-

As an emerging material, graphene has become a research hotspot in the field of anti-corrosion because of its excellent chemical inertia and permeability resistance. In this paper, combined with the latest research results, the applications of graphene film and graphene powders in the field of anti-corrosion are discussed more comprehensively. First, the anti-corrosion mechanisms of graphene (mainly including barrier effect, shielding effect, corrosion inhibition synergy, enhancement of coating adhesion, cathodic protection, and self-healing effect) and its corresponding coating preparation methods (graphene film prepared by chemical vapor deposition method and composite coatings prepared with graphene powders) are introduced. Then, the influences of different factors such as defects, conductivity, oxidation degree, flake size, and content of graphene on the anti-corrosion performance are discussed. Finally, various methods are comprehensively compared with each other, and future development is prospected. This paper not only reviews the existing work, but also has a certain reference value for preparing graphene materials with better corrosion resistance in the future.

-

Keywords:

- graphene /

- coating /

- metals /

- anti-corrosion

[1] Pan H 2018 MATEC Web. Conf. 207 03010

Google Scholar

Google Scholar

[2] Ma L W, Ren C H, Wang J K, Liu T, Yang H, Wang Y J, Huang Y, Zhang D W 2020 Chem. Eng. J. DOI: 10.1016/j.cej.2020.127854Google Scholar

[3] Sadawy M, Saad S, Abdel-Karim R 2020 Trans. Nonferrous Met. Soc. China 30 2067

Google Scholar

Google Scholar

[4] Glover C F, Cain T W, Scully J R 2019 Corros. Sci. 149 195

Google Scholar

Google Scholar

[5] Tasic Z Z, Mihajlovic M B P, Radovanovic M B, Simonovic A T, Antonijevic M M 2018 J. Mol. Struct. 1159 46

Google Scholar

Google Scholar

[6] Qiang Y J, Zhang S T, Xu S Y, Li W P 2016 J. Colloid Interface Sci. 472 52

Google Scholar

Google Scholar

[7] Peng T Y, Xiao R H, Rong Z Y, Liu H B, Hu Q Y, Wang S H, Li X, Zhang J M 2020 Chem. Asian J. 15 3915

Google Scholar

Google Scholar

[8] Tang H Y, Qu Z P, Wang L, Ye H Y, Fan X J, Zhang G Q 2019 Phys. Chem. Chem. Phys. 21 18179

Google Scholar

Google Scholar

[9] Suleiman R K 2019 J. Adhes. Sci. Technol. 34 1

Google Scholar

Google Scholar

[10] Huang H W, Sheng X X, Tian Y Q, Zhang L, Chen Y, Zhang X Y 2020 Ind. Eng. Chem. Res. 59 15424

Google Scholar

Google Scholar

[11] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[12] Kyhl L, Nielsen S F, Cabo A G, Cassidy A, Miwa J A, Hornekaer L 2015 Faraday Discuss. 180 495

Google Scholar

Google Scholar

[13] Wang M, Tang M, Chen S, Ci H, Wang K, Shi L, Lin L, Ren H, Shan J, Gao P 2017 Adv. Mater. 29 1703882

Google Scholar

Google Scholar

[14] Ding R, Li W H, Wang X, Gui T J, Li B J, Han P, Tian H W, Liu A, Wang X, Liu X J, Gao X, Wang W, Song L Y 2018 J. Alloys Compd. 764 1039

Google Scholar

Google Scholar

[15] Krishnan M A, Aneja K S, Shaikh A, Bohm S, Raja V S 2018 RSC Adv. 8 499

Google Scholar

Google Scholar

[16] Chauhan D S, Quraishi M A, Ansari K R, Saleh T A 2020 Prog. Org. Coat. 147 105741

Google Scholar

Google Scholar

[17] Ollik K, Lieder M 2020 Coatings 10 883

Google Scholar

Google Scholar

[18] Lin Y T, Don T M, Wong C J, Meng F C, Lin Y J, Lee S Y, Lee C F, Chiu W Y 2019 Surf. Coat. Technol. 374 1128

Google Scholar

Google Scholar

[19] Parhizkar N, Shahrabi T, Ramezanzadeh B 2017 Corros. Sci. 123 55

Google Scholar

Google Scholar

[20] Ding R, Wang X, Jiang J, Gui T, Li W 2017 J. Mater. Eng. Perform. 764 3319

Google Scholar

Google Scholar

[21] Xiong L, Liu J, Li Y, Li S, Yu M 2019 Prog. Org. Coat. 135 228

Google Scholar

Google Scholar

[22] Qing F, Shen C, Jia R, Zhan L, Li X 2017 MRS Bull. 42 819

Google Scholar

Google Scholar

[23] Li X S, Cai W W, An J H, Kim S, Nah J, Yang D X, Piner R, Velamakanni A, Jung I, Tutuc E, Banerjee S K, Colombo L, Ruoff R S 2009 Science 324 1312

Google Scholar

Google Scholar

[24] Chen S S, Brown L, Levendorf M, Cai W W, Ju S Y, Edgeworth J, Li X S, Magnuson C W, Velamakanni A, Piner R D, Kang J Y, Park J, Ruoff R S 2011 ACS Nano 5 1321

Google Scholar

Google Scholar

[25] Kirkland N T, Schiller T, Medhekar N, Birbilis N 2012 Corros. Sci. 56 1

Google Scholar

Google Scholar

[26] Pu N W, Shi G N, Liu Y M, Sun X, Chang J K, Sun C L, Ger M D, Chen C Y, Wang P C, Peng Y Y 2015 J. Power Sources 282 248

Google Scholar

Google Scholar

[27] Zhu M, Du Z, Yin Z, Zhou W, Liu Z 2016 ACS Appl. Mater. Interfaces 8 502

Google Scholar

Google Scholar

[28] 张晓波, 青芳竹, 李雪松 2019 68 096801

Google Scholar

Google Scholar

Zhang X B, Qing F Z, Li X S 2019 Acta Phys. Sin. 68 096801

Google Scholar

Google Scholar

[29] Zheng Z, Liu Y, Bai Y, Zhang J, Han Z, Ren L 2016 Colloids Surf., A 500 64

Google Scholar

Google Scholar

[30] Yang S, Zhu S, Hong R 2020 Coatings 10 1215

Google Scholar

Google Scholar

[31] Xu H, Zang J, Yuan Y, Tian P, Wang Y 2019 Appl. Surf. Sci. 492 199

Google Scholar

Google Scholar

[32] Xiao F, Qian C, Guo M, Wang J, Yan X, Li H, Yue L 2018 Prog. Org. Coat. 125 79

Google Scholar

Google Scholar

[33] He W T, Zhu L Q, Chen H N, Nan H Y, Li W P, Liu H C, Wang Y 2013 Appl. Surf. Sci. 279 416

Google Scholar

Google Scholar

[34] Szeptycka B, Gajewska-Midzialek A, Babul T 2016 J. Mater. Eng. Perform. 25 3134

Google Scholar

Google Scholar

[35] Feng L, Zhang S T, Qiang Y J, Xu Y, Guo L, Madkour L H, Chen S J 2018 Materials 11 1042

Google Scholar

Google Scholar

[36] Bokati K S, Dehghanian C 2018 J. Environ. Chem. Eng. 6 1613

Google Scholar

Google Scholar

[37] Guo L, Obot I B, Zheng X W, Shen X, Qiang Y J, Kaya S, Kaya C 2017 Appl. Surf. Sci. 406 301

Google Scholar

Google Scholar

[38] Hippolyte C N, Serge B Y, Didier D G, Juan C, Albert T 2018 Int. J. Biol. Chem. Sci. 12 1008

Google Scholar

Google Scholar

[39] Cen H, Chen Z 2021 Colloids Surf., A. 615 126216

Google Scholar

Google Scholar

[40] Baig N, Chauhan D S, Saleh T A, Quraishi M A 2019 New J. Chem. 43 2328

Google Scholar

Google Scholar

[41] Zhao D, Wang M, Xu Y, Zhang Z, Ge X 2014 Surf. Coat. Technol. 238 15

Google Scholar

Google Scholar

[42] Ye Y, Chen H, Zou Y, Ye Y, Zhao H 2020 Corros. Sci. 174 108825

Google Scholar

Google Scholar

[43] Kasaeian M, Ghasemi E, Ramezanzadeh B, Mahdavian M, Bahlakeh G 2018 Corros. Sci. 145 119

Google Scholar

Google Scholar

[44] Cui G, Bi Z, Zhang R, Liu J, Yu X, Li Z 2019 Chem. Eng. J. 373 104

Google Scholar

Google Scholar

[45] Banhart F, Kotakoski J, Krasheninnikov A V 2011 ACS Nano 5 26

Google Scholar

Google Scholar

[46] Rhodes D, Chae S H, Ribeiro-Palau R, Hone J 2019 Nat. Mater. 18 541

Google Scholar

Google Scholar

[47] Hong J, Lee J B, Lee S, Seo J, Lee H, Park J Y, Ahn J H, Il Seo T, Lee T, Lee H B R 2016 NPG Asia Mater. 8 e262

Google Scholar

Google Scholar

[48] Ji D, Wen X, Foller T, You Y, Joshi R 2020 Nanomaterials 10 2511

Google Scholar

Google Scholar

[49] Prasai D, Tuberquia J C, Harl R R, Jennings G K, Bolotin K I 2012 ACS Nano 6 1102

Google Scholar

Google Scholar

[50] Zhou F, Li Z T, Shenoy G J, Li L, Liu H T 2013 ACS Nano 7 6939

Google Scholar

Google Scholar

[51] Hsieh Y P, Hofmann M, Chang K W, Jhu J G, Li Y Y, Chen K Y, Yang C C, Chang W S, Chen L C 2014 ACS Nano 8 443

Google Scholar

Google Scholar

[52] Zhao Z, Hou T, Wu N, Jiao S, Zhou K, Yin J, Suk J, Cui X, Zhang M, Li S, Qu Y, Xie W, Li X B, Zhao C, Fu Y, Hong R D, Guo S, Lin D, Cai W, Mai W, Luo Z, Tian Y, Lai Y, Liu Y, Colombo L, Hao Y 2021 Nano Lett. 21 1161

Google Scholar

Google Scholar

[53] Liu T, Zhao H C, Mao F X, Li J Y 2019 Mater. Res. Express 6 125619

Google Scholar

Google Scholar

[54] Jun Y S, Sy S, Ahn W, Zarrin H, Rasen L, Tjandra R, Amoli B M, Zhao B X, Chiu G, Yu A P 2015 Carbon 95 653

Google Scholar

Google Scholar

[55] Guerrero-Contreras J, Caballero-Briones F 2015 Mater. Chem. Phys. 153 209

Google Scholar

Google Scholar

[56] Krishnamoorthy K, Veerapandian M, Yun K, Kim S J 2013 Carbon 53 38

Google Scholar

Google Scholar

[57] Sato J, Higurashi K, Fukuda K, Sugimoto W 2011 Electrochemistry 79 337

Google Scholar

Google Scholar

[58] Ramezanzadeh B, Bahlakeh G, Moghadam M H M, Miraftab R 2018 Chem. Eng. J. 335 737

Google Scholar

Google Scholar

[59] Um J G, Jun Y S, Alhumade H, Krithivasan H, Lui G, Yu A P 2018 RSC Adv. 8 17091

Google Scholar

Google Scholar

[60] Liao Z J, Zhang T C, Qiao S, Zhang L Y H 2017 Environ. Mater. Sci. 94 012072

Google Scholar

Google Scholar

[61] Cai K W, Zuo S X, Luo S P, Yao C, Liu W J, Ma J F, Mao H H, Li Z Y 2016 RSC Adv. 6 95965

Google Scholar

Google Scholar

[62] Kumar C S, Sumitesh D 2017 J. Nanosci. Nanotechnol. 17 2130

Google Scholar

Google Scholar

[63] Gupta R K, Malviya M, Ansari K R, Lgaz H, Quraishi M A 2019 Mater. Chem. Phys. 236 121727

Google Scholar

Google Scholar

[64] Haruna K, Saleh T A, Obot I B, Umoren S A 2019 Prog. Org. Coat. 128 157

Google Scholar

Google Scholar

[65] Du P, Wang J, Zhao H, Liu G, Wang L 2019 Dalton Trans. 48 13064

Google Scholar

Google Scholar

[66] Zhang Z, Qi J, Zhao M, Shang N, Cheng Y, Qiao R, Zhang Z, Ding M, Li X, Liu K, Xu X, Liu K, Liu C, Wu M 2020 Chin. Phys. Lett. 37 108101

Google Scholar

Google Scholar

[67] Wang Y, Qing F, Jia Y, Duan Y, Shen C, Hou Y, Niu Y, Shi H, Li X 2021 Chem. Eng. J. 405 127014

Google Scholar

Google Scholar

[68] 孙垚垚, 宋家乐, 郑斌, 曾煜, 胡颖, 李炜光 2021 无机盐工业 https://kns.cnki.net/kcms/detail/12.1069.TQ.20210129.1525.006.html

Sun Y Y, Sun J L, Zheng B, Zeng Y, Hu Y, Li W G 2021 Inorg. Chem. Ind.

[69] Yang X B, Cui D W, Qu Y 2017 Electron. Compon. Mater. 36 83

Google Scholar

Google Scholar

-

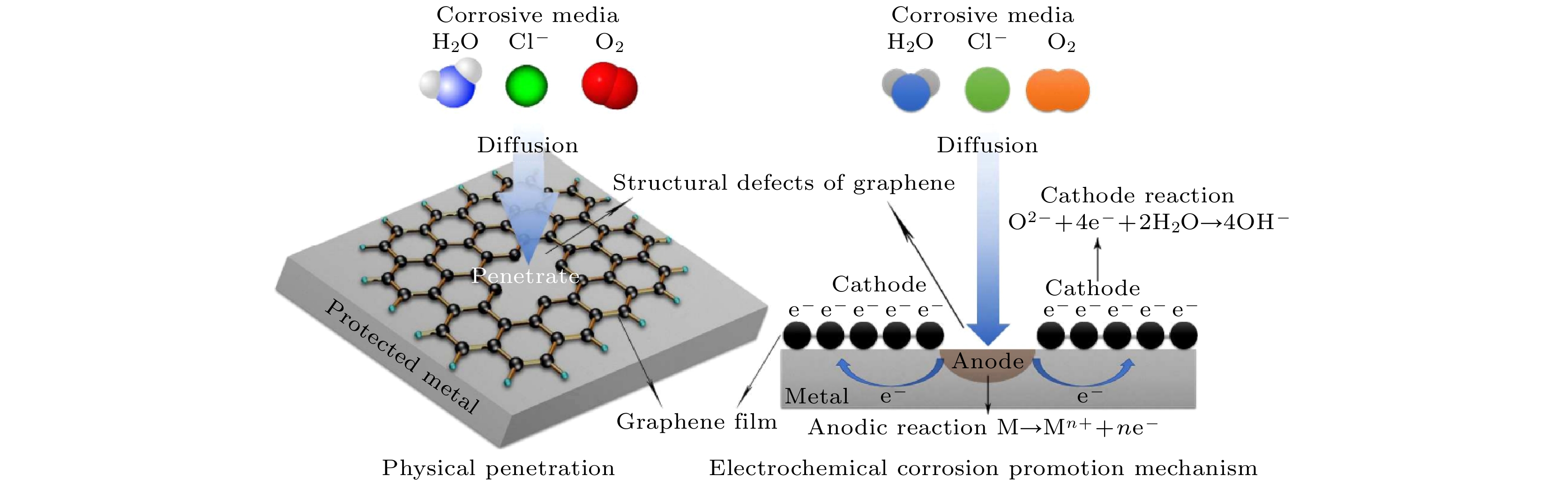

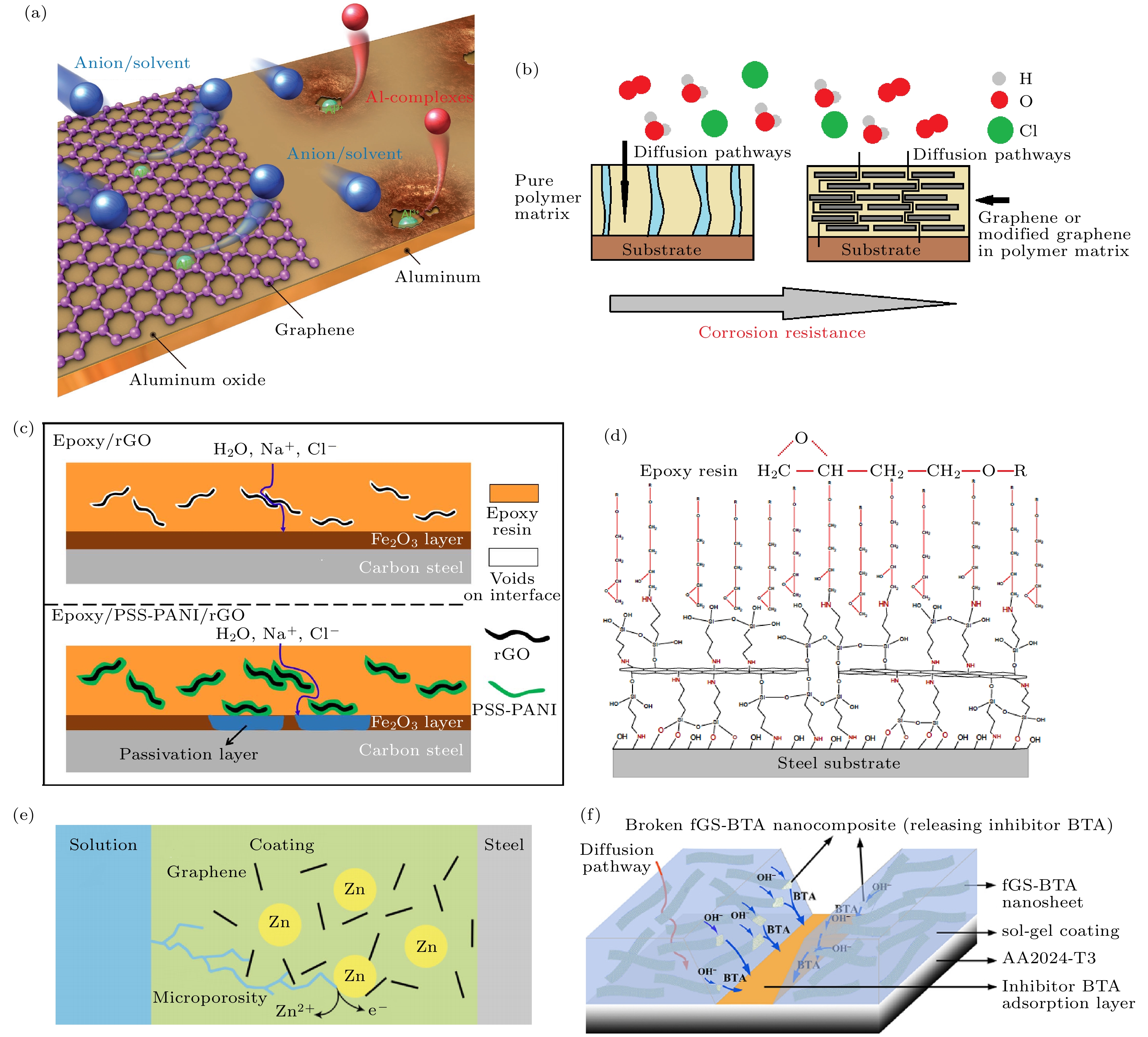

图 1 石墨烯防腐作用机理 (a) 阻隔作用[13]; (b) 屏蔽作用[17]; (c) 缓蚀作用[18]; (d) 加固作用[19]; (e) 阴极保护作用[20]; (f) 自修复作用[21]

Figure 1. Anticorrosion mechanism of graphene: (a) Barrier effect[13]; (b) shielding effect[17]; (c) corrosion inhibition synergy[18]; (d) enhancement of coating adhesion[19]; (e) cathodic protection[20]; (f) self-healing effect[21].

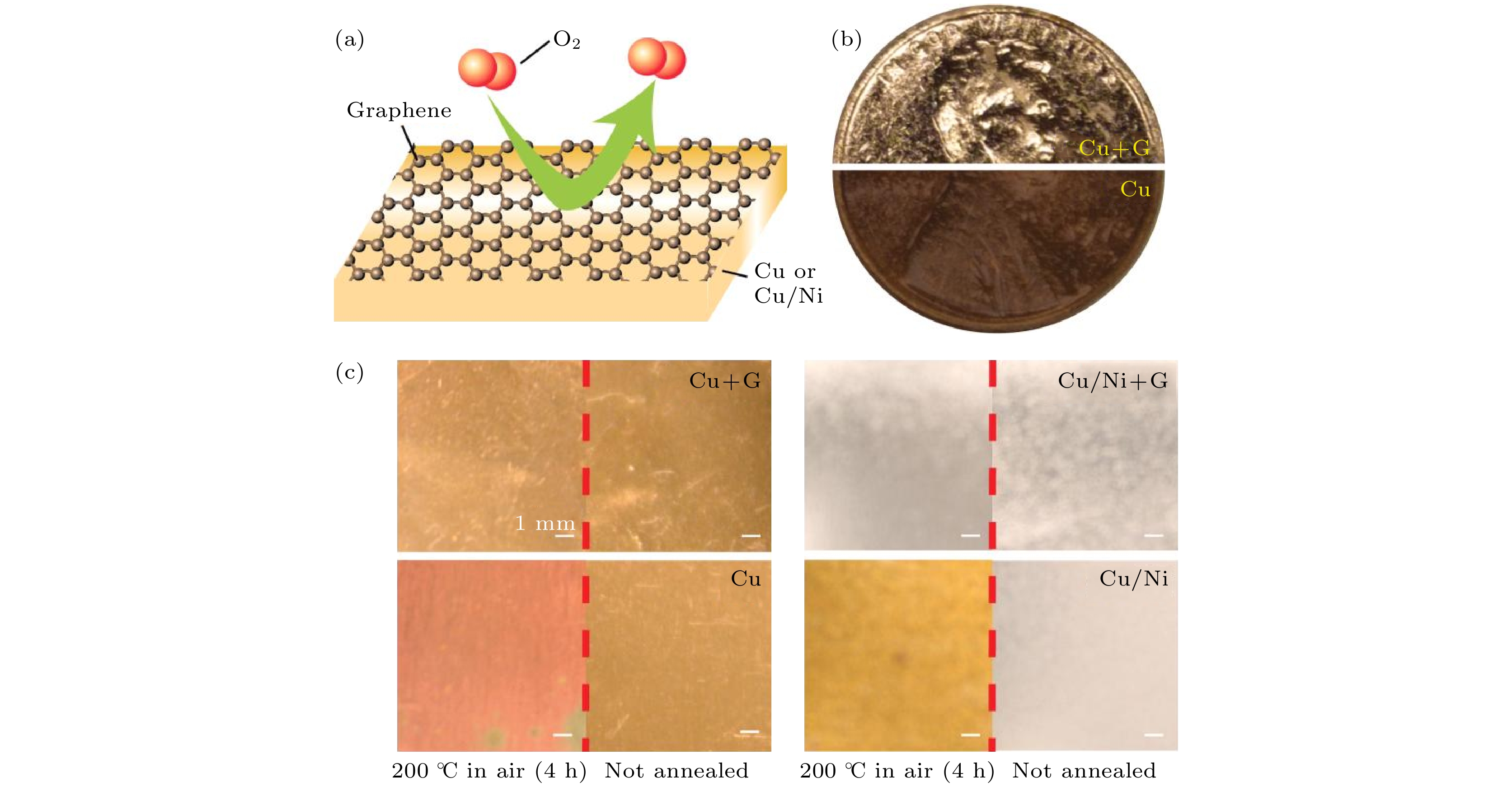

图 2 CVD石墨烯防腐性能[24] (a) 石墨烯作为化学惰性扩散阻挡层示意图; (b) 硬币经过H2O2浸泡(30%, 2 min)后的照片; (c) 带有和不带有石墨烯涂层的铜和铜镍合金在空气中退火(200 °C, 4 h)的照片

Figure 2. Performance of CVD graphene as an anticorrosion layer[24]: (a) Schematics of graphene as a chemically inert diffusion barrier; (b) photograph showing graphene coated (upper) and uncoated (lower) penny after H2O2 treatment (30%, 2 min); (c) photographs of Cu and Cu/Ni foils with and without graphene coating taken before and after annealing in air (200 °C, 4 h).

图 10 在单层石墨烯(SLG)和多层石墨烯(FLG)中进行分子扩散的原子尺度模拟示意图[52] (a) 水分子在有缺陷的SLG中扩散需要的能量和示意图; (b) 氧气和水分子等物质易在SLG中扩散并使Cu表面氧化的情况示意图; (c) 水分子在有缺陷的双层石墨烯(BLG)中扩散需要的能量和示意图; (d) 示意图显示即使三层石墨烯包含多个晶界(GB)缺陷, 氧气和水分子也难以穿过多晶三层石墨烯并与下面的Cu表面接触

Figure 10. Atomic-scale simulations of molecular diffusion through SLG and FLG[52]: (a) Schematics and the calculated energy barrier for a water molecule to diffuse through a defective SLG; (b) schematic showing the easiness of reactive species such as oxygen and water molecules to diffuse through SLG and oxidize the Cu surface; (c) schematics and the calculated energy barrier for a water molecule to diffuse through a defective BLG; (d) schematic showing the difficulties for oxygen and water molecules to diffuse through polycrystalline trilayer graphene and contact with the underlying Cu surface, even when the trilayer graphene contains multiple GB defects.

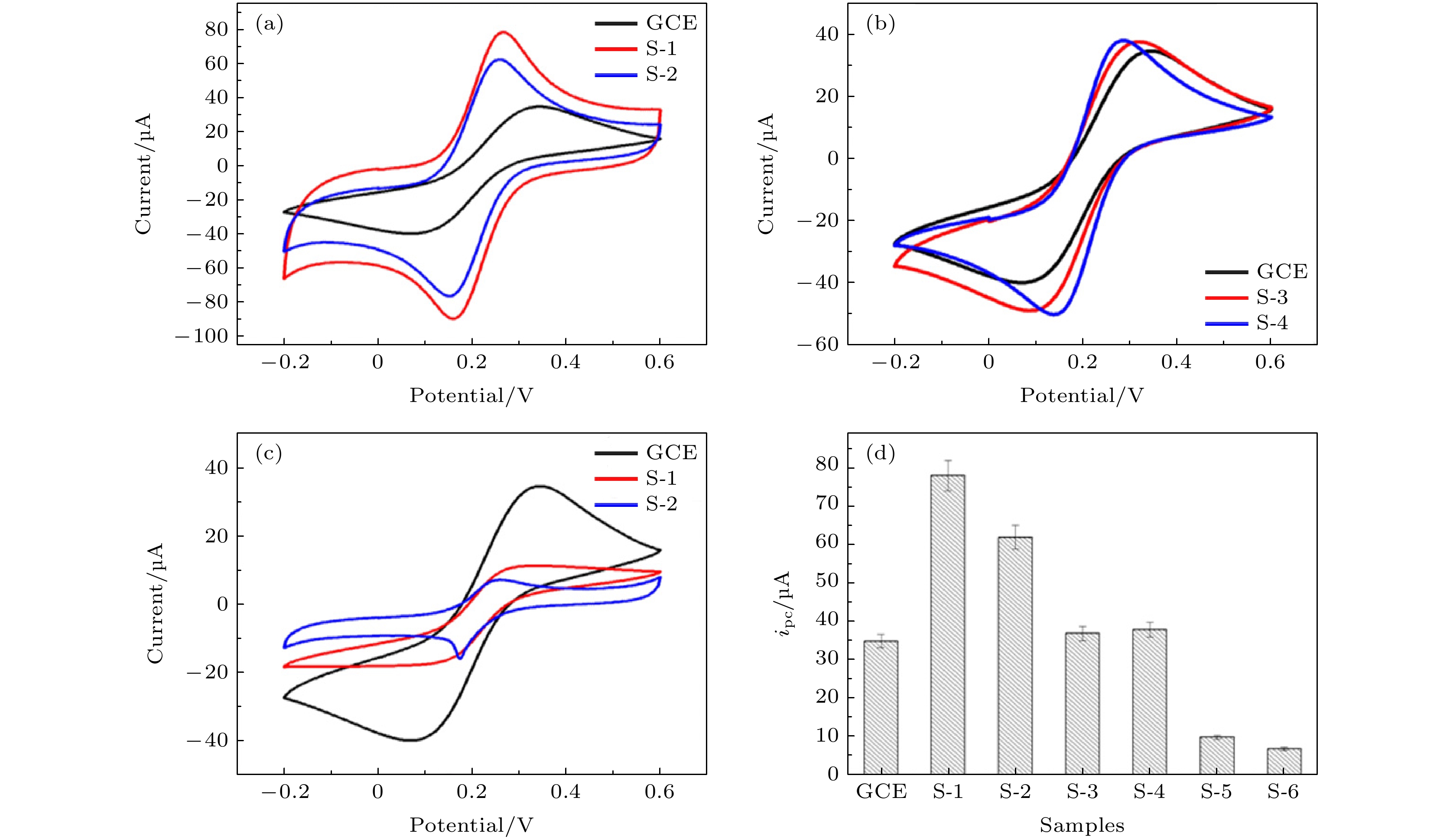

图 11 (a)−(c) 在含有0.1 mol/L KCl溶液的5 mmol/L K3[Fe(CN)6]溶液中通过循环伏安法修饰玻碳电极(GCE)上的GO样品(S-1至S-6); (d) 具有不同氧化水平的样品的Ipc[56]

Figure 11. (a)−(c) Cyclic voltammetry of GO samples (S-1 to S-6) modified on GCE in 5 mmol/L K3[Fe(CN)6] containing 0.1 mol/L KCl solution; (d) Ipc of the samples with different oxidation levels[56].

图 12 PU/GnP复合材料的横截面SEM图像(质量分数为1%的GnP, 其中(a)−(d)为低倍率; (e)−(f)为高倍率) (a), (e) PU/H100; (b), (f) PU/M25; (c), (g) PU/M5; (d), (h) PU/C750[59]

Figure 12. Cross-sectional SEM images for the PU/GnP composites (GnP with weight fraction of 1%, (a)−(d) low magnification, (e)−(f) high magnification): (a), (e) PU/H100; (b), (f) PU/M25; (c), (g) PU/M5; (d), (h) PU/C750[59].

-

[1] Pan H 2018 MATEC Web. Conf. 207 03010

Google Scholar

Google Scholar

[2] Ma L W, Ren C H, Wang J K, Liu T, Yang H, Wang Y J, Huang Y, Zhang D W 2020 Chem. Eng. J. DOI: 10.1016/j.cej.2020.127854Google Scholar

[3] Sadawy M, Saad S, Abdel-Karim R 2020 Trans. Nonferrous Met. Soc. China 30 2067

Google Scholar

Google Scholar

[4] Glover C F, Cain T W, Scully J R 2019 Corros. Sci. 149 195

Google Scholar

Google Scholar

[5] Tasic Z Z, Mihajlovic M B P, Radovanovic M B, Simonovic A T, Antonijevic M M 2018 J. Mol. Struct. 1159 46

Google Scholar

Google Scholar

[6] Qiang Y J, Zhang S T, Xu S Y, Li W P 2016 J. Colloid Interface Sci. 472 52

Google Scholar

Google Scholar

[7] Peng T Y, Xiao R H, Rong Z Y, Liu H B, Hu Q Y, Wang S H, Li X, Zhang J M 2020 Chem. Asian J. 15 3915

Google Scholar

Google Scholar

[8] Tang H Y, Qu Z P, Wang L, Ye H Y, Fan X J, Zhang G Q 2019 Phys. Chem. Chem. Phys. 21 18179

Google Scholar

Google Scholar

[9] Suleiman R K 2019 J. Adhes. Sci. Technol. 34 1

Google Scholar

Google Scholar

[10] Huang H W, Sheng X X, Tian Y Q, Zhang L, Chen Y, Zhang X Y 2020 Ind. Eng. Chem. Res. 59 15424

Google Scholar

Google Scholar

[11] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[12] Kyhl L, Nielsen S F, Cabo A G, Cassidy A, Miwa J A, Hornekaer L 2015 Faraday Discuss. 180 495

Google Scholar

Google Scholar

[13] Wang M, Tang M, Chen S, Ci H, Wang K, Shi L, Lin L, Ren H, Shan J, Gao P 2017 Adv. Mater. 29 1703882

Google Scholar

Google Scholar

[14] Ding R, Li W H, Wang X, Gui T J, Li B J, Han P, Tian H W, Liu A, Wang X, Liu X J, Gao X, Wang W, Song L Y 2018 J. Alloys Compd. 764 1039

Google Scholar

Google Scholar

[15] Krishnan M A, Aneja K S, Shaikh A, Bohm S, Raja V S 2018 RSC Adv. 8 499

Google Scholar

Google Scholar

[16] Chauhan D S, Quraishi M A, Ansari K R, Saleh T A 2020 Prog. Org. Coat. 147 105741

Google Scholar

Google Scholar

[17] Ollik K, Lieder M 2020 Coatings 10 883

Google Scholar

Google Scholar

[18] Lin Y T, Don T M, Wong C J, Meng F C, Lin Y J, Lee S Y, Lee C F, Chiu W Y 2019 Surf. Coat. Technol. 374 1128

Google Scholar

Google Scholar

[19] Parhizkar N, Shahrabi T, Ramezanzadeh B 2017 Corros. Sci. 123 55

Google Scholar

Google Scholar

[20] Ding R, Wang X, Jiang J, Gui T, Li W 2017 J. Mater. Eng. Perform. 764 3319

Google Scholar

Google Scholar

[21] Xiong L, Liu J, Li Y, Li S, Yu M 2019 Prog. Org. Coat. 135 228

Google Scholar

Google Scholar

[22] Qing F, Shen C, Jia R, Zhan L, Li X 2017 MRS Bull. 42 819

Google Scholar

Google Scholar

[23] Li X S, Cai W W, An J H, Kim S, Nah J, Yang D X, Piner R, Velamakanni A, Jung I, Tutuc E, Banerjee S K, Colombo L, Ruoff R S 2009 Science 324 1312

Google Scholar

Google Scholar

[24] Chen S S, Brown L, Levendorf M, Cai W W, Ju S Y, Edgeworth J, Li X S, Magnuson C W, Velamakanni A, Piner R D, Kang J Y, Park J, Ruoff R S 2011 ACS Nano 5 1321

Google Scholar

Google Scholar

[25] Kirkland N T, Schiller T, Medhekar N, Birbilis N 2012 Corros. Sci. 56 1

Google Scholar

Google Scholar

[26] Pu N W, Shi G N, Liu Y M, Sun X, Chang J K, Sun C L, Ger M D, Chen C Y, Wang P C, Peng Y Y 2015 J. Power Sources 282 248

Google Scholar

Google Scholar

[27] Zhu M, Du Z, Yin Z, Zhou W, Liu Z 2016 ACS Appl. Mater. Interfaces 8 502

Google Scholar

Google Scholar

[28] 张晓波, 青芳竹, 李雪松 2019 68 096801

Google Scholar

Google Scholar

Zhang X B, Qing F Z, Li X S 2019 Acta Phys. Sin. 68 096801

Google Scholar

Google Scholar

[29] Zheng Z, Liu Y, Bai Y, Zhang J, Han Z, Ren L 2016 Colloids Surf., A 500 64

Google Scholar

Google Scholar

[30] Yang S, Zhu S, Hong R 2020 Coatings 10 1215

Google Scholar

Google Scholar

[31] Xu H, Zang J, Yuan Y, Tian P, Wang Y 2019 Appl. Surf. Sci. 492 199

Google Scholar

Google Scholar

[32] Xiao F, Qian C, Guo M, Wang J, Yan X, Li H, Yue L 2018 Prog. Org. Coat. 125 79

Google Scholar

Google Scholar

[33] He W T, Zhu L Q, Chen H N, Nan H Y, Li W P, Liu H C, Wang Y 2013 Appl. Surf. Sci. 279 416

Google Scholar

Google Scholar

[34] Szeptycka B, Gajewska-Midzialek A, Babul T 2016 J. Mater. Eng. Perform. 25 3134

Google Scholar

Google Scholar

[35] Feng L, Zhang S T, Qiang Y J, Xu Y, Guo L, Madkour L H, Chen S J 2018 Materials 11 1042

Google Scholar

Google Scholar

[36] Bokati K S, Dehghanian C 2018 J. Environ. Chem. Eng. 6 1613

Google Scholar

Google Scholar

[37] Guo L, Obot I B, Zheng X W, Shen X, Qiang Y J, Kaya S, Kaya C 2017 Appl. Surf. Sci. 406 301

Google Scholar

Google Scholar

[38] Hippolyte C N, Serge B Y, Didier D G, Juan C, Albert T 2018 Int. J. Biol. Chem. Sci. 12 1008

Google Scholar

Google Scholar

[39] Cen H, Chen Z 2021 Colloids Surf., A. 615 126216

Google Scholar

Google Scholar

[40] Baig N, Chauhan D S, Saleh T A, Quraishi M A 2019 New J. Chem. 43 2328

Google Scholar

Google Scholar

[41] Zhao D, Wang M, Xu Y, Zhang Z, Ge X 2014 Surf. Coat. Technol. 238 15

Google Scholar

Google Scholar

[42] Ye Y, Chen H, Zou Y, Ye Y, Zhao H 2020 Corros. Sci. 174 108825

Google Scholar

Google Scholar

[43] Kasaeian M, Ghasemi E, Ramezanzadeh B, Mahdavian M, Bahlakeh G 2018 Corros. Sci. 145 119

Google Scholar

Google Scholar

[44] Cui G, Bi Z, Zhang R, Liu J, Yu X, Li Z 2019 Chem. Eng. J. 373 104

Google Scholar

Google Scholar

[45] Banhart F, Kotakoski J, Krasheninnikov A V 2011 ACS Nano 5 26

Google Scholar

Google Scholar

[46] Rhodes D, Chae S H, Ribeiro-Palau R, Hone J 2019 Nat. Mater. 18 541

Google Scholar

Google Scholar

[47] Hong J, Lee J B, Lee S, Seo J, Lee H, Park J Y, Ahn J H, Il Seo T, Lee T, Lee H B R 2016 NPG Asia Mater. 8 e262

Google Scholar

Google Scholar

[48] Ji D, Wen X, Foller T, You Y, Joshi R 2020 Nanomaterials 10 2511

Google Scholar

Google Scholar

[49] Prasai D, Tuberquia J C, Harl R R, Jennings G K, Bolotin K I 2012 ACS Nano 6 1102

Google Scholar

Google Scholar

[50] Zhou F, Li Z T, Shenoy G J, Li L, Liu H T 2013 ACS Nano 7 6939

Google Scholar

Google Scholar

[51] Hsieh Y P, Hofmann M, Chang K W, Jhu J G, Li Y Y, Chen K Y, Yang C C, Chang W S, Chen L C 2014 ACS Nano 8 443

Google Scholar

Google Scholar

[52] Zhao Z, Hou T, Wu N, Jiao S, Zhou K, Yin J, Suk J, Cui X, Zhang M, Li S, Qu Y, Xie W, Li X B, Zhao C, Fu Y, Hong R D, Guo S, Lin D, Cai W, Mai W, Luo Z, Tian Y, Lai Y, Liu Y, Colombo L, Hao Y 2021 Nano Lett. 21 1161

Google Scholar

Google Scholar

[53] Liu T, Zhao H C, Mao F X, Li J Y 2019 Mater. Res. Express 6 125619

Google Scholar

Google Scholar

[54] Jun Y S, Sy S, Ahn W, Zarrin H, Rasen L, Tjandra R, Amoli B M, Zhao B X, Chiu G, Yu A P 2015 Carbon 95 653

Google Scholar

Google Scholar

[55] Guerrero-Contreras J, Caballero-Briones F 2015 Mater. Chem. Phys. 153 209

Google Scholar

Google Scholar

[56] Krishnamoorthy K, Veerapandian M, Yun K, Kim S J 2013 Carbon 53 38

Google Scholar

Google Scholar

[57] Sato J, Higurashi K, Fukuda K, Sugimoto W 2011 Electrochemistry 79 337

Google Scholar

Google Scholar

[58] Ramezanzadeh B, Bahlakeh G, Moghadam M H M, Miraftab R 2018 Chem. Eng. J. 335 737

Google Scholar

Google Scholar

[59] Um J G, Jun Y S, Alhumade H, Krithivasan H, Lui G, Yu A P 2018 RSC Adv. 8 17091

Google Scholar

Google Scholar

[60] Liao Z J, Zhang T C, Qiao S, Zhang L Y H 2017 Environ. Mater. Sci. 94 012072

Google Scholar

Google Scholar

[61] Cai K W, Zuo S X, Luo S P, Yao C, Liu W J, Ma J F, Mao H H, Li Z Y 2016 RSC Adv. 6 95965

Google Scholar

Google Scholar

[62] Kumar C S, Sumitesh D 2017 J. Nanosci. Nanotechnol. 17 2130

Google Scholar

Google Scholar

[63] Gupta R K, Malviya M, Ansari K R, Lgaz H, Quraishi M A 2019 Mater. Chem. Phys. 236 121727

Google Scholar

Google Scholar

[64] Haruna K, Saleh T A, Obot I B, Umoren S A 2019 Prog. Org. Coat. 128 157

Google Scholar

Google Scholar

[65] Du P, Wang J, Zhao H, Liu G, Wang L 2019 Dalton Trans. 48 13064

Google Scholar

Google Scholar

[66] Zhang Z, Qi J, Zhao M, Shang N, Cheng Y, Qiao R, Zhang Z, Ding M, Li X, Liu K, Xu X, Liu K, Liu C, Wu M 2020 Chin. Phys. Lett. 37 108101

Google Scholar

Google Scholar

[67] Wang Y, Qing F, Jia Y, Duan Y, Shen C, Hou Y, Niu Y, Shi H, Li X 2021 Chem. Eng. J. 405 127014

Google Scholar

Google Scholar

[68] 孙垚垚, 宋家乐, 郑斌, 曾煜, 胡颖, 李炜光 2021 无机盐工业 https://kns.cnki.net/kcms/detail/12.1069.TQ.20210129.1525.006.html

Sun Y Y, Sun J L, Zheng B, Zeng Y, Hu Y, Li W G 2021 Inorg. Chem. Ind.

[69] Yang X B, Cui D W, Qu Y 2017 Electron. Compon. Mater. 36 83

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 16856

- PDF Downloads: 577

- Cited By: 0

DownLoad:

DownLoad: