-

The existence of serious hysteresis effect for regular perovskite solar cells (PSCs) will affect their performances, however, the inverted PSCs can significantly suppress the hysteresis effect. To data, it has been very rarely reported to simulate the inverted planar heterojunction PSCs. In this paper, the effects of hole transport material (HTM), electron transport material (ETM), and ITO work function on performance of inverted MAPbI3 solar cells are carefully investigated in order to design the high-performance inverted PSCs. The inverted MAPbI3 solar cells using Cu2O, CuSCN, or NiOx as HTM, and PC61BM, TiO2, or ZnO as ETM are simulated with the program AMPS-1D. Simulation results reveal that i) the inverted MAPbI3 solar cells choosing NiOx as HTM can effectively improve the photovoltaic performance, and the excellent photovoltaic performance obtained by using TiO2 as ETM is almost the same as by using ZnO as ETM; ii) the ITO work function increasing from 4.6 eV to 5.0 eV can significantly enhance the photovoltaic performances of Cu2O— based and CuSCN— based inverted MAPbI3 solar cells, and the NiOx— based inverted MAPbI3 solar cells have only a minor photovoltaic performance enhancement; iii) based on the reported ITO work function between 4.6 eV and 4.8 eV, the maximum power conversion efficiency (PCE) of 27.075% and 29.588% for CuSCN— based and NiOx— based inverted MAPbI3 solar cells are achieved when the ITO work function reaches 4.8 eV. The numerical simulation gives that the increase of hole mobility in CuSCN and NiOx for ITO/CuSCN/MAPbI3/TiO2/Al and ITO/NiOx/MAPbI3/TiO2/Al can greatly improve the device performance. Experimentally, the maximum hole mobility 0.1 cm2·V–1·s–1 in CuSCN restricts the photovoltaic performance improvement of CuSCN— based inverted MAPbI3 solar cells, which means that there is still room for the improvement of cell performance through increasing the hole mobility in CuSCN. It is found that NiOx with a reasonable energy-band structure and high hole mobility 120 cm2·V–1·s–1 is an ideal HTM in inverted MAPbI3 solar cells. However, the increasing of electron mobility in TiO2 cannot improve the device photovoltaic performance of inverted MAPbI3 solar cells. These simulation results reveal the effects of ETM, HTM, and ITO work function on the photovoltaic performance of inverted MAPbI3 solar cells. Our researches may help to design the high-performance inverted PSCs.

-

Keywords:

- inverted structure /

- halide perovskite solar cells /

- photovoltaic performance /

- numerical simulation

[1] Zhou H P, Chen Q, Li G, Luo S, Song T B, Duan H S, Hong Z, You J B, Liu Y S, Yang Y 2014 Science 345 542

Google Scholar

Google Scholar

[2] Yin W J, Shi T T, Yan Y T 2014 Appl. Phys. Lett. 104 063903

Google Scholar

Google Scholar

[3] Boix P P, Nonomura K, Mathews N, Mhaisalkar S G 2014 Mater. Today 17 16

Google Scholar

Google Scholar

[4] Akihiro K, Kenjiro T, Yasuo S, Tsutomu M 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[5] Meng L, You J B, Yang Y 2018 Nat. Commun. 9 5265

Google Scholar

Google Scholar

[6] Snaith H J, Abate A, Ball J M, Eperon G E, Leijtens T, Noel N K, Stranks S D, Wang J T, Wojciechowski K, Zhang W 2014 J. Phys. Chem. Lett. 5 1511

Google Scholar

Google Scholar

[7] Saliba M 2018 Science 359 388

Google Scholar

Google Scholar

[8] Yu S, Yan Y, Chen Y, Chábera P, Zheng K, Liang Z 2019 J. Mater. Chem. A 7 2015

Google Scholar

Google Scholar

[9] Liu T H, Chen K, Hu Q, Zhu R, Gong Q H 2016 Adv. Energy Mater. 6 1600457

Google Scholar

Google Scholar

[10] Jeng J Y, Chiang Y F, Lee M H, Peng S R, Guo T F, Chen P, Wen T C 2013 Adv. Mater 25 3727

Google Scholar

Google Scholar

[11] Li J W, Dong Q S, Li N, Wang L D 2017 Adv. Energy Mater. 7 1602922

Google Scholar

Google Scholar

[12] Shi J J, Zhang H Y, Xu X, Li D M, Luo Y H, Meng Q B 2016 Small 12 5288

Google Scholar

Google Scholar

[13] Kakavelakis G, Maksudov T, Konios D, Paradisanos I, Kioseoglou G, Stratakis E, Kymakis E 2017 Adv. Energy Mater. 7 1602120

Google Scholar

Google Scholar

[14] Wang K C, Shen P S, Li M H, Chen S, Lin M W, Chen P, Guo T F 2014 ACS Appl. Mater. Interfaces 6 11851

Google Scholar

Google Scholar

[15] Chen W, Wu Y Z, Yue Y F, Liu J, Zhang W J, Yang X D, Chen H, Bi E B, Ashraful I, Grätzel M, Han L Y 2015 Science 350 944

Google Scholar

Google Scholar

[16] Bi C, Wang Q, Shao Y, Yuan Y, Xiao Z, Huang J 2015 Nat. Commun. 6 8747

Google Scholar

Google Scholar

[17] Shao Y C, Yuan Y B, Huang J S 2016 Nat. Energy 1 15001

Google Scholar

Google Scholar

[18] Kuang C Y, Tang G, Jiu T G, Yang H, Liu H B, Li B R, Luo W N, Li X G, Zhang W J, Lu F S, Fang J F, Li Y L 2015 Nano Lett. 15 2756

Google Scholar

Google Scholar

[19] Luo D Y, Yang W Q, Wang Z P, Sadhanala A, Hu Q, Su R, Shivanna R, Trindade G F, Watts J F, Xu Z J, Liu T H, Chen K, Ye F J, Wu P, Zhao L C, Wu J, Tu Y G, Zhang Y F, Yang X Y, Zhang W, Friend R H, Gong Q H, Snaith H J, Zhu R 2018 Science 360 1442

Google Scholar

Google Scholar

[20] Fonash S, Arch J, Cuiffi J, et al. A One-Dimensional Device Simulation Program for the Analysis of Microelectronic and Photonic Structures http://www.emprl.psu.edu/amps[1997-1-1]

[21] Zhang A, Chen Y L, Yan J 2016 Ieee J. Quantum Elect. 52 1600106

Google Scholar

Google Scholar

[22] Onoda-Yamamuro N, Matsuo T, Suga H 1992 J. Phys. Chem. Solids. 53 935

Google Scholar

Google Scholar

[23] Laban W A, Etgar L 2013 Energ. Environ Sci. 6 3249

Google Scholar

Google Scholar

[24] Stoumpos C C, Malliakas C D, Kanatzidis M G 2013 Inorg. Chem. 52 9019

Google Scholar

Google Scholar

[25] Rode D L 1975 Semiconductors and Semimetals (New York: Academic) pp1–89

[26] Muth J F, Kolbas R M, Sharma A K, Oktabrsky S, Narayan J 1999 J. Appl. Phys. 85 7884

Google Scholar

Google Scholar

[27] Moormann H, Kohl D, Heiland G 1980 Surf. Sci. 100 302

Google Scholar

Google Scholar

[28] Hagemark K J, Chacka L C 1975 J. Solid State Chem. 15 261

Google Scholar

Google Scholar

[29] Kim K J, Park Y R 2001 Appl. Phys. Lett. 78 475

Google Scholar

Google Scholar

[30] Wojciechowski K, Saliba M, Leijtens T, Abate A, Snaith H J 2014 Energ. Environ. Sci. 7 1142

Google Scholar

Google Scholar

[31] Liu F, Zhu J, Wei J F, Li Y, Lv M, Yang S F, Zhang B, Yao J X, Dai S Y 2014 Appl. Phys. Lett. 104 253508

Google Scholar

Google Scholar

[32] Jaffe J E, Kaspar T C, Droubay T C, Varga T, Bowden M E, Exarhos G J 2010 J. Phys. Chem. C 114 9111

Google Scholar

Google Scholar

[33] Kaiser I, Ernst K, Fischer C H, Konenkamp R, Rost C, Sieber I, Lux-Steiner M C 2001 Sol. Energy Mater. Sol. Cells. 67 89

Google Scholar

Google Scholar

[34] Pattanasattayavong P, Ndjawa G O N, Zhao K, Chou K W, Yaacobi-Gross N, O’Regan B C, Amassian A, Anthopoulos T D 2013 Chem. Commun. 49 4154

Google Scholar

Google Scholar

[35] Pattanasattayavong P, Yaacobi-Gross N, Zhao K, Ndjawa G O N, Li J H, Yan F, O’Regan B C, Amassiann A, Anthopoulos T D 2013 Adv. Mater 25 1504

Google Scholar

Google Scholar

[36] Rao V, Smakula A 1965 J. Appl. Phys. 36 2031

Google Scholar

Google Scholar

[37] Ratcliff E L, Meyer J, Steirer K X, Armstrong N R, Olson D, Kahn A 2012 Org. Electron. 13 744

Google Scholar

Google Scholar

[38] Wu H B, Wang L S 1997 J. Chem. Phys. 107 16

Google Scholar

Google Scholar

[39] Liu M H, Zhou Z J, Zhang P P, Tian Q W, Zhou W H, Kou D X, Wu S X 2016 Opt. Express 24 1349

Google Scholar

Google Scholar

[40] Rakhshani A E 1991 J. Appl. Phys. 69 2365

Google Scholar

Google Scholar

[41] Ghijsen J, Tjeng L H, van Elp J, Eskes H, Westerink J, Sawatzky G A 1988 Phys. Rev. B 38 11322

Google Scholar

Google Scholar

[42] Zuo C T, Ding L M 2015 Small 11 5528

Google Scholar

Google Scholar

[43] Matsumura H, Fujii A, Kitatani T 1996 Jpn. J. Appl. Phys. 35 5631

Google Scholar

Google Scholar

[44] Shewchun J, Dubow J, Wilmsen C W, Singh R, Burk D, Wager J F 1979 J. Appl. Phys. 50 2832

Google Scholar

Google Scholar

[45] Park Y, Choong V, Gao Y, Hsieh B R, Tang C W 1996 Appl. Phys. Lett. 68 2699

Google Scholar

Google Scholar

[46] Balasubramanian N, Subrahmanyam A 1991 J. Electrochem. Soc. 138 322

Google Scholar

Google Scholar

[47] Nehate S D, Prakash A, DossMani P, Sundaram, K B 2018 ECS J. Solid State Sc. 7 87

-

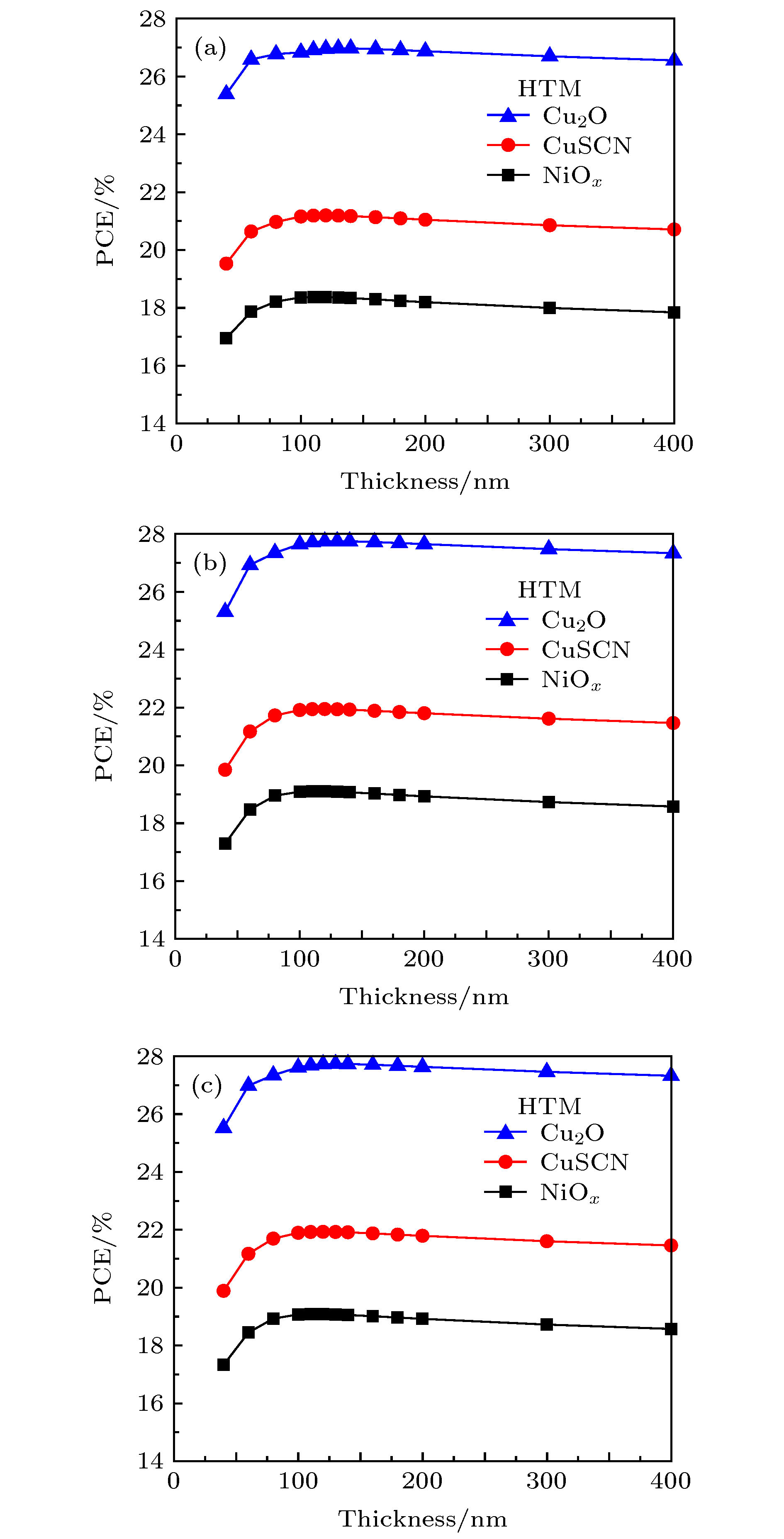

图 2 模拟反式钙钛矿太阳电池 (a) ITO/HTM/MAPbI3/PC61BM/Al, (b) ITO/HTM/MAPbI3/TiO2/Al, (c) ITO/HTM/MAPbI3/ZnO/Al的PCE随MAPbI3厚度的变化, 前、后电极的功函数分别是4.6 eV (ITO) 和4.3 eV (Al)

Figure 2. The PCE of inverted perovskite solar cells for (a) ITO/HTM/MAPbI3/PC61BM/Al, (b) ITO/HTM/MAPbI3/TiO2/Al, and (c) ITO/HTM/MAPbI3/ZnO/Al simulated with the MAPbI3 thickness. Front and back contact work function: 4.6 eV (ITO) and 4.3 eV (Al), respectively.

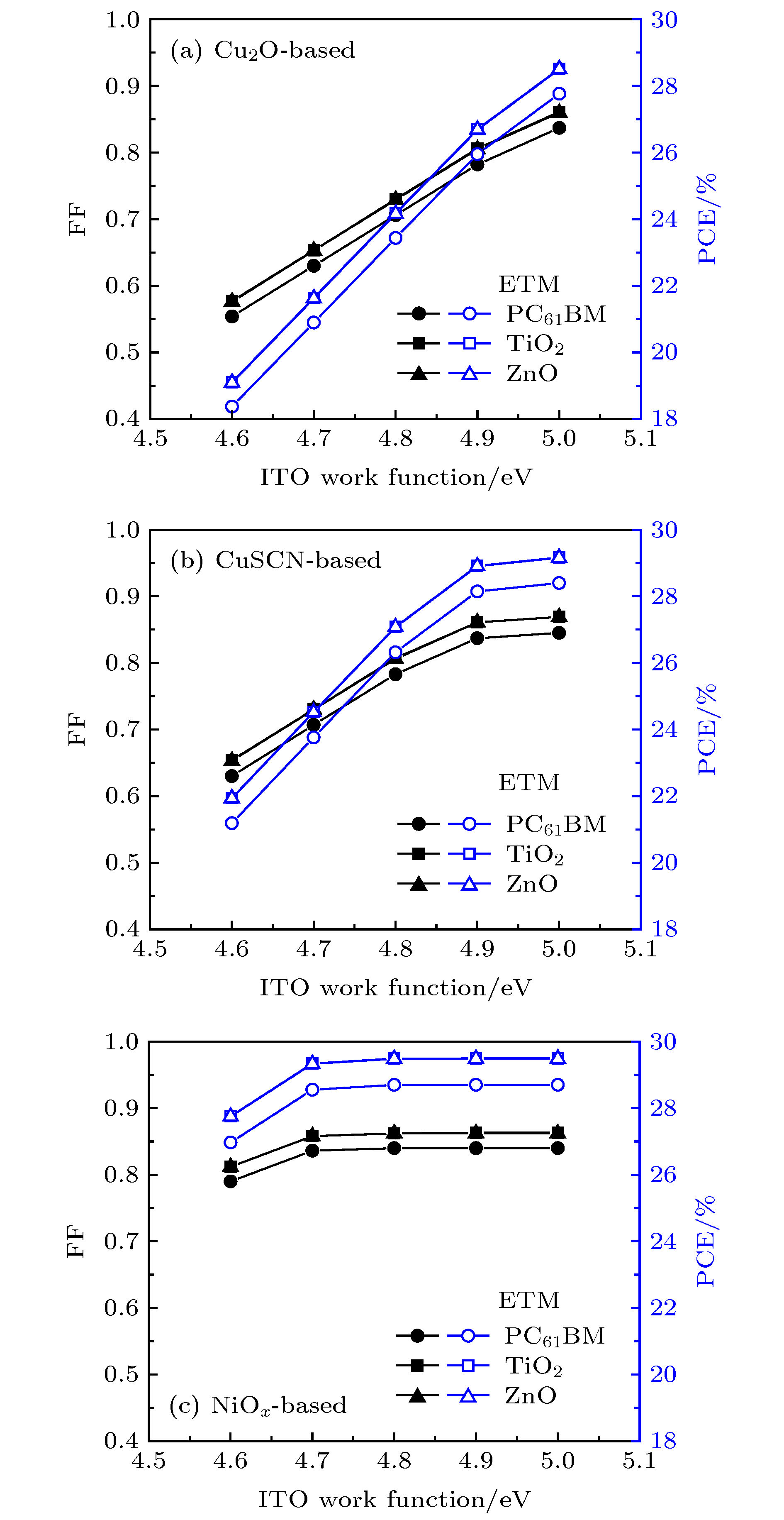

图 3 模拟反式钙钛矿太阳电池 (a) ITO/CuO2/MAPbI3/ETM/Al; (b) ITO/CuSCN/MAPbI3/ETM/Al; (c) ITO/NiOx/MAPbI3/ETM/Al的PCE和FF随ITO功函数的变化, ETM表示PC61BM, TiO2, ZnO

Figure 3. Simulation for PCE and FF of inverted perovskite solar cells for (a) ITO/CuO2/MAPbI3/ETM/Al, (b) ITO/CuSCN/MAPbI3/ETM/Al, and (c) ITO/NiOx/MAPbI3/ETM/Al solar cells as a function of ITO work function, here ETM is PC61BM, TiO2, or ZnO.

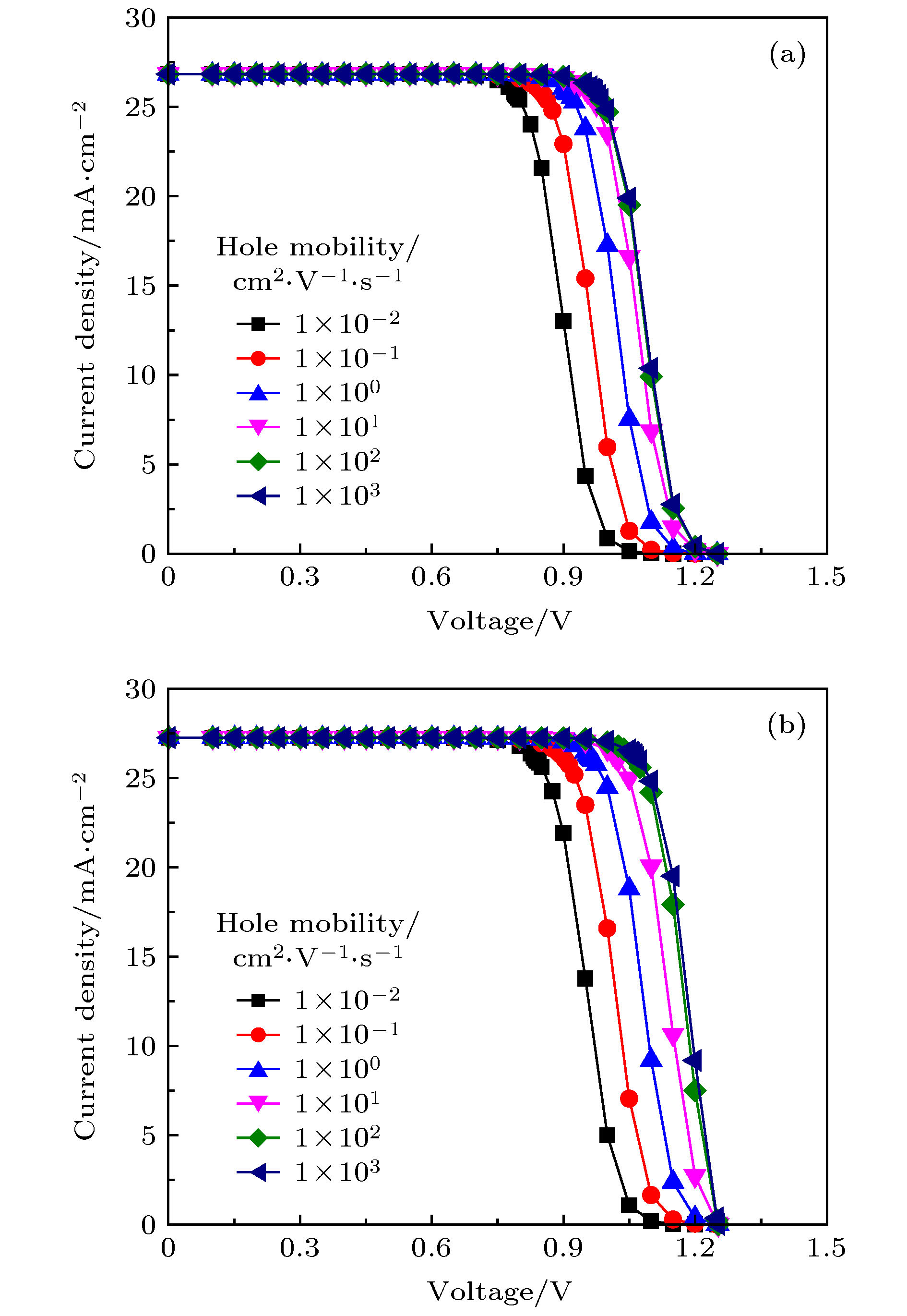

图 4 太阳能电池的伏安特性随CuSCN和NiOx中空穴迁移率变化的函数, 前、后电极的功函数分别是: 4.6 eV (ITO) 和4.3 eV (Al) (a) ITO/CuSCN/MAPbI3/TiO2/Al; (b) ITO/NiOx/MAPbI3/TiO2/Al

Figure 4. J-V characteristics of solar cell as a function of hole mobility in CuSCN and NiOx. Front and back contact work function is 4.6 eV (ITO) and 4.3 eV (Al), respectively: (a) ITO/CuSCN/MAPbI3/TiO2/Al; (b) ITO/NiOx/MAPbI3/TiO2/Al.

表 1 AMPS-1D采用的MAPbI3 和ETM参数

Table 1. AMPS-1D parameters set for MAPbI3 and ETM.

Parameters MAPbI3 ZnO TiO2 PC61BM Dielectric constant 23.3[22] 8.12[25] 100[30] 3.9[18] Band gap/eV 1.51[23] 3.40[26] 3.2[31] 1.9[9] Electron affinity/eV 3.93[23] 4.19[27] 4.0[31] 3.9[9] Thickness/nm 40-400 90 90 90 Electron and hole mobility/cm2·V–1·s–1 50, 50[24] 150, 0.0001[28] 0.006, 0.006[30] 0.0005, 0.0001[18] Acceptor concentration/cm–3 (2.14 × 1017)[23] 0 0 0 Donor concentration/cm–3 0 (5 × 1019)[29] (5 × 1019)[30] 5 × 1019 Effective conduction band density/cm–3 1.66 × 1019 4.49 × 1018 1.0 × 1021 2.5 × 1020 Effective valence band density/cm–3 5.41 × 1018 5.39 × 1018 2.0 × 1020 2.5 × 1020 表 2 AMPS-1D采用的HTM参数

Table 2. AMPS-1D parameters set for HTM.

Parameters CuSCN NiOx Cu2O Dielectric constant 10[32] 11.9[36] 8.8[40] Band gap/eV 3.4[33] 3.7[37] 2.17[41] Electron affinity/eV 1.9[33] 1.5[38] 3.3[42] Thickness/nm 200 200 200 Electron and hole mobility/cm2·V–1·s–1 0.0001, 0.01—0.10[34] 0.0001, 120[39] 0.0001, 10[43] Acceptor concentration/cm–3 (5 × 1018)[35] (2.66 × 1017)[15] (5 × 1015)[43] Donor concentration/cm–3 0 0 0 Effective conduction band density/cm–3 1.79 × 1019 2.5 × 1019 2.5 × 1019 Effective valence band density/cm–3 2.51 × 1019 2.5 × 1019 2.5 × 1019 -

[1] Zhou H P, Chen Q, Li G, Luo S, Song T B, Duan H S, Hong Z, You J B, Liu Y S, Yang Y 2014 Science 345 542

Google Scholar

Google Scholar

[2] Yin W J, Shi T T, Yan Y T 2014 Appl. Phys. Lett. 104 063903

Google Scholar

Google Scholar

[3] Boix P P, Nonomura K, Mathews N, Mhaisalkar S G 2014 Mater. Today 17 16

Google Scholar

Google Scholar

[4] Akihiro K, Kenjiro T, Yasuo S, Tsutomu M 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[5] Meng L, You J B, Yang Y 2018 Nat. Commun. 9 5265

Google Scholar

Google Scholar

[6] Snaith H J, Abate A, Ball J M, Eperon G E, Leijtens T, Noel N K, Stranks S D, Wang J T, Wojciechowski K, Zhang W 2014 J. Phys. Chem. Lett. 5 1511

Google Scholar

Google Scholar

[7] Saliba M 2018 Science 359 388

Google Scholar

Google Scholar

[8] Yu S, Yan Y, Chen Y, Chábera P, Zheng K, Liang Z 2019 J. Mater. Chem. A 7 2015

Google Scholar

Google Scholar

[9] Liu T H, Chen K, Hu Q, Zhu R, Gong Q H 2016 Adv. Energy Mater. 6 1600457

Google Scholar

Google Scholar

[10] Jeng J Y, Chiang Y F, Lee M H, Peng S R, Guo T F, Chen P, Wen T C 2013 Adv. Mater 25 3727

Google Scholar

Google Scholar

[11] Li J W, Dong Q S, Li N, Wang L D 2017 Adv. Energy Mater. 7 1602922

Google Scholar

Google Scholar

[12] Shi J J, Zhang H Y, Xu X, Li D M, Luo Y H, Meng Q B 2016 Small 12 5288

Google Scholar

Google Scholar

[13] Kakavelakis G, Maksudov T, Konios D, Paradisanos I, Kioseoglou G, Stratakis E, Kymakis E 2017 Adv. Energy Mater. 7 1602120

Google Scholar

Google Scholar

[14] Wang K C, Shen P S, Li M H, Chen S, Lin M W, Chen P, Guo T F 2014 ACS Appl. Mater. Interfaces 6 11851

Google Scholar

Google Scholar

[15] Chen W, Wu Y Z, Yue Y F, Liu J, Zhang W J, Yang X D, Chen H, Bi E B, Ashraful I, Grätzel M, Han L Y 2015 Science 350 944

Google Scholar

Google Scholar

[16] Bi C, Wang Q, Shao Y, Yuan Y, Xiao Z, Huang J 2015 Nat. Commun. 6 8747

Google Scholar

Google Scholar

[17] Shao Y C, Yuan Y B, Huang J S 2016 Nat. Energy 1 15001

Google Scholar

Google Scholar

[18] Kuang C Y, Tang G, Jiu T G, Yang H, Liu H B, Li B R, Luo W N, Li X G, Zhang W J, Lu F S, Fang J F, Li Y L 2015 Nano Lett. 15 2756

Google Scholar

Google Scholar

[19] Luo D Y, Yang W Q, Wang Z P, Sadhanala A, Hu Q, Su R, Shivanna R, Trindade G F, Watts J F, Xu Z J, Liu T H, Chen K, Ye F J, Wu P, Zhao L C, Wu J, Tu Y G, Zhang Y F, Yang X Y, Zhang W, Friend R H, Gong Q H, Snaith H J, Zhu R 2018 Science 360 1442

Google Scholar

Google Scholar

[20] Fonash S, Arch J, Cuiffi J, et al. A One-Dimensional Device Simulation Program for the Analysis of Microelectronic and Photonic Structures http://www.emprl.psu.edu/amps[1997-1-1]

[21] Zhang A, Chen Y L, Yan J 2016 Ieee J. Quantum Elect. 52 1600106

Google Scholar

Google Scholar

[22] Onoda-Yamamuro N, Matsuo T, Suga H 1992 J. Phys. Chem. Solids. 53 935

Google Scholar

Google Scholar

[23] Laban W A, Etgar L 2013 Energ. Environ Sci. 6 3249

Google Scholar

Google Scholar

[24] Stoumpos C C, Malliakas C D, Kanatzidis M G 2013 Inorg. Chem. 52 9019

Google Scholar

Google Scholar

[25] Rode D L 1975 Semiconductors and Semimetals (New York: Academic) pp1–89

[26] Muth J F, Kolbas R M, Sharma A K, Oktabrsky S, Narayan J 1999 J. Appl. Phys. 85 7884

Google Scholar

Google Scholar

[27] Moormann H, Kohl D, Heiland G 1980 Surf. Sci. 100 302

Google Scholar

Google Scholar

[28] Hagemark K J, Chacka L C 1975 J. Solid State Chem. 15 261

Google Scholar

Google Scholar

[29] Kim K J, Park Y R 2001 Appl. Phys. Lett. 78 475

Google Scholar

Google Scholar

[30] Wojciechowski K, Saliba M, Leijtens T, Abate A, Snaith H J 2014 Energ. Environ. Sci. 7 1142

Google Scholar

Google Scholar

[31] Liu F, Zhu J, Wei J F, Li Y, Lv M, Yang S F, Zhang B, Yao J X, Dai S Y 2014 Appl. Phys. Lett. 104 253508

Google Scholar

Google Scholar

[32] Jaffe J E, Kaspar T C, Droubay T C, Varga T, Bowden M E, Exarhos G J 2010 J. Phys. Chem. C 114 9111

Google Scholar

Google Scholar

[33] Kaiser I, Ernst K, Fischer C H, Konenkamp R, Rost C, Sieber I, Lux-Steiner M C 2001 Sol. Energy Mater. Sol. Cells. 67 89

Google Scholar

Google Scholar

[34] Pattanasattayavong P, Ndjawa G O N, Zhao K, Chou K W, Yaacobi-Gross N, O’Regan B C, Amassian A, Anthopoulos T D 2013 Chem. Commun. 49 4154

Google Scholar

Google Scholar

[35] Pattanasattayavong P, Yaacobi-Gross N, Zhao K, Ndjawa G O N, Li J H, Yan F, O’Regan B C, Amassiann A, Anthopoulos T D 2013 Adv. Mater 25 1504

Google Scholar

Google Scholar

[36] Rao V, Smakula A 1965 J. Appl. Phys. 36 2031

Google Scholar

Google Scholar

[37] Ratcliff E L, Meyer J, Steirer K X, Armstrong N R, Olson D, Kahn A 2012 Org. Electron. 13 744

Google Scholar

Google Scholar

[38] Wu H B, Wang L S 1997 J. Chem. Phys. 107 16

Google Scholar

Google Scholar

[39] Liu M H, Zhou Z J, Zhang P P, Tian Q W, Zhou W H, Kou D X, Wu S X 2016 Opt. Express 24 1349

Google Scholar

Google Scholar

[40] Rakhshani A E 1991 J. Appl. Phys. 69 2365

Google Scholar

Google Scholar

[41] Ghijsen J, Tjeng L H, van Elp J, Eskes H, Westerink J, Sawatzky G A 1988 Phys. Rev. B 38 11322

Google Scholar

Google Scholar

[42] Zuo C T, Ding L M 2015 Small 11 5528

Google Scholar

Google Scholar

[43] Matsumura H, Fujii A, Kitatani T 1996 Jpn. J. Appl. Phys. 35 5631

Google Scholar

Google Scholar

[44] Shewchun J, Dubow J, Wilmsen C W, Singh R, Burk D, Wager J F 1979 J. Appl. Phys. 50 2832

Google Scholar

Google Scholar

[45] Park Y, Choong V, Gao Y, Hsieh B R, Tang C W 1996 Appl. Phys. Lett. 68 2699

Google Scholar

Google Scholar

[46] Balasubramanian N, Subrahmanyam A 1991 J. Electrochem. Soc. 138 322

Google Scholar

Google Scholar

[47] Nehate S D, Prakash A, DossMani P, Sundaram, K B 2018 ECS J. Solid State Sc. 7 87

Catalog

Metrics

- Abstract views: 9389

- PDF Downloads: 181

- Cited By: 0

DownLoad:

DownLoad: