-

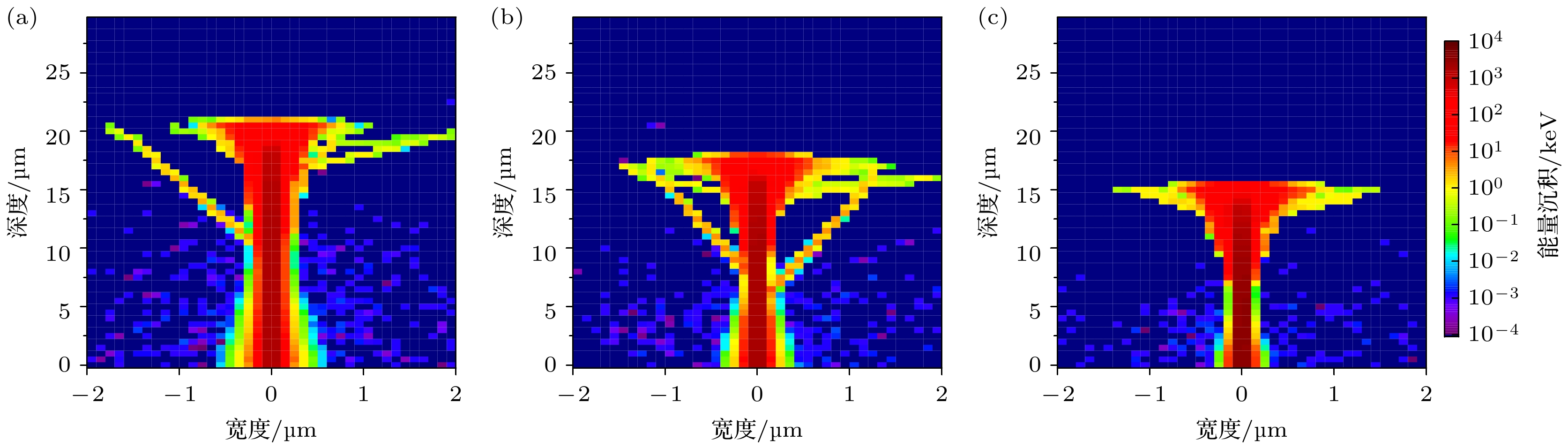

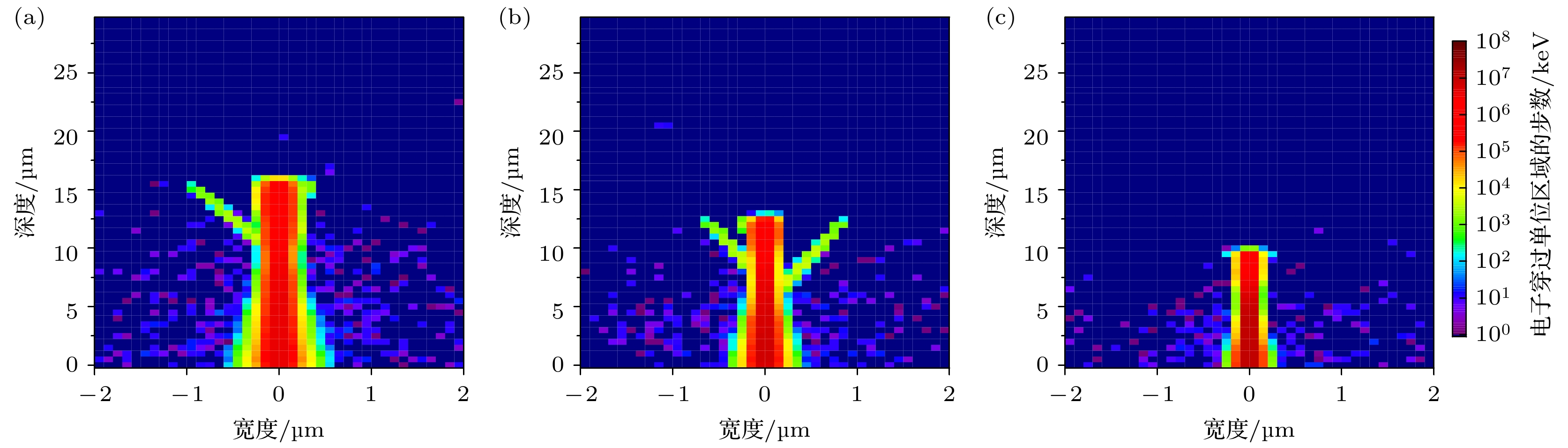

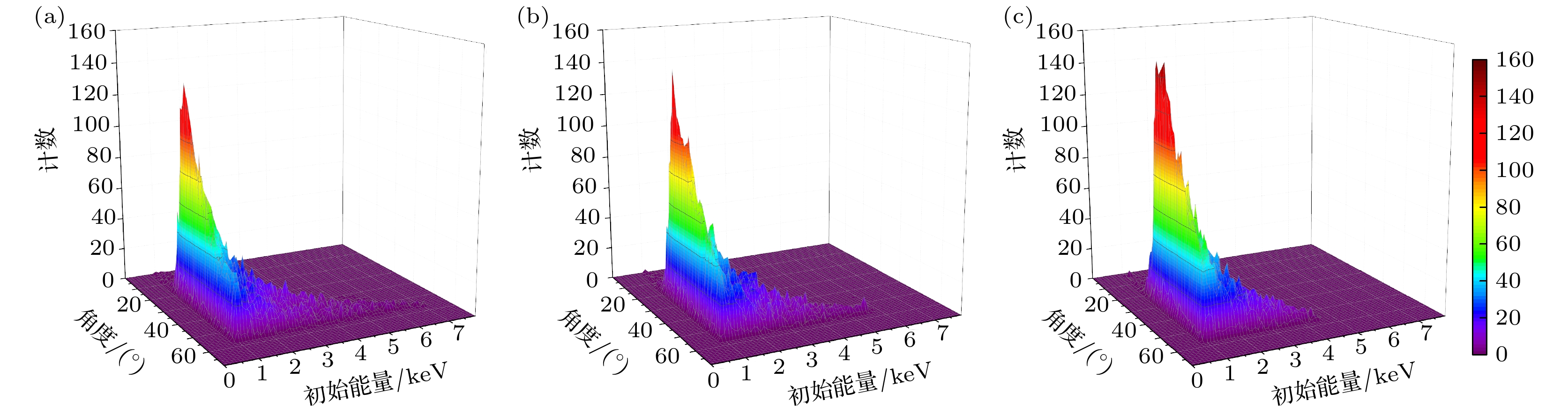

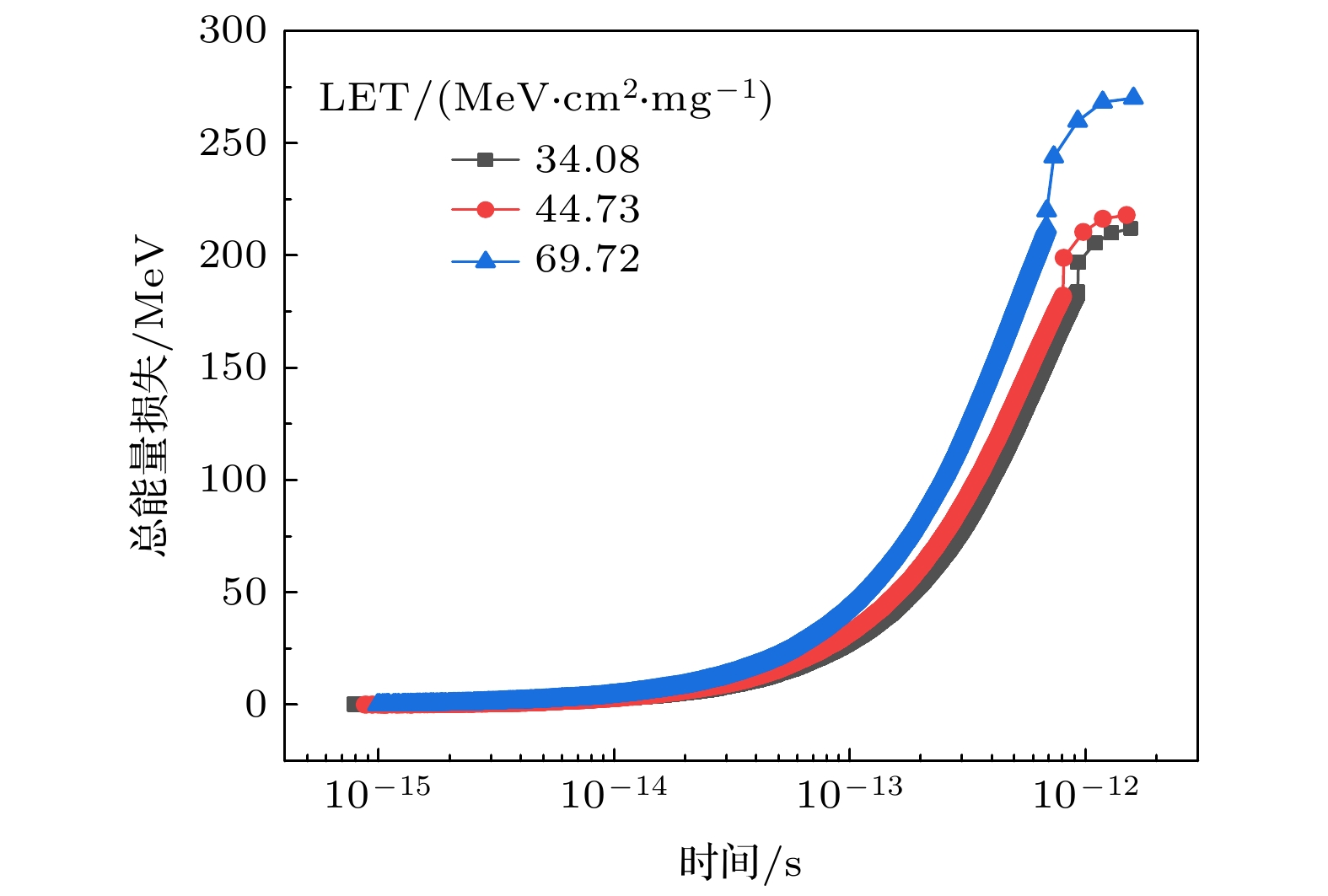

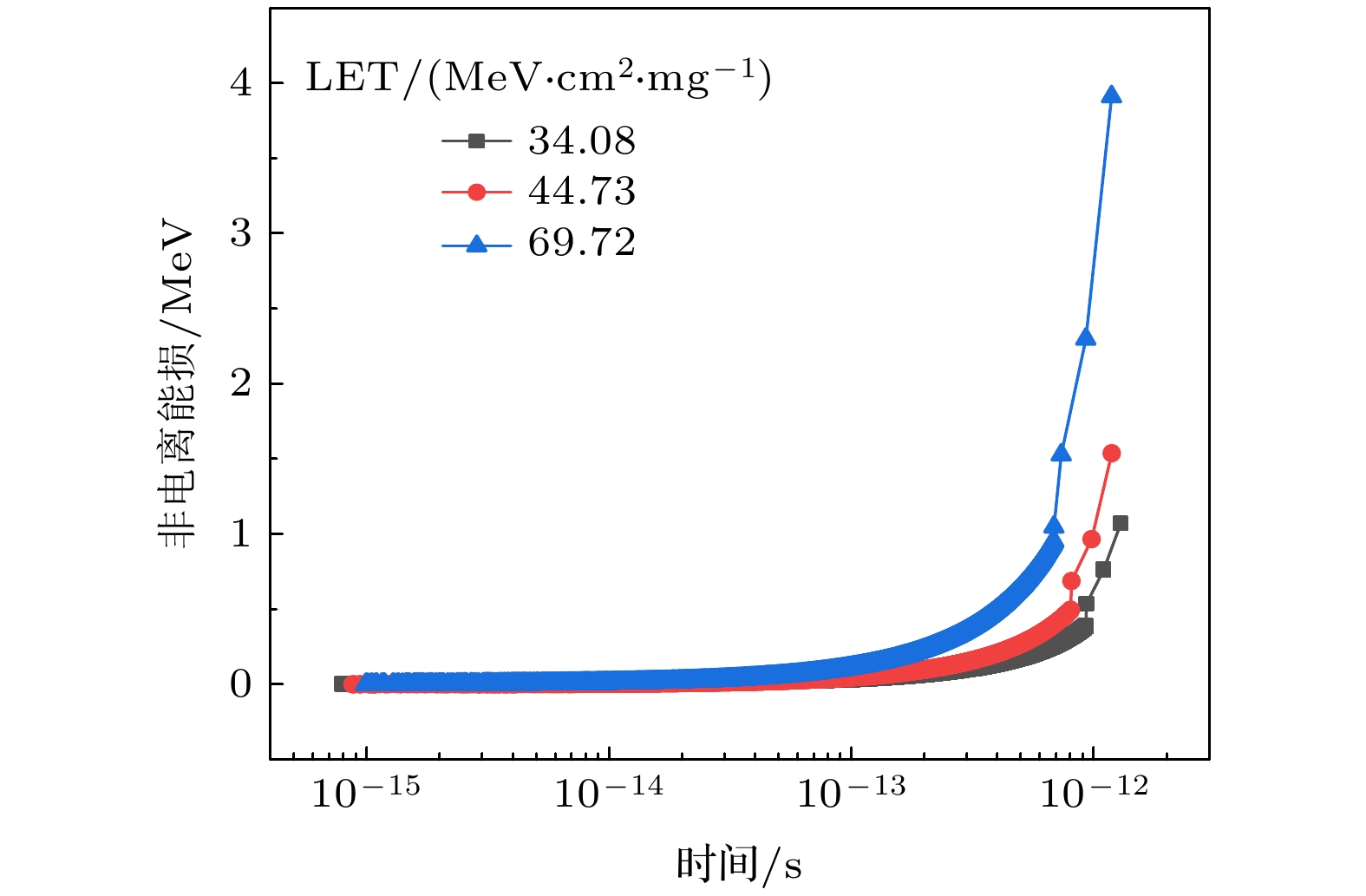

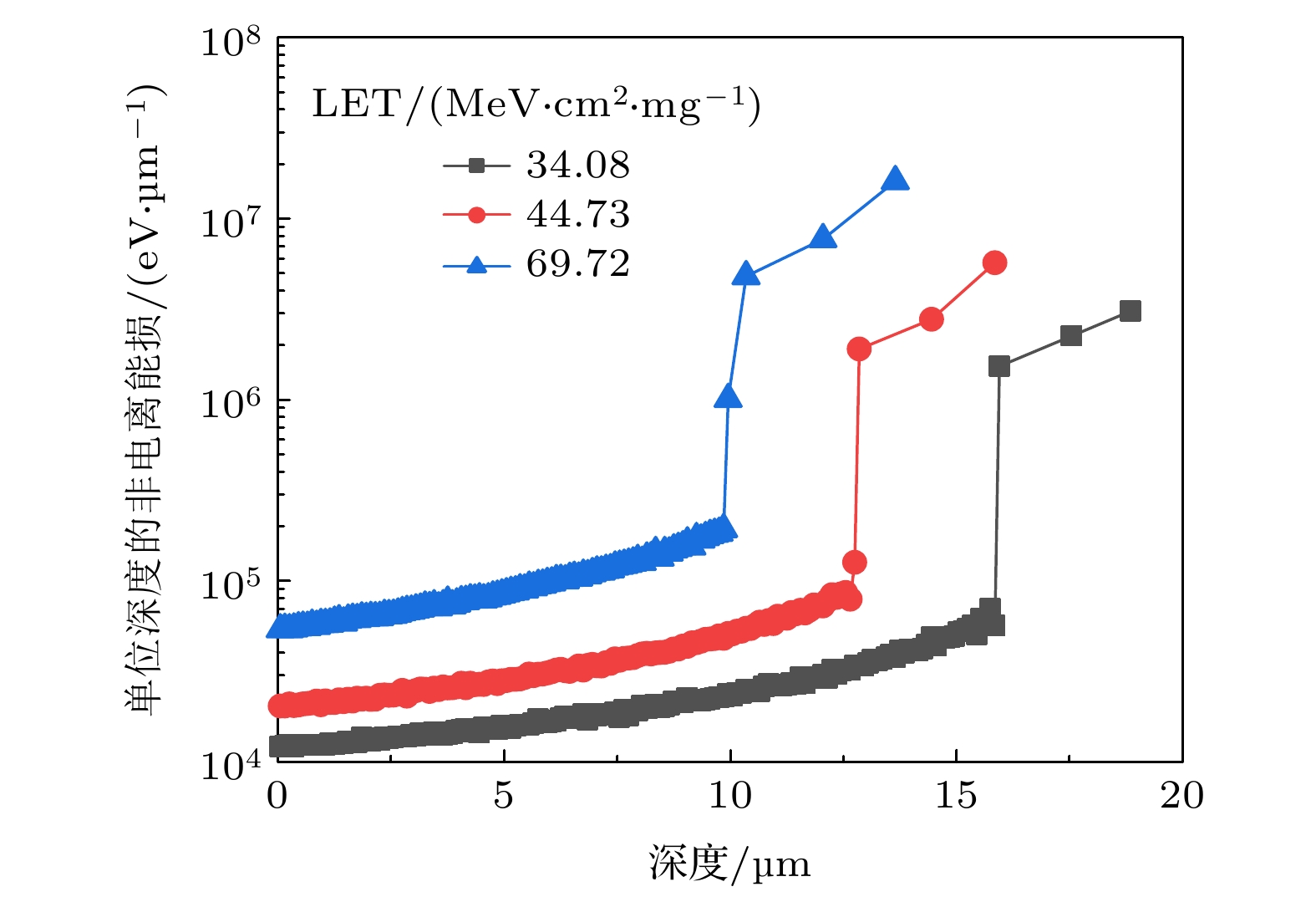

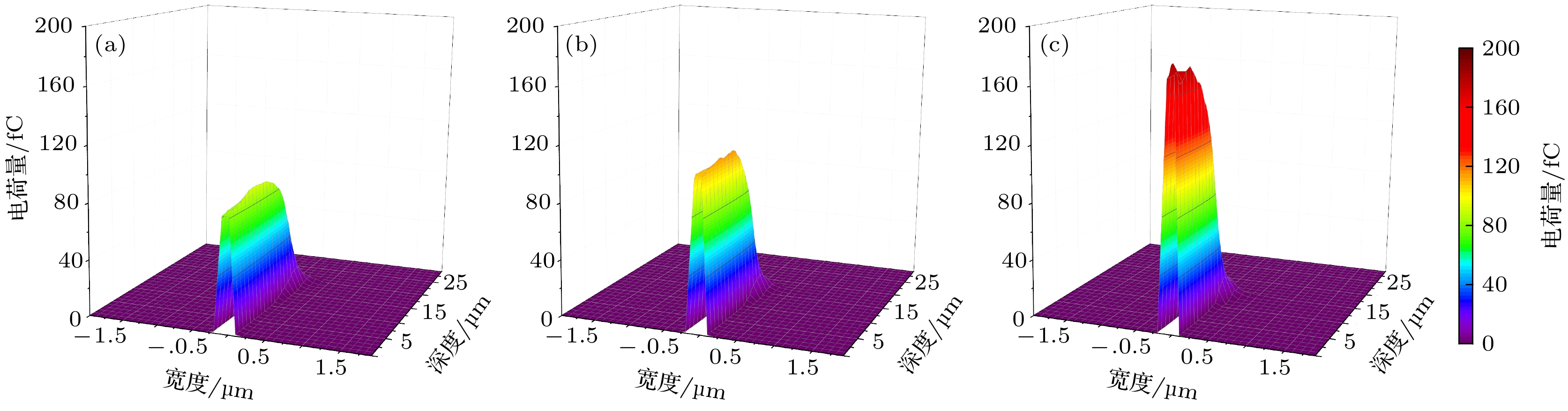

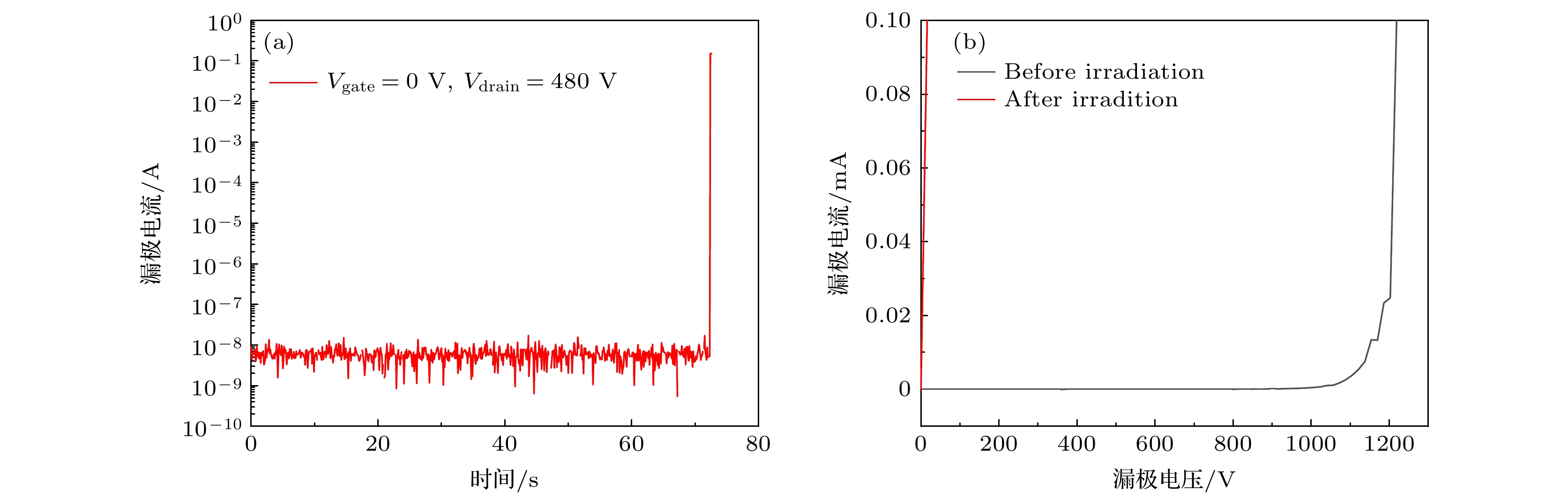

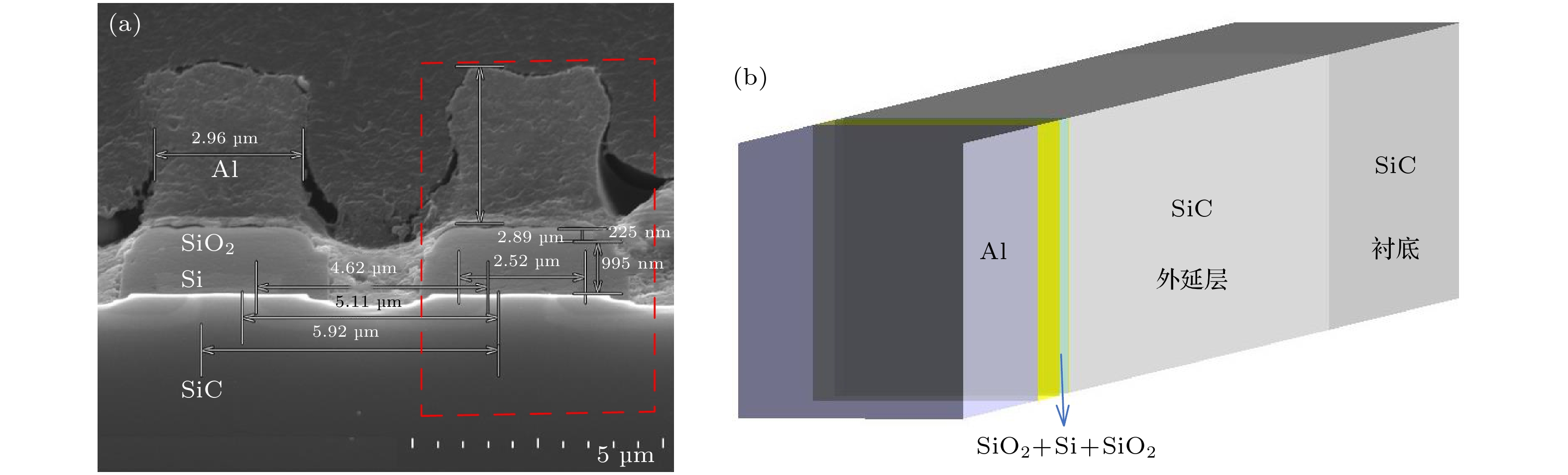

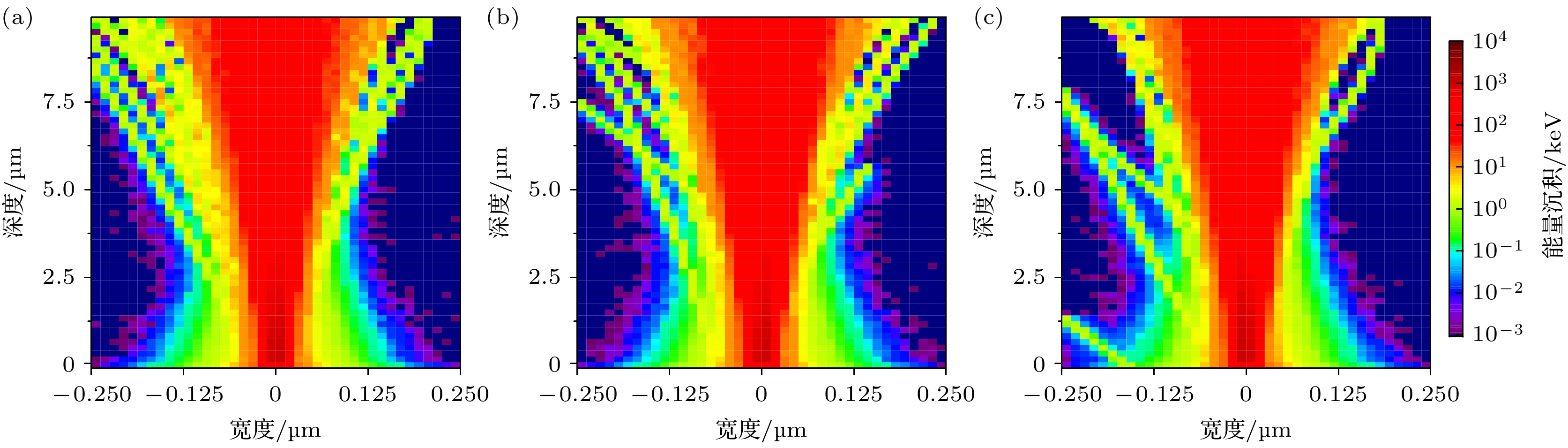

利用蒙特卡罗方法, 模拟计算了不同线性能量传输(liner energy transfer, LET)的重离子在碳化硅中的能量损失, 模拟结果表明: 重离子在碳化硅中单位深度的能量损失受离子能量和入射深度共同影响; 能量损失主要由初级重离子和次级电子产生, 非电离能量损失只占总能量损失的1%左右; 随着LET的增大, 次级电子的初始角度和能量分布越来越集中; 重离子诱导产生的电荷沉积峰值位置在重离子径迹中心, 在垂直于入射深度方向上呈高斯线性减小分布. 利用锎源进行碳化硅MOSFET单粒子烧毁试验, 结合TCAD模拟得到不同漏极电压下器件内部电场分布, 在考虑电场作用的蒙特卡罗模拟中发现: 碳化硅MOSFET外延层的电场强度越大, 重离子受电场作用在外延层运动的路径越长、沉积能量越多, 次级电子越容易偏向电场方向运动导致局部能量沉积过高.Using the Monte Carlo method, the energy losses in silicon carbide of heavy ions with different linear energy transfers (LETs) are simulated and calculated. The simulation results show that the energy loss per unit depth of heavy ions in silicon carbide is affected by both the ion energy and the incident depth. Primary heavy ions and secondary electrons mainly cause energy loss, and the non-ionization energy loss only accounts for about 1% of the total energy loss. With the increase of LET, the initial angle and energy distribution of the secondary electrons become more and more concentrated. The peak position of the generated charge deposition is in the center of the heavy-ion track, and the distribution is linearly decreasing in Gaussian form in the direction perpendicular to the incident depth. In the californium source experiment of SiC MOSFET, when the drain voltage is 480 V, the device has a single event burnout, and the breakdown voltage of SiC MOSFET is less than 1 V after burnout has occurred. With the experimental results, we carry out the TCAD simulation of SiC MOSFET and obtain the electric field distribution inside the device under different drain voltages. The electric field parameters are used in the Monte Carlo simulation of SiC MOSFET with considering the metal layer. It is found in the Monte Carlo simulation that the greater the electric field of the epitaxial layer, the longer the path of heavy ions moving on the epitaxial layer is and the more the deposited energy, and that the secondary electrons are more likely to move in the direction of the electric field as the electric field increases, resulting in excessive energy deposition in local areas.

-

Keywords:

- Monte Carlo method /

- silicon carbide /

- heavy ion /

- energy loss /

- electric field

[1] Elasser A, Chow T P 2002 Proc. IEEE 90 969

Google Scholar

Google Scholar

[2] Johnson C M, Wright N G, Uren M J, Hilton K P, Rahimo M, Hinchley D A, Knights A P, Morrison D J, Horsfall A B, Ortolland S, O’Neill A G 2001 IEE Proc.: Circuits Devices Syst. 148 101

Google Scholar

Google Scholar

[3] Cooper, Jr J A 1997 Phys. Status Solidi A 162 305

Google Scholar

Google Scholar

[4] 周拥华, 张义门, 张玉明, 孟祥志 2004 11 3710

Google Scholar

Google Scholar

Zhou Y H, Zhang Y M, Zhang Y M, Meng X Z 2004 Acta Phys. Sin. 11 3710

Google Scholar

Google Scholar

[5] 秦希峰, 梁毅, 王凤翔, 李双, 付刚, 季艳菊 2011 60 066101

Google Scholar

Google Scholar

Qin X F, Liang Y, Wang F X, Li S, Fu G, Ji Y J 2011 Acta Phys. Sin. 60 066101

Google Scholar

Google Scholar

[6] Zhang X 2013 Ph. D. Dissertation (Nashville: Vanderbilt University)

[7] 白玉新, 刘俊琴, 李雪, 曹英健, 张建国, 仲悦 2011 航天标准化 03 10

Google Scholar

Google Scholar

Bai Y X, Liu J Q, Li X, Cao Y J, Zhang J G, Zhong Y 2011 Aerospace Standardization 03 10

Google Scholar

Google Scholar

[8] 张林, 张义门, 张玉明, 韩超, 马永吉 2009 58 2737

Google Scholar

Google Scholar

Zhou L, Zhang Y M, Zhang Y M, Han C, Man Y J 2009 Acta Phys. Sin. 58 2737

Google Scholar

Google Scholar

[9] Messenger S R, Burke E A, Summers G P, Xapsos M A, Walters R J, Jackson E M, Weaver B D 1999 IEEE Trans. Nucl. Sci. 46 1595

Google Scholar

Google Scholar

[10] Messenger S R, Burke E A, Xapsos M A, Summers G P, Walters R J, Jun I 2003 IEEE Trans. Nucl. Sci. 50 1919

Google Scholar

Google Scholar

[11] Mizuta E, Kuboyama S, Abe H, Iwata Y, Tamura T 2014 IEEE Trans. Nucl. Sci. 61 1924

Google Scholar

Google Scholar

[12] Witulski A F, Arslanbekov R, Raman A, Schrimpf R D, Sternberg A L, Galloway K F, Javanainen A, Grider D, Lichtenwalner D J, Hull B 2017 IEEE Trans. Nucl. Sci. 65 256

Google Scholar

Google Scholar

[13] Javanainen A, Galloway K F, Nicklaw C, Bosser A L, Cavrois V F, Lauenstein J M, Pintacuda F, Reed R A, Schrimpf R D, Weller R A, Virtanen A 2016 IEEE Trans. Nucl. Sci. 64 415

Google Scholar

Google Scholar

[14] Javanainen A, Turowski M, Galloway K F, Nicklaw C, Cavrois V F, Bosser A, Lauenstein J M, Muschitiello M, Pintacuda F, Reed R A, Schrimpf R D, Weller R A, Virtanen A 2017 IEEE Trans. Nucl. Sci. 64 2031

Google Scholar

Google Scholar

[15] 于庆奎, 曹爽, 张洪伟, 梅博, 孙毅, 王贺, 李晓亮, 吕贺, 李鹏伟, 唐民 2019 原子能科学技术 53 2114

Google Scholar

Google Scholar

Yu Q K, Cao S, Zhang H W, Mei B, Sun Y, Wang H, Li X L, Lv H, Li P W, Tang M 2019 Atom. Energ. Sci. Technol. 53 2114

Google Scholar

Google Scholar

[16] 郭达禧, 贺朝会, 臧航, 席建琦, 马梨, 杨涛, 张鹏 2013 原子能科学技术 47 1222

Google Scholar

Google Scholar

Guo D X, He C H, Zang H, Xi J Q, Ma L, Yang T, Zhang P 2013 Atom. Energ. Sci. Technol. 47 1222

Google Scholar

Google Scholar

[17] 陈世彬, 张义门, 陈雨生, 黄流兴, 张玉明 2001 高能物理与核物理 25 365

Google Scholar

Google Scholar

Chen S B, Zhang Y M, Chen Y S, Huang L X, Zhang Y M 2001 High Energ. Phys. Nucl. 25 365

Google Scholar

Google Scholar

[18] 申帅帅, 贺朝会, 李永宏 2018 67 182401

Google Scholar

Google Scholar

Shen S S, He C H, Li Y H 2018 Acta Phys. Sin. 67 182401

Google Scholar

Google Scholar

[19] Kuboyama S, Kamezawa C, Ikeda N, Hirao T, Ohyama H 2006 IEEE Trans. Nucl. Sci. 53 3343

Google Scholar

Google Scholar

[20] Kuboyama S, Kamezawa C, Satoh Y, Hirao T, Ohyama H 2007 IEEE Trans. Nucl. Sci. 54 2379

Google Scholar

Google Scholar

[21] Casey M C, Lauenstein J M, Topper A D, Wilcox E P, Kim H, Phan A M, LaBel K A 2012 The 3rd Annual NEPP Electronic Technology Workshop, Greenbelt, Maryland, USA, June 11−13, 2012 p561

[22] Lauenstein J M, Casey M C, LaBel K A, Topper A D, Wilcox E P, Kim H, Phan A M 2014 The 5th Annual NEPP Electronic Technology Workshop, Greenbelt, Maryland, USA, June 17−19, 2014 p561

[23] Abbate C, Busatto G, Cova P, Delmonte N, Giuliani F, Iannuzzo F, Sanseverino A, Velardi F 2014 Microelectron. Reliab. 54 2200

Google Scholar

Google Scholar

[24] Ziegler J F, Ziegler M D, Biersack J P 2010 Nucl. Instrum. Methods Phys. Res., Sect. B 268 1818

Google Scholar

Google Scholar

[25] Evseev I G, Schelin H R, Paschuk S A, Milhoretto E, Setti J A P, Yevseyeva O, Assis J T, Hormaza J M, Dıáz K S, Lopes R T 2010 Appl. Radiat. Isot. 68 948

Google Scholar

Google Scholar

[26] Guide for physics Lists, Collaboration G https://geant4-userdoc.web.cern.ch/UsersGuides/PhysicsListGuide/html/index.html/ [2021-4-15]

[27] Physics reference manual, Collaboration G https://geant4-userdoc.web.cern.ch/UsersGuides/PhysicsReferenceManual/html/index.html/ [2021-4-15]

[28] Berger M J, Inokuti M, Andersen H H, Bichsel H, Powers D, Seltzer S M, Thwaites D, Watt D E 1993 J. Int. Commission Radiat. Units Meas. 25 49

[29] 侯东明, 刘杰, 孙友梅, 姚会军, 段敬来, 尹经敏, 莫丹, 张苓, 陈艳峰 2008 原子能科学技术 07 622

Google Scholar

Google Scholar

Hou D M, Liu J, Sun Y M, Yao H J, Duan J L, Yin J M, Mo D, Zhang L, Chen Y F 2008 Atom. Energ. Sci. Technol. 07 622

Google Scholar

Google Scholar

[30] Hu P P, Liu J, Zhang S X, Maaz K, Zeng J, Zhai P F, Xu L J, Cao Y R, Duan J L, Li Z Z, Sun M Y, Ma X H 2018 Nucl. Instrum. Methods Phys. Res., Sect. B 430 59

Google Scholar

Google Scholar

[31] Ball D R, Galloway K F, Johnson R A, Alles M L, Sternberg A L, Sierawski B D, Witulski A F, Reed R A, Schrimpf R D, Hutson J M, Javanainen A, Lauenstein J M 2019 IEEE Trans. Nucl. Sci. 67 22

Google Scholar

Google Scholar

-

表 1 选取的重离子种类、能量及其在材料中的射程

Table 1. Selected heavy ion, energy and range of heavy ions in silicon carbide.

重离子 能量/MeV SiC中射程/μm@SRIM SiC中射程/μm@Geant4 SiC中LET /(MeV·cm2·mg–1) Si中LET /(MeV·cm2·mg–1) 铜 (Cu+) 212 22.01 21.5 34.08 32.2 溴 (Br+) 218 19.97 18.5 44.73 42 碘 (I+) 270 19.21 16.5 69.72 65 -

[1] Elasser A, Chow T P 2002 Proc. IEEE 90 969

Google Scholar

Google Scholar

[2] Johnson C M, Wright N G, Uren M J, Hilton K P, Rahimo M, Hinchley D A, Knights A P, Morrison D J, Horsfall A B, Ortolland S, O’Neill A G 2001 IEE Proc.: Circuits Devices Syst. 148 101

Google Scholar

Google Scholar

[3] Cooper, Jr J A 1997 Phys. Status Solidi A 162 305

Google Scholar

Google Scholar

[4] 周拥华, 张义门, 张玉明, 孟祥志 2004 11 3710

Google Scholar

Google Scholar

Zhou Y H, Zhang Y M, Zhang Y M, Meng X Z 2004 Acta Phys. Sin. 11 3710

Google Scholar

Google Scholar

[5] 秦希峰, 梁毅, 王凤翔, 李双, 付刚, 季艳菊 2011 60 066101

Google Scholar

Google Scholar

Qin X F, Liang Y, Wang F X, Li S, Fu G, Ji Y J 2011 Acta Phys. Sin. 60 066101

Google Scholar

Google Scholar

[6] Zhang X 2013 Ph. D. Dissertation (Nashville: Vanderbilt University)

[7] 白玉新, 刘俊琴, 李雪, 曹英健, 张建国, 仲悦 2011 航天标准化 03 10

Google Scholar

Google Scholar

Bai Y X, Liu J Q, Li X, Cao Y J, Zhang J G, Zhong Y 2011 Aerospace Standardization 03 10

Google Scholar

Google Scholar

[8] 张林, 张义门, 张玉明, 韩超, 马永吉 2009 58 2737

Google Scholar

Google Scholar

Zhou L, Zhang Y M, Zhang Y M, Han C, Man Y J 2009 Acta Phys. Sin. 58 2737

Google Scholar

Google Scholar

[9] Messenger S R, Burke E A, Summers G P, Xapsos M A, Walters R J, Jackson E M, Weaver B D 1999 IEEE Trans. Nucl. Sci. 46 1595

Google Scholar

Google Scholar

[10] Messenger S R, Burke E A, Xapsos M A, Summers G P, Walters R J, Jun I 2003 IEEE Trans. Nucl. Sci. 50 1919

Google Scholar

Google Scholar

[11] Mizuta E, Kuboyama S, Abe H, Iwata Y, Tamura T 2014 IEEE Trans. Nucl. Sci. 61 1924

Google Scholar

Google Scholar

[12] Witulski A F, Arslanbekov R, Raman A, Schrimpf R D, Sternberg A L, Galloway K F, Javanainen A, Grider D, Lichtenwalner D J, Hull B 2017 IEEE Trans. Nucl. Sci. 65 256

Google Scholar

Google Scholar

[13] Javanainen A, Galloway K F, Nicklaw C, Bosser A L, Cavrois V F, Lauenstein J M, Pintacuda F, Reed R A, Schrimpf R D, Weller R A, Virtanen A 2016 IEEE Trans. Nucl. Sci. 64 415

Google Scholar

Google Scholar

[14] Javanainen A, Turowski M, Galloway K F, Nicklaw C, Cavrois V F, Bosser A, Lauenstein J M, Muschitiello M, Pintacuda F, Reed R A, Schrimpf R D, Weller R A, Virtanen A 2017 IEEE Trans. Nucl. Sci. 64 2031

Google Scholar

Google Scholar

[15] 于庆奎, 曹爽, 张洪伟, 梅博, 孙毅, 王贺, 李晓亮, 吕贺, 李鹏伟, 唐民 2019 原子能科学技术 53 2114

Google Scholar

Google Scholar

Yu Q K, Cao S, Zhang H W, Mei B, Sun Y, Wang H, Li X L, Lv H, Li P W, Tang M 2019 Atom. Energ. Sci. Technol. 53 2114

Google Scholar

Google Scholar

[16] 郭达禧, 贺朝会, 臧航, 席建琦, 马梨, 杨涛, 张鹏 2013 原子能科学技术 47 1222

Google Scholar

Google Scholar

Guo D X, He C H, Zang H, Xi J Q, Ma L, Yang T, Zhang P 2013 Atom. Energ. Sci. Technol. 47 1222

Google Scholar

Google Scholar

[17] 陈世彬, 张义门, 陈雨生, 黄流兴, 张玉明 2001 高能物理与核物理 25 365

Google Scholar

Google Scholar

Chen S B, Zhang Y M, Chen Y S, Huang L X, Zhang Y M 2001 High Energ. Phys. Nucl. 25 365

Google Scholar

Google Scholar

[18] 申帅帅, 贺朝会, 李永宏 2018 67 182401

Google Scholar

Google Scholar

Shen S S, He C H, Li Y H 2018 Acta Phys. Sin. 67 182401

Google Scholar

Google Scholar

[19] Kuboyama S, Kamezawa C, Ikeda N, Hirao T, Ohyama H 2006 IEEE Trans. Nucl. Sci. 53 3343

Google Scholar

Google Scholar

[20] Kuboyama S, Kamezawa C, Satoh Y, Hirao T, Ohyama H 2007 IEEE Trans. Nucl. Sci. 54 2379

Google Scholar

Google Scholar

[21] Casey M C, Lauenstein J M, Topper A D, Wilcox E P, Kim H, Phan A M, LaBel K A 2012 The 3rd Annual NEPP Electronic Technology Workshop, Greenbelt, Maryland, USA, June 11−13, 2012 p561

[22] Lauenstein J M, Casey M C, LaBel K A, Topper A D, Wilcox E P, Kim H, Phan A M 2014 The 5th Annual NEPP Electronic Technology Workshop, Greenbelt, Maryland, USA, June 17−19, 2014 p561

[23] Abbate C, Busatto G, Cova P, Delmonte N, Giuliani F, Iannuzzo F, Sanseverino A, Velardi F 2014 Microelectron. Reliab. 54 2200

Google Scholar

Google Scholar

[24] Ziegler J F, Ziegler M D, Biersack J P 2010 Nucl. Instrum. Methods Phys. Res., Sect. B 268 1818

Google Scholar

Google Scholar

[25] Evseev I G, Schelin H R, Paschuk S A, Milhoretto E, Setti J A P, Yevseyeva O, Assis J T, Hormaza J M, Dıáz K S, Lopes R T 2010 Appl. Radiat. Isot. 68 948

Google Scholar

Google Scholar

[26] Guide for physics Lists, Collaboration G https://geant4-userdoc.web.cern.ch/UsersGuides/PhysicsListGuide/html/index.html/ [2021-4-15]

[27] Physics reference manual, Collaboration G https://geant4-userdoc.web.cern.ch/UsersGuides/PhysicsReferenceManual/html/index.html/ [2021-4-15]

[28] Berger M J, Inokuti M, Andersen H H, Bichsel H, Powers D, Seltzer S M, Thwaites D, Watt D E 1993 J. Int. Commission Radiat. Units Meas. 25 49

[29] 侯东明, 刘杰, 孙友梅, 姚会军, 段敬来, 尹经敏, 莫丹, 张苓, 陈艳峰 2008 原子能科学技术 07 622

Google Scholar

Google Scholar

Hou D M, Liu J, Sun Y M, Yao H J, Duan J L, Yin J M, Mo D, Zhang L, Chen Y F 2008 Atom. Energ. Sci. Technol. 07 622

Google Scholar

Google Scholar

[30] Hu P P, Liu J, Zhang S X, Maaz K, Zeng J, Zhai P F, Xu L J, Cao Y R, Duan J L, Li Z Z, Sun M Y, Ma X H 2018 Nucl. Instrum. Methods Phys. Res., Sect. B 430 59

Google Scholar

Google Scholar

[31] Ball D R, Galloway K F, Johnson R A, Alles M L, Sternberg A L, Sierawski B D, Witulski A F, Reed R A, Schrimpf R D, Hutson J M, Javanainen A, Lauenstein J M 2019 IEEE Trans. Nucl. Sci. 67 22

Google Scholar

Google Scholar

计量

- 文章访问数: 9606

- PDF下载量: 225

- 被引次数: 0

下载:

下载: