-

TiNiSn基 half-Heusler高温热电材料具有较高的功率因子, 但其也具有较高的晶格热导率, 这极大地阻碍了其热电性能的提升. 本文采用熔融旋甩快淬与放电等离子烧结工艺制备TiNiCoxSn (x = 0—0.05)样品, 研究磁性Co元素掺杂对材料的相组成、微观结构和热电性能. 结果表明, 该制备工艺能够直接获得纳米晶的TiNiCoxSn样品. 在纳米晶影响下的样品的热导率明显低于块体材料的热导率, 平均降幅约为17.8%. 在Co掺杂后样品的晶粒尺寸进一步降低, 与TiNiSn基体相比, TiNiCoxSn样品的热导率显著降低, 最大降幅约为38.9%, 其中晶格热导率最低值为3.19 W/(m·K), 最大降幅约为42.6%. 随着Co掺杂量x的增大TiNiCoxSn样品出现n/p转变, 电导率随x增大而逐渐下降, 电输运性能劣化, 功率因子缓慢减小, 其中TiNiSn样品在700 K时获得29.56 W/(m·K2)的最高功率因子. ZT值随Co掺杂量x的增大而逐渐降低, TiNiSn样品在900 K时的最大ZT值为0.48. 本工作表明采用熔融旋甩制备工艺及磁性Co掺杂能够有效降低TiNiSn材料的热导率.

-

关键词:

- TiNiSn /

- 热电材料 /

- 熔融旋甩 /

- half-Heusler

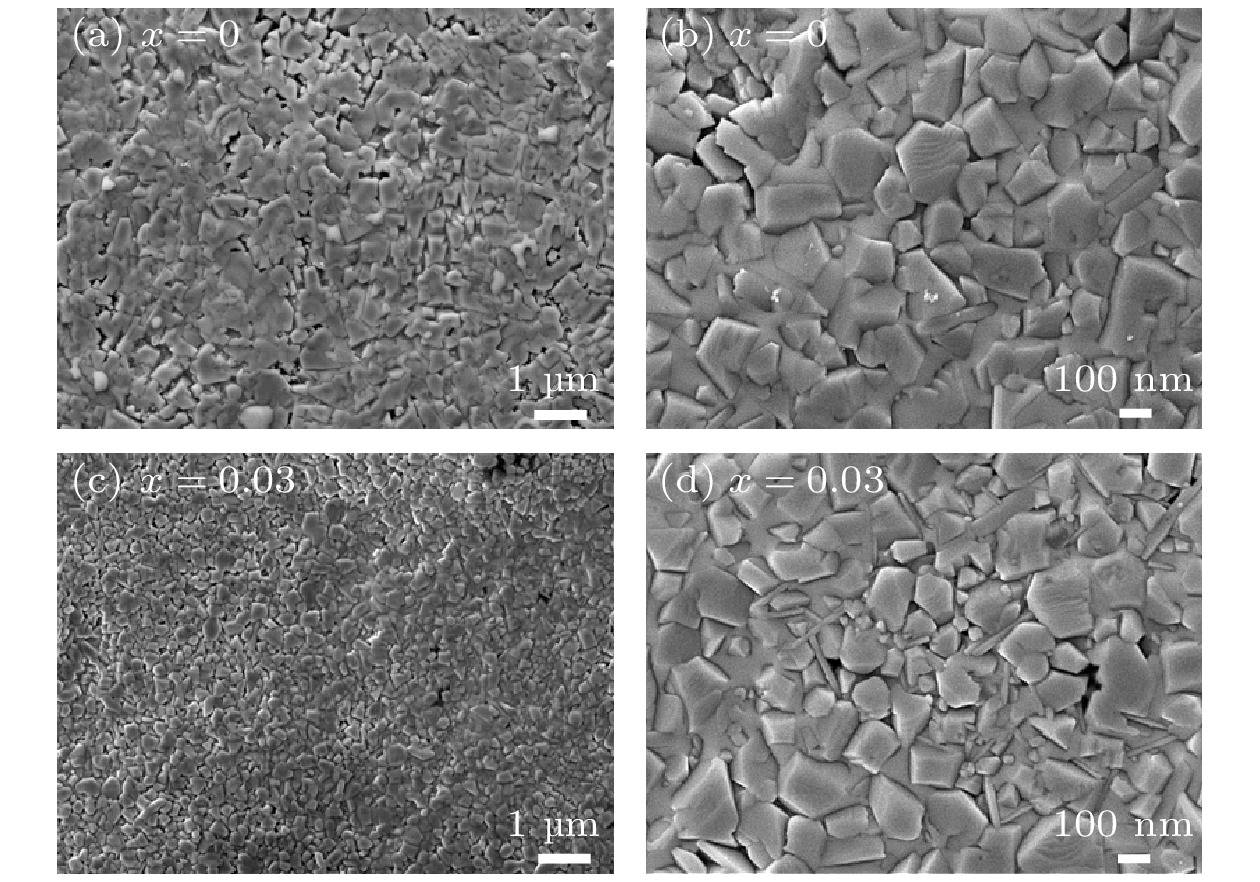

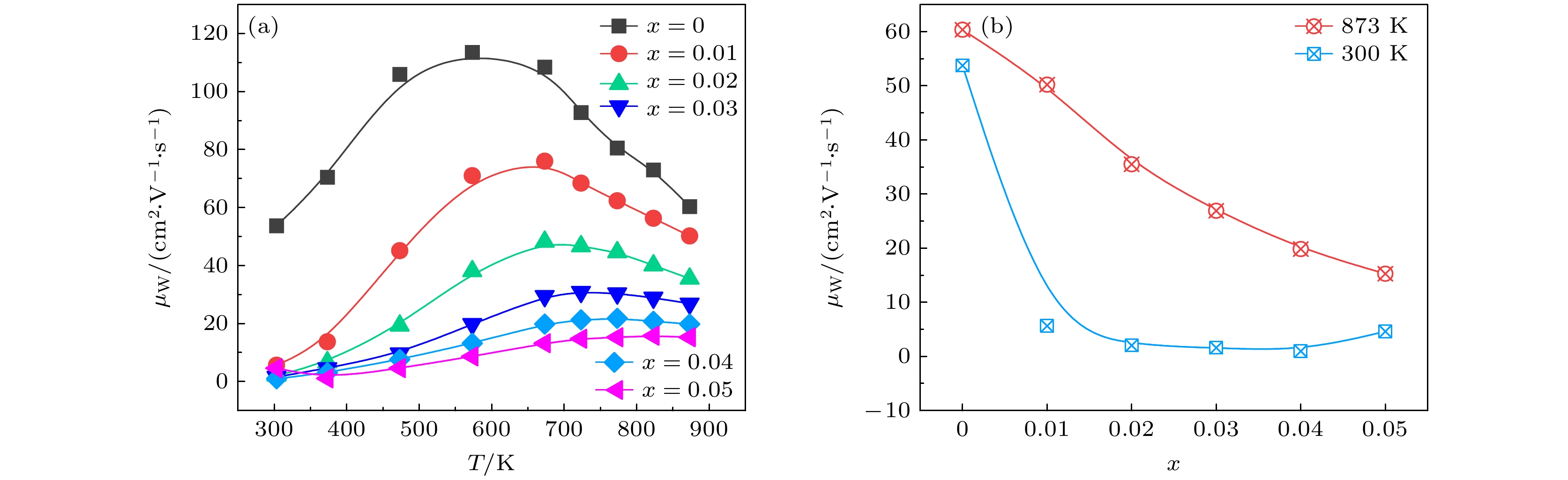

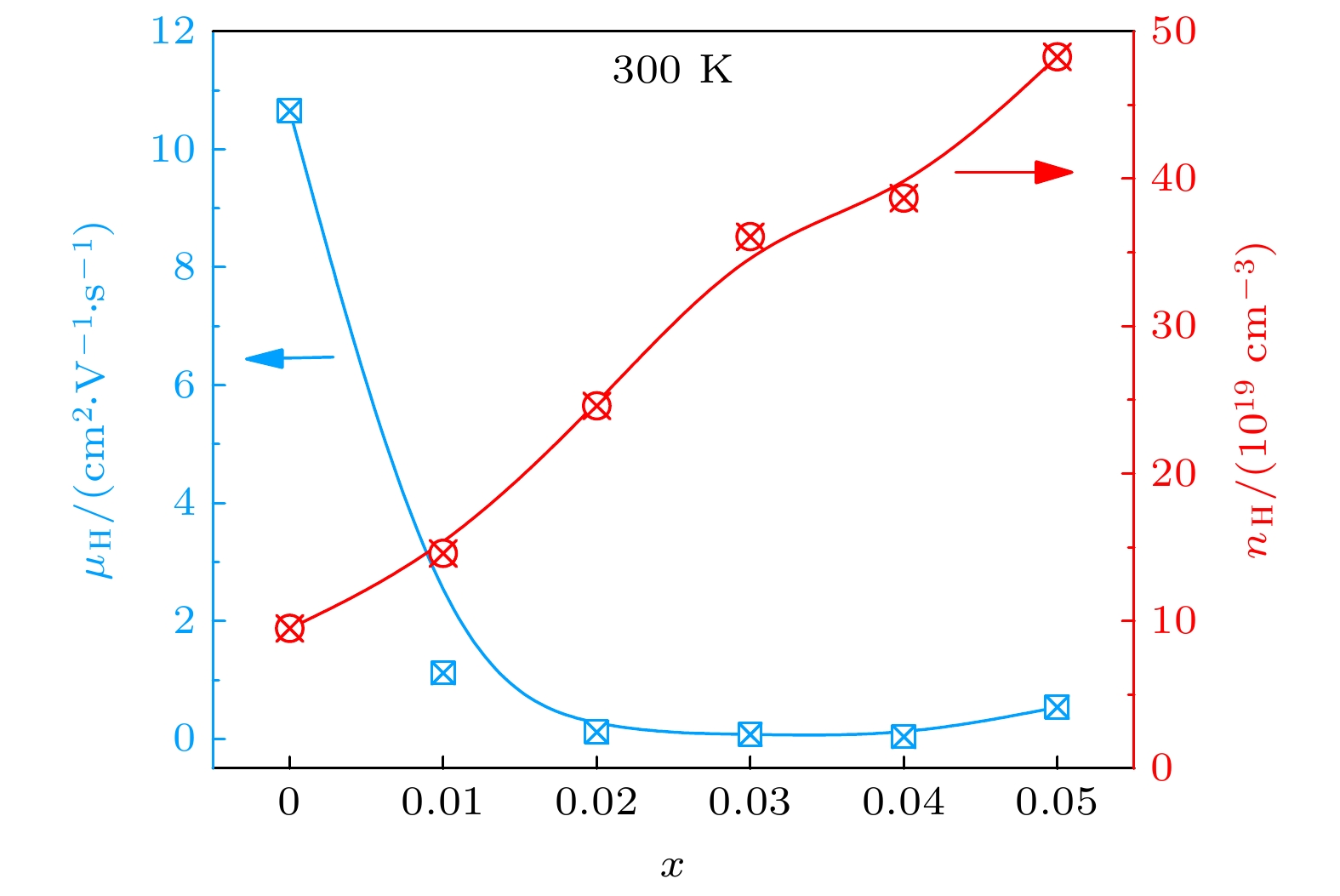

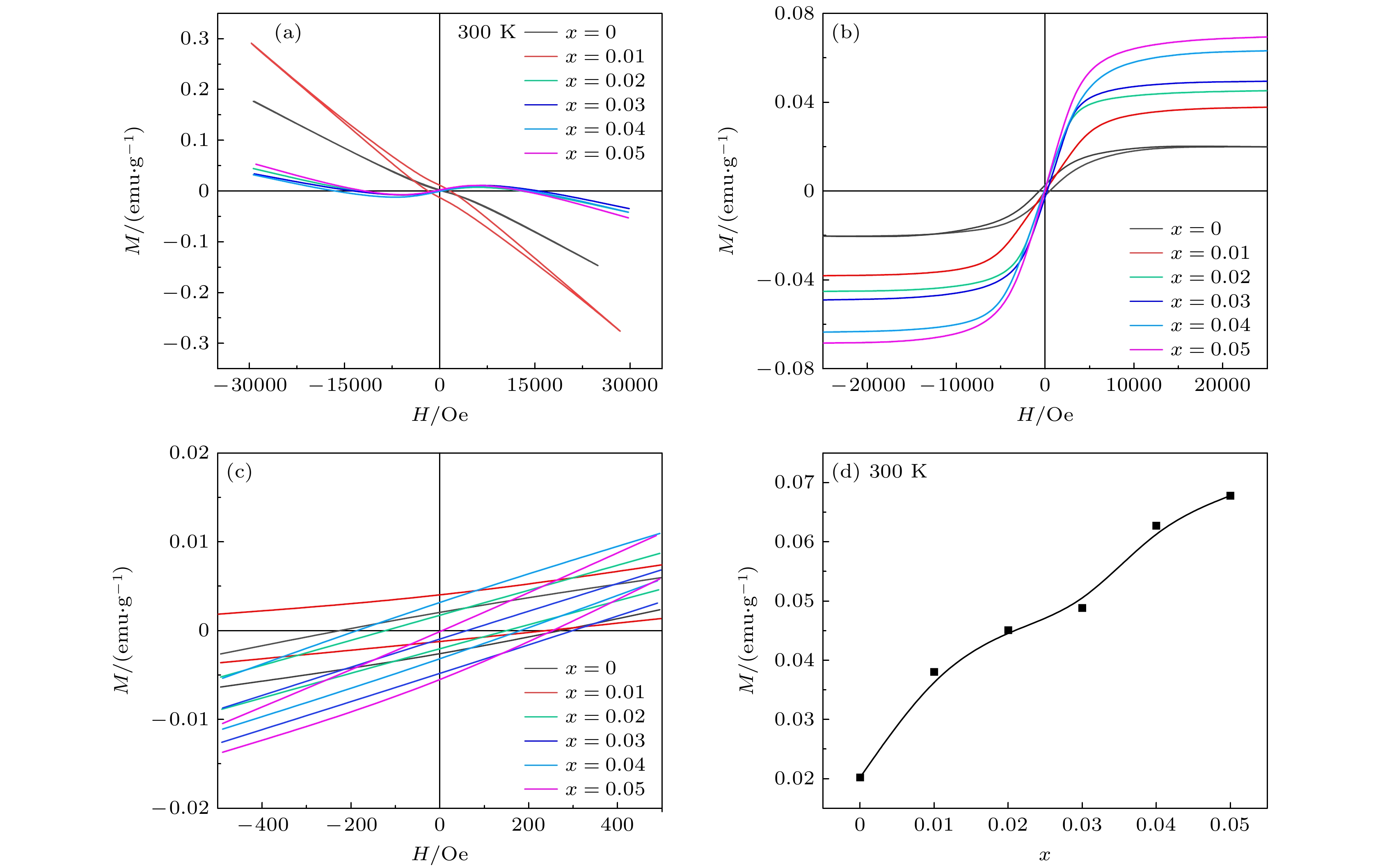

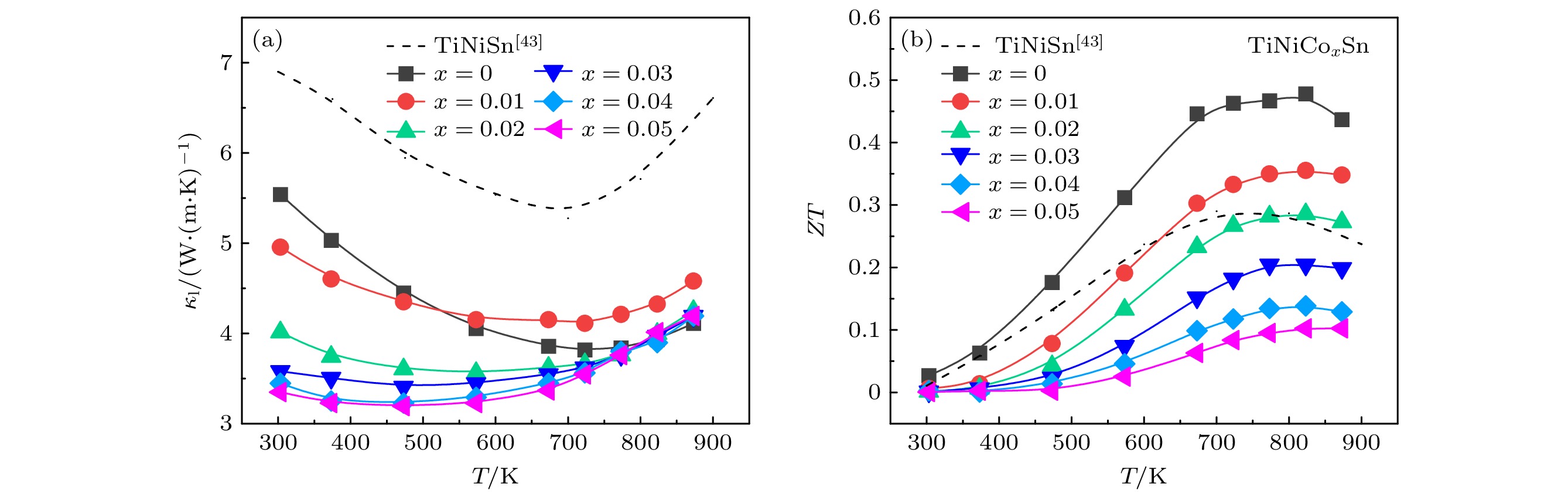

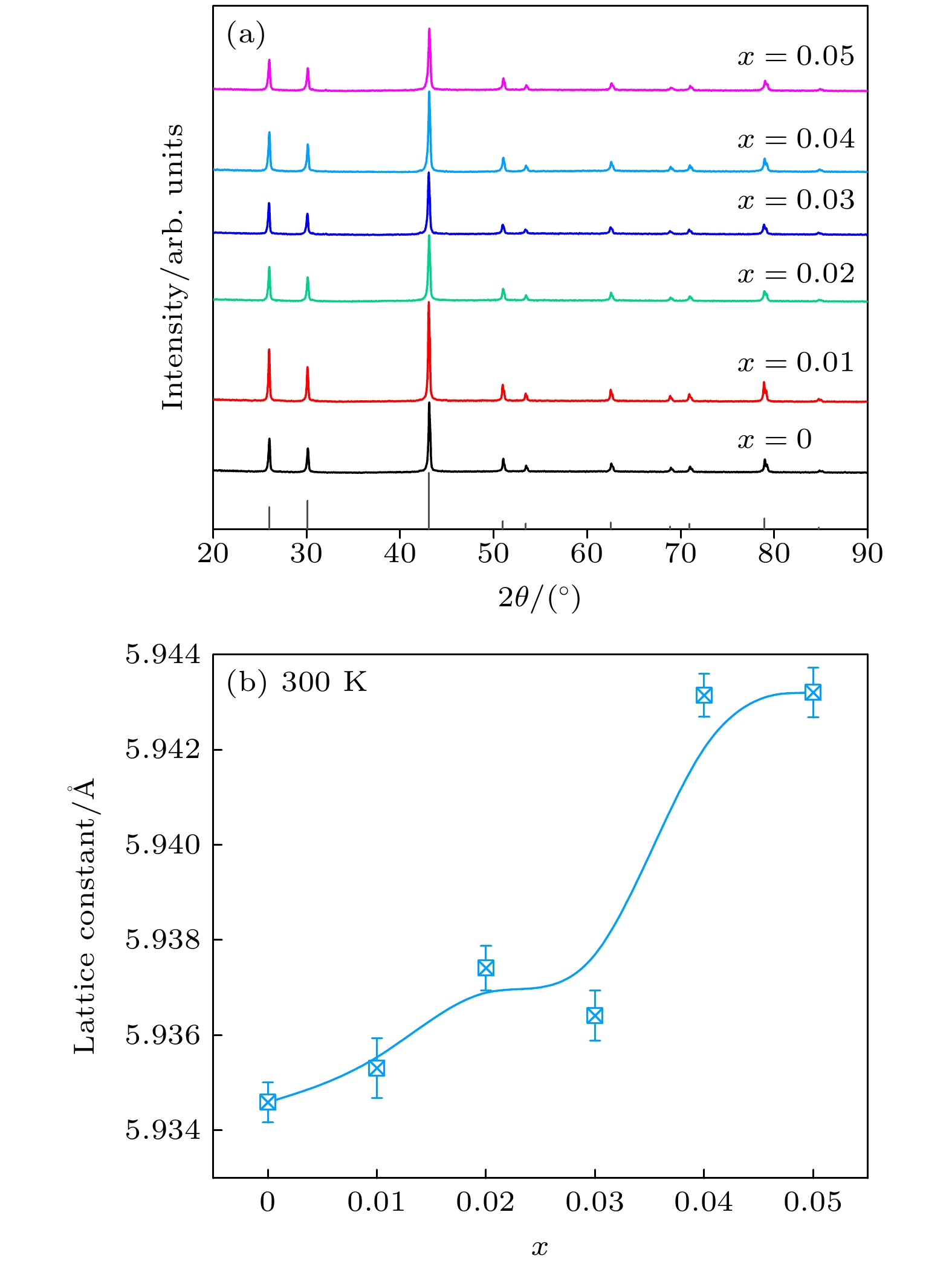

Although TiNiSn-based half-Heusler thermoelectric materials obtain high power factors, their high lattice thermal conductivity greatly hinders the improvement of thermoelectric properties. In this work, TiNiCoxSn (x = 0–0.05) samples are prepared by melt spinning combined with spark plasma sintering method, and their phase, microstructure and thermoelectric properties are studied. The XRD results show that the main phase of all samples is TiNiSn phase, and no any other impurity phases are found, indicating that the high purity single phase can be prepared by rapid quenching process combined with SPS process. In the solidification process, the large cooling rate (105–106 K/s) is conducive to obtaining the uniform nanocrystalline structure. The grains are closely packed, with grain sizes in a range of 200–600 nm. The grain sizes decrease to 50–400 nm for the Co-doping samples, which indicates that Co doping can reduce the grain size. For the x = 0 sample, the thermal conductivity of the rapid quenching sample is significantly lower than that of bulk sample, with an average decrease of about 17.8%. Compared with the TiNiSn matrix, the Co-doping sample has the thermal conductivity that decreases significantly, and the maximum decrease can reach about 38.9%. The minimum value of lattice thermal conductivity of TiNiCoxSn samples is 3.19 W/(m·K). Therefore, Co doping can significantly reduce the κl values of TiNiCoxSn (x = 0.01–0.05) samples. With the increase of Co doping amount x, n/p transition is observed in the TiNiCoxSn samples, resulting in gradually reducing the conductivity and the power factor, and finally deteriorating the electrical transport performance, of which, the TiNiSn sample obtains the highest power factor of 29.56 W/(m·K2) at 700 K. The ZT value decreases with the Co doping amount x increasing, and the maximum ZT value of TiNiSn sample at 900 K is 0.48. This work shows that the thermal conductivity of TiNiSn can be effectively reduced by using the melt spinning process and magnetic Co doping.-

Keywords:

- TiNiSn /

- thermoelectric materials /

- melt spinning /

- half-Heusler

[1] 杨士冠, 林鑫, 何俊松, 翟立军, 程林, 吕明豪, 刘虹霞, 张艳, 孙志刚 2023 72 228401

Google Scholar

Google Scholar

Yang S G, Lin X, He J S, Zhai L J, Cheng L, Lü M H, Liu H X, Zhang Y, Sun Z G 2023 Acta Phys. Sin. 72 228401

Google Scholar

Google Scholar

[2] Luo F, Zhu C, Wang J, He X, Yang Z, Ke S, Zhang Y, Liu H, Sun Z G 2022 ACS Appl. Mater. Interfaces. 14 45503

Google Scholar

Google Scholar

[3] Ma S F, Li C C, Wei P, Zhu W T, Nie X L, Sang X H, Zhang Q J, Zhao W Y 2020 J. Mater. Chem. A 8 4816

Google Scholar

Google Scholar

[4] Shi L, Chen J, Zhang G, Li B 2012 Phys. Lett. A 376 978

Google Scholar

Google Scholar

[5] Ouyang Y, Zhang Z, Li D, Chen J, Zhang G 2019 Ann. Phys. Berlin 531 4

Google Scholar

Google Scholar

[6] He J, Hu Y X, Li D F, Chen J 2021 Nano Res. 15 3804

[7] Xiao F, Hangarter C, Yoo B, Rheem Y, Lee K H, Myung N V 2008 Electrochimica Acta 53 8103

Google Scholar

Google Scholar

[8] Jiang B B, Wang W, Liu S X, Wang Y, Wang C F, Chen Y N, Xie L, Huang M Y, He J Q 2022 Science 377 208

Google Scholar

Google Scholar

[9] Gelbstein Y, Rosenberg Y, Sadia Y, Dariel M P 2010 J. Phys. Chem. C. 114 13126

[10] Komisarchik G, Gelbstein Y, Fuks D 2017 Intermetallics 89 16

Google Scholar

Google Scholar

[11] Liu H T, Sun Q, Zhong Y, Deng Q, Gan L, Lü F L, Shi X L, Chen Z G, Ang R 2022 Nano Energy 91 106706

Google Scholar

Google Scholar

[12] Pochet P, Caliste D 2012 Mat. Sci. Semicon. Proc. 15 675

Google Scholar

Google Scholar

[13] Khan M R, Gopidi H R, Wlazło M, Malyi O I 2023 J. Phys. Chem. Lett. 14 1962

Google Scholar

Google Scholar

[14] Kaller M, Fuks D, Gelbstein Y 2017 J. Alloy Compd. 729 446

Google Scholar

Google Scholar

[15] Chauhan N S, Bathula S, Vishwakarma A, Bhardwaj R, Gahtori B, Kumar A, Dhar A 2018 ACS Appl. Energy Mater. 1 757

Google Scholar

Google Scholar

[16] Lim W Y S, Zhang D, Duran S S F, Tan X Y, Tan C K I, Xu J, Suwardi A 2021 Front Mater. 8 745

[17] Wang J, Luo F, Zhu C, Wang J, He X, Zhang Y, Liu H, Sun Z G 2023 J. Mater. Chem. 11 4056

Google Scholar

Google Scholar

[18] Zhu C, Wang J, Zhu X Q, Zhang S, Xu F, Luo F, Wang J F, Zhang Y, Liu H X, Sun Z G 2023 J. Mater. Chem. A 11 1268

Google Scholar

Google Scholar

[19] 陈树权, 王剑, 杨振, 朱璨, 罗丰, 祝鑫强, 徐峰, 王嘉赋, 张艳, 刘虹霞, 孙志刚 2023 72 068401

Google Scholar

Google Scholar

Chen S Q, Wang J, Yang Z, Zhu C, Luo F, Zhu X Q, Xu F, Wang J F, Zhang Y, Liu H X, Sun Z G 2023 Acta Phys. Sin. 72 068401

Google Scholar

Google Scholar

[20] Santos R, Yamini S A, Dou S X 2018 J. Mater. Chem. A 6 3328

Google Scholar

Google Scholar

[21] Berry T, Fu C, Auffermann G, Fecher G H, Schnelle W, Serrano-Sanchez F, Yue Y, Liang H, Felser C 2017 Chem. Mater. 29 7042

Google Scholar

Google Scholar

[22] Downie R, Maclaren D, Bos J W 2014 J. Mater. Chem. A 2 6107

Google Scholar

Google Scholar

[23] Sanad M F, Shalan A E, Abdellatif S O, Serea E S A, Adly M S, Ahsan M A 2020 Top Curr. Chem. 378 48

Google Scholar

Google Scholar

[24] Wang J, Zhu C, Luo F, Wang J F, He X, Zhang Y, Liu H X, Sun Z G 2023 ACS Appl. Mater. Interfaces 15 8105

Google Scholar

Google Scholar

[25] Lü W Y, Liu W D, Li M, Hong M, Guo K, Luo J, Xing J, Sun Q, Xu S, Zou J 2022 Chem. Eng. J. 446 137278

Google Scholar

Google Scholar

[26] Hu B, Shi X L, Zou J, Chen Z G 2022 Chem. Eng. J. 437 135268

Google Scholar

Google Scholar

[27] Liu H X, Zhang S, Zhang Y, Zong S T, Li W, Zhu C, Luo F, Wang J, Sun Z G 2022 ACS Appl. Energy Mater. 5 15093

Google Scholar

Google Scholar

[28] Zhu T J, Liu Y T, Fu C G, Heremans J P, Snyder J G, Zhao X B 2017 Adv. Mater. 29 1605884

Google Scholar

Google Scholar

[29] Van Du N, Nam W H, Cho J Y, Binh N V, Huy P T, Tuan D A, Shin W H, Lee S 2021 J. Alloy Compd. 886 161293

Google Scholar

Google Scholar

[30] Pei Y Z, Shi X Y, Lalonde A, Wang H, Chen L D, Snyder G J 2011 Nature 473 66

Google Scholar

Google Scholar

[31] Poudel B, Hao Q, Ma Y, Lan Y C, Minnich A, Yu B, Yan X, Wang D Z, Muto A, Vashaee D, Chen X Y, Liu J M, Dresselhaus M S, Chen G, Ren Z F 2008 Science 320 634

Google Scholar

Google Scholar

[32] Zhao L D, Tan G J, Hao S Q, He J Q, Pei Y L, Chi H, Wang H, Gong S K, Xu H B, Dravid V P, Uher C, Snyder G J, Wolverton C, Kanatzidis M G 2016 Science 351 141

Google Scholar

Google Scholar

[33] Hohl H, Ramirez A P, Goldmann C, Ernst G, Wölfing B, Bucher E 1999 J. Phys. Condens. Mat. 11 1697

Google Scholar

Google Scholar

[34] Chauhan N S, Raghuvanshi P R, Tyagi K, Johari K K, Tyagi L, Gahtori B, Bathula S, Bhattacharya A, Mahanti S D, Singh V N 2020 J. Phys. Condens. Mat. 124 8584

[35] Shutoh N, Sakurada S 2005 J. Alloy Compd. 389 204

Google Scholar

Google Scholar

[36] Cho J, Park T, Bae K W, Kim H S, Choi S M, Kim S I, Kim S W 2021 Materials 14 4029

Google Scholar

Google Scholar

[37] He J S, Shen Y C, Zhai L J, Luo F, Zhang Y, Liu H X, Hu J F, Sun Z G 2024 J. Alloy Compd. 975 172808

Google Scholar

Google Scholar

[38] Wang J F, Luo F, Zhu C, Zhang S, Yang Z, Wang J F, He X, Zhang Y, Sun Z G 2022 J. Appl. Phys. 132 135103

Google Scholar

Google Scholar

[39] Dresselhaus M S, Chen G, Tang M Y, Yang R, Lee H, Wang D, Ren Z F, Fleurial J P, Gogna P 2007 Adv. Mater. 19 1043

Google Scholar

Google Scholar

[40] Dresselhaus M, Chen G, Ren Z F, Dresselhaus G, Henry A, Fleurial J P 2009 JOM 61 86

Google Scholar

Google Scholar

[41] Yang J, Yip H L, Jen A K Y 2013 Adv. Energy Mater. 3 549

Google Scholar

Google Scholar

[42] Kim K S, Kim Y M, Mun H, Kim J, Park J, Borisevich A Y, Lee K H, Kim S W 2017 Adv. Mater. 29 1702091

Google Scholar

Google Scholar

[43] Katayama T, Kim S W, Kimura Y, Mishima Y 2003 J. Electron. Mater. 32 1160

Google Scholar

Google Scholar

[44] Li C C, Zhao W Y, Zhang Q J 2022 Sci. Bull. 67 891

Google Scholar

Google Scholar

[45] Zhao W Y, Liu Z Y, Sun Z G, Zhang Q J, Wei P, Mu X, Zhou H Y, Li C C, Ma S F, He D Q, Ji P X, Zhu W T, Nie X L, Su X L, Tang X F, Shen B G, Dong X L, Yang J H, Liu Y, Shi J 2017 Nature 549 247

Google Scholar

Google Scholar

[46] Luo F, Wang J, Zhu C, He X, Zhang S, Wang J F, Liu H X, Sun Z G 2022 J. Mater. Chem. A 10 9655

Google Scholar

Google Scholar

[47] Romaka V, Stadnyk Y V, Fruchart D, Dominuk T, Romaka L, Rogl P, Goryn A M 2009 Semiconductors 43 1124

Google Scholar

Google Scholar

[48] 罗丰2023 博士学位论文 (武汉: 武汉理工大学)

Luo F 2023 Ph. D. Dissertation (Wuhan: Wuhan University of Technology

[49] An D C, Wang J J, Zhang J, Zhai X, Kang Z P, Fan W H, Yan J, Liu Y Q, Lu L, Jia C L, Wuttig M, Cojocaru-Mirédin O, Chen S P, Wang W X, Snyder G J, Yu Y 2021 Energy Environ. Sci. 14 5469

Google Scholar

Google Scholar

[50] Drymiotis F, Lashley J C, Fisk Z, Peterson E, Nakatsuji S 2003 Philos. Mag. 83 3169

Google Scholar

Google Scholar

[51] Kim H S, Gibbs Z M, Tang Y L, Wang H, Snyder G J 2015 APL Mater. 3 041506

Google Scholar

Google Scholar

[52] Baranovskiy A, Harush M, Amouyal Y 2019 Adv. Theor. Simul. 2 54

[53] Chi H, Liu W, Sun K, Su X L, Wang G Y, Lošt'ák P, Kucek V, Drašar Č, Uher C 2013 Phys. Rev. B 88 045202

Google Scholar

Google Scholar

[54] Lkhagvasuren E, Fu C, Fecher G H, Auffermann G, Kreiner G, Schnelle W, Felser C 2017 J. Phys. D Appl. Phys. 50 425502

Google Scholar

Google Scholar

[55] Gong B, Li Y, Liu F S, Zhu J X, Wang X, Ao W Q, Zhang C H, Li J Q, Xie H P, Zhu T J 2019 ACS Appl. Mater. Interface 11 13397

Google Scholar

Google Scholar

[56] Mao J, Zhou J, Zhu H, Liu Z, Zhang H, He R, Chen G, Ren Z F 2017 Chem. Mater. 29 14

[57] Yan J X, Liu F S, Ma G H, Gong B, Zhu J X, Wang X, Ao W Q, Zhang C H, Li Y, Li J Q 2018 Scripta Mater. 157 129

Google Scholar

Google Scholar

[58] Liu Y T, Xie H H, Fu C G, Snyder G J, Zhao X B, Zhu T J 2015 J. Mater. Chem. A 3 22716

Google Scholar

Google Scholar

-

图 3 TiNiCoxSn薄带的SEM图 (a) TiNiSn微观图; (b) TiNiSn局部放大图; (c) TiNiCo0.03Sn微观图; (d) TiNiCo0.03Sn局部放大图

Fig. 3. SEM images of TiNiCoxSn ribbons: (a) Microscopic image of TiNiSn; (b) local enlarged image of TiNiSn ribbon; (c) microscopic image of TiNiCo0.03Sn; (d) local enlarged image of TiNiCo0.03Sn ribbon.

图 4 TiNiCoxSn块体截面的EPMA图 (a) TiNiSn微观图; (b) TiNiSn局部放大图; (c) TiNiCo0.03Sn微观图; (d) TiNiCo0.03Sn局部放大图

Fig. 4. EPMA diagrams of TiNiCoxSn block section: (a) Microscopic image of TiNiSn; (b) local enlarged image of TiNiSn sample; (c) microscopic image of TiNiCo0.03Sn; (d) local enlarged image of TiNiCo0.03Sn sample.

图 8 (a) TiNiCoxSn样品在室温下磁化强度随磁场的变化关系; (b) TiNiCoxSn样品的铁磁性; (c) 零点附近局部放大图; (d) 最大饱和磁化强度随掺杂量的关系

Fig. 8. (a) Room temperature M-H curves of TiNiCoxSn samples, (b) the ferromagnetic singals of TiNiCoxSn samples, (c) the enlarged M-H curves near zero point; (d) relation of saturation magnetization with doping amount x.

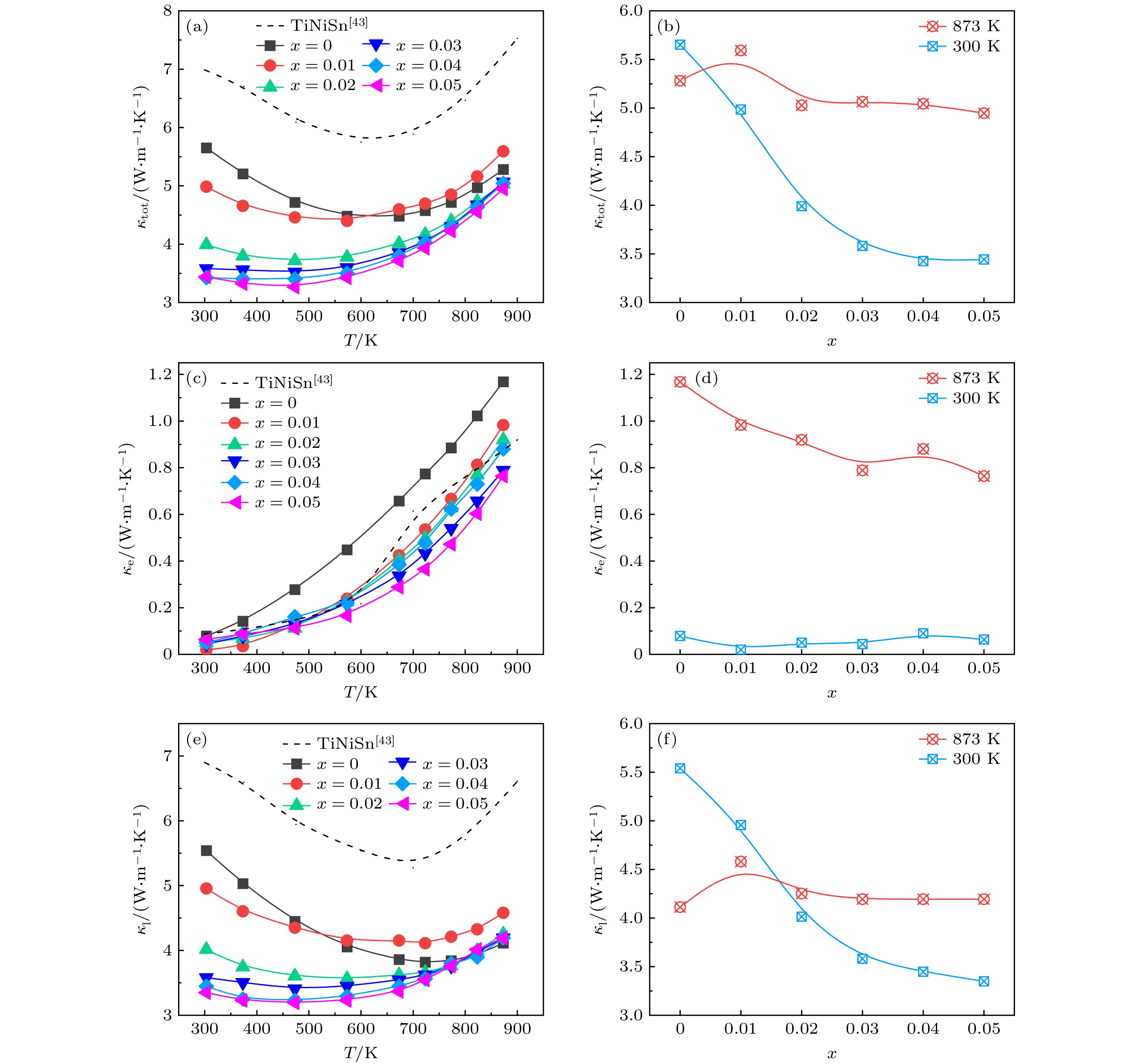

图 9 (a) 热导率κtot随温度变化的关系; (b) κtot随掺杂量x的变化关系; (c) 电子热导率κe随温度的变化关系; (d) κe随掺杂量x的变化关系; (e)晶格热导率κl随温度的变化关系; (f) κl随掺杂量x的变化关系

Fig. 9. (a) Thermal conductivities κtot as a function of temperature; (b) κtot as a function of doping amount x; (c) electronic thermal conductivities κe as a function of temperature; (d) κe as a function of doping amount x; (e) lattice thermal conductivities κl as a function of temperature; (e) thermal conductivities κl as a function of temperature; (f) dependence of κl on doping amount x.

-

[1] 杨士冠, 林鑫, 何俊松, 翟立军, 程林, 吕明豪, 刘虹霞, 张艳, 孙志刚 2023 72 228401

Google Scholar

Google Scholar

Yang S G, Lin X, He J S, Zhai L J, Cheng L, Lü M H, Liu H X, Zhang Y, Sun Z G 2023 Acta Phys. Sin. 72 228401

Google Scholar

Google Scholar

[2] Luo F, Zhu C, Wang J, He X, Yang Z, Ke S, Zhang Y, Liu H, Sun Z G 2022 ACS Appl. Mater. Interfaces. 14 45503

Google Scholar

Google Scholar

[3] Ma S F, Li C C, Wei P, Zhu W T, Nie X L, Sang X H, Zhang Q J, Zhao W Y 2020 J. Mater. Chem. A 8 4816

Google Scholar

Google Scholar

[4] Shi L, Chen J, Zhang G, Li B 2012 Phys. Lett. A 376 978

Google Scholar

Google Scholar

[5] Ouyang Y, Zhang Z, Li D, Chen J, Zhang G 2019 Ann. Phys. Berlin 531 4

Google Scholar

Google Scholar

[6] He J, Hu Y X, Li D F, Chen J 2021 Nano Res. 15 3804

[7] Xiao F, Hangarter C, Yoo B, Rheem Y, Lee K H, Myung N V 2008 Electrochimica Acta 53 8103

Google Scholar

Google Scholar

[8] Jiang B B, Wang W, Liu S X, Wang Y, Wang C F, Chen Y N, Xie L, Huang M Y, He J Q 2022 Science 377 208

Google Scholar

Google Scholar

[9] Gelbstein Y, Rosenberg Y, Sadia Y, Dariel M P 2010 J. Phys. Chem. C. 114 13126

[10] Komisarchik G, Gelbstein Y, Fuks D 2017 Intermetallics 89 16

Google Scholar

Google Scholar

[11] Liu H T, Sun Q, Zhong Y, Deng Q, Gan L, Lü F L, Shi X L, Chen Z G, Ang R 2022 Nano Energy 91 106706

Google Scholar

Google Scholar

[12] Pochet P, Caliste D 2012 Mat. Sci. Semicon. Proc. 15 675

Google Scholar

Google Scholar

[13] Khan M R, Gopidi H R, Wlazło M, Malyi O I 2023 J. Phys. Chem. Lett. 14 1962

Google Scholar

Google Scholar

[14] Kaller M, Fuks D, Gelbstein Y 2017 J. Alloy Compd. 729 446

Google Scholar

Google Scholar

[15] Chauhan N S, Bathula S, Vishwakarma A, Bhardwaj R, Gahtori B, Kumar A, Dhar A 2018 ACS Appl. Energy Mater. 1 757

Google Scholar

Google Scholar

[16] Lim W Y S, Zhang D, Duran S S F, Tan X Y, Tan C K I, Xu J, Suwardi A 2021 Front Mater. 8 745

[17] Wang J, Luo F, Zhu C, Wang J, He X, Zhang Y, Liu H, Sun Z G 2023 J. Mater. Chem. 11 4056

Google Scholar

Google Scholar

[18] Zhu C, Wang J, Zhu X Q, Zhang S, Xu F, Luo F, Wang J F, Zhang Y, Liu H X, Sun Z G 2023 J. Mater. Chem. A 11 1268

Google Scholar

Google Scholar

[19] 陈树权, 王剑, 杨振, 朱璨, 罗丰, 祝鑫强, 徐峰, 王嘉赋, 张艳, 刘虹霞, 孙志刚 2023 72 068401

Google Scholar

Google Scholar

Chen S Q, Wang J, Yang Z, Zhu C, Luo F, Zhu X Q, Xu F, Wang J F, Zhang Y, Liu H X, Sun Z G 2023 Acta Phys. Sin. 72 068401

Google Scholar

Google Scholar

[20] Santos R, Yamini S A, Dou S X 2018 J. Mater. Chem. A 6 3328

Google Scholar

Google Scholar

[21] Berry T, Fu C, Auffermann G, Fecher G H, Schnelle W, Serrano-Sanchez F, Yue Y, Liang H, Felser C 2017 Chem. Mater. 29 7042

Google Scholar

Google Scholar

[22] Downie R, Maclaren D, Bos J W 2014 J. Mater. Chem. A 2 6107

Google Scholar

Google Scholar

[23] Sanad M F, Shalan A E, Abdellatif S O, Serea E S A, Adly M S, Ahsan M A 2020 Top Curr. Chem. 378 48

Google Scholar

Google Scholar

[24] Wang J, Zhu C, Luo F, Wang J F, He X, Zhang Y, Liu H X, Sun Z G 2023 ACS Appl. Mater. Interfaces 15 8105

Google Scholar

Google Scholar

[25] Lü W Y, Liu W D, Li M, Hong M, Guo K, Luo J, Xing J, Sun Q, Xu S, Zou J 2022 Chem. Eng. J. 446 137278

Google Scholar

Google Scholar

[26] Hu B, Shi X L, Zou J, Chen Z G 2022 Chem. Eng. J. 437 135268

Google Scholar

Google Scholar

[27] Liu H X, Zhang S, Zhang Y, Zong S T, Li W, Zhu C, Luo F, Wang J, Sun Z G 2022 ACS Appl. Energy Mater. 5 15093

Google Scholar

Google Scholar

[28] Zhu T J, Liu Y T, Fu C G, Heremans J P, Snyder J G, Zhao X B 2017 Adv. Mater. 29 1605884

Google Scholar

Google Scholar

[29] Van Du N, Nam W H, Cho J Y, Binh N V, Huy P T, Tuan D A, Shin W H, Lee S 2021 J. Alloy Compd. 886 161293

Google Scholar

Google Scholar

[30] Pei Y Z, Shi X Y, Lalonde A, Wang H, Chen L D, Snyder G J 2011 Nature 473 66

Google Scholar

Google Scholar

[31] Poudel B, Hao Q, Ma Y, Lan Y C, Minnich A, Yu B, Yan X, Wang D Z, Muto A, Vashaee D, Chen X Y, Liu J M, Dresselhaus M S, Chen G, Ren Z F 2008 Science 320 634

Google Scholar

Google Scholar

[32] Zhao L D, Tan G J, Hao S Q, He J Q, Pei Y L, Chi H, Wang H, Gong S K, Xu H B, Dravid V P, Uher C, Snyder G J, Wolverton C, Kanatzidis M G 2016 Science 351 141

Google Scholar

Google Scholar

[33] Hohl H, Ramirez A P, Goldmann C, Ernst G, Wölfing B, Bucher E 1999 J. Phys. Condens. Mat. 11 1697

Google Scholar

Google Scholar

[34] Chauhan N S, Raghuvanshi P R, Tyagi K, Johari K K, Tyagi L, Gahtori B, Bathula S, Bhattacharya A, Mahanti S D, Singh V N 2020 J. Phys. Condens. Mat. 124 8584

[35] Shutoh N, Sakurada S 2005 J. Alloy Compd. 389 204

Google Scholar

Google Scholar

[36] Cho J, Park T, Bae K W, Kim H S, Choi S M, Kim S I, Kim S W 2021 Materials 14 4029

Google Scholar

Google Scholar

[37] He J S, Shen Y C, Zhai L J, Luo F, Zhang Y, Liu H X, Hu J F, Sun Z G 2024 J. Alloy Compd. 975 172808

Google Scholar

Google Scholar

[38] Wang J F, Luo F, Zhu C, Zhang S, Yang Z, Wang J F, He X, Zhang Y, Sun Z G 2022 J. Appl. Phys. 132 135103

Google Scholar

Google Scholar

[39] Dresselhaus M S, Chen G, Tang M Y, Yang R, Lee H, Wang D, Ren Z F, Fleurial J P, Gogna P 2007 Adv. Mater. 19 1043

Google Scholar

Google Scholar

[40] Dresselhaus M, Chen G, Ren Z F, Dresselhaus G, Henry A, Fleurial J P 2009 JOM 61 86

Google Scholar

Google Scholar

[41] Yang J, Yip H L, Jen A K Y 2013 Adv. Energy Mater. 3 549

Google Scholar

Google Scholar

[42] Kim K S, Kim Y M, Mun H, Kim J, Park J, Borisevich A Y, Lee K H, Kim S W 2017 Adv. Mater. 29 1702091

Google Scholar

Google Scholar

[43] Katayama T, Kim S W, Kimura Y, Mishima Y 2003 J. Electron. Mater. 32 1160

Google Scholar

Google Scholar

[44] Li C C, Zhao W Y, Zhang Q J 2022 Sci. Bull. 67 891

Google Scholar

Google Scholar

[45] Zhao W Y, Liu Z Y, Sun Z G, Zhang Q J, Wei P, Mu X, Zhou H Y, Li C C, Ma S F, He D Q, Ji P X, Zhu W T, Nie X L, Su X L, Tang X F, Shen B G, Dong X L, Yang J H, Liu Y, Shi J 2017 Nature 549 247

Google Scholar

Google Scholar

[46] Luo F, Wang J, Zhu C, He X, Zhang S, Wang J F, Liu H X, Sun Z G 2022 J. Mater. Chem. A 10 9655

Google Scholar

Google Scholar

[47] Romaka V, Stadnyk Y V, Fruchart D, Dominuk T, Romaka L, Rogl P, Goryn A M 2009 Semiconductors 43 1124

Google Scholar

Google Scholar

[48] 罗丰2023 博士学位论文 (武汉: 武汉理工大学)

Luo F 2023 Ph. D. Dissertation (Wuhan: Wuhan University of Technology

[49] An D C, Wang J J, Zhang J, Zhai X, Kang Z P, Fan W H, Yan J, Liu Y Q, Lu L, Jia C L, Wuttig M, Cojocaru-Mirédin O, Chen S P, Wang W X, Snyder G J, Yu Y 2021 Energy Environ. Sci. 14 5469

Google Scholar

Google Scholar

[50] Drymiotis F, Lashley J C, Fisk Z, Peterson E, Nakatsuji S 2003 Philos. Mag. 83 3169

Google Scholar

Google Scholar

[51] Kim H S, Gibbs Z M, Tang Y L, Wang H, Snyder G J 2015 APL Mater. 3 041506

Google Scholar

Google Scholar

[52] Baranovskiy A, Harush M, Amouyal Y 2019 Adv. Theor. Simul. 2 54

[53] Chi H, Liu W, Sun K, Su X L, Wang G Y, Lošt'ák P, Kucek V, Drašar Č, Uher C 2013 Phys. Rev. B 88 045202

Google Scholar

Google Scholar

[54] Lkhagvasuren E, Fu C, Fecher G H, Auffermann G, Kreiner G, Schnelle W, Felser C 2017 J. Phys. D Appl. Phys. 50 425502

Google Scholar

Google Scholar

[55] Gong B, Li Y, Liu F S, Zhu J X, Wang X, Ao W Q, Zhang C H, Li J Q, Xie H P, Zhu T J 2019 ACS Appl. Mater. Interface 11 13397

Google Scholar

Google Scholar

[56] Mao J, Zhou J, Zhu H, Liu Z, Zhang H, He R, Chen G, Ren Z F 2017 Chem. Mater. 29 14

[57] Yan J X, Liu F S, Ma G H, Gong B, Zhu J X, Wang X, Ao W Q, Zhang C H, Li Y, Li J Q 2018 Scripta Mater. 157 129

Google Scholar

Google Scholar

[58] Liu Y T, Xie H H, Fu C G, Snyder G J, Zhao X B, Zhu T J 2015 J. Mater. Chem. A 3 22716

Google Scholar

Google Scholar

计量

- 文章访问数: 4514

- PDF下载量: 61

- 被引次数: 0

下载:

下载: