-

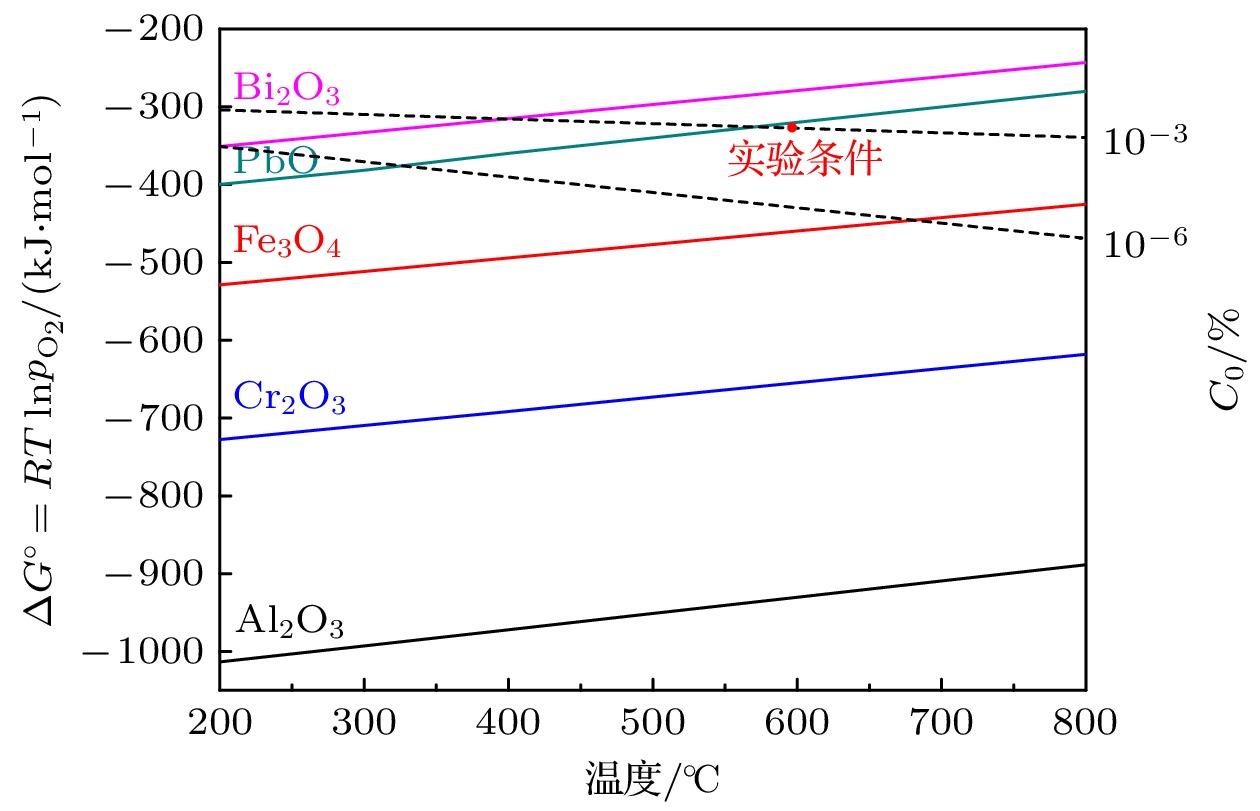

铁素体/马氏体钢, 如T91钢和SIMP钢, 被选为第4代铅冷快堆和加速器驱动系统(ADS)的主要候选结构材料. 但容器钢与液态铅铋共晶(LBE)在高温下的相容性限制了它们的应用. 铁素体/马氏体钢在600 ℃的LBE中腐蚀严重. 为了保护铁素体/马氏体钢免受高温LBE腐蚀, 在钢表面制备AlOx (x < 1.5)涂层. 本文采用磁控溅射法在T91钢和SIMP钢表面制备了AlOx涂层. 对表面有涂层的T91钢和SIMP钢以及表面无涂层的T91钢和SIMP钢在600 ℃的饱和氧浓度的LBE中腐蚀300 h和700 h的结果进行比较. 结果表明, 涂层钢表面的氧化层比无涂层钢表面的氧化层薄, 这表明AlOx涂层可以有效防止铁、铬和氧元素的快速扩散. 然而, 在LBE中腐蚀700 h后, AlOx涂层出现裂纹, 表面有涂层的T91钢和SIMP钢均遭受到明显的氧化腐蚀, 说明该涂层在600 ℃的LBE中可以在短时间内保护基体免受高温腐蚀. 但是涂层在600 ℃的LBE 中不能长时间保持稳定. 这可能是由于此次实验条件制备的AlOx涂层膜基结合力不强或制备的AlOx涂层里面存在大量的金属铝和结构缺陷. AlOx涂层在LBE中的高温稳定性有待进一步研究.Ferritic/martensitic steels, such as T91 steel and SIMP steel, are chosen as the main candidates of structural materials for the Generation IV lead-cooled fast reactors and accelerator driven system. However, the compatibility between container steel and liquid Pb-Bi eutectic (LBE) at high temperature limits their applications. The corrosion of ferritic/martensitic steels is serious in LBE at 600 ℃. In order to avoid corroding the ferritic/martensitic steels in LBE, it is proposed to coat AlOx (x < 1.5) on the steel surface. The AlOx coating is conducted on T91 steel and SIMP steel by magnetron sputtering. In this exploratory work, the corrosion results of AlOx coating steel are compared with the corrosion results of the uncoated steel in LBE with a saturated oxygen concentration at 600 ℃ for 300 h and 700 h. The results show that the AlOx coating can effectively prevent the iron chromium and oxygen from diffusing, so the oxide scale of the coated steel is thinner than that of the uncoated steel. However, the coating cracks after 700 h corrosion in LBE. Meanwhile, T91 steel and SIMP steel also suffer serious oxidative corrosion, indicating that the coating can protect the substrate from being corroded by 600 ℃ static LBE in a short time. However, the coating cannot keep stable for a long time in LBE at 600 ℃. This may be due to the weak film base bonding force of AlOx coating prepared under the experimental conditions, or a large number of metal aluminum and structural defects existing in AlOx coating. It is needed to further study the stability of AlOx coating in LBE at elevated temperature.

-

Keywords:

- T91 steel /

- SIMP steel /

- AlOx coating /

- liquid Pb-Bi eutectic /

- oxide layer /

- thermal expansion coefficient

[1] Sar F, Mhiaoui S, Gasser J G 2007 J. Non. Cryst. Solids. 353 3622

Google Scholar

Google Scholar

[2] Sobolev V 2007 J. Nucl. Mater. 362 235

Google Scholar

Google Scholar

[3] Zhang J 2014 Adv. Eng. Mater. 16 349

Google Scholar

Google Scholar

[4] Zhang J, Ning L 2008 J. Nucl. Mater. 373 351

Google Scholar

Google Scholar

[5] Xu Y C, Zhang Y G, Li X Y, Liu W, Li D D, Liu C S, Pan B C, Wang Z G 2017 Corros. Sci. 118 1

Google Scholar

Google Scholar

[6] Barbier F, Rusanov A 2001 J. Nucl. Mater. 296 231

Google Scholar

Google Scholar

[7] Martinelli L, Jean-Louis C, Fanny B C 2011 Nucl. Eng. Des. 241 1288

Google Scholar

Google Scholar

[8] Concetta F 2015 Handbook on Lead-bismuth Eutectic Alloy and Lead Properties, Materials Compatibility, Thermal-hydraulics and Technologies (2015 Edition-Introduction) (OECD Nuclear Energy Agency)

[9] Zhang J 2009 Corros. Sci. 51 1207

Google Scholar

Google Scholar

[10] Takaya S, Furukawa T, Müller G, Heinzel A, Jianu A, Weisenburger A, Aoto K, Inoue M, Okuda T, Abe F, Ohnuki S, Fujisawa T, Kimura A 2012 J. Nucl. Mater. 428 125

Google Scholar

Google Scholar

[11] Srinivasan P B, Kumar M 2009 Mater. Chem. Phys. 115 179

Google Scholar

Google Scholar

[12] Müller G, Schumacher G, Zimmermann F 2000 J. Nucl. Mater. 278 85

Google Scholar

Google Scholar

[13] Deloffre P, Balbaud-Célérier F, Terlain A 2004 J. Nucl. Mater. 335 180

Google Scholar

Google Scholar

[14] Weisenburger A, Heinzel A, Müller G, Muscher H, Rousanov A 2008 J. Nucl. Mater. 376 274

Google Scholar

Google Scholar

[15] Fetzer R, Weisenburger A, Jianu A, Müller G 2012 Corros. Sci. 55 213

Google Scholar

Google Scholar

[16] Short M P, Ballinger R G, Hänninen H E 2013 J. Nucl. Mater. 434 259

Google Scholar

Google Scholar

[17] Hosemann P, Thau H T, Johnson A L, Maloy S A, Li N 2008 J. Nucl. Mater. 373 246

Google Scholar

Google Scholar

[18] Takaya S, Furukawa T, Aoto K, Müller G, Weisenburger A, Heinzel A, Inoue M, Okuda T, Abe F, Ohnuki S, Fujisawa T and Kimura A 2009 J. Nucl. Mater. 386–388 507

Google Scholar

Google Scholar

[19] Takaya S, Furukawa T, Inoue M, Fujisawa T, Okuda T, Abe F, Ohnuki S, Kimura A 2010 J. Nucl. Mater. 398 132

Google Scholar

Google Scholar

[20] Heinzel A, Kondo M, Takahashi M 2006 J. Nucl. Mater. 350 264

Google Scholar

Google Scholar

[21] Kurata Y, Futakawa M, Saito S 2004 J. Nucl. Mater. 335 501

Google Scholar

Google Scholar

[22] Ferré F G, Mairov A, Iadicicco D, Vanazzi M, Bassini S, Utili M, Tarantino M, Bragaglia M, Lamastra F R, Nanni F, Ceseracciu L, Serruys Y, Trocellier P, Beck L, Sridharan K, Beghi M G , Di Fonzo F 2017 Corros. Sci. 124 80

Google Scholar

Google Scholar

[23] Glasbrenner H, Gröschel F 2006 J. Nucl. Mater. 356 213

Google Scholar

Google Scholar

[24] Weisenburger A, Jianu A, Doyle S, Bruns M, Fetzer R, Heinzel A, Del Giacco M, An W, Müller G 2013 J. Nucl. Mater 437 282

Google Scholar

Google Scholar

[25] Ferré G, Ormellese M, Fonzo F D, Beghi M G 2013 Corros. Sci. 77 375

Google Scholar

Google Scholar

[26] Sordo F, Abánades A, Lafuente A, Martínez-Val J M, Perlado M 2009 Nucl. Eng. Des. 239 2573

Google Scholar

Google Scholar

[27] Borgstedt H U, Frees G 1995 Liquid Metal Systems. (New York: Springer) p339

[28] Ellingham H J T 1994 J. Soc. Chem. Ind. 63 125

[29] Yeliseyeva O, Tsisar V, Zhou Z 2013 J. Nucl. Mater. 442 434

Google Scholar

Google Scholar

[30] Weisenburger A, Schroer C, Jianu A, Heinzel A, Konys J, Steiner H, Müller G, Fazio C, Gessi A, Babayan S, Kobzova A, Martinelli L, Ginestar K, Balbaud-Célerier F, Martín-Muñoz F J, Soler Crespo L 2011 J. Nucl. Mater. 415 260

Google Scholar

Google Scholar

[31] Weisenburger A, Mansani L, Schumacher G, Müller G 2014 Nucl. Eng. Des. 273 584

Google Scholar

Google Scholar

[32] Martinelli L, Balbaud-Célérier F, Terlain A, Bosonnet S, Picard G, Santarini G 2008 Corros. Sci. 50 2537

Google Scholar

Google Scholar

[33] Martinelli L, Balbaud-Célérier F, Picard G, Santarini G 2008 Corros. Sci. 50 2549

Google Scholar

Google Scholar

[34] Miorin E, Montagner F, Zin V, Giuranno D, Deambrosis S M 2019 Surf. Coat. Technol. 377 124890

Google Scholar

Google Scholar

[35] Comstock M 2009 J. Nucl. Mater. 382 272

Google Scholar

Google Scholar

[36] Tan L, Machut M T, Sridharan K 2007 J. Nucl. Mater. 371 161

Google Scholar

Google Scholar

[37] Li B S, Liao Q, Zhang H P, Shen T L, Ge F F, Nabil D 2021 Corros. Sci. 187 109477

Google Scholar

Google Scholar

[38] Zhang L L, Yan W, Shi Q Q, Li Y F, Shen Y Y, Yang K 2020 Corros. Sci. 167 108519

Google Scholar

Google Scholar

[39] Liu J, Yan W, Sha W, Wang W, Shan Y Y, Yang K 2016 J. Nucl. Mater. 473 189

Google Scholar

Google Scholar

[40] Li Y, Wang S, Sun P, Xu D, Ren M, Guo Y, Lin G 2017 Corros. Sci. 128 241

Google Scholar

Google Scholar

[41] Shi Q, Liu J, Luan H, Yang Z, Wang W, Yan W, Shan Y, Yang K 2015 J. Nucl. Mater. 457 135

Google Scholar

Google Scholar

[42] Behnamian Y, Mostafaei A, Kohandehghan A, Amirkhiz B S, Serate D, Sun Y, Liu S, Aghaie E, Zeng Y, Chmielus M, Zheng W, Guzonas D 2016 Corros. Sci. 106 188

Google Scholar

Google Scholar

[43] Martinelli L, Balbaud-Célérier F, Terlian A, Delpech S, Santarini G, Favergeon J, Moulin G, Tabarant M, Picard G 2008 Corros. Sci. 50 2523

Google Scholar

Google Scholar

[44] Bian L Z, Chen Z Y, Wang L J, Li F S, Chou K C 2017 J. Iron. Steel. Res. Int. 24 77

Google Scholar

Google Scholar

[45] Huntz A M, Maréchal L, Lesage B, Molins R 2006 Appl. Surf. Sci. 252 7781

Google Scholar

Google Scholar

[46] Melander A 1997 Int. J. Fatigue 19 13

Google Scholar

Google Scholar

[47] Wang Q S, Wang W Q, Shi Z M 2018 E. Science. 113 012146

Google Scholar

Google Scholar

[48] Echsler H, Martinez E A, Singheiser L, Quadakkers W J 2004 Mater. Sci. Eng. A 384 1

Google Scholar

Google Scholar

[49] Hayashi H, Watanabe M, Inaba H 2000 Thermochim Acta. 359 77

Google Scholar

Google Scholar

[50] Mavko G, Mukerji T, Dvorkin J 2009 The Rock Physics Handbook: Elasticity and Hooke's law 2 21

Google Scholar

Google Scholar

-

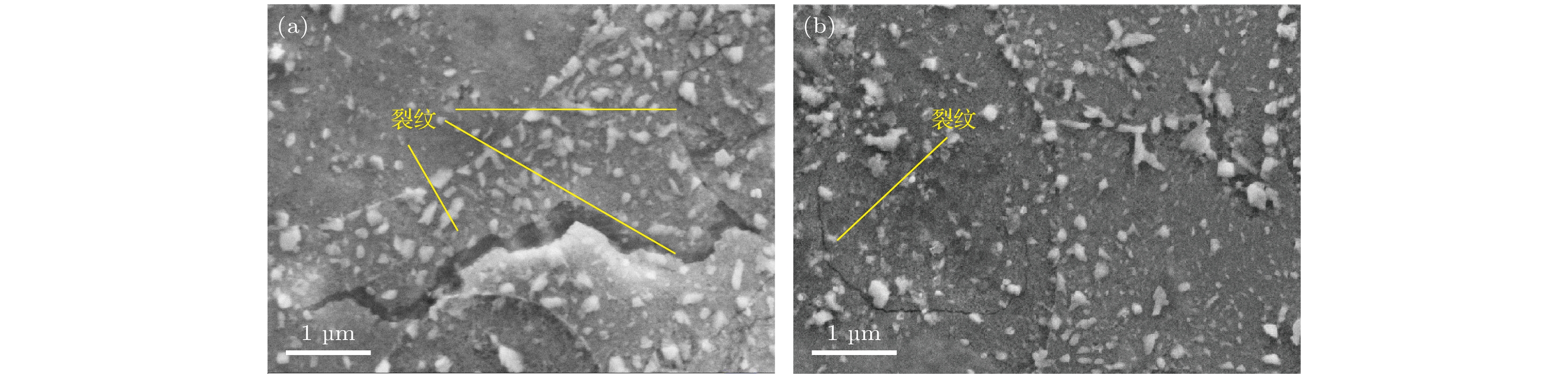

图 4 T91钢和SIMP钢在600 ℃的LBE中腐蚀300 h和700 h后的表面SEM图 (a) LBE中腐蚀300 h后无涂层的T91钢表面; (b) LBE中腐蚀300 h后有涂层的T91钢表面; (c) LBE中腐蚀300 h后无涂层的SIMP钢表面; (d) LBE中腐蚀300 h后有涂层的SIMP钢表面; (e) LBE中腐蚀700 h后无涂层的T91钢表面; (f) LBE中腐蚀700 h后有涂层的T91钢表面; (g) LBE中腐蚀700 h后无涂层的SIMP钢表面; (h) LBE中腐蚀700 h后无涂层的SIMP钢表面

Fig. 4. SEM images showing the surface morphology of SIMP and T91 steels after 300 h and 700 h corrosion in LBE at 600 ℃: (a) The uncoated surface of T91 steel in LBE for 300 h; (b) the coated surface of T91 steel in LBE for 300 h; (c) the uncoated surface of SIMP steel in LBE for 300 h; (d) the coated surface of SIMP steel in LBE for 300 h; (e) the uncoated surface of T91 steel in LBE for 700 h; (f) the coated surface of T91 steel in LBE for 700 h; (g) the uncoated surface of SIMP steel in LBE for 700 h; (h) the coated surface of SIMP steel in LBE for 700 h.

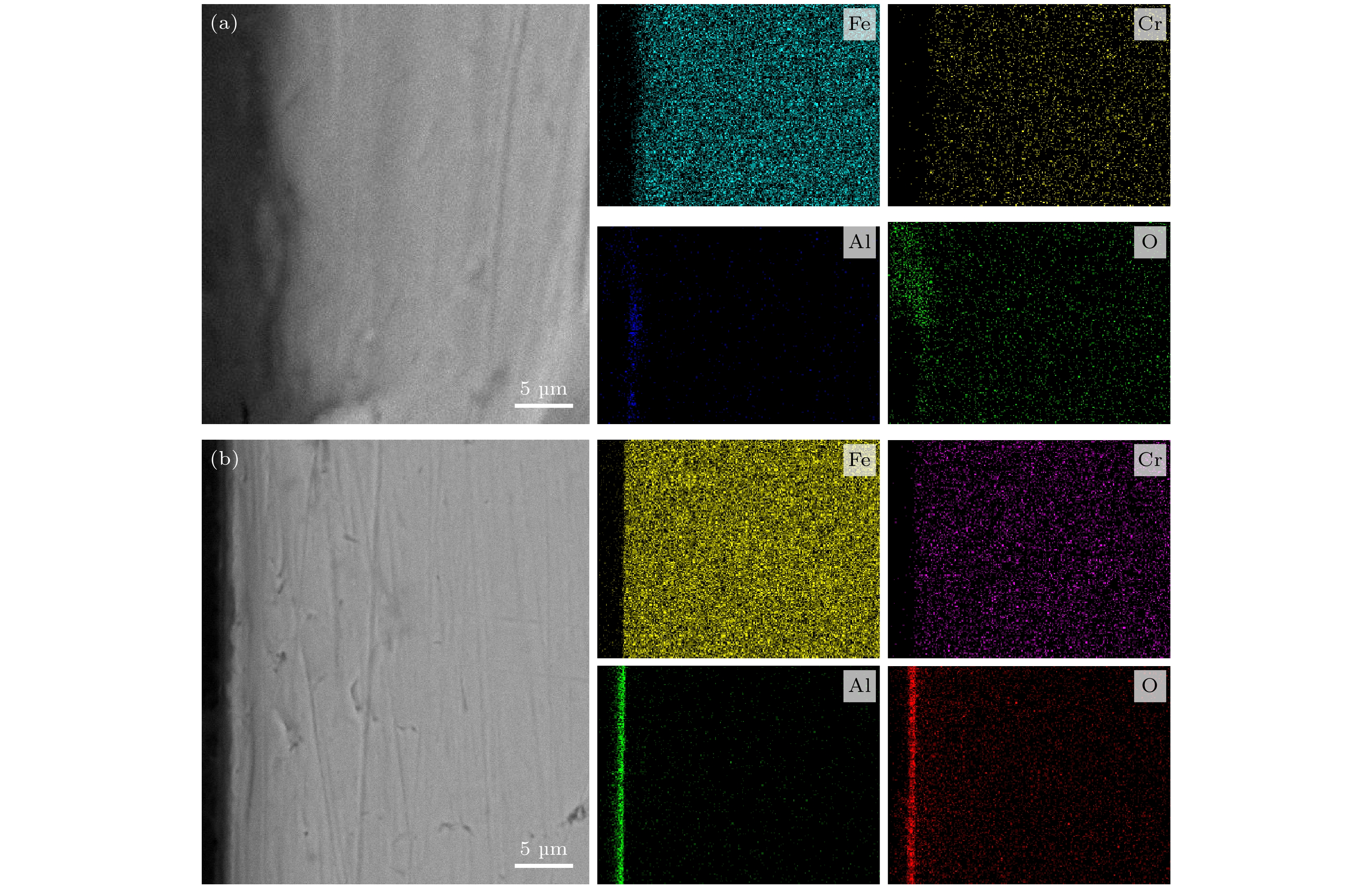

图 7 在600 ℃的LBE中腐蚀300 h后T91钢和SIMP钢的横截面SEM图像和EDS线性分析(扫描方向从左到右) (a), (b)涂层T91钢; (c), (d)无涂层T91钢; (e), (f)涂层SIMP钢; (g), (h)无涂层SIMP钢

Fig. 7. Cross-sectional SEM images and EDS linear analysis of T91 and SIMP steels after 300 h corrosion in LBE at 600 ℃: (a), (b) The coated T91; (c), (d) the uncoated T91; (e), (f) the coated SIMP; (g), (h) the uncoated SIMP.

图 9 T91钢和SIMP钢在600℃的LBE中腐蚀700 h后的横截面SEM图像和EDS线性分析(扫描方向从左到右) (a), (b)涂层T91钢; (c), (d)无涂层T91钢; (e), (f)涂层SIMP钢; (g), (h)无涂层SIMP钢.

Fig. 9. Cross-sectional SEM images and EDS linear analysis of T91 and SIMP steels after 700 h corrosion in LBE at 600 ℃: (a), (b) The coated T91; (c), (d) the uncoated T91; (e), (f) the coated SIMP; (g), (h) the uncoated SIMP.

表 1 研究钢材的化学成分(质量分数)

Table 1. Chemical compositions of the studied steels (mass fraction%)

元素 Fe Cr Ni Mo V Si C Nb N Ta W T91 Bal 8.50 0.25 0.95 0.19 0.20 0.10 0.067 0.05 — — SIMP Bal 10.50 — — 0.20 1.40 0.20 0.01 — 0.15 1.50 表 2 磁控溅射制备AlOx薄膜的典型工艺参数(1 sccm = 1 mL/min)

Table 2. Typical process parameters of the AlOx films prepared by magnetron sputtering

靶功率/W 频率 /kHz O2 流量/sccm 氩气流量/sccm 靶温度/℃ 沉积速率/(nm·min–1) 400 350 8.6 32 25 9 表 3 T91钢和SIMP钢在600 ℃静态LBE下表面氧化物在图4标记位置的EDS点分析

Table 3. EDS analyses of the surface oxides of T91 and SIMP steel exposed to static LBE at 600 ℃ in Fig. 4.

原子分数/% 元素 Fe Cr O Al Pb Si Point A 43.89 — 55.12 — 0.34 0.65 Point B 0.89 — 61.9 36.4 — 0.81 Point C 42.7 — 54.37 — 0.38 2.55 Point D 3.01 — 58.63 34.6 — 3.76 Point E 44.21 — 54.30 — 0.88 0.61 Point F 41.17 — 58.26 — — 0.57 Point G 40.59 — 55.23 — 0.60 3.58 Point H 32.51 — 63.80 — — 3.69 -

[1] Sar F, Mhiaoui S, Gasser J G 2007 J. Non. Cryst. Solids. 353 3622

Google Scholar

Google Scholar

[2] Sobolev V 2007 J. Nucl. Mater. 362 235

Google Scholar

Google Scholar

[3] Zhang J 2014 Adv. Eng. Mater. 16 349

Google Scholar

Google Scholar

[4] Zhang J, Ning L 2008 J. Nucl. Mater. 373 351

Google Scholar

Google Scholar

[5] Xu Y C, Zhang Y G, Li X Y, Liu W, Li D D, Liu C S, Pan B C, Wang Z G 2017 Corros. Sci. 118 1

Google Scholar

Google Scholar

[6] Barbier F, Rusanov A 2001 J. Nucl. Mater. 296 231

Google Scholar

Google Scholar

[7] Martinelli L, Jean-Louis C, Fanny B C 2011 Nucl. Eng. Des. 241 1288

Google Scholar

Google Scholar

[8] Concetta F 2015 Handbook on Lead-bismuth Eutectic Alloy and Lead Properties, Materials Compatibility, Thermal-hydraulics and Technologies (2015 Edition-Introduction) (OECD Nuclear Energy Agency)

[9] Zhang J 2009 Corros. Sci. 51 1207

Google Scholar

Google Scholar

[10] Takaya S, Furukawa T, Müller G, Heinzel A, Jianu A, Weisenburger A, Aoto K, Inoue M, Okuda T, Abe F, Ohnuki S, Fujisawa T, Kimura A 2012 J. Nucl. Mater. 428 125

Google Scholar

Google Scholar

[11] Srinivasan P B, Kumar M 2009 Mater. Chem. Phys. 115 179

Google Scholar

Google Scholar

[12] Müller G, Schumacher G, Zimmermann F 2000 J. Nucl. Mater. 278 85

Google Scholar

Google Scholar

[13] Deloffre P, Balbaud-Célérier F, Terlain A 2004 J. Nucl. Mater. 335 180

Google Scholar

Google Scholar

[14] Weisenburger A, Heinzel A, Müller G, Muscher H, Rousanov A 2008 J. Nucl. Mater. 376 274

Google Scholar

Google Scholar

[15] Fetzer R, Weisenburger A, Jianu A, Müller G 2012 Corros. Sci. 55 213

Google Scholar

Google Scholar

[16] Short M P, Ballinger R G, Hänninen H E 2013 J. Nucl. Mater. 434 259

Google Scholar

Google Scholar

[17] Hosemann P, Thau H T, Johnson A L, Maloy S A, Li N 2008 J. Nucl. Mater. 373 246

Google Scholar

Google Scholar

[18] Takaya S, Furukawa T, Aoto K, Müller G, Weisenburger A, Heinzel A, Inoue M, Okuda T, Abe F, Ohnuki S, Fujisawa T and Kimura A 2009 J. Nucl. Mater. 386–388 507

Google Scholar

Google Scholar

[19] Takaya S, Furukawa T, Inoue M, Fujisawa T, Okuda T, Abe F, Ohnuki S, Kimura A 2010 J. Nucl. Mater. 398 132

Google Scholar

Google Scholar

[20] Heinzel A, Kondo M, Takahashi M 2006 J. Nucl. Mater. 350 264

Google Scholar

Google Scholar

[21] Kurata Y, Futakawa M, Saito S 2004 J. Nucl. Mater. 335 501

Google Scholar

Google Scholar

[22] Ferré F G, Mairov A, Iadicicco D, Vanazzi M, Bassini S, Utili M, Tarantino M, Bragaglia M, Lamastra F R, Nanni F, Ceseracciu L, Serruys Y, Trocellier P, Beck L, Sridharan K, Beghi M G , Di Fonzo F 2017 Corros. Sci. 124 80

Google Scholar

Google Scholar

[23] Glasbrenner H, Gröschel F 2006 J. Nucl. Mater. 356 213

Google Scholar

Google Scholar

[24] Weisenburger A, Jianu A, Doyle S, Bruns M, Fetzer R, Heinzel A, Del Giacco M, An W, Müller G 2013 J. Nucl. Mater 437 282

Google Scholar

Google Scholar

[25] Ferré G, Ormellese M, Fonzo F D, Beghi M G 2013 Corros. Sci. 77 375

Google Scholar

Google Scholar

[26] Sordo F, Abánades A, Lafuente A, Martínez-Val J M, Perlado M 2009 Nucl. Eng. Des. 239 2573

Google Scholar

Google Scholar

[27] Borgstedt H U, Frees G 1995 Liquid Metal Systems. (New York: Springer) p339

[28] Ellingham H J T 1994 J. Soc. Chem. Ind. 63 125

[29] Yeliseyeva O, Tsisar V, Zhou Z 2013 J. Nucl. Mater. 442 434

Google Scholar

Google Scholar

[30] Weisenburger A, Schroer C, Jianu A, Heinzel A, Konys J, Steiner H, Müller G, Fazio C, Gessi A, Babayan S, Kobzova A, Martinelli L, Ginestar K, Balbaud-Célerier F, Martín-Muñoz F J, Soler Crespo L 2011 J. Nucl. Mater. 415 260

Google Scholar

Google Scholar

[31] Weisenburger A, Mansani L, Schumacher G, Müller G 2014 Nucl. Eng. Des. 273 584

Google Scholar

Google Scholar

[32] Martinelli L, Balbaud-Célérier F, Terlain A, Bosonnet S, Picard G, Santarini G 2008 Corros. Sci. 50 2537

Google Scholar

Google Scholar

[33] Martinelli L, Balbaud-Célérier F, Picard G, Santarini G 2008 Corros. Sci. 50 2549

Google Scholar

Google Scholar

[34] Miorin E, Montagner F, Zin V, Giuranno D, Deambrosis S M 2019 Surf. Coat. Technol. 377 124890

Google Scholar

Google Scholar

[35] Comstock M 2009 J. Nucl. Mater. 382 272

Google Scholar

Google Scholar

[36] Tan L, Machut M T, Sridharan K 2007 J. Nucl. Mater. 371 161

Google Scholar

Google Scholar

[37] Li B S, Liao Q, Zhang H P, Shen T L, Ge F F, Nabil D 2021 Corros. Sci. 187 109477

Google Scholar

Google Scholar

[38] Zhang L L, Yan W, Shi Q Q, Li Y F, Shen Y Y, Yang K 2020 Corros. Sci. 167 108519

Google Scholar

Google Scholar

[39] Liu J, Yan W, Sha W, Wang W, Shan Y Y, Yang K 2016 J. Nucl. Mater. 473 189

Google Scholar

Google Scholar

[40] Li Y, Wang S, Sun P, Xu D, Ren M, Guo Y, Lin G 2017 Corros. Sci. 128 241

Google Scholar

Google Scholar

[41] Shi Q, Liu J, Luan H, Yang Z, Wang W, Yan W, Shan Y, Yang K 2015 J. Nucl. Mater. 457 135

Google Scholar

Google Scholar

[42] Behnamian Y, Mostafaei A, Kohandehghan A, Amirkhiz B S, Serate D, Sun Y, Liu S, Aghaie E, Zeng Y, Chmielus M, Zheng W, Guzonas D 2016 Corros. Sci. 106 188

Google Scholar

Google Scholar

[43] Martinelli L, Balbaud-Célérier F, Terlian A, Delpech S, Santarini G, Favergeon J, Moulin G, Tabarant M, Picard G 2008 Corros. Sci. 50 2523

Google Scholar

Google Scholar

[44] Bian L Z, Chen Z Y, Wang L J, Li F S, Chou K C 2017 J. Iron. Steel. Res. Int. 24 77

Google Scholar

Google Scholar

[45] Huntz A M, Maréchal L, Lesage B, Molins R 2006 Appl. Surf. Sci. 252 7781

Google Scholar

Google Scholar

[46] Melander A 1997 Int. J. Fatigue 19 13

Google Scholar

Google Scholar

[47] Wang Q S, Wang W Q, Shi Z M 2018 E. Science. 113 012146

Google Scholar

Google Scholar

[48] Echsler H, Martinez E A, Singheiser L, Quadakkers W J 2004 Mater. Sci. Eng. A 384 1

Google Scholar

Google Scholar

[49] Hayashi H, Watanabe M, Inaba H 2000 Thermochim Acta. 359 77

Google Scholar

Google Scholar

[50] Mavko G, Mukerji T, Dvorkin J 2009 The Rock Physics Handbook: Elasticity and Hooke's law 2 21

Google Scholar

Google Scholar

计量

- 文章访问数: 9324

- PDF下载量: 127

- 被引次数: 0

下载:

下载: