-

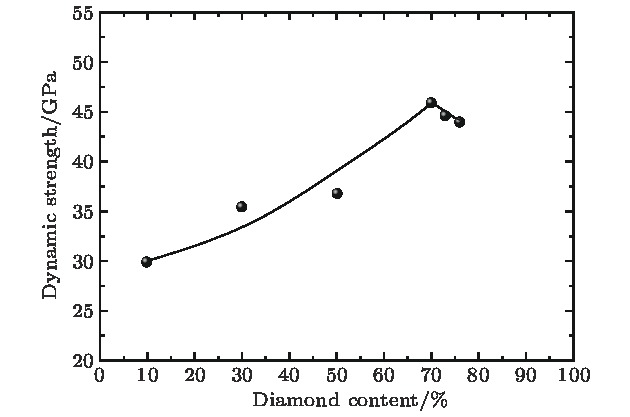

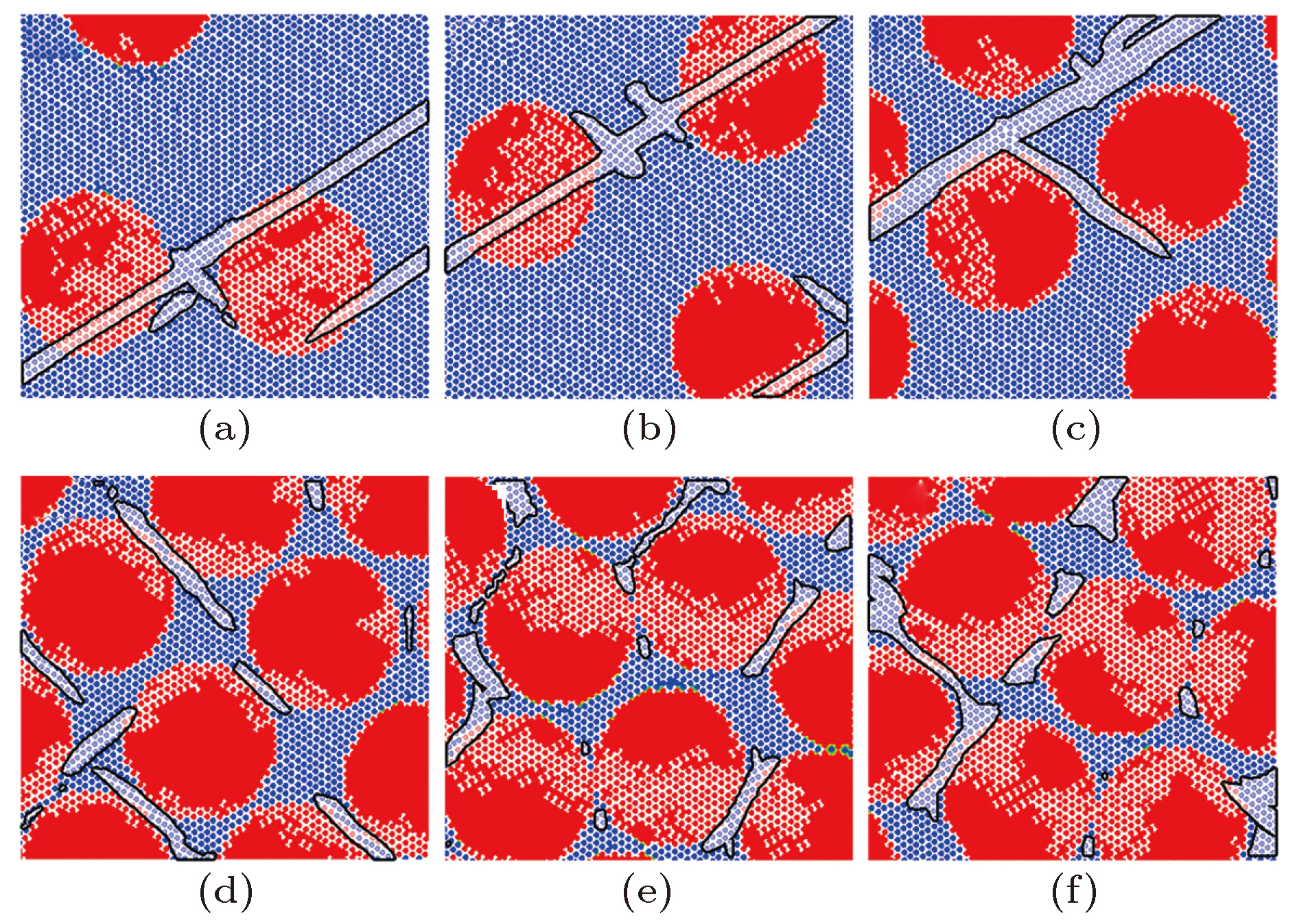

Unlike the ductile materials, the failure seriously limits the strength of the brittle medium. To understand the mechanism of controlling the dynamic impact strength of diamond-SiC superhard composite under shock wave compression, the numerical simulation is conducted with a lattice-spring model that can describe the mechanical properties of diamond-SiC superhard composite quantitatively. For the simulation, the diamond-SiC superhard composite is constructed by different volume content of diamond and SiC particles. The obtainted shock wave profiles indicate that the dynamic impact strength first increases and then decreases with the increase of diamond content in the sample. The analysis based on the meso-scale damage pattern reveals that such a variation of dynamic impact strength corresponds to three damage evolution modes. When the diamond content increases to a value between 10%–50% in volume percentage, the long slip bands are first dominated, and then becomes short slip bands when the diamond content is 70%, and damage happens mainly in SiC matrix whereas most of the diamond particles are not damaged. When the diamond content is above a critical value of 70% in volume percentage, even the short slip bands are limited heavily, which makes it difficult to relax the shear stress on diamond particles and causes serious damage to diamond particles, finally results in the reduction of dynamic strength.

-

Keywords:

- diamond /

- SiC /

- superhard composite /

- dynamic strength /

- mesoscopic damage

[1] Liu Y S, Hu C H, Men J, Feng W, Cheng L F, Zhang L T 2015 J. Eur. Ceram. Soc. 35 2233

Google Scholar

Google Scholar

[2] Zhao Z F, Liu Y S, Feng W, Zhang Q, Cheng L F, Zhang L T 2017 Diam. Relat. Mater. 74 1

Google Scholar

Google Scholar

[3] Ekimov E A, Gavriliuk A G, Palosz B, Gierlotka S, Dluzewski P, Tatianin E, Kluev Y, Naletov M, Presz A 2000 Appl. Phys. Lett. 77 954

Google Scholar

Google Scholar

[4] Yang Z L, He X B, Wu M, Zhang L, Ma A, Liu R J, Hu H F, Zhang Y D, Qu X H 2013 Ceram. Int. 39 3399

Google Scholar

Google Scholar

[5] Zhao Y S, Qian J, Daemen L L, Pantea C, Zhang J Z, Voronin G A, Zerda T W 2004 Appl. Phys. Lett. 84 1356

Google Scholar

Google Scholar

[6] Lu K 2016 Nature Rev. Mater. 1 16019

Google Scholar

Google Scholar

[7] Huang Q, Yu D L, Xu B, Hu W T, Ma Y M, Wang Y B, Zhao Z S, Wen B, He J L, Liu Z Y, Tian Y J 2014 Nature 510 250

Google Scholar

Google Scholar

[8] Cheng Z, Zhou H, Lu Q, Gao H, Lu L 2018 Science 362 1925

Google Scholar

Google Scholar

[9] Yang M X, Yan D S, Yuan F P, Jiang P, Ma E, Wu X L 2018 PNAS 115 7224

Google Scholar

Google Scholar

[10] Mayer G 2005 Science 310 1144

Google Scholar

Google Scholar

[11] Weaver J C, Milliron G W, Miserez A, Evans-Lutterodt K, Herrera S, Gallana I, Mershon W J, Swanson B, Zavattieri P, DiMasi E, Kisailus D 2012 Science 336 1275

Google Scholar

Google Scholar

[12] Lian Y P, Zhang X, Liu Y 2012 Theor. Appl. Mech. Lett. 2 021003

Google Scholar

Google Scholar

[13] Gusev A A 2004 Phys. Rev. Lett. 93 034302

Google Scholar

Google Scholar

[14] Yu Y, Wang W Q, He H L, Lu T C 2014 Phys. Rev. E 89 043309

Google Scholar

Google Scholar

[15] Yu Y, Wang W Q, He H L, Jiang T L, Huan Q, Zhang F P, Li Y Q, Lu T C 2015 J. Appl. Phys. 117 125901

Google Scholar

Google Scholar

[16] Núñez Valdez M, Umemoto K, Wentzcovitch R M 2012 Appl. Phys. Lett. 101 171902

Google Scholar

Google Scholar

[17] Varshney D, Shriya S, Varshney M, Singh N, Khenata R 2015 J. Theor. Appl. Phys. 9 221

Google Scholar

Google Scholar

[18] Griffith A A, Eng M V I 1921 Phil. Trans. R. Soc. Lond. A 221 163

Google Scholar

Google Scholar

[19] Qu R T, Zhang Z F 2013 Sci. Rep. 3 1117

Google Scholar

Google Scholar

[20] Barenblatt G I 1962 Adv. Appl. Mech. 7 55

Google Scholar

Google Scholar

[21] Novikov N V, Dub S N 1991 J. Hard. Mater. 2 3

[22] 罗恩 B 著 (龚江宏 译) 2010 脆性固体断裂力学 (北京: 高等教育出版社) 第44, 45页

Lawn B (translated by Gong J H) 2010 Fracture of Brittle Solid (Beijing: Higher Education Press) pp44, 45 (in Chinese)

[23] Liu Y S, Hu C H, Feng W, Men J, Cheng L F, Zhang L T 2014 J. Eur. Ceram. Soc. 34 3489

Google Scholar

Google Scholar

[24] Matthey B, Höhn S, Wolfrum A K, Mühle U, Motylenko M, Rafaja D, Michaelis A, Herrmann M 2017 J. Eur. Ceram. Soc. 37 1917

Google Scholar

Google Scholar

[25] 姜太龙, 喻寅, 宦强, 李永强, 贺红亮 2015 64 188301

Google Scholar

Google Scholar

Jiang T L, Yu Y, Huan Q, Li Y Q, He H L 2015 Acta Phys. Sin. 64 188301

Google Scholar

Google Scholar

[26] Grady D E 1998 Mech. Mater. 29 181

Google Scholar

Google Scholar

[27] Eremin M O 2016 Phys. Mesomech. 19 452

Google Scholar

Google Scholar

[28] Lapin J, Štamborská M, Pelachová T, Bajana O 2018 Mater. Sci. Eng. A 721 1

Google Scholar

Google Scholar

[29] Salamone S, Aghajanian M, Horner S E, Zheng J Q 2015 Adv. Ceram. Armor. XI 600 111

[30] Lasalvia J C, Campbell J, Swab J J, Mccauley J W 2010 JOM 62 16

[31] Petel O E, Ouellet S 2017 J. Appl. Phys. 122 025108

[32] Petel O E, Ouellet S, Loiseau J, Frost D L, Higgins A J 2015 Int. J. Impact Eng. 85 83

Google Scholar

Google Scholar

[33] Petel O E, Ouellet S, Loiseau J, Marr B J, Frost D L, Higgins A J 2013 Appl. Phys. Lett. 102 064103

[34] Sun Y, Yu Z, Wang Z, Liu X 2015 Constr. Build. Mater. 96 484

Google Scholar

Google Scholar

-

图 1 金刚石-碳化硅超硬复合材料中金刚石颗粒不同含量(体积百分比) (a) 10%; (b) 30%; (c) 50%; (d) 70%; (e) 73%; (f) 76%; 红色区域表示金刚石颗粒, 蓝色区域表示碳化硅基体

Figure 1. Diamond particle content in diamond-SiC superhard composites (in volume percentage): (a) 10%; (b) 30%; (c) 50%; (d) 70%; (e) 73%; (f) 76%. The red areas represent diamond particles, and the blue areas are the SiC matrix

图 4 在1300 m/s活塞驱动下, 金刚石-碳化硅超硬复合材料中金刚石颗粒不同含量的损伤演化特征, 其中金刚石颗粒含量(体积百分比)分别是(a) 10%; (b) 30%; (c) 50%; (d) 70%; (e) 73%; (f) 76%; 黑色带状区域是扩展滑移带

Figure 4. Damage evolution of diamond-SiC superhard composite with different diamond particle content in volume percentage: (a) 10%; (b) 30%; (c) 50%; (d) 70%; (e) 73%; (f) 76%. The piston velocity is 1300 m/s. The thin black lines are slip bands occurred in SiC matrix.

-

[1] Liu Y S, Hu C H, Men J, Feng W, Cheng L F, Zhang L T 2015 J. Eur. Ceram. Soc. 35 2233

Google Scholar

Google Scholar

[2] Zhao Z F, Liu Y S, Feng W, Zhang Q, Cheng L F, Zhang L T 2017 Diam. Relat. Mater. 74 1

Google Scholar

Google Scholar

[3] Ekimov E A, Gavriliuk A G, Palosz B, Gierlotka S, Dluzewski P, Tatianin E, Kluev Y, Naletov M, Presz A 2000 Appl. Phys. Lett. 77 954

Google Scholar

Google Scholar

[4] Yang Z L, He X B, Wu M, Zhang L, Ma A, Liu R J, Hu H F, Zhang Y D, Qu X H 2013 Ceram. Int. 39 3399

Google Scholar

Google Scholar

[5] Zhao Y S, Qian J, Daemen L L, Pantea C, Zhang J Z, Voronin G A, Zerda T W 2004 Appl. Phys. Lett. 84 1356

Google Scholar

Google Scholar

[6] Lu K 2016 Nature Rev. Mater. 1 16019

Google Scholar

Google Scholar

[7] Huang Q, Yu D L, Xu B, Hu W T, Ma Y M, Wang Y B, Zhao Z S, Wen B, He J L, Liu Z Y, Tian Y J 2014 Nature 510 250

Google Scholar

Google Scholar

[8] Cheng Z, Zhou H, Lu Q, Gao H, Lu L 2018 Science 362 1925

Google Scholar

Google Scholar

[9] Yang M X, Yan D S, Yuan F P, Jiang P, Ma E, Wu X L 2018 PNAS 115 7224

Google Scholar

Google Scholar

[10] Mayer G 2005 Science 310 1144

Google Scholar

Google Scholar

[11] Weaver J C, Milliron G W, Miserez A, Evans-Lutterodt K, Herrera S, Gallana I, Mershon W J, Swanson B, Zavattieri P, DiMasi E, Kisailus D 2012 Science 336 1275

Google Scholar

Google Scholar

[12] Lian Y P, Zhang X, Liu Y 2012 Theor. Appl. Mech. Lett. 2 021003

Google Scholar

Google Scholar

[13] Gusev A A 2004 Phys. Rev. Lett. 93 034302

Google Scholar

Google Scholar

[14] Yu Y, Wang W Q, He H L, Lu T C 2014 Phys. Rev. E 89 043309

Google Scholar

Google Scholar

[15] Yu Y, Wang W Q, He H L, Jiang T L, Huan Q, Zhang F P, Li Y Q, Lu T C 2015 J. Appl. Phys. 117 125901

Google Scholar

Google Scholar

[16] Núñez Valdez M, Umemoto K, Wentzcovitch R M 2012 Appl. Phys. Lett. 101 171902

Google Scholar

Google Scholar

[17] Varshney D, Shriya S, Varshney M, Singh N, Khenata R 2015 J. Theor. Appl. Phys. 9 221

Google Scholar

Google Scholar

[18] Griffith A A, Eng M V I 1921 Phil. Trans. R. Soc. Lond. A 221 163

Google Scholar

Google Scholar

[19] Qu R T, Zhang Z F 2013 Sci. Rep. 3 1117

Google Scholar

Google Scholar

[20] Barenblatt G I 1962 Adv. Appl. Mech. 7 55

Google Scholar

Google Scholar

[21] Novikov N V, Dub S N 1991 J. Hard. Mater. 2 3

[22] 罗恩 B 著 (龚江宏 译) 2010 脆性固体断裂力学 (北京: 高等教育出版社) 第44, 45页

Lawn B (translated by Gong J H) 2010 Fracture of Brittle Solid (Beijing: Higher Education Press) pp44, 45 (in Chinese)

[23] Liu Y S, Hu C H, Feng W, Men J, Cheng L F, Zhang L T 2014 J. Eur. Ceram. Soc. 34 3489

Google Scholar

Google Scholar

[24] Matthey B, Höhn S, Wolfrum A K, Mühle U, Motylenko M, Rafaja D, Michaelis A, Herrmann M 2017 J. Eur. Ceram. Soc. 37 1917

Google Scholar

Google Scholar

[25] 姜太龙, 喻寅, 宦强, 李永强, 贺红亮 2015 64 188301

Google Scholar

Google Scholar

Jiang T L, Yu Y, Huan Q, Li Y Q, He H L 2015 Acta Phys. Sin. 64 188301

Google Scholar

Google Scholar

[26] Grady D E 1998 Mech. Mater. 29 181

Google Scholar

Google Scholar

[27] Eremin M O 2016 Phys. Mesomech. 19 452

Google Scholar

Google Scholar

[28] Lapin J, Štamborská M, Pelachová T, Bajana O 2018 Mater. Sci. Eng. A 721 1

Google Scholar

Google Scholar

[29] Salamone S, Aghajanian M, Horner S E, Zheng J Q 2015 Adv. Ceram. Armor. XI 600 111

[30] Lasalvia J C, Campbell J, Swab J J, Mccauley J W 2010 JOM 62 16

[31] Petel O E, Ouellet S 2017 J. Appl. Phys. 122 025108

[32] Petel O E, Ouellet S, Loiseau J, Frost D L, Higgins A J 2015 Int. J. Impact Eng. 85 83

Google Scholar

Google Scholar

[33] Petel O E, Ouellet S, Loiseau J, Marr B J, Frost D L, Higgins A J 2013 Appl. Phys. Lett. 102 064103

[34] Sun Y, Yu Z, Wang Z, Liu X 2015 Constr. Build. Mater. 96 484

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 16402

- PDF Downloads: 147

- Cited By: 0

DownLoad:

DownLoad: