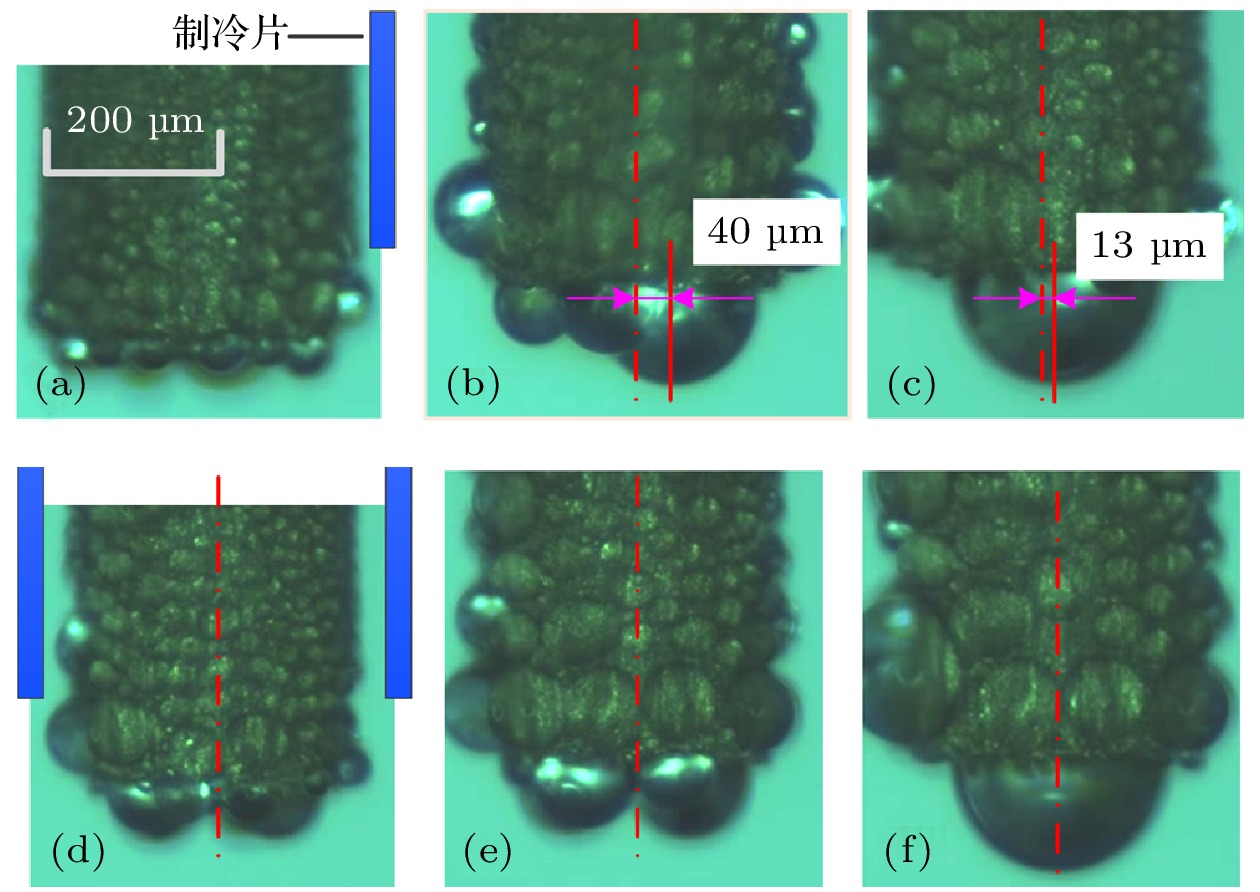

图 7 冷凝进程 (a) 非对称初始生长; (b) 非对称偏移40 μm; (c) 非对称偏移13 μm; (d) 对称初始生长; (e) 对称双液滴; (f) 对称单液滴

Fig. 7. Processes of droplet condensation: (a) Asymmetric growth in the initial stage; (b) 40 μm offset; (c) 13 μm offset; (d) symmetrical growth in the initial stage; (e) two symmetrical droplets; (f) one symmetrical droplet.

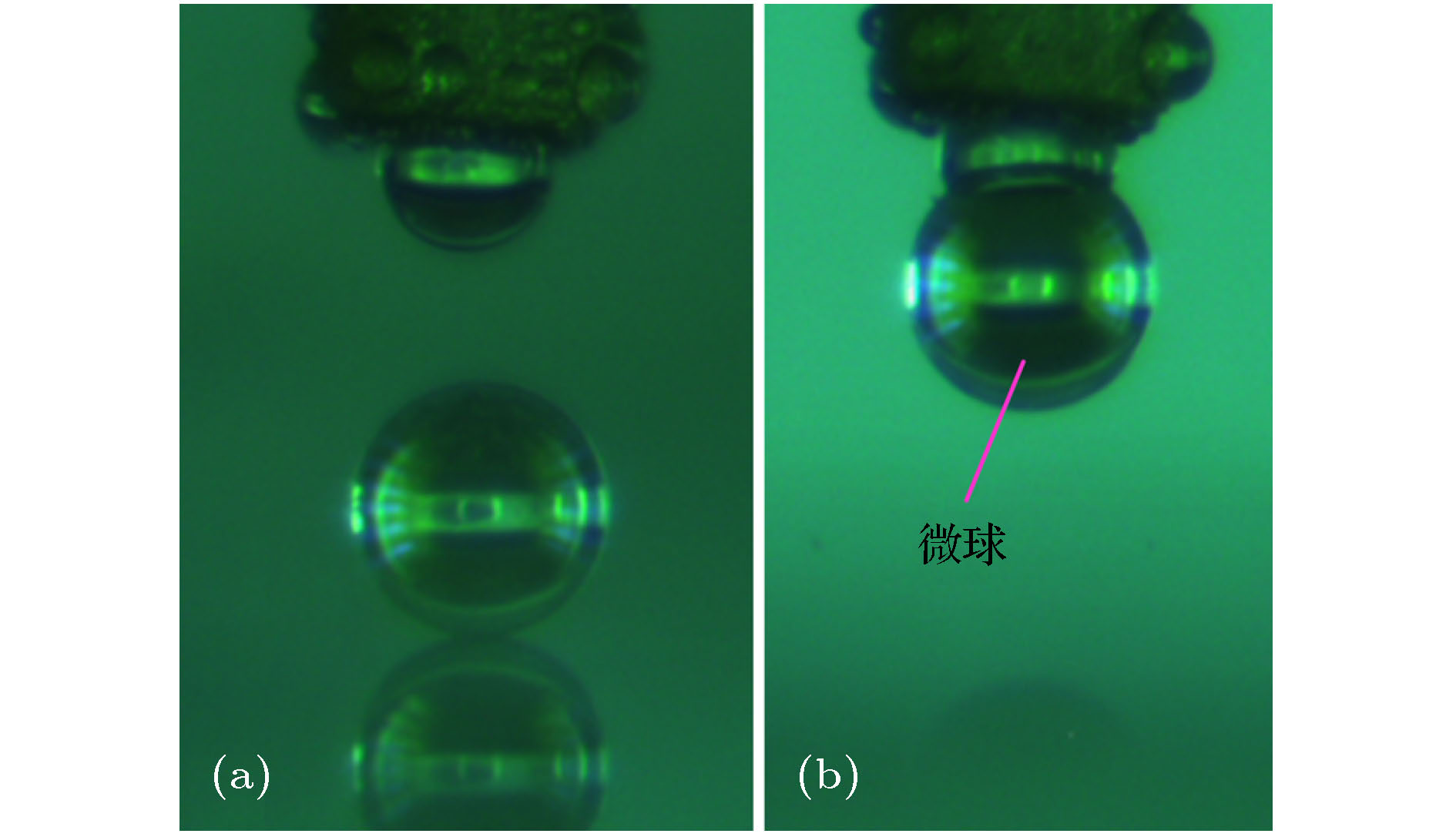

图 9 亲疏水端面冷凝 (a) 未处理端面冷凝; (b) 液滴侧移; (c) 表面微结构; (d) 疏水端面冷凝; (e) 稳定液滴

Fig. 9. Droplet condensation on hydrophilic and hydrophobic surface: (a) Droplet condensation on the hydrophilic surface; (b) droplet sliding; (c) microstructures on hydrophobic surface; (d) and (e) a stable droplet is formed on the hydrophobic surface.

-

[1] Yao T, Chisholm N G, Steager E B, Stebe K J 2020 Appl. Phys. Lett. 116 043702

Google Scholar

Google Scholar

[2] Wang K, Gu Z, Liu S, Li J, Xiao S, Song Q 2016 Opt. Lett. 41 555

Google Scholar

Google Scholar

[3] Vasudev A, Zhe J 2008 Appl. Phys. Lett. 93 103503

Google Scholar

Google Scholar

[4] Fantoni G, Hansen H N, Santochi M 2013 CIRP Ann. Manuf. Technol. 62 17

Google Scholar

Google Scholar

[5] Bhushan B, Ling X 2009 J. Colloid Interface Sci. 329 196

Google Scholar

Google Scholar

[6] Wang L F, Chu Z Q, Fan Z H, Rong, W B 2014 Adv. Mater. Res. 971 915

Google Scholar

Google Scholar

[7] Fuchiwaki O, Kumagai K 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems Tokyo, Japan, November 3−7, 2013 p1003

[8] Obata K J, Motokado T, Saito S, Takahashi K 2004 J. Fluid Mech. 498 113

Google Scholar

Google Scholar

[9] Chang B, Zhu Z, Koverola M, Zhou Q 2017 Micromachines 8 361

Google Scholar

Google Scholar

[10] Chang B, Shah A, Routa I, Lipsanen H, Zhou Q 2012 Appl. Phys. Lett. 101 114105

Google Scholar

Google Scholar

[11] Shah A, Chang B, Suihkonen S, Zhou Q, Lipsanen H 2013 J. Microelectromech. Syst. 22 739

Google Scholar

Google Scholar

[12] 张勤, 甘裕明, 黄维军, 青山尚之 2014 机器人 36 430

Google Scholar

Google Scholar

Zhang Q, Gan Y M, Huang W J, Aoyama H 2014 Robot 36 430

Google Scholar

Google Scholar

[13] Ji X, Zhou D, Dai C, Xu J 2019 Int. J. Heat Mass Transfer 132 52

Google Scholar

Google Scholar

[14] 兰忠, 朱霞, 彭本利, 林勐, 马学虎 2012 61 150508

Google Scholar

Google Scholar

Lan Z, Zhu X, Peng B L, Lin M, Ma X H 2012 Acta Phys. Sin. 61 150508

Google Scholar

Google Scholar

[15] 刘天庆, 孙玮, 李香琴, 孙相彧, 艾宏儒 2014 63 086801

Google Scholar

Google Scholar

Liu T Q, Sun W, Li X Q, Sun X Y, Ai H R 2014 Acta Phys. Sin. 63 086801

Google Scholar

Google Scholar

[16] 吴兵兵, 吴化平, 张征, 董晨晨, 柴国钟 2015 64 176801

Google Scholar

Google Scholar

Wu B B, Wu H P, Zhang Z, Dong C C, Chai G Z 2015 Acta Phys. Sin. 64 176801

Google Scholar

Google Scholar

[17] 周建臣, 耿兴国, 林可君, 张永建, 臧渡洋 2014 63 216801

Google Scholar

Google Scholar

Zhou J C, Geng X G, Lin K J, Zhang Y J, Zang D Y 2014 Acta Phys. Sin. 63 216801

Google Scholar

Google Scholar

[18] Fan Z, Rong W, Tian Y, Wei X, Gao J 2019 Appl. Phys. Lett. 114 013703

Google Scholar

Google Scholar

[19] Wang L, Su F, Xu H, Rong W, Xie H 2016 Particuology 27 122

Google Scholar

Google Scholar

[20] Miljkovic N, Enright R, Wang E N 2013 J. Heat Transfer 135 111004

Google Scholar

Google Scholar

[21] Fan Z, Wang L, Rong W, Sun L 2015 Appl. Phys. Lett. 106 084105

Google Scholar

Google Scholar

计量

- 文章访问数: 7331

- PDF下载量: 75

- 被引次数: 0

下载:

下载: