-

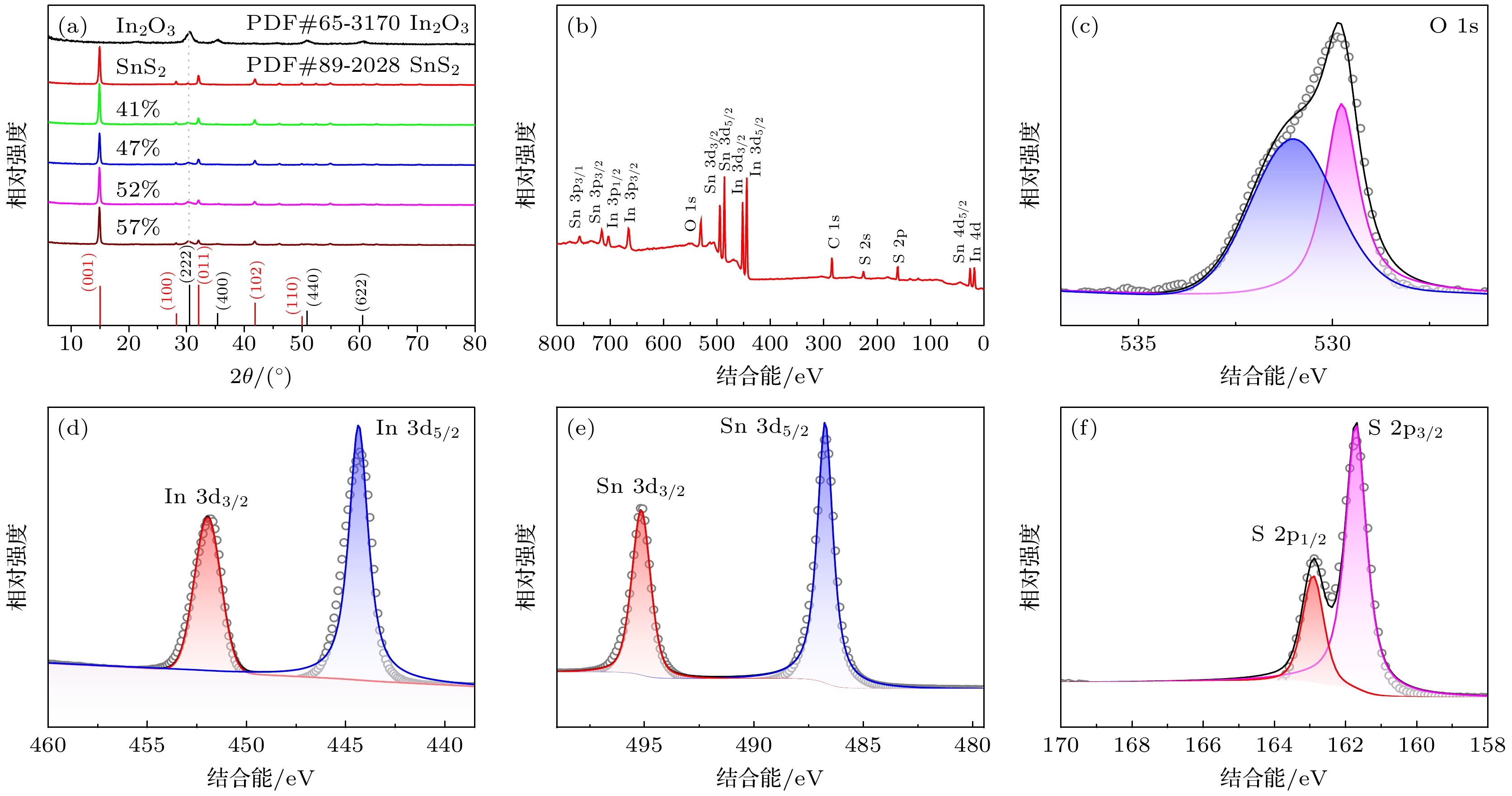

NO2是一种有毒气体, 能与空气中的其他有机化合物发生反应, 造成空气污染并对人体有很大的危害. 因此, 需要一种气体传感器来检测NO2. 然而, 传统的NO2传感器很难在室温(25 ℃)下工作. 本研究报告了SnS2/In2O3的室温(25 ℃) NO2气体传感, 采用热注入法和水热法制备了In2O3量子点和SnS2纳米片. 凭借SnS2独特的二维结构, 在其上装饰In2O3, 复合增强了其传感性能, 产品采用X射线衍射(XRD)、扫描电子显微镜(SEM)、高分辨率透射电子显微镜(HR-TEM)和X射线光电子能谱仪(XPS)进行表征. 结果表明, SnS2/In2O3传感器对体积分数为1×10–6 NO2的响应为26.6, 响应和恢复时间分别为146 s和243 s. 由于异质结结构增加了活性位点的数量, 加速了气体的传输, 促进了电荷转移和气体解吸, 提高了NO2气体传感性能. 这种优异的传感性能在NO2检测中具有广阔的应用前景.

-

关键词:

- 气体传感 /

- SnS2/In2O3 /

- NO2 /

- 室温

NO2 is a toxic gas that can react with other organic compounds in the air, causing air pollution and posing a significant harm to human health. Therefore, a gas sensor that can detect NO2 is needed. However, conventional NO2 gas sensors are difficult to operate at room temperature (25 ℃). In this work, NO2 gas sensing based on SnS2/In2O3, which can operate at room temperature (25 ℃), is reported. In2O3 quantum dots and SnS2 nanosheets are prepared by the hot-injection method and hydrothermal method. By using the unique two-dimensional structure of SnS2, In2O3 is decorated on it, and the composite enhances its sensing performance. The products are characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), high-resolution transmission electron microscopy (HR-TEM), and X-ray photoelectron spectroscopy (XPS). The results demonstrate that the composites prepared by 52% In2O3 exhibit the best sensing response. The fabricated sensor shows a response range from 26.6 to NO2 of 1×10–6 in volume fraction, fast response and short recovery time at room temperature (25 ℃). Moreover, this sensor demonstrates excellent reproducibility and selectivity. The heterojunction structure increases the number of active sites and accelerates the gas transport, which promotes charge transfer and gas desorption to improve NO2 gas sensing performance. This excellent sensing performance has a great application prospect in NO2 detection.-

Keywords:

- gas sensing /

- SnS2/In2O3 /

- NO2 /

- room temperature

[1] Copat C, Cristaldi A, Fiore M, Grasso A, Zuccarello P, Signorelli S S, Conti G O, Ferrante M 2020 Environ. Res. 191 110129

Google Scholar

Google Scholar

[2] Cibella F, Cuttitta G, Della Maggiore R, Ruggieri S, Panunzi S, De Gaetano A, Bucchieri S, Drago G, Melis M R, La Grutta S, Viegi G 2015 Environ Res. 138 8

Google Scholar

Google Scholar

[3] Wang J, Shen H, Xia Y, Komarneni S 2021 Ceram. Int. 47 7353

Google Scholar

Google Scholar

[4] Xu Y, Zheng L, Yang C, Zheng W, Liu X, Zhang J 2020 ACS Appl. Mater. Interfaces 12 20704

Google Scholar

Google Scholar

[5] Fang H R, Li S, Zhao H M, Deng J, Wang D, Li J 2022 Sens. Actuators, B 352 131068

Google Scholar

Google Scholar

[6] Mahajan S, Jagtap S 2020 Appl. Mater. Today 18 100483

Google Scholar

Google Scholar

[7] Zhang B W, Fang D, Fang X, Zhao H B, Wang D K, Li J H, Wang X H, Wang D B 2021 Rare Met. 41 982

Google Scholar

Google Scholar

[8] Gao L, Cheng Z, Xiang Q, Zhang Y, Xu J 2015 Sens. Actuators, B 208 436

Google Scholar

Google Scholar

[9] Wang M S, Wang Y W, Li X J, Ge C X, Hussain S, Liu G W, Qiao G J 2020 Sens. Actuators, B 316 128050

Google Scholar

Google Scholar

[10] Maeng S, Kim S W, Lee D H, Moon S E, Kim K C, Maiti A 2014 ACS Appl. Mater. Interfaces 6 357

Google Scholar

Google Scholar

[11] Shah S, Han S, Hussain S, Liu G, Shi T, Shaheen A, Xu Z, Wang M, Qiao G 2022 Ceram. Int. 48 12291

Google Scholar

Google Scholar

[12] Gu D, Li X, Zhao Y, Wang J 2017 Sens. Actuators, B 244 67

Google Scholar

Google Scholar

[13] Ahmad I, Zhou Z, Li H Y, Zang S Q 2020 Sens. Actuators, B 304 127379

Google Scholar

Google Scholar

[14] Liu Y L, Wang L L, Wang H R, Xiong M Y, Yang T Q, Zakharova G S 2016 Sens. Actuators, B 236 529

Google Scholar

Google Scholar

[15] Hou M, Gao J Y, Yang L, Guo S H, Hu T, Li Y X 2021 Appl. Surf. Sci. 535 147666

Google Scholar

Google Scholar

[16] Wu J, Zhang D, Cao Y 2018 J. Colloid Interface Sci. 529 556

Google Scholar

Google Scholar

[17] Patil S P, Patil V L, Vanalakar S A, Shendage S S, Pawar S A, Kim J H, Ryu J, Patil D R, Patil P S 2022 Mater. Lett. 306 130916

Google Scholar

Google Scholar

[18] Liu H, Su Y, Chen P, Wang Y 2013 J. Mol. Catal. A: Chem. 378 285

Google Scholar

Google Scholar

[19] Price L S, Parkin I P, Hardy A M E, Clark R J H, Hibbert T G, Molloy K C 1999 Chem. Mater. 11 1792

Google Scholar

Google Scholar

[20] Kim Y H, Phan D T, Ahn S, Nam K H, Park C M, Jeon K J 2018 Sens. Actuators, B 255 616

Google Scholar

Google Scholar

[21] He Q, Zeng Z, Yin Z, Li H, Wu S, Huang X, Zhang H 2012 Small 8 2994

Google Scholar

Google Scholar

[22] Vanalakar S A, Patil V L, Harale N S, Vhanalakar S A, Gang M G, Kim J Y, Patil P S, Kim J H 2015 Sens. Actuators, B 221 1195

Google Scholar

Google Scholar

[23] Patil S P, Patil V L, Shendage S S, Harale N S, Vanalakar S A, Kim J H, Patil P S 2016 Ceram. Int. 42 16160

Google Scholar

Google Scholar

[24] Fang H R, Li S, Jiang W J, Zhao H M, Han C S, Li J, Wang G, Zhang Y, Wang S, Deng J, Feng B, Wang D 2022 Sens. Actuators, B 368 132225

Google Scholar

Google Scholar

[25] Yang B X, Myung N V, Tran T T 2021 Adv. Electron. Mater. 7 2100271

Google Scholar

Google Scholar

[26] Cheng M, Wu Z, Liu G, Zhao L, Gao Y, Zhang B, Liu F, Yan X, Liang X, Sun P, Lu G 2019 Sens. Actuators, B 291 216

Google Scholar

Google Scholar

[27] Ferro R, Rodríguez J A, Bertrand P 2008 Thin Solid Films 516 2225

Google Scholar

Google Scholar

-

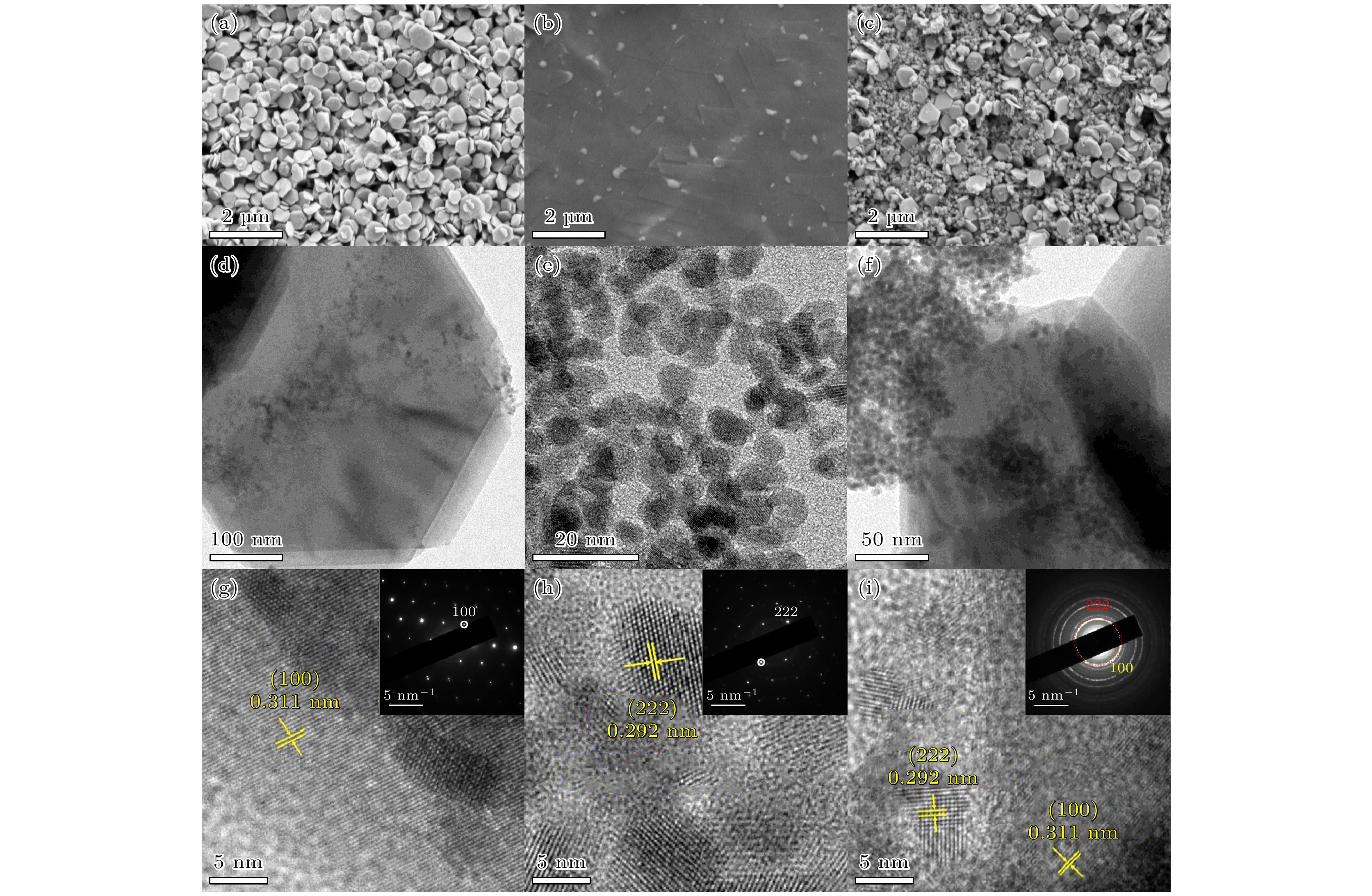

图 1 (a) SnS2, (b) In2O3量子点, (c) SnS2/In2O3的SEM图. (d), (g) SnS2, (e), (h) In2O3, (f), (i) SnS2/In2O3的HR-TEM图和SAED图

Fig. 1. SEM images of (a) SnS2 nanoplates, (b) In2O3 QDs and (c) SnS2/In2O3 composites. HR-TEM images and SAED patterns with a 5 nm scale of (d), (g) accordion-like SnS2 nanoplates, (e), (h) In2O3 QDs and (f), (i) SnS2/In2O3 composites.

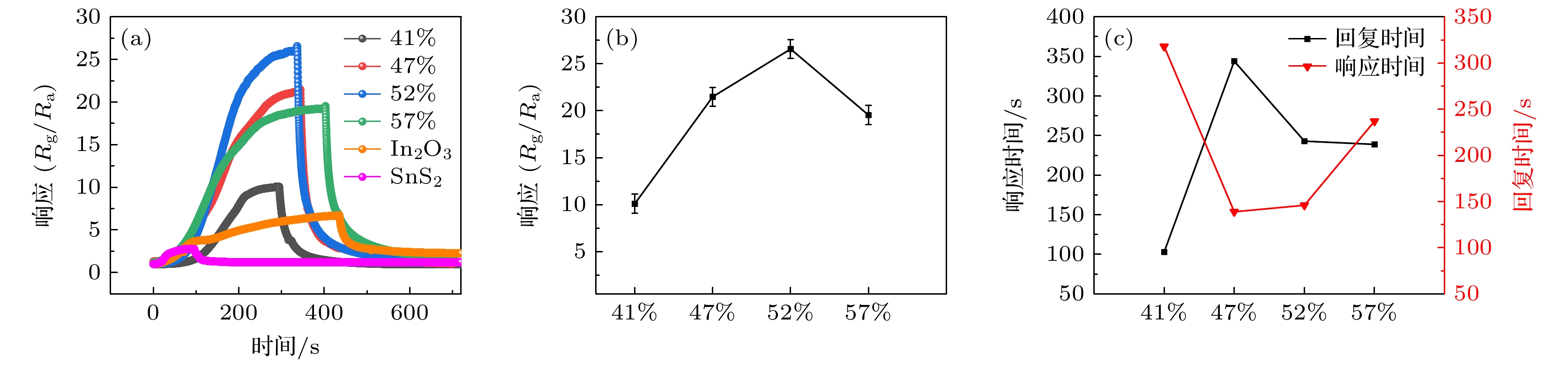

图 3 SnS2纳米片、In2O3量子点和SnS2/In2O3复合材料的气敏性能 (a), (b) 不同SnS2/In2O3比例的复合材料对体积分数为1×10–6 NO2 的响应大小及变化情况; (b) 不同SnS2/In2O3比例的复合材料对体积分数为1×10–6 NO2的响应变化情况; (c) 室温下不同SnS2/In2O3比例的复合材料对体积分数为1×10–6 NO2 响应和恢复时间的变化情况

Fig. 3. Gas-sensing properties of SnS2 nanoplates, In2O3 QDs and SnS2/In2O3 composites: (a) Response sensitivity to 1×10–6 NO2 of volume fraction of all composites of different SnS2/In2O3 concentration; (b) variation of response sensitivity to 1×10–6 NO2 of volume fraction of all composites of different SnS2/In2O3 concentration; (c) variation of response and recovery time to 1×10–6 NO2 of volume fraction of all composites of different SnS2/In2O3 concentration.

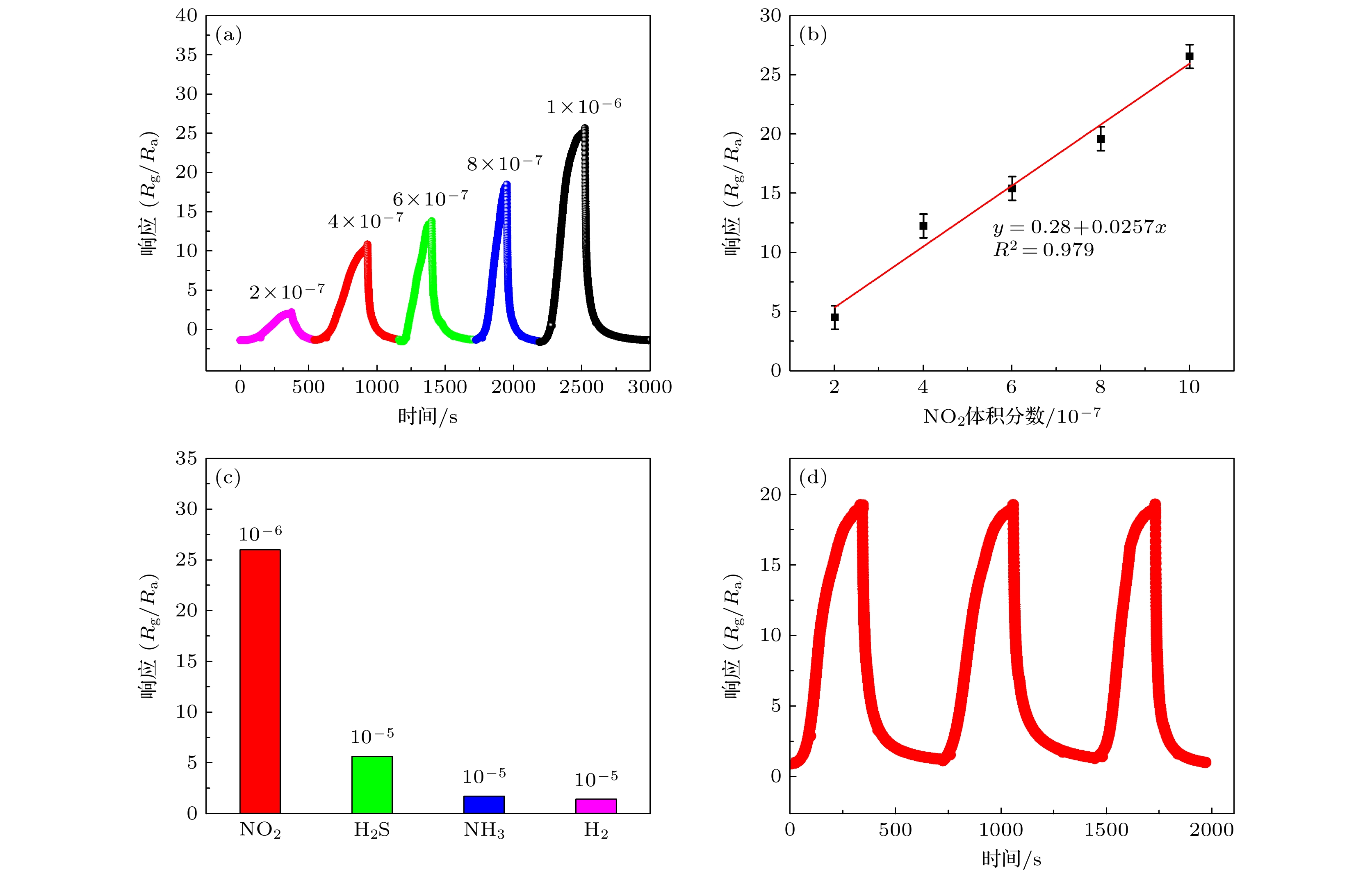

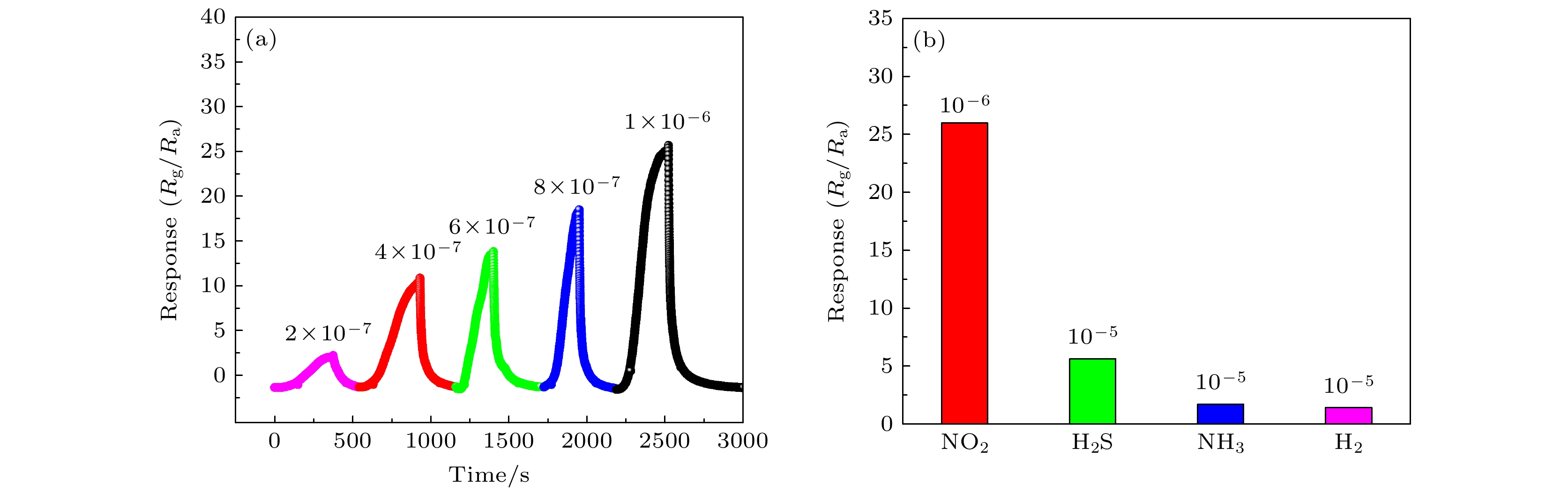

图 4 (a) 52%传感器对不同NO2浓度的电阻时间曲线; (b) 52%传感器对不同NO2浓度的线性拟合曲线; (c) 传感器的选择性; (d) 52%传感器对体积分数为8×10–7 NO2的重复性曲线

Fig. 4. (a) Resistance time curves of 52% sensor to different NO2 concentrations; (b) the fitting curves of 52% sensor to different NO2 concentrations; (c) selectivity of the sensor; (d) repeatability curves of 52% sensor toward NO2 of volume fraction of 8×10–7.

表 1 不同传感材料的NO2气敏性能比较

Table 1. Performance comparison of NO2 sensors based on different composites.

Material Temp./℃ NO2 concentration/×10–6 Response Response/recovery time/s Ref. SnS2-nanosheets 250 10 2.49 6/40 [20] SnO2/SnS2 80 1 1.8 159/297 [12] Monolayer MoS2 25 1.2 1.06 >1800 [21] In2O3 microspheres 250 20 37 5/20 [22] In2O3 thin films 200 5 10 —/— [23] In2O3 nanocubes 50 3 10 21/522 [17] SnS2/In2O3 25 1 26.6 146/243 This work -

[1] Copat C, Cristaldi A, Fiore M, Grasso A, Zuccarello P, Signorelli S S, Conti G O, Ferrante M 2020 Environ. Res. 191 110129

Google Scholar

Google Scholar

[2] Cibella F, Cuttitta G, Della Maggiore R, Ruggieri S, Panunzi S, De Gaetano A, Bucchieri S, Drago G, Melis M R, La Grutta S, Viegi G 2015 Environ Res. 138 8

Google Scholar

Google Scholar

[3] Wang J, Shen H, Xia Y, Komarneni S 2021 Ceram. Int. 47 7353

Google Scholar

Google Scholar

[4] Xu Y, Zheng L, Yang C, Zheng W, Liu X, Zhang J 2020 ACS Appl. Mater. Interfaces 12 20704

Google Scholar

Google Scholar

[5] Fang H R, Li S, Zhao H M, Deng J, Wang D, Li J 2022 Sens. Actuators, B 352 131068

Google Scholar

Google Scholar

[6] Mahajan S, Jagtap S 2020 Appl. Mater. Today 18 100483

Google Scholar

Google Scholar

[7] Zhang B W, Fang D, Fang X, Zhao H B, Wang D K, Li J H, Wang X H, Wang D B 2021 Rare Met. 41 982

Google Scholar

Google Scholar

[8] Gao L, Cheng Z, Xiang Q, Zhang Y, Xu J 2015 Sens. Actuators, B 208 436

Google Scholar

Google Scholar

[9] Wang M S, Wang Y W, Li X J, Ge C X, Hussain S, Liu G W, Qiao G J 2020 Sens. Actuators, B 316 128050

Google Scholar

Google Scholar

[10] Maeng S, Kim S W, Lee D H, Moon S E, Kim K C, Maiti A 2014 ACS Appl. Mater. Interfaces 6 357

Google Scholar

Google Scholar

[11] Shah S, Han S, Hussain S, Liu G, Shi T, Shaheen A, Xu Z, Wang M, Qiao G 2022 Ceram. Int. 48 12291

Google Scholar

Google Scholar

[12] Gu D, Li X, Zhao Y, Wang J 2017 Sens. Actuators, B 244 67

Google Scholar

Google Scholar

[13] Ahmad I, Zhou Z, Li H Y, Zang S Q 2020 Sens. Actuators, B 304 127379

Google Scholar

Google Scholar

[14] Liu Y L, Wang L L, Wang H R, Xiong M Y, Yang T Q, Zakharova G S 2016 Sens. Actuators, B 236 529

Google Scholar

Google Scholar

[15] Hou M, Gao J Y, Yang L, Guo S H, Hu T, Li Y X 2021 Appl. Surf. Sci. 535 147666

Google Scholar

Google Scholar

[16] Wu J, Zhang D, Cao Y 2018 J. Colloid Interface Sci. 529 556

Google Scholar

Google Scholar

[17] Patil S P, Patil V L, Vanalakar S A, Shendage S S, Pawar S A, Kim J H, Ryu J, Patil D R, Patil P S 2022 Mater. Lett. 306 130916

Google Scholar

Google Scholar

[18] Liu H, Su Y, Chen P, Wang Y 2013 J. Mol. Catal. A: Chem. 378 285

Google Scholar

Google Scholar

[19] Price L S, Parkin I P, Hardy A M E, Clark R J H, Hibbert T G, Molloy K C 1999 Chem. Mater. 11 1792

Google Scholar

Google Scholar

[20] Kim Y H, Phan D T, Ahn S, Nam K H, Park C M, Jeon K J 2018 Sens. Actuators, B 255 616

Google Scholar

Google Scholar

[21] He Q, Zeng Z, Yin Z, Li H, Wu S, Huang X, Zhang H 2012 Small 8 2994

Google Scholar

Google Scholar

[22] Vanalakar S A, Patil V L, Harale N S, Vhanalakar S A, Gang M G, Kim J Y, Patil P S, Kim J H 2015 Sens. Actuators, B 221 1195

Google Scholar

Google Scholar

[23] Patil S P, Patil V L, Shendage S S, Harale N S, Vanalakar S A, Kim J H, Patil P S 2016 Ceram. Int. 42 16160

Google Scholar

Google Scholar

[24] Fang H R, Li S, Jiang W J, Zhao H M, Han C S, Li J, Wang G, Zhang Y, Wang S, Deng J, Feng B, Wang D 2022 Sens. Actuators, B 368 132225

Google Scholar

Google Scholar

[25] Yang B X, Myung N V, Tran T T 2021 Adv. Electron. Mater. 7 2100271

Google Scholar

Google Scholar

[26] Cheng M, Wu Z, Liu G, Zhao L, Gao Y, Zhang B, Liu F, Yan X, Liang X, Sun P, Lu G 2019 Sens. Actuators, B 291 216

Google Scholar

Google Scholar

[27] Ferro R, Rodríguez J A, Bertrand P 2008 Thin Solid Films 516 2225

Google Scholar

Google Scholar

计量

- 文章访问数: 4485

- PDF下载量: 262

- 被引次数: 0

下载:

下载: