-

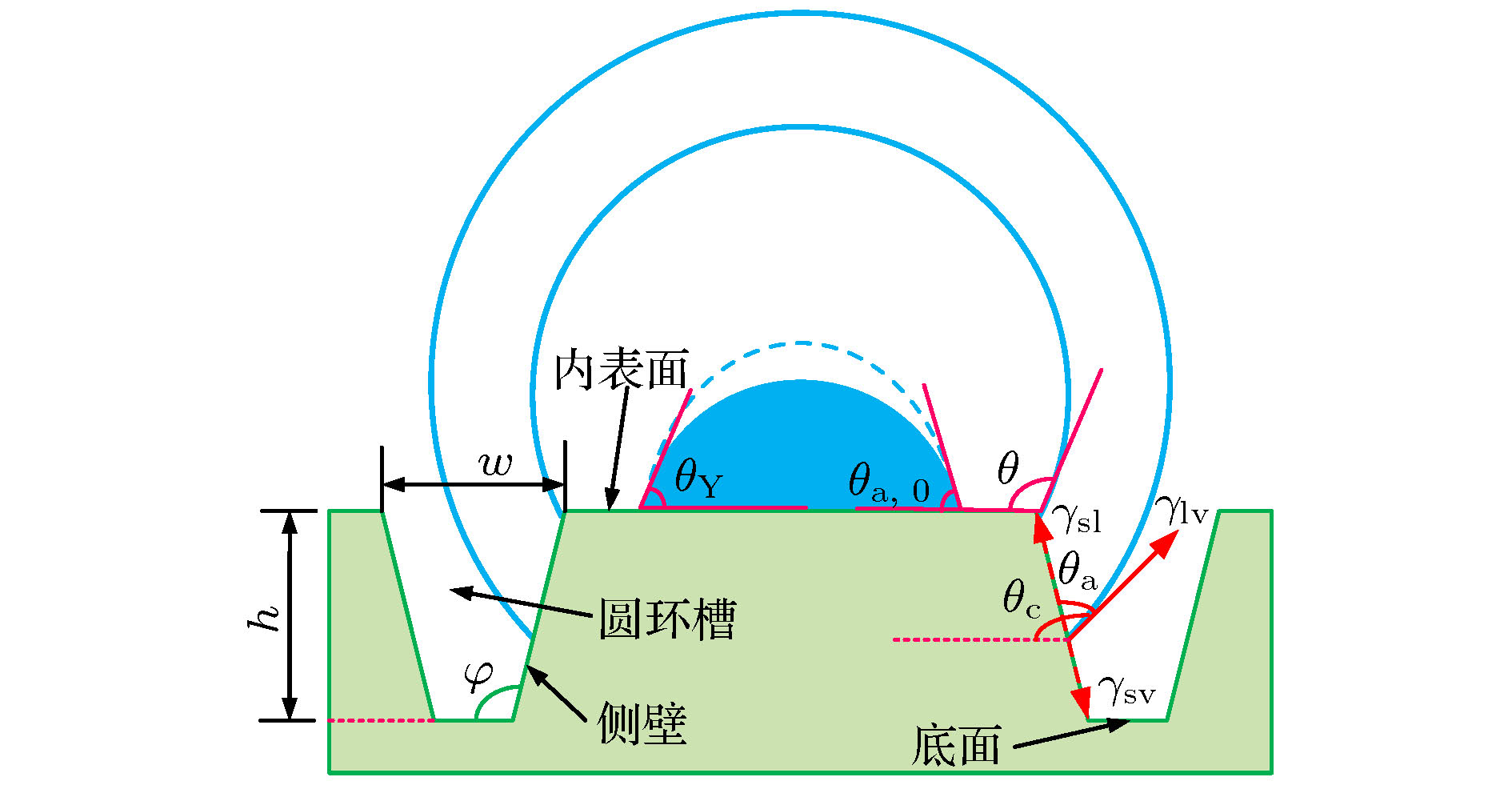

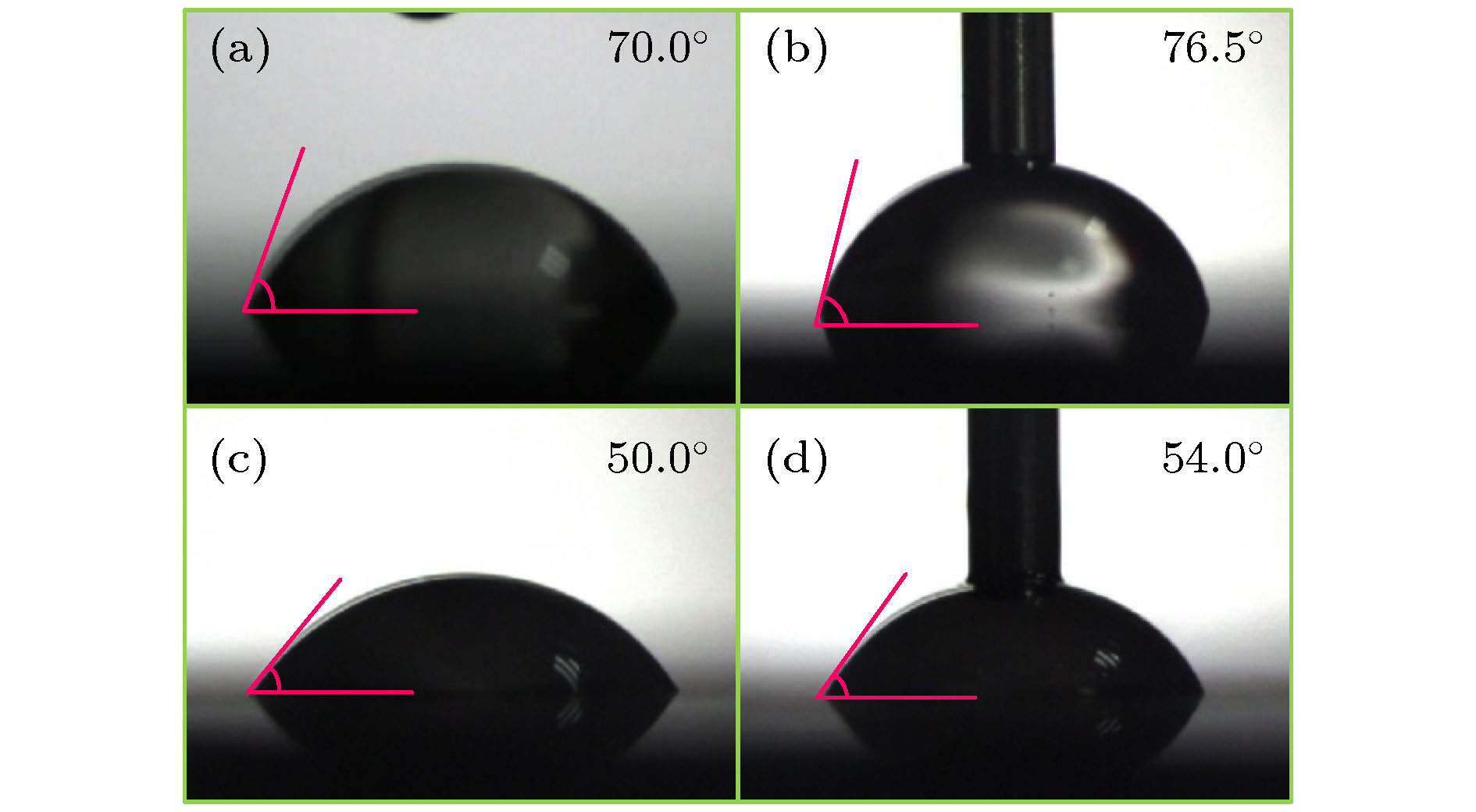

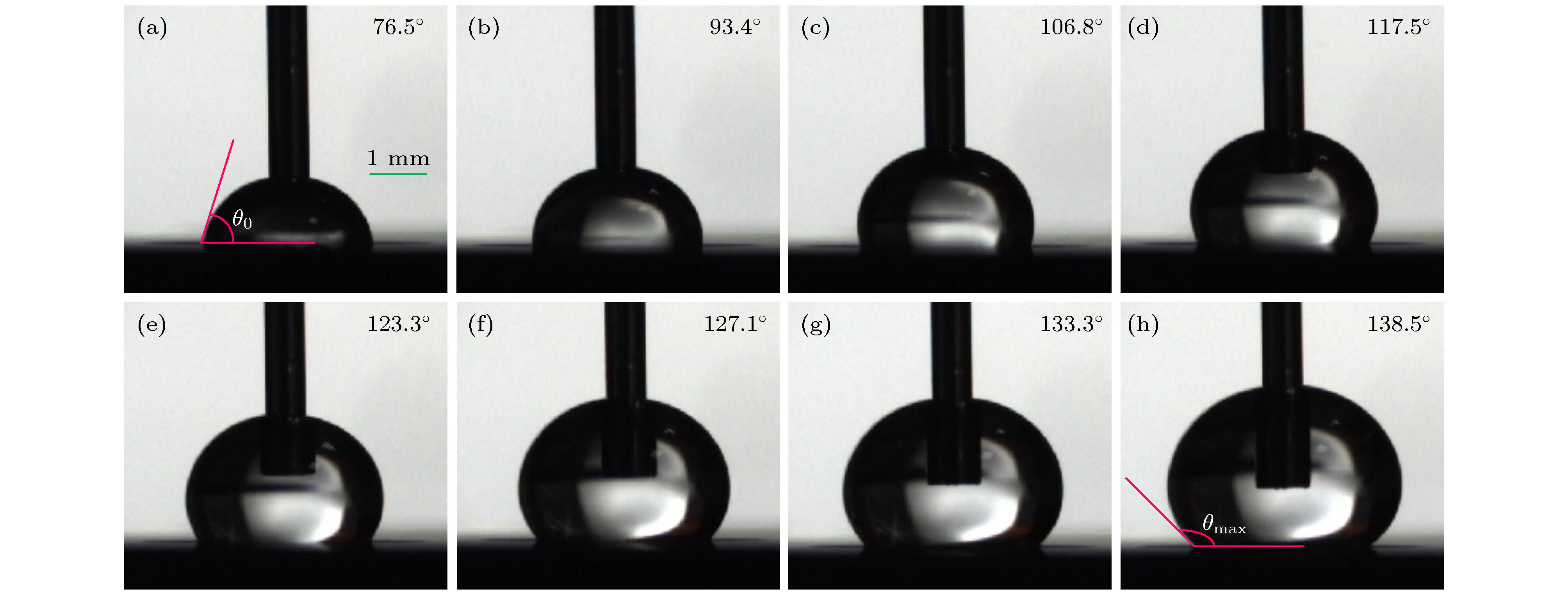

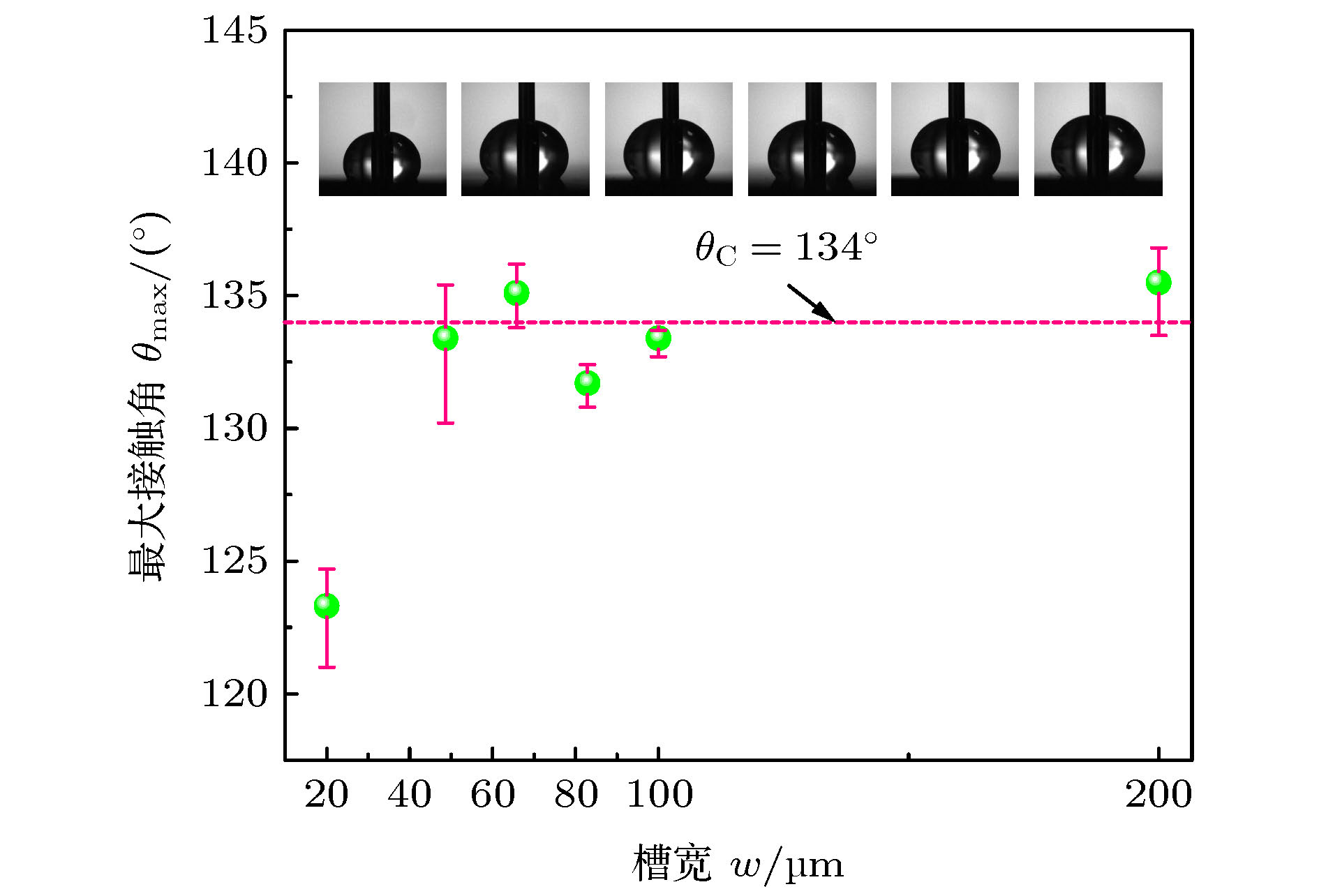

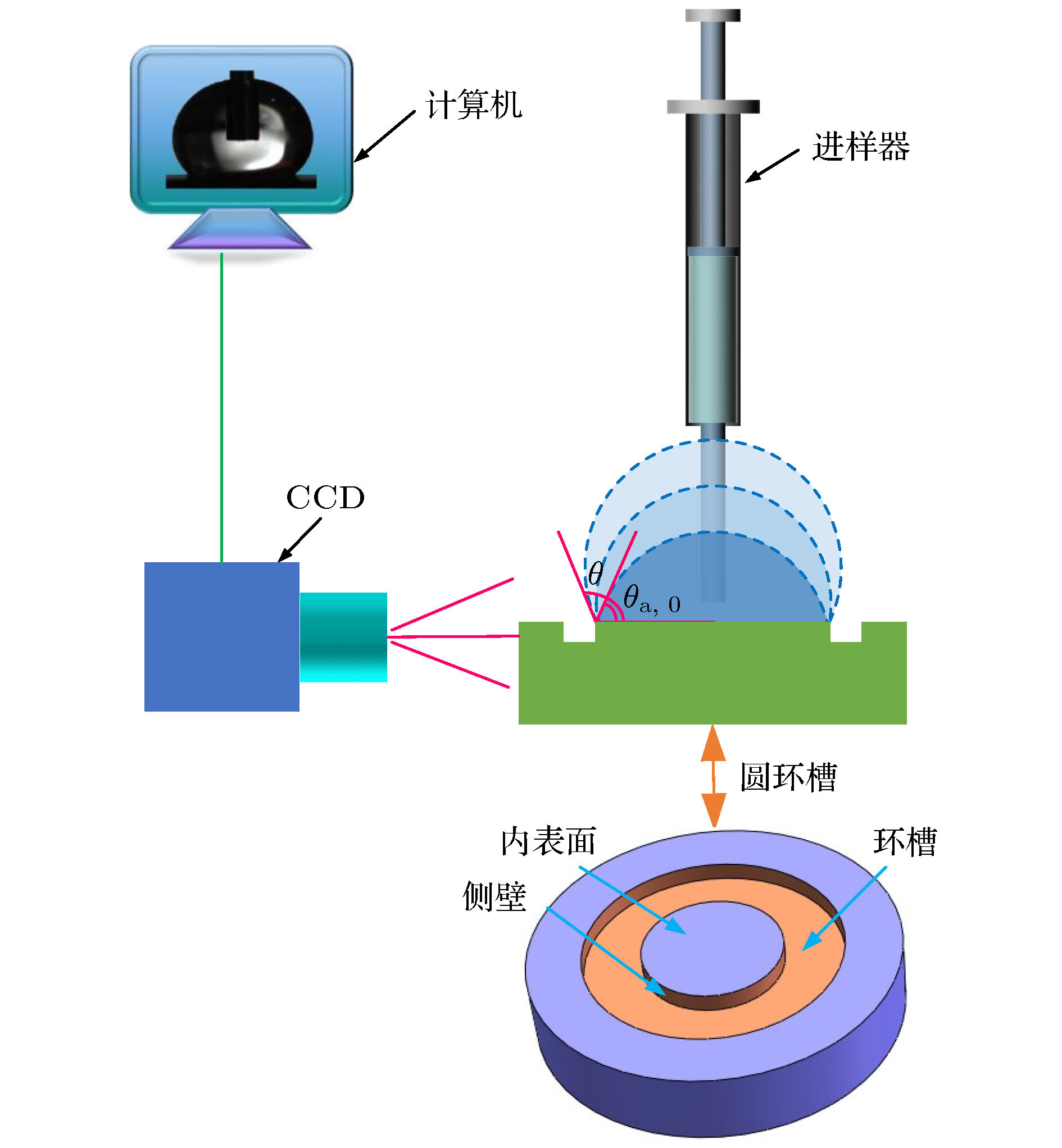

To reduce the run-off of fluid in sealing system, especially in the multiphase medium and extreme operating conditions, it is necessary to investigate the wetting and spreading behavior in silicon carbon (SiC) sealing face. Considering the sealing performance, ring-grooved structures with a varying depth (h) and width (w) are fabricated on SiC substrates by laser marking machine. The radius of structure’ inner surface is 1.5 mm, less than the capillary length of water. Then, experimental equipment is designed to observe the profile and the spreading behaviors of droplet on the surface, and the wetting performance and pinning effect are discussed, and the influences of depth and width of ring-grooves on the wetting performance can be obtained. The results show that the contact angle (CA) and the advancing contact angle (ACA) of smooth SiC surface are 70° and 76.5°, respectively. And the values decrease to CA 50° and ACA 54° after laser processing, which may be due to the average roughness (Ra) increasing from 0.1 μm in smooth surface to 0.8 μm in laser machined surface, making the hydrophilic surface more hydrophilic. The CA on the edge of ring-grooves increases to 138.5°, the control of fluid can be realized. When the droplet spreads along the radius direction before reaching the edge of groove, its CA keeps 76.5°. Once it reaches the edge, the position of contact line remains constant or changes slowly along the wall of groove(we are more inclined to the latter), and thus making the CA increase with the droplet volume increasing, until reaching a maximum apparent contact angle (θmax). And θmax in the experiment is less than that from the Gibbs equation, which is perhaps because of the mechanical vibration, the roughness of the wall or the liquid viscosity effect. After that, the droplet collapses, and spreads along the groove area, or even flows over the outer edge of the ring groove. The influences of h and w of groove are then studied, showing that θmax first increases linearly and then tends to be stable with the increase of h, and the depth of groove has a critical value (hc) of 80 μm. When h < hc, the droplet moves along the wall to the bottom of groove, the droplet collapses after reaching the bottom under the surface tension function. However, when h ≥ hc, the droplet is in a stable condition, and collapses with the increase of volume. When h = 100 μm, a critical value of width (wc) of 40 μm exists for the geometrical relationships of ACA in wall between h and w. If w is too small, the droplet will contact the outer diameter of ring groove, which finally makes the droplet collapse and spread on the smooth surface. The present research can conduce to understanding the pinning effect in the solid edge and the spreading behavior of droplets in SiC surface.

-

Keywords:

- SiC /

- ring-grooved structures /

- droplet spreading /

- edge effect

[1] 赵亚溥 2012 表面与界面物理力学 (北京: 科学出版社) 第171−200页

Zhao Y P 2012 Surface and Interface Physical Mechanics (Beijing: Science Press) pp171−200 (in Chinese)

[2] Fang G, Amirfazli A 2012 Langmuir 28 9421

Google Scholar

Google Scholar

[3] Qiao X X, Zhang X J, Chen P, Tian Y, Meng Y G 2020 Chin. Phys. B 29 372

Google Scholar

Google Scholar

[4] 余剑武, 陆岳托, 罗红, 仝瑞庆, 宋金英 http://kns.cnki.net/kcms/detail/50.1083.TG.20200617.1532.036.html [2020-08-10]

Yu J W, Lu Y T, Luo H, Tong R Q, Song J G http://kns.cnki.net/kcms/detail/50.1083.TG.20200617.1532.036.html [2020-08-10] (in Chinese)

[5] 叶学民, 张湘珊, 李明兰, 李春曦 2018 67 156

Google Scholar

Google Scholar

Ye X M, Zhang X S, Li M L, Li C X 2018 Acta. Phys. Sin. 67 156

Google Scholar

Google Scholar

[6] 焦云龙, 刘小君, 刘琨 2016 力学学报 48 353

Google Scholar

Google Scholar

Jiao Y L, Liu X J, Liu K 2016 Chin. J. Theor. Appl. Mech. 48 353

Google Scholar

Google Scholar

[7] 雍佳乐, 杨青, 陈烽, 侯洵 2019 科学通报 64 1213

Google Scholar

Google Scholar

Yong J L, Yang Q, Chen F, Hou X 2019 Chin. Sci. Bull. 64 1213

Google Scholar

Google Scholar

[8] 王鹏伟, 刘明杰, 江雷 2016 65 61

Google Scholar

Google Scholar

Wang P W, Liu M J, Jiang L 2016 Acta. Phys. Sin. 65 61

Google Scholar

Google Scholar

[9] Chang B, Shah A, Routa I, Lipsanen H, Zhou Q 2014 J. Micro-Bio. Robot. 9 1

Google Scholar

Google Scholar

[10] Dejarld M, Nothern D, Millunchick J M 2014 J. Appl. Phys. 115 106

Google Scholar

Google Scholar

[11] Hong W, Tang L J, Sun W X, Ji B W, Yang B, Liu J Q 2019 J. Microelectromech. S. 99 1

Google Scholar

Google Scholar

[12] Shardt O, Waghmare P R, Derksen J J, Mitra S K 2014 RSC. Adv. 4 14781

Google Scholar

Google Scholar

[13] Hu L, Wu M, Chen W Y, Xie H B, Fu X 2017 Exp. Therm. Fluid. Sci. 87 50

Google Scholar

Google Scholar

[14] 郑益华 2020 博士学位论文 (长春: 吉林大学)

Zheng Y H 2020 Ph. D. Dissertation (Changchun: Jilin University) (in Chinese)

[15] Gibbs J W, Donnan F G, Haas A (edited by) 1936 A commentary on the scientific writings of J. Willard Gibbs (Vol.1) (New Harven: Yale University Press) pp675−676

[16] Du J, Michielsen S, Lee H J 2010 Langmuir 26 16000

Google Scholar

Google Scholar

[17] 乔小溪, 张向军, 陈平, 田煜, 孟永钢 2020 69 205

Google Scholar

Google Scholar

Qiao X X, Zhang X J, Chen P, Tian Y, Meng Y G 2020 Acta. Phys. Sin. 69 205

Google Scholar

Google Scholar

[18] Kim D, Jeong M, Kang K W, Ryu S 2020 Langmuir 36 6061

Google Scholar

Google Scholar

[19] Wang Z L, Kui L, Zhao Y P 2019 J. Collid. Interf. Sci. 552 563

Google Scholar

Google Scholar

[20] Ma B J, Shan L, Dogruoz B, Agonafer D 2019 Langmuir 35 12264

Google Scholar

Google Scholar

[21] Tóth T, Ferraro D, Chiarello E, Pierno M, Mistura G, Bissacco G, Semprebon C 2011 Langmuir 27 4742

Google Scholar

Google Scholar

[22] Oliver J F, Huh C, Mason S G 1977 J. Collid. Interf. Sci. 59 568

Google Scholar

Google Scholar

[23] Zhang J, Gao X, Jiang L 2007 Langmuir 23 3230

Google Scholar

Google Scholar

[24] Kalinin Y V, Berejnov V, Thorne R E 2009 Langmuir 25 5391

Google Scholar

Google Scholar

[25] Tsoumpas Y, Dehaeck S, Galvagno M, Rednikov A, Ottevaere H 2014 Langmuir 30 11847

Google Scholar

Google Scholar

[26] Mueller J, Haghparastmojaveri N, Alan T, Neild A 2013 Appl. Phys. Lett. 102 041605

Google Scholar

Google Scholar

[27] Wang Z L, Chen E H, Zhao Y P 2018 Sci. China Tech. Sci. 61 309

Google Scholar

Google Scholar

[28] Extrand C W 2005 Langmuir 21 10370

Google Scholar

Google Scholar

[29] 王茜, 韩素立, 郭峰, 李超 2019 摩擦学学报 39 340

Google Scholar

Google Scholar

Wang Q, Han S L, Guo F, Li C 2019 Tribology 39 340

Google Scholar

Google Scholar

[30] Young T 1805 Phil. Trans. 95 65

Google Scholar

Google Scholar

[31] 赵亚溥 2020 理性力学教程 (北京: 科学出版社) 第492页

Zhao Y P 2020 Course of Rational Mechanics (Beijing: Science Press) p492 (in Chinese)

[32] Mayama H, Nonomura Y 2011 Langmuir 27 3550

Google Scholar

Google Scholar

-

图 4 SiC圆环槽表面接触角 (a) 光滑平面固态接触角; (b) 光滑表面前进接触角; (c) 织构表面固有接触角; (d) 织构表面前进接触角

Figure 4. SiC ring groove surface contact angle: (a)Smooth plane static contact angle; (b) smooth surface advancing contact angle; (c) static contact angle of textured surface; (d) advancing contact angle of textured surface.

表 1 SiC圆环槽几何参数表

Table 1. Structural parameters of ring grooved on SiC surface.

序号 内径di/ mm 槽深h/μm 槽宽w/μm 序号 内径di/mm 槽深h/μm 槽宽w/μm 1 3 20 1000 2 3 100 20 50 40 80 60 100 80 200 100 290 200 480 620 -

[1] 赵亚溥 2012 表面与界面物理力学 (北京: 科学出版社) 第171−200页

Zhao Y P 2012 Surface and Interface Physical Mechanics (Beijing: Science Press) pp171−200 (in Chinese)

[2] Fang G, Amirfazli A 2012 Langmuir 28 9421

Google Scholar

Google Scholar

[3] Qiao X X, Zhang X J, Chen P, Tian Y, Meng Y G 2020 Chin. Phys. B 29 372

Google Scholar

Google Scholar

[4] 余剑武, 陆岳托, 罗红, 仝瑞庆, 宋金英 http://kns.cnki.net/kcms/detail/50.1083.TG.20200617.1532.036.html [2020-08-10]

Yu J W, Lu Y T, Luo H, Tong R Q, Song J G http://kns.cnki.net/kcms/detail/50.1083.TG.20200617.1532.036.html [2020-08-10] (in Chinese)

[5] 叶学民, 张湘珊, 李明兰, 李春曦 2018 67 156

Google Scholar

Google Scholar

Ye X M, Zhang X S, Li M L, Li C X 2018 Acta. Phys. Sin. 67 156

Google Scholar

Google Scholar

[6] 焦云龙, 刘小君, 刘琨 2016 力学学报 48 353

Google Scholar

Google Scholar

Jiao Y L, Liu X J, Liu K 2016 Chin. J. Theor. Appl. Mech. 48 353

Google Scholar

Google Scholar

[7] 雍佳乐, 杨青, 陈烽, 侯洵 2019 科学通报 64 1213

Google Scholar

Google Scholar

Yong J L, Yang Q, Chen F, Hou X 2019 Chin. Sci. Bull. 64 1213

Google Scholar

Google Scholar

[8] 王鹏伟, 刘明杰, 江雷 2016 65 61

Google Scholar

Google Scholar

Wang P W, Liu M J, Jiang L 2016 Acta. Phys. Sin. 65 61

Google Scholar

Google Scholar

[9] Chang B, Shah A, Routa I, Lipsanen H, Zhou Q 2014 J. Micro-Bio. Robot. 9 1

Google Scholar

Google Scholar

[10] Dejarld M, Nothern D, Millunchick J M 2014 J. Appl. Phys. 115 106

Google Scholar

Google Scholar

[11] Hong W, Tang L J, Sun W X, Ji B W, Yang B, Liu J Q 2019 J. Microelectromech. S. 99 1

Google Scholar

Google Scholar

[12] Shardt O, Waghmare P R, Derksen J J, Mitra S K 2014 RSC. Adv. 4 14781

Google Scholar

Google Scholar

[13] Hu L, Wu M, Chen W Y, Xie H B, Fu X 2017 Exp. Therm. Fluid. Sci. 87 50

Google Scholar

Google Scholar

[14] 郑益华 2020 博士学位论文 (长春: 吉林大学)

Zheng Y H 2020 Ph. D. Dissertation (Changchun: Jilin University) (in Chinese)

[15] Gibbs J W, Donnan F G, Haas A (edited by) 1936 A commentary on the scientific writings of J. Willard Gibbs (Vol.1) (New Harven: Yale University Press) pp675−676

[16] Du J, Michielsen S, Lee H J 2010 Langmuir 26 16000

Google Scholar

Google Scholar

[17] 乔小溪, 张向军, 陈平, 田煜, 孟永钢 2020 69 205

Google Scholar

Google Scholar

Qiao X X, Zhang X J, Chen P, Tian Y, Meng Y G 2020 Acta. Phys. Sin. 69 205

Google Scholar

Google Scholar

[18] Kim D, Jeong M, Kang K W, Ryu S 2020 Langmuir 36 6061

Google Scholar

Google Scholar

[19] Wang Z L, Kui L, Zhao Y P 2019 J. Collid. Interf. Sci. 552 563

Google Scholar

Google Scholar

[20] Ma B J, Shan L, Dogruoz B, Agonafer D 2019 Langmuir 35 12264

Google Scholar

Google Scholar

[21] Tóth T, Ferraro D, Chiarello E, Pierno M, Mistura G, Bissacco G, Semprebon C 2011 Langmuir 27 4742

Google Scholar

Google Scholar

[22] Oliver J F, Huh C, Mason S G 1977 J. Collid. Interf. Sci. 59 568

Google Scholar

Google Scholar

[23] Zhang J, Gao X, Jiang L 2007 Langmuir 23 3230

Google Scholar

Google Scholar

[24] Kalinin Y V, Berejnov V, Thorne R E 2009 Langmuir 25 5391

Google Scholar

Google Scholar

[25] Tsoumpas Y, Dehaeck S, Galvagno M, Rednikov A, Ottevaere H 2014 Langmuir 30 11847

Google Scholar

Google Scholar

[26] Mueller J, Haghparastmojaveri N, Alan T, Neild A 2013 Appl. Phys. Lett. 102 041605

Google Scholar

Google Scholar

[27] Wang Z L, Chen E H, Zhao Y P 2018 Sci. China Tech. Sci. 61 309

Google Scholar

Google Scholar

[28] Extrand C W 2005 Langmuir 21 10370

Google Scholar

Google Scholar

[29] 王茜, 韩素立, 郭峰, 李超 2019 摩擦学学报 39 340

Google Scholar

Google Scholar

Wang Q, Han S L, Guo F, Li C 2019 Tribology 39 340

Google Scholar

Google Scholar

[30] Young T 1805 Phil. Trans. 95 65

Google Scholar

Google Scholar

[31] 赵亚溥 2020 理性力学教程 (北京: 科学出版社) 第492页

Zhao Y P 2020 Course of Rational Mechanics (Beijing: Science Press) p492 (in Chinese)

[32] Mayama H, Nonomura Y 2011 Langmuir 27 3550

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8742

- PDF Downloads: 88

- Cited By: 0

DownLoad:

DownLoad: