-

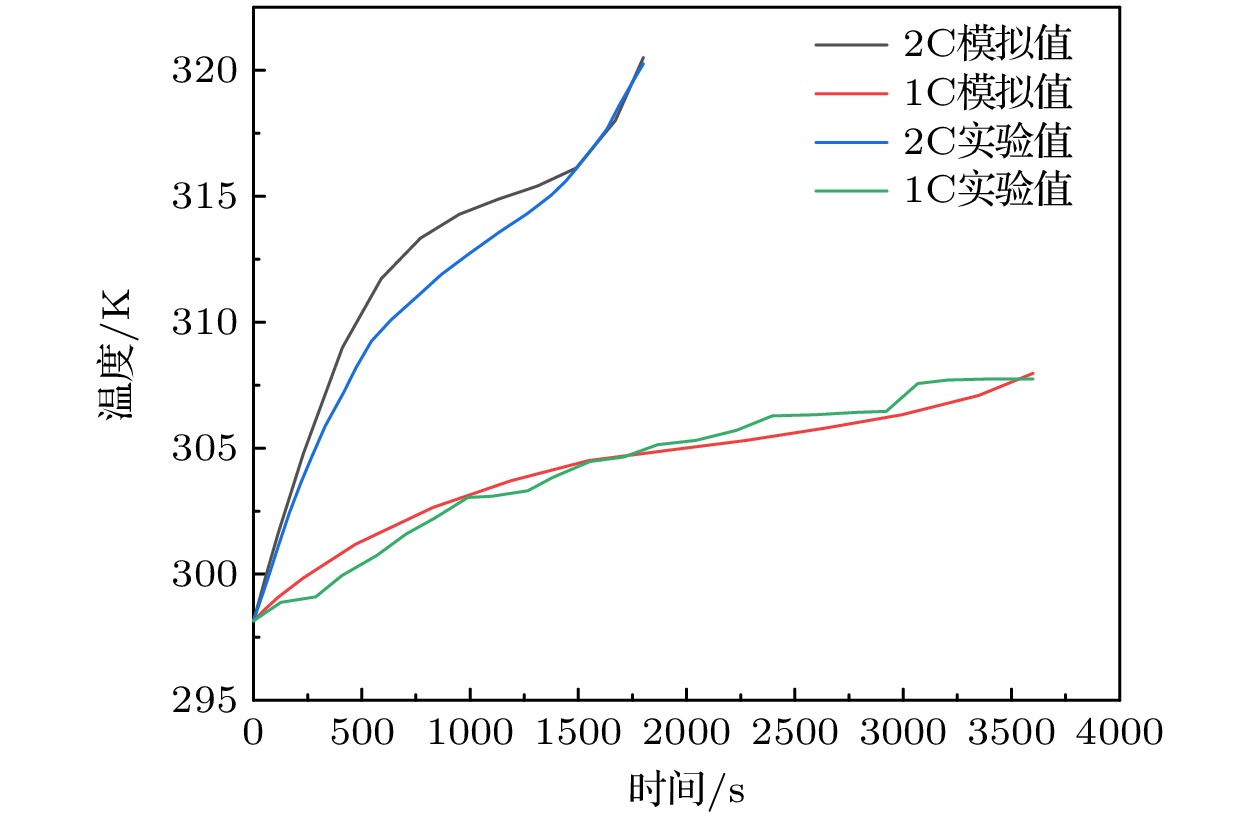

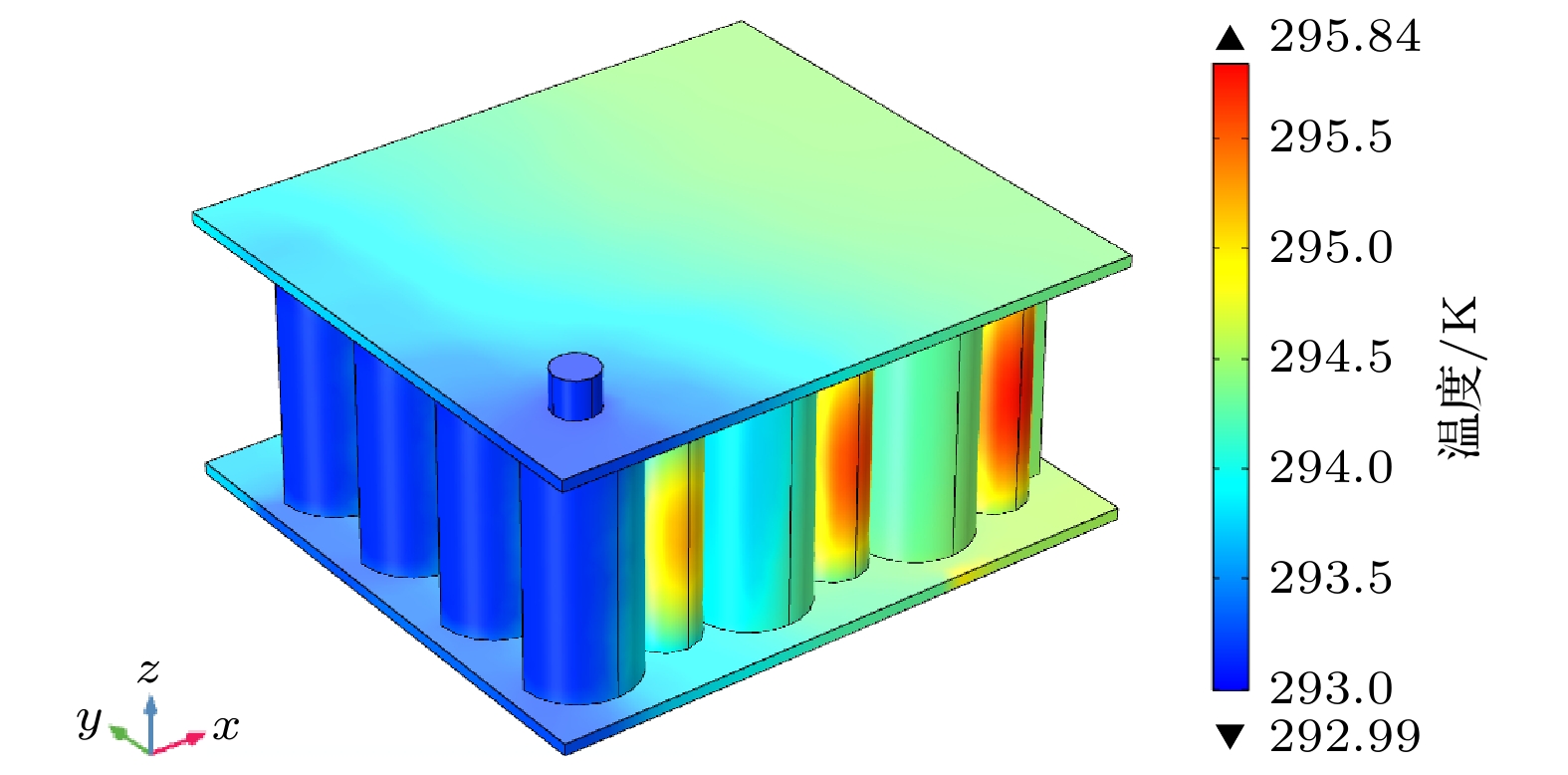

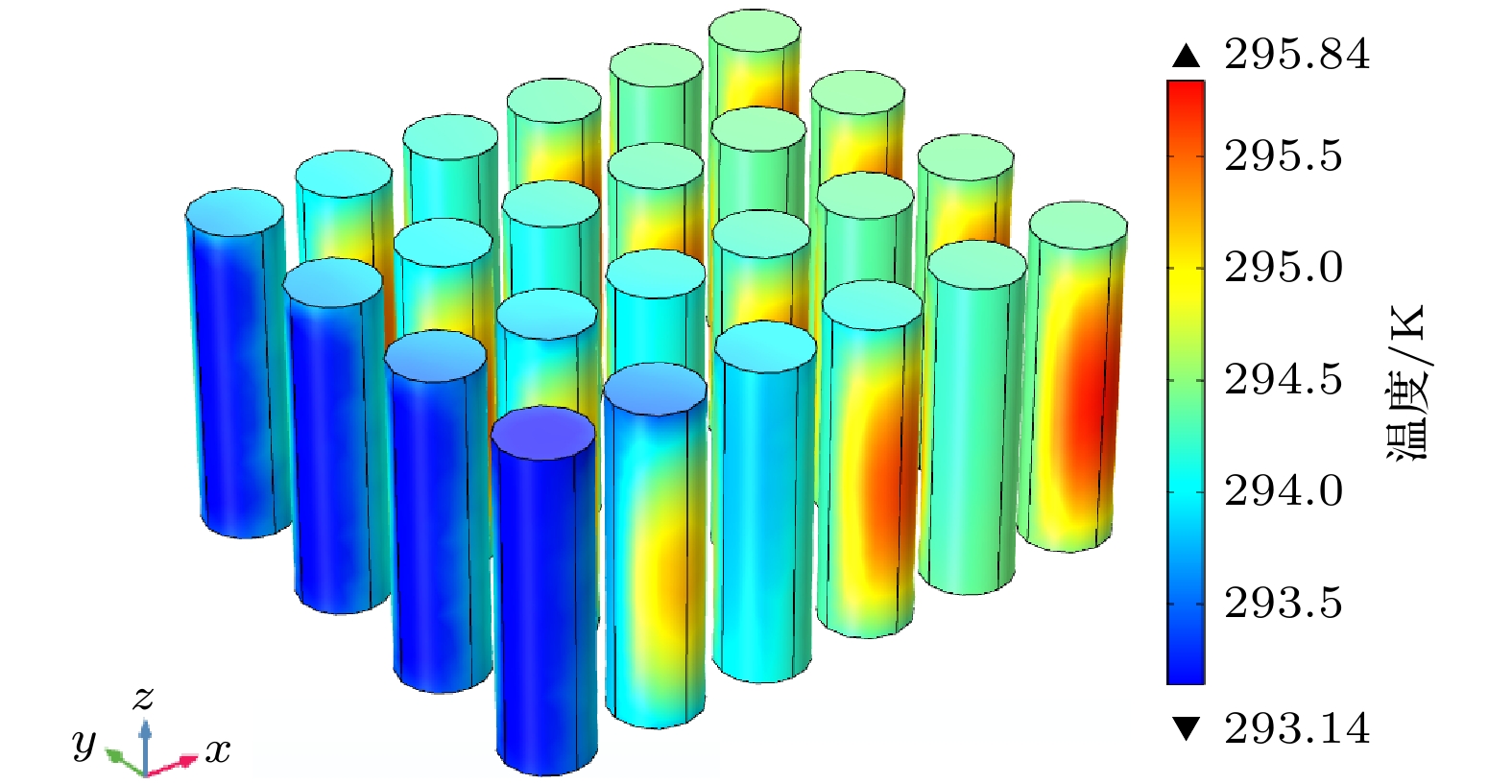

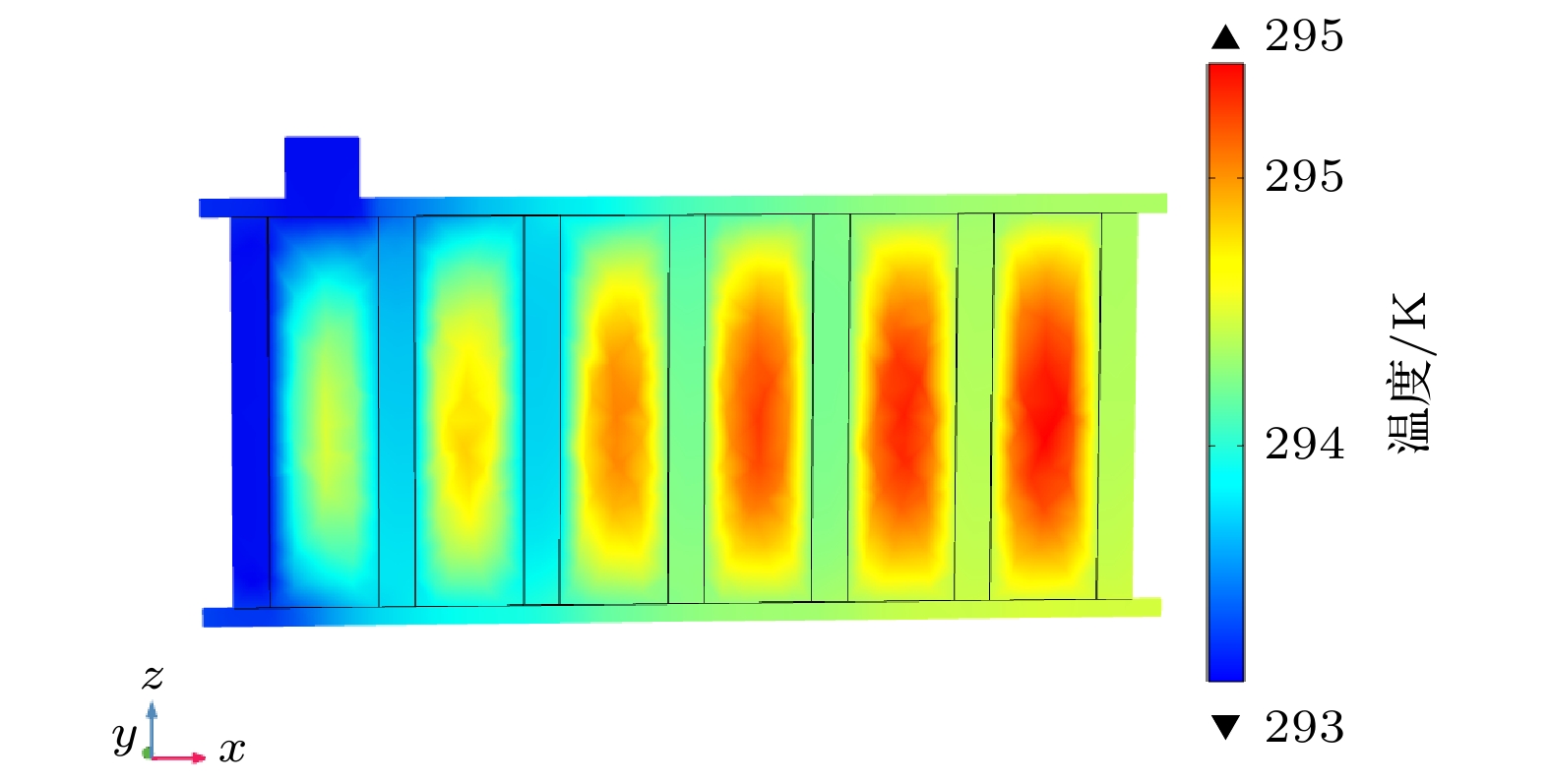

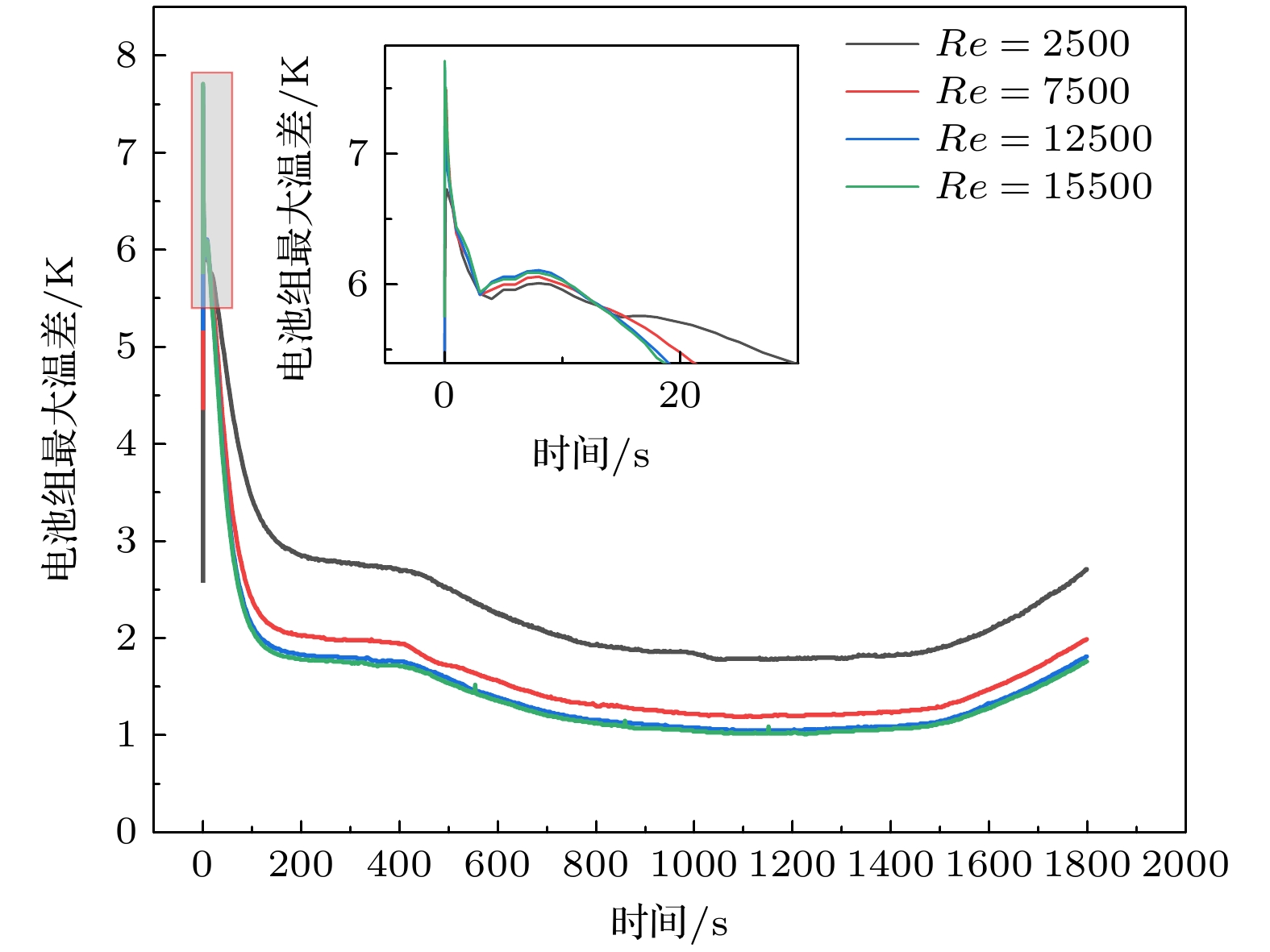

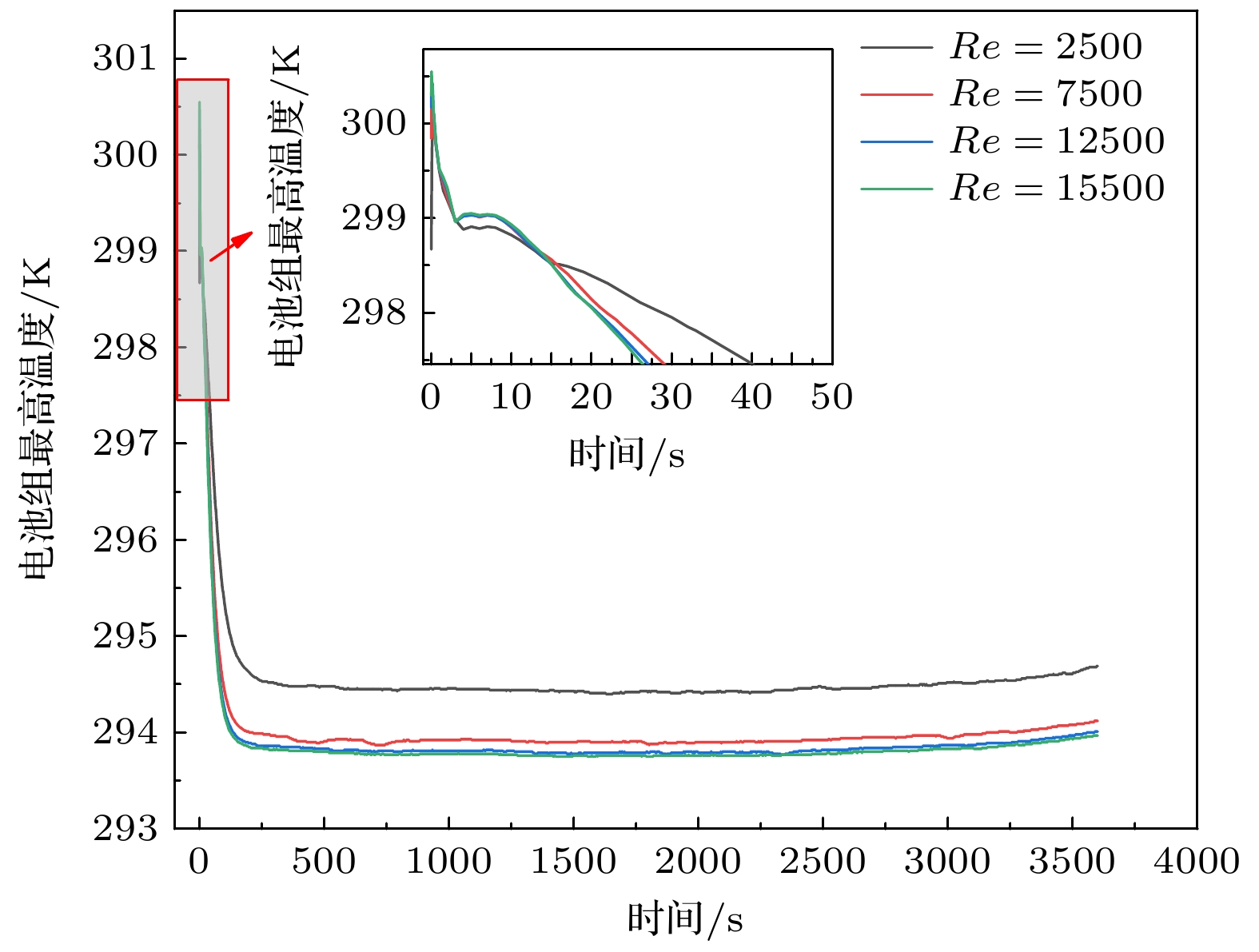

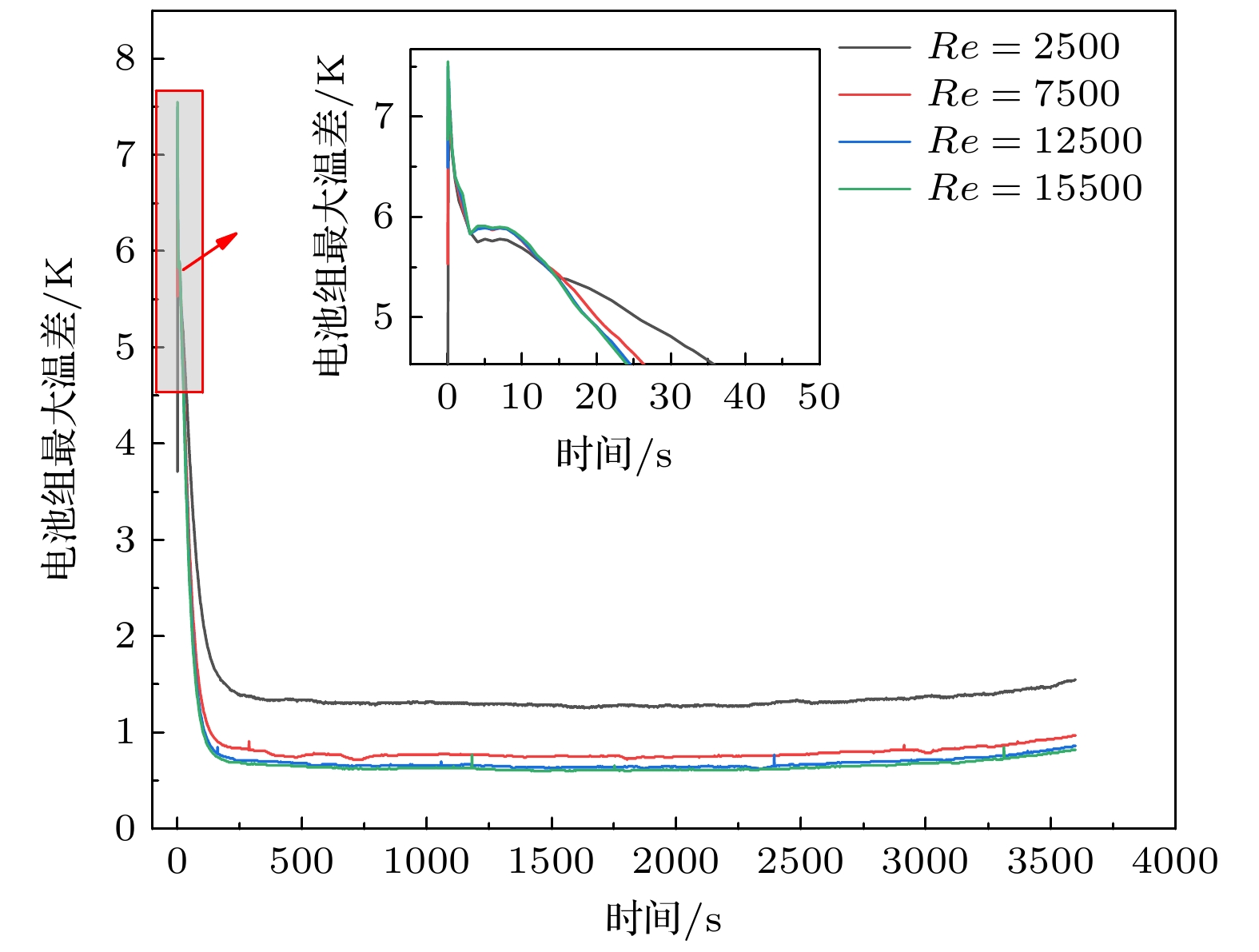

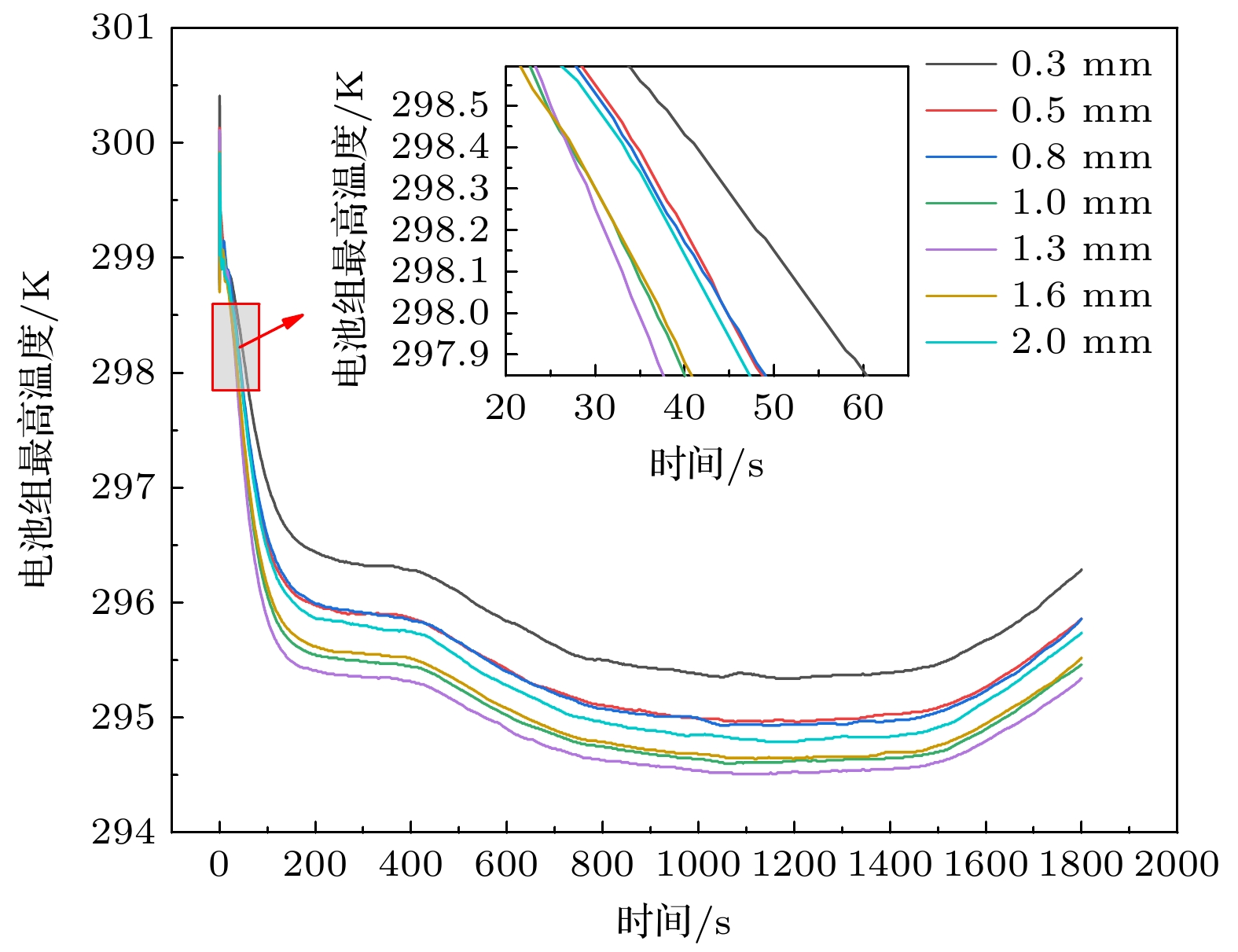

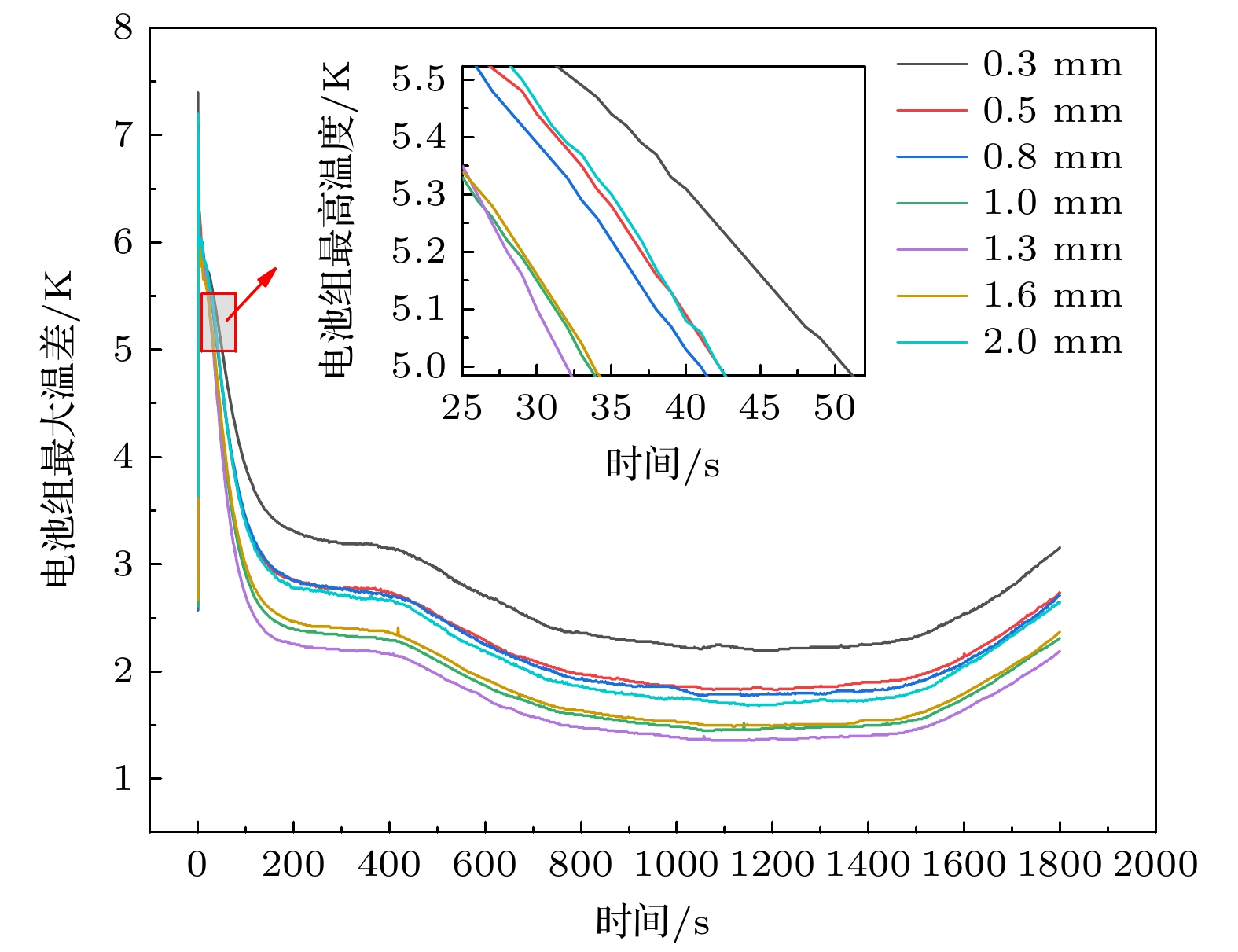

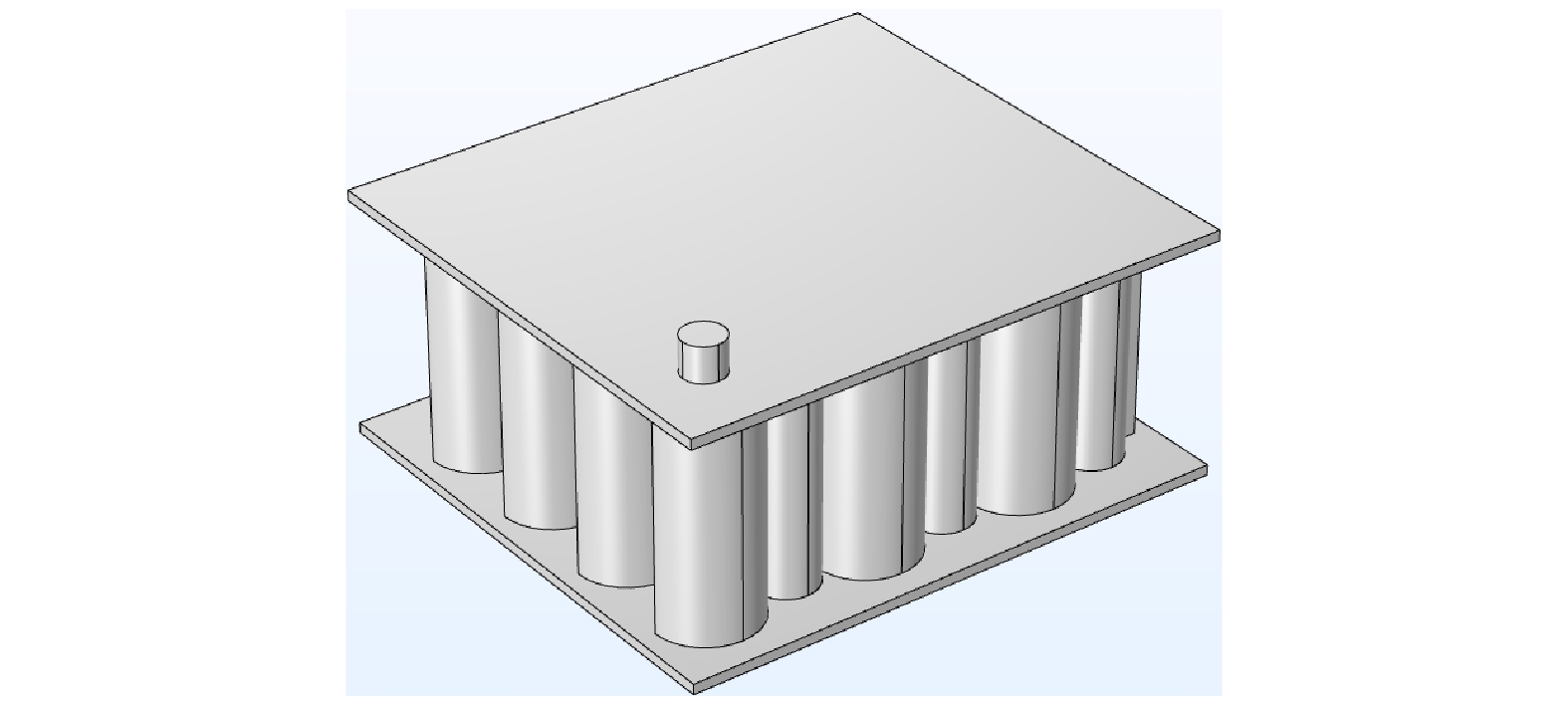

A detailed three-dimensional thermal model is developed to examine the thermal behaviour of a lithium-ion battery. This model is a cross-flow liquid cooling model, which can make the heat dissipation of lithium-ion battery pack achieve higher safety. Two kinds of fluids are used for cooling, and the polynomial fitting function is used as the heat source term of lithium battery pack. The battery temperature distribution under the conditions of different Reynolds numbers, different numbers of micro-channel and different micro-channel radii are studied for this model. The simulation results show that the maximum battery temperature is 295.84 K, the minimum battery temperature is 293.14 K, and the maximum temperature difference of the battery pack is 2.7 K. The maximum temperature and temperature difference of the battery under the model are in line with the reasonable operating temperature range of lithium-ion battery pack. The maximum temperature of battery pack decreases with the increase of Reynolds number, but the effect of Reynolds number on heat dissipation of lithium-ion battery pack has a critical value. As the number of micro-channels increases, the maximum temperature of the battery string decreases. However, when the number of micro-channels increases to a certain value, the maximum temperature of the battery pack decreases slowly. The maximum temperature of the battery pack does not decrease monotonically as the radius of the micro-channel increases. Orthogonal analysis results show that the Reynolds number has the greatest influence on the cooling effect of the model, followed by the size of the micro-channel radius, and the number of micro-channels has the least influence. The optimized liquid cooling model can effectively reduce the maximum temperature of lithium-ion battery in theory, and the maximum temperature of lithium-ion battery decreases by 26.24 K in comparison with that of single battery at 2C discharge rate. The reliability of the cross-flow channel model is proved by numerical analysis, and it is also proved that the cross-flow channel has an equilibrium point between the perturbation gain and the flow retarding effect. The heat dissipation effect of lithium- ion battery pack is correlated with the number and radius of micro-channels, but not a single positive correlation. Reasonably increasing the number and size of micro-channels can effectively enhance the heat dissipation effect of battery pack.

-

Keywords:

- lithium-ion battery pack /

- temperature distribution /

- numerical simulation /

- orthogonal text

[1] Saw L H, Tay A, Zhang L W 2015 Thermal Measurement Modeling and Management Symposium San Francisco, USA, March 28, 2015 p298

[2] Nitta N, Wu F, Lee J T, Yushin G 2015 Mater. Today Phys. 18 5

Google Scholar

Google Scholar

[3] Chen S C, Wan C C, Wang Y Y 2005 J. Power Sources 140 111

Google Scholar

Google Scholar

[4] Jaguemont J, Boulon L, Dubé Y 2016 Appl. Energy 164 99

Google Scholar

Google Scholar

[5] Jung D Y, Lee B H, Sun W K 2002 J. Power Sources 109 1

Google Scholar

Google Scholar

[6] Rao Z, Wang S, Zhang G 2011 Energy Convers. Manage. 52 3408

Google Scholar

Google Scholar

[7] Pesaran A A 2002 J. Power Sources 110 377

Google Scholar

Google Scholar

[8] Menale C, D’Annibale F, Mazzarotta B, Bubbico R 2019 Energy 182 57

Google Scholar

Google Scholar

[9] Liu H, Wei Z, He W, Zhao J 2017 Energy Convers. Manage. 150 304

Google Scholar

Google Scholar

[10] Sardari P T, Giddings D, Gillott M, Walker G S, Grant D 2019 Energy Convers. Manage. 201 112

Google Scholar

Google Scholar

[11] Mahdi J M, Mohammed H I, Hashim E T, Talebizadehsardari P, Nsofor E C 2020 Appl. Energy 257 113

Google Scholar

Google Scholar

[12] Shah K, Mckee C, Chalise D, Jain A 2016 Energy 113 852

Google Scholar

Google Scholar

[13] Pesaran A A 2001 Advanced Automotive Battery Conference Las Vegas, USA, February 6–8, 2001 p2

[14] Pesaran A A, Keyser M, Burch S1999 Proceedings of the 4th Vehicle Thermal Management Systems London, UK, May 24–27, 1999 p1

[15] Jarrett A, Kim I Y 2011 J. Power Sources 196 10359

Google Scholar

Google Scholar

[16] Han J Q, Qiu D D, Zhu A 2018 Appl. Therm. Eng. 132 508

Google Scholar

Google Scholar

[17] Bernadi D, Pawlikowski E 1985 J. Electrochem. Soc. 132 5

Google Scholar

Google Scholar

[18] 王一宇 2020 硕士学位论文 (青岛: 青岛科技大学)

Wang Y Y 2020 M. S. Thesis (Qingdao: Qingdao University of Science and Technology) (in Chinese)

[19] 廖永平 1984 正交试验法在机械工业中的应用 (北京: 中国农业机械出版) 第39—45页

Liao Y P 1984 Application of Orthogonal Test Method in Mechanical Industry (Beijing: China Agricultural Machinery Press) pp39–45

-

表 1 三维传热模型参数

Table 1. Three-dimensional heat transfer model parameters

参数 ρ/(kg·m–3) Cp/(J·kg–1·K–1) Λ/(W·m–1·K–1) Μ/(Pa·s) 锂电池 2776 1075 各向异性 — 乙二醇 1068 3319 0.387 — 水 ρ(T) Cp(T) λ(T) μ(T) 铝 2702 237 903 — 表 2 具体信息表

Table 2. Specific information.

微通道半径/mm 电池组最高温度/K 电池组最大温差/K 0.3 296.26 3.16 0.5 295.86 2.73 0.8 295.84 2.70 1.0 295.46 2.31 1.3 295.34 2.19 1.6 295.52 2.37 2.0 295.74 2.65 表 3 正交试验表

Table 3. Orthogonal test.

序号 雷诺数

(因素A)微通道半径/mm

(因素B)微通道个数/个

(因素C)锂电池组的温度/K 1 2500 0.3 3 296.33 2 2500 0.5 4 296.35 3 2500 0.8 5 295.54 4 2500 1.3 7 295.47 5 7500 0.3 4 295.57 6 7500 0.5 3 295.18 7 7500 0.8 7 295.13 8 7500 1.3 5 294.96 9 12500 0.3 5 295.03 10 12500 0.5 7 294.50 11 12500 0.8 4 294.91 12 12500 1.3 3 294.84 13 15500 0.3 4 294.91 14 15500 0.5 3 294.83 15 15500 0.8 7 294.87 16 15500 1.3 5 294.71 表 4 极差分析表

Table 4. Range analysis.

名称 因素A 因素B 因素C Z1 1183.74 1181.84 1181.18 Z2 1180.84 1180.86 1181.74 Z3 1179.28 1180.50 1180.29 Z4 1179.32 1179.98 1179.97 Z1算术平均值 295.935 295.46 295.295 Z2算术平均值 295.21 295.215 295.435 Z3算术平均值 294.82 295.125 295.0725 Z4算术平均值 294.83 294.995 294.9925 极差 0.725 0.465 0.4425 主次顺序 A>B>C 优水平 A4 B4 C3 优组合 A4 B4 C3 -

[1] Saw L H, Tay A, Zhang L W 2015 Thermal Measurement Modeling and Management Symposium San Francisco, USA, March 28, 2015 p298

[2] Nitta N, Wu F, Lee J T, Yushin G 2015 Mater. Today Phys. 18 5

Google Scholar

Google Scholar

[3] Chen S C, Wan C C, Wang Y Y 2005 J. Power Sources 140 111

Google Scholar

Google Scholar

[4] Jaguemont J, Boulon L, Dubé Y 2016 Appl. Energy 164 99

Google Scholar

Google Scholar

[5] Jung D Y, Lee B H, Sun W K 2002 J. Power Sources 109 1

Google Scholar

Google Scholar

[6] Rao Z, Wang S, Zhang G 2011 Energy Convers. Manage. 52 3408

Google Scholar

Google Scholar

[7] Pesaran A A 2002 J. Power Sources 110 377

Google Scholar

Google Scholar

[8] Menale C, D’Annibale F, Mazzarotta B, Bubbico R 2019 Energy 182 57

Google Scholar

Google Scholar

[9] Liu H, Wei Z, He W, Zhao J 2017 Energy Convers. Manage. 150 304

Google Scholar

Google Scholar

[10] Sardari P T, Giddings D, Gillott M, Walker G S, Grant D 2019 Energy Convers. Manage. 201 112

Google Scholar

Google Scholar

[11] Mahdi J M, Mohammed H I, Hashim E T, Talebizadehsardari P, Nsofor E C 2020 Appl. Energy 257 113

Google Scholar

Google Scholar

[12] Shah K, Mckee C, Chalise D, Jain A 2016 Energy 113 852

Google Scholar

Google Scholar

[13] Pesaran A A 2001 Advanced Automotive Battery Conference Las Vegas, USA, February 6–8, 2001 p2

[14] Pesaran A A, Keyser M, Burch S1999 Proceedings of the 4th Vehicle Thermal Management Systems London, UK, May 24–27, 1999 p1

[15] Jarrett A, Kim I Y 2011 J. Power Sources 196 10359

Google Scholar

Google Scholar

[16] Han J Q, Qiu D D, Zhu A 2018 Appl. Therm. Eng. 132 508

Google Scholar

Google Scholar

[17] Bernadi D, Pawlikowski E 1985 J. Electrochem. Soc. 132 5

Google Scholar

Google Scholar

[18] 王一宇 2020 硕士学位论文 (青岛: 青岛科技大学)

Wang Y Y 2020 M. S. Thesis (Qingdao: Qingdao University of Science and Technology) (in Chinese)

[19] 廖永平 1984 正交试验法在机械工业中的应用 (北京: 中国农业机械出版) 第39—45页

Liao Y P 1984 Application of Orthogonal Test Method in Mechanical Industry (Beijing: China Agricultural Machinery Press) pp39–45

计量

- 文章访问数: 7582

- PDF下载量: 145

- 被引次数: 0

下载:

下载: