-

采用高压原位阻抗谱测量技术对锐钛矿TiO2多晶的电输运性质进行了系统研究. 在6.4, 11.5和24.6 GPa压力处发现了晶粒和晶界的电阻、参数因子和弛豫频率的反常变化行为. 研究分析表明: 6.4和11.5 GPa压力点分别对应着TiO2由锐钛矿转变为α-PbO2, 再转变为斜锆石的结构相变, 当压力高于24.6 GPa时, TiO2完全转变为斜锆石相. 通过分析晶粒和晶界电阻在压力作用下的变化行为可知, 本征缺陷的存在对TiO2高压下电输运性质的变化起着关键的作用. 在6.4 GPa压力处, 相变的发生导致缺陷的作用发生了变化, 由作为复合中心的深能级缺陷转变为向导带和价带提供载流子的浅能级缺陷, 并且作为浅能级缺陷存在至实验最高压力点38.9 GPa, 浅能级缺陷在能带中的位置也随着相变发生而改变. 晶粒和晶界的激活能随着压力升高而降低, 表明高压下载流子在晶粒和晶界的输运变得更加容易. 此外, TiO2晶粒和晶界的弛豫频率比值随压力的升高而不断减小, 高压下的晶界效应不明显.The electrical transport properties of anatase TiO2 polycrystalline have been systematically investigated by using high pressure in-situ impedance spectroscopy measurements. The anomalous behaviors of resistance, parameter factor and relaxation frequency of grain and grain boundary can be found at 6.4, 11.5 and 24.6 GPa. The results indicate that the first two discontinuous points (6.4 and 11.5 GPa) correspond to the phase transitions of TiO2 from anatase to α-PbO2 and then to baddeleyite, respectively. Above 24.6 GPa, TiO2 completely transforms into the baddeleyite phase. Based on the change of grain resistance and grain boundary resistance under pressure, intrinsic defects play a crucial effect in the electrical transport properties of TiO2 at high pressures. At 6.4 GPa, the occurrence of phase transition gives rise to the variation of defects’ role, from a deep energy level defect (as a recombination centre) changes into a shallow energy level defect (providing carriers for the conduction and valence bands). In addition, the position of defect in energy band changes with pressure increasing. The phase transition of TiO2 at 6.4 GPa is the rearrangement of TiO6 octahedron, while the other one at 11.5 GPa can be attributed to the migration of oxygen Schottky defects from inner to surface. Combining the packing factor and relaxation frequency, the electrical transport properties of TiO2 under pressure are revealed, the packing factor and the relaxation frequency are closely related to the mobility and the carrier concentration, respectively. The activation energy of grain and grain boundary decrease with the pressure elevating, indicating that the transport of carriers in grain and grain boundary become easier under pressure, and the former is smoother than the latter owing to the activation energy of grain being smaller than that of grain boundary in the same pressure range. Moreover, the relaxation frequency ratio of TiO2 grain and TiO2 grain boundary decreases with pressure increasing, and the grain boundary effect under high pressure is not obvious.

-

Keywords:

- high pressure /

- TiO2 /

- defects /

- grain boundary

[1] Augustynski J 1993 Electrochim. Acta. 38 43

Google Scholar

Google Scholar

[2] Pezhooli N, Rahimi J, Hasti F, Maleki A 2022 Sci. Rep. 12 9885

Google Scholar

Google Scholar

[3] Crossland E J W, Noel N, Sivaram V, Leijtens T, Alexander-Webber J A, Snaith H J 2013 Nature 495 215

Google Scholar

Google Scholar

[4] Reza K M, Kurny A, Gulshan F 2017 Appl. Water. Sci. 7 1569

Google Scholar

Google Scholar

[5] 韩迪仪, 顾阳, 胡涛政, 董雯, 倪亚贤 2021 70 038103

Google Scholar

Google Scholar

Han D Y, Gu Y, Hu T Z, Dong W, Ni Y X 2021 Acta Phys. Sin. 70 038103

Google Scholar

Google Scholar

[6] Liu L, Chan J, Sham T K 2010 J. Phys. Chem. C 114 21353

Google Scholar

Google Scholar

[7] San-Miguel A 2006 Chem. Soc. Rev. 35 876

Google Scholar

Google Scholar

[8] Lu X, Yang W, Quan Z, Lin T, Bai L, Wang L, Huang F, Zhao Y 2014 J. Am. Chem. Soc. 136 419

Google Scholar

Google Scholar

[9] Dong Z, Xiao F, Zhao A, Liu L, Sham T K, Song Y 2016 RSC Adv. 6 76142

Google Scholar

Google Scholar

[10] Liu F, Dong Z H, Liu L L 2019 J. Phys.: Condens. Matter 31 395403

Google Scholar

Google Scholar

[11] Huang Y, Chen F, Li X, Yuan Y, Dong H, Samanta S, Zhang J, Yang K 2016 J. Appl. Phys. 119 184

Google Scholar

Google Scholar

[12] Dong Z H, Song Y 2015 Can. J. Chem. 93 165

Google Scholar

Google Scholar

[13] Ji T, Gao Y, Qin T, Yue D, Gao C 2021 J. Phys. Chem. C 125 3364

Google Scholar

Google Scholar

[14] Li Q J, Liu B B 2016 Chin. Phys. B 25 076107

Google Scholar

Google Scholar

[15] Hearne G R, Zhao J, Dawe A M, Pischedda V, Maaza M, Nieuwoudt M K, Kibasomba P, Nemraoui O, Comins J D, Witcomb M J 2004 Phys. Rev. B 70 134102

Google Scholar

Google Scholar

[16] Haines J, Leger J M 1993 Physica B 192 233

Google Scholar

Google Scholar

[17] Kurita S, Ohta S, Sekiya T 2002 High Pressure Res. 22 319

Google Scholar

Google Scholar

[18] Ohsaka T, Yamaoka S, Shimomura O 1979 Solid State Commun. 30 34

Google Scholar

Google Scholar

[19] Liu L G, Mernagh T P 1992 Eur. J. Mineral. 4 45

Google Scholar

Google Scholar

[20] Lagarec K, Desgreniers S 1995 Solid State Commun. 94 519

Google Scholar

Google Scholar

[21] Sekiya T, Ohta S, Kamei S, Hanakawa M, KuritaS 2001 J. Phys. Chem. Solids 62 717

Google Scholar

Google Scholar

[22] Arlt T, Bermejo M, Blanco M A, Gerward L, Jiang J Z, Olsen J S, Recio J M 2000 Phys. Rev. B 61 14414

Google Scholar

Google Scholar

[23] Swamy V, Dubrovinsky L S, Dubrovinskaia N A, Langenhorst F, Simionovici A S, Drakopoulos M, Dmitriev V, Weber H P 2005 Solid State Commun. 134 541

Google Scholar

Google Scholar

[24] Swamy V, Dubrovinsky L S, Dubrovinskaia N A, Simionovici A S, Drakopoulos M, Dmitriev V, Weber H P 2003 Solid State Commun. 125 111

Google Scholar

Google Scholar

[25] Swamy V, Kuznetsov A, Dubrovinsky L S, McMillan P F, Prakapenka V B, Shen G, Muddle B C 2006 Phys. Rev. Lett. 96 135702

Google Scholar

Google Scholar

[26] Li Q, Cheng B, Yang X, Liu R, Zou B 2013 J. Phys. Chem. C 117 8516

Google Scholar

Google Scholar

[27] Li Q, Cheng B, Tian B, Liu R, Liu B, Wang F, Chen Z, Zou B, Cui T, Liu B 2014 RSC Adv. 4 12873

Google Scholar

Google Scholar

[28] Wang Q, Wang X, Li J, Qin T, Sang D, Liu J, Ke F, Wang X, Li Y, Liu C 2021 J. Mater. Chem. C 9 4764

Google Scholar

Google Scholar

[29] Zhang H, Zhang G, Wang J, Wang Q, Liu C 2021 J. Alloys Compd. 857 157482

Google Scholar

Google Scholar

[30] Su N, Sun M, Wang Q, Jin J, Sui J, Liu C, Gao C 2021 J. Phys. Chem. C 125 2713

Google Scholar

Google Scholar

[31] 王春杰, 王月, 高春晓 2020 69 147202

Google Scholar

Google Scholar

Wang C J, Wang Y, Gao C X 2020 Acta Phys. Sin. 69 147202

Google Scholar

Google Scholar

[32] Wang J, Zhang G, Liu H, Wang Q, Shen W, Yan Y, Liu C, Han Y, Gao C 2017 Appl. Phys. Lett. 111 031907

Google Scholar

Google Scholar

[33] Duan S, Wang Q, Zou B, Jiang J, Liu K, Zhang G, Zhang, Sang D, Xu Z, Geng Y, Li J, Wang X, Li Y, Liu C 2022 Appl. Phys. Lett. 121 263904

Google Scholar

Google Scholar

[34] Piermarini G J, Block S, Barnett J D, Forman R A, 1975 J. Appl. Phys. 46 2774

Google Scholar

Google Scholar

[35] 曹楚南, 张鉴清 2002 电化学阻抗谱导论 (典藏版 1) (北京: 科学出版社) 第21页

Cao C N, Zhang J Q 2002 Introduction to Electrochemical Impedance Spectroscopy (Vol. 1) (Beijing: Science Press) p21 (in Chinese)

[36] Guo X, Yoshino T 2013 Earth Planet. Sci. Lett. 369–370 239

[37] Guo X, Yoshino T, Katayama I 2011 Phys. Earth Planet. Inter. 188 69

Google Scholar

Google Scholar

[38] Rahman A U, Rafiq M A, Maaz K, Karim S, Cho S O, Hasan M M 2012 J. Appl. Phys. 112 063718

Google Scholar

Google Scholar

[39] Ali H, Karim S, Rafiq M A, Maaz K, Ahmad M 2014 J. Alloys Compd. 612 64

Google Scholar

Google Scholar

[40] Rahman A U, Rafifiq M A, Hasan M M, Maaz K, Karim S, Cho S O 2013 J. Nanopart Res. 15 1703

Google Scholar

Google Scholar

[41] Liu J, Yan J, Shi Q, Dong H, Zhang J, Wang Z, Huang W, Chen B, Zhang H 2019 J. Phys. Chem. C 123 4094

Google Scholar

Google Scholar

[42] Ma X G, Liang P, Miao L, Bie S W, Zhang C K, Xu L, Jiang J J 2009 Phys. Status. Solidi. (b) 246 2132

Google Scholar

Google Scholar

[43] Sekiya T, Ohta S, Kurita S 2008 Int. J. Mod. Phys. B 15 3952

[44] Zhu T, Gao S P 2014 J. Phys. Chem. C 118 11385

Google Scholar

Google Scholar

[45] Liu Q J, Zhang N C, Liu F S, Liu Z T 2014 Phys. Scr. 89 075703

Google Scholar

Google Scholar

[46] Lin X, Wu J, Lu X, Shan Z, Wang W, Huang F 2009 Phys. Chem. Chem. Phys. 11 10047

Google Scholar

Google Scholar

[47] Wu J, Huang F, Shan Z, Wang Y 2011 Dalton Trans. 40 6906

Google Scholar

Google Scholar

[48] Keyan H U, Zian X U, Liu Y, Huang F 2020 Chem. Res. Chin. Univ. 36 1102

Google Scholar

Google Scholar

[49] Plata J J, Márquez A M, Sanz J F 2013 J. Phys. Chem. C 117 14502

Google Scholar

Google Scholar

[50] Park N G, van de Lagemaa J, Frank A J 2000 J. Phys. Chem. B 104 8989

Google Scholar

Google Scholar

[51] 刘恩科, 朱秉升, 罗晋生 2012 半导体物理学 (第7版) (北京: 电子工业出版社) 第109页

Liu E K, Zhu B S, Luo J S 2012 The Physics of Semiconductors (Vol. 7) (Beijing: Electronic Industry Press) p109 (in Chinese)

[52] Ohta S, Sekiya T, Kurita S 2001 Phys. Status. Solidi. (b) 223 265

Google Scholar

Google Scholar

[53] Muscat J, Swamy V, Harrison N M 2002 Phys. Rev. B 65 224112

Google Scholar

Google Scholar

[54] Wang Q, Lian G, Dickey E C 2004 Acta Mater. 52 809

Google Scholar

Google Scholar

[55] Bharathi K K, Markandeyulu G, Ramana C V 2011 J. Electrochem. Soc. 158 G71

Google Scholar

Google Scholar

-

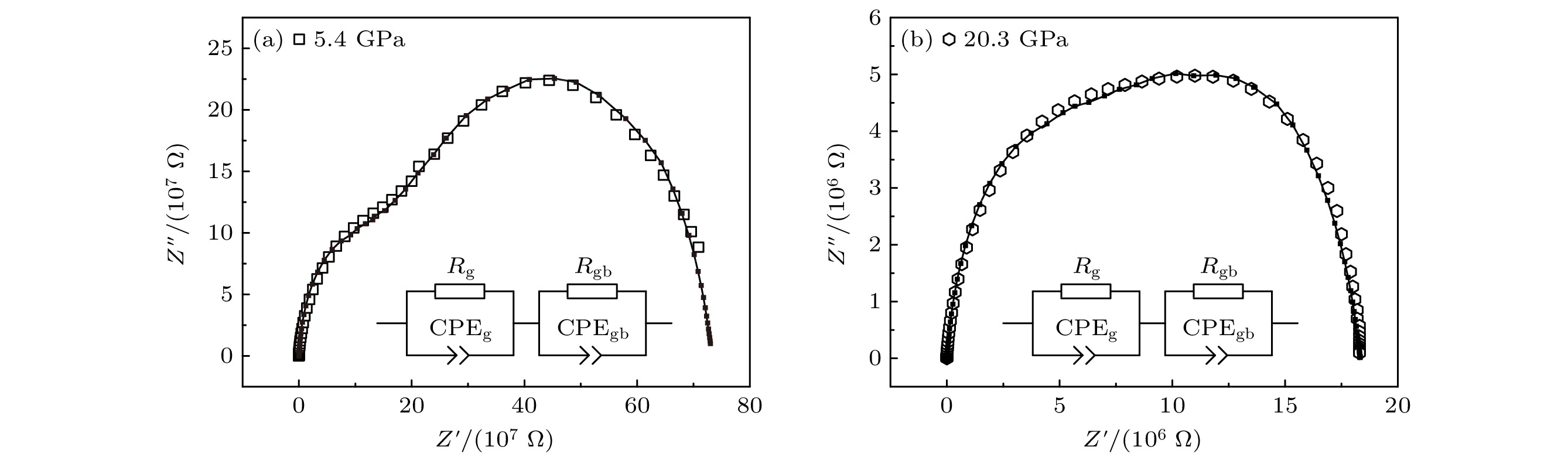

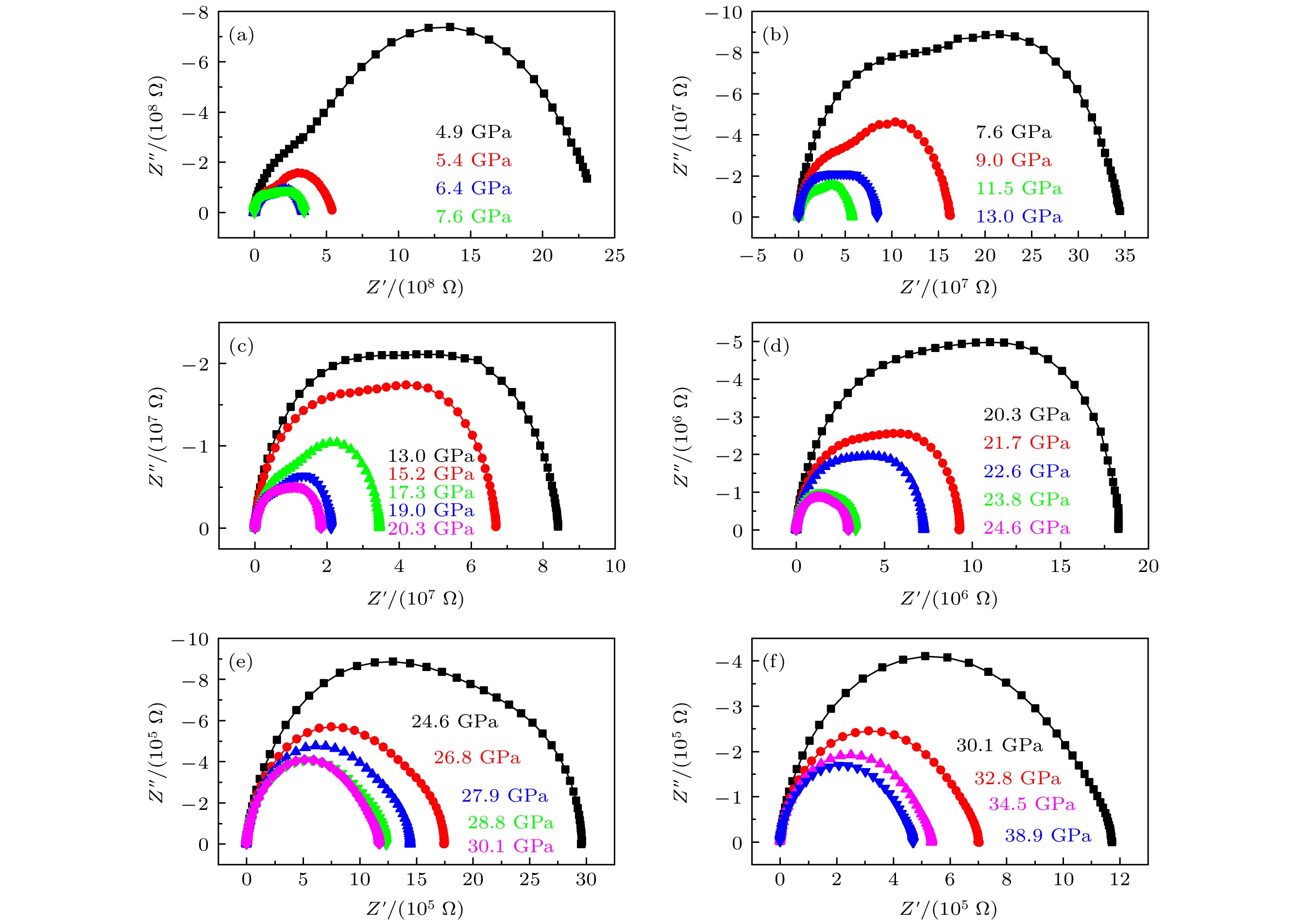

图 1 TiO2在不同压力下的Nyquist谱图 (a) 4.9—7.6 GPa; (b) 7.6—13.0 GPa; (c) 13.0—20.3 GPa; (d) 20.3—24.6 GPa; (e) 24.6—30.1 GPa; (f) 30.1—38.9 GPa

Fig. 1. Nyquist impedance spectra of TiO2 at different pressures: (a) 4.9–7.6 GPa; (b) 7.6–13.0 GPa; (c) 13.0–20.3 GPa; (d) 20.3–24.6 GPa; (e) 24.6–30.1 GPa; (f) 30.1–38.9 GPa.

表 1 激活能随压力的变化关系

Table 1. Pressure dependence of activation energy.

Pressure region/GPa dE/dP/(meV·GPa–1) Grain Grain boundary 0—6.4 –11.51 –22.79 6.4—11.5 –7.59 –9.33 11.5—24.6 –6.16 –6.82 24.6—38.9 –3.54 –4.91 -

[1] Augustynski J 1993 Electrochim. Acta. 38 43

Google Scholar

Google Scholar

[2] Pezhooli N, Rahimi J, Hasti F, Maleki A 2022 Sci. Rep. 12 9885

Google Scholar

Google Scholar

[3] Crossland E J W, Noel N, Sivaram V, Leijtens T, Alexander-Webber J A, Snaith H J 2013 Nature 495 215

Google Scholar

Google Scholar

[4] Reza K M, Kurny A, Gulshan F 2017 Appl. Water. Sci. 7 1569

Google Scholar

Google Scholar

[5] 韩迪仪, 顾阳, 胡涛政, 董雯, 倪亚贤 2021 70 038103

Google Scholar

Google Scholar

Han D Y, Gu Y, Hu T Z, Dong W, Ni Y X 2021 Acta Phys. Sin. 70 038103

Google Scholar

Google Scholar

[6] Liu L, Chan J, Sham T K 2010 J. Phys. Chem. C 114 21353

Google Scholar

Google Scholar

[7] San-Miguel A 2006 Chem. Soc. Rev. 35 876

Google Scholar

Google Scholar

[8] Lu X, Yang W, Quan Z, Lin T, Bai L, Wang L, Huang F, Zhao Y 2014 J. Am. Chem. Soc. 136 419

Google Scholar

Google Scholar

[9] Dong Z, Xiao F, Zhao A, Liu L, Sham T K, Song Y 2016 RSC Adv. 6 76142

Google Scholar

Google Scholar

[10] Liu F, Dong Z H, Liu L L 2019 J. Phys.: Condens. Matter 31 395403

Google Scholar

Google Scholar

[11] Huang Y, Chen F, Li X, Yuan Y, Dong H, Samanta S, Zhang J, Yang K 2016 J. Appl. Phys. 119 184

Google Scholar

Google Scholar

[12] Dong Z H, Song Y 2015 Can. J. Chem. 93 165

Google Scholar

Google Scholar

[13] Ji T, Gao Y, Qin T, Yue D, Gao C 2021 J. Phys. Chem. C 125 3364

Google Scholar

Google Scholar

[14] Li Q J, Liu B B 2016 Chin. Phys. B 25 076107

Google Scholar

Google Scholar

[15] Hearne G R, Zhao J, Dawe A M, Pischedda V, Maaza M, Nieuwoudt M K, Kibasomba P, Nemraoui O, Comins J D, Witcomb M J 2004 Phys. Rev. B 70 134102

Google Scholar

Google Scholar

[16] Haines J, Leger J M 1993 Physica B 192 233

Google Scholar

Google Scholar

[17] Kurita S, Ohta S, Sekiya T 2002 High Pressure Res. 22 319

Google Scholar

Google Scholar

[18] Ohsaka T, Yamaoka S, Shimomura O 1979 Solid State Commun. 30 34

Google Scholar

Google Scholar

[19] Liu L G, Mernagh T P 1992 Eur. J. Mineral. 4 45

Google Scholar

Google Scholar

[20] Lagarec K, Desgreniers S 1995 Solid State Commun. 94 519

Google Scholar

Google Scholar

[21] Sekiya T, Ohta S, Kamei S, Hanakawa M, KuritaS 2001 J. Phys. Chem. Solids 62 717

Google Scholar

Google Scholar

[22] Arlt T, Bermejo M, Blanco M A, Gerward L, Jiang J Z, Olsen J S, Recio J M 2000 Phys. Rev. B 61 14414

Google Scholar

Google Scholar

[23] Swamy V, Dubrovinsky L S, Dubrovinskaia N A, Langenhorst F, Simionovici A S, Drakopoulos M, Dmitriev V, Weber H P 2005 Solid State Commun. 134 541

Google Scholar

Google Scholar

[24] Swamy V, Dubrovinsky L S, Dubrovinskaia N A, Simionovici A S, Drakopoulos M, Dmitriev V, Weber H P 2003 Solid State Commun. 125 111

Google Scholar

Google Scholar

[25] Swamy V, Kuznetsov A, Dubrovinsky L S, McMillan P F, Prakapenka V B, Shen G, Muddle B C 2006 Phys. Rev. Lett. 96 135702

Google Scholar

Google Scholar

[26] Li Q, Cheng B, Yang X, Liu R, Zou B 2013 J. Phys. Chem. C 117 8516

Google Scholar

Google Scholar

[27] Li Q, Cheng B, Tian B, Liu R, Liu B, Wang F, Chen Z, Zou B, Cui T, Liu B 2014 RSC Adv. 4 12873

Google Scholar

Google Scholar

[28] Wang Q, Wang X, Li J, Qin T, Sang D, Liu J, Ke F, Wang X, Li Y, Liu C 2021 J. Mater. Chem. C 9 4764

Google Scholar

Google Scholar

[29] Zhang H, Zhang G, Wang J, Wang Q, Liu C 2021 J. Alloys Compd. 857 157482

Google Scholar

Google Scholar

[30] Su N, Sun M, Wang Q, Jin J, Sui J, Liu C, Gao C 2021 J. Phys. Chem. C 125 2713

Google Scholar

Google Scholar

[31] 王春杰, 王月, 高春晓 2020 69 147202

Google Scholar

Google Scholar

Wang C J, Wang Y, Gao C X 2020 Acta Phys. Sin. 69 147202

Google Scholar

Google Scholar

[32] Wang J, Zhang G, Liu H, Wang Q, Shen W, Yan Y, Liu C, Han Y, Gao C 2017 Appl. Phys. Lett. 111 031907

Google Scholar

Google Scholar

[33] Duan S, Wang Q, Zou B, Jiang J, Liu K, Zhang G, Zhang, Sang D, Xu Z, Geng Y, Li J, Wang X, Li Y, Liu C 2022 Appl. Phys. Lett. 121 263904

Google Scholar

Google Scholar

[34] Piermarini G J, Block S, Barnett J D, Forman R A, 1975 J. Appl. Phys. 46 2774

Google Scholar

Google Scholar

[35] 曹楚南, 张鉴清 2002 电化学阻抗谱导论 (典藏版 1) (北京: 科学出版社) 第21页

Cao C N, Zhang J Q 2002 Introduction to Electrochemical Impedance Spectroscopy (Vol. 1) (Beijing: Science Press) p21 (in Chinese)

[36] Guo X, Yoshino T 2013 Earth Planet. Sci. Lett. 369–370 239

[37] Guo X, Yoshino T, Katayama I 2011 Phys. Earth Planet. Inter. 188 69

Google Scholar

Google Scholar

[38] Rahman A U, Rafiq M A, Maaz K, Karim S, Cho S O, Hasan M M 2012 J. Appl. Phys. 112 063718

Google Scholar

Google Scholar

[39] Ali H, Karim S, Rafiq M A, Maaz K, Ahmad M 2014 J. Alloys Compd. 612 64

Google Scholar

Google Scholar

[40] Rahman A U, Rafifiq M A, Hasan M M, Maaz K, Karim S, Cho S O 2013 J. Nanopart Res. 15 1703

Google Scholar

Google Scholar

[41] Liu J, Yan J, Shi Q, Dong H, Zhang J, Wang Z, Huang W, Chen B, Zhang H 2019 J. Phys. Chem. C 123 4094

Google Scholar

Google Scholar

[42] Ma X G, Liang P, Miao L, Bie S W, Zhang C K, Xu L, Jiang J J 2009 Phys. Status. Solidi. (b) 246 2132

Google Scholar

Google Scholar

[43] Sekiya T, Ohta S, Kurita S 2008 Int. J. Mod. Phys. B 15 3952

[44] Zhu T, Gao S P 2014 J. Phys. Chem. C 118 11385

Google Scholar

Google Scholar

[45] Liu Q J, Zhang N C, Liu F S, Liu Z T 2014 Phys. Scr. 89 075703

Google Scholar

Google Scholar

[46] Lin X, Wu J, Lu X, Shan Z, Wang W, Huang F 2009 Phys. Chem. Chem. Phys. 11 10047

Google Scholar

Google Scholar

[47] Wu J, Huang F, Shan Z, Wang Y 2011 Dalton Trans. 40 6906

Google Scholar

Google Scholar

[48] Keyan H U, Zian X U, Liu Y, Huang F 2020 Chem. Res. Chin. Univ. 36 1102

Google Scholar

Google Scholar

[49] Plata J J, Márquez A M, Sanz J F 2013 J. Phys. Chem. C 117 14502

Google Scholar

Google Scholar

[50] Park N G, van de Lagemaa J, Frank A J 2000 J. Phys. Chem. B 104 8989

Google Scholar

Google Scholar

[51] 刘恩科, 朱秉升, 罗晋生 2012 半导体物理学 (第7版) (北京: 电子工业出版社) 第109页

Liu E K, Zhu B S, Luo J S 2012 The Physics of Semiconductors (Vol. 7) (Beijing: Electronic Industry Press) p109 (in Chinese)

[52] Ohta S, Sekiya T, Kurita S 2001 Phys. Status. Solidi. (b) 223 265

Google Scholar

Google Scholar

[53] Muscat J, Swamy V, Harrison N M 2002 Phys. Rev. B 65 224112

Google Scholar

Google Scholar

[54] Wang Q, Lian G, Dickey E C 2004 Acta Mater. 52 809

Google Scholar

Google Scholar

[55] Bharathi K K, Markandeyulu G, Ramana C V 2011 J. Electrochem. Soc. 158 G71

Google Scholar

Google Scholar

计量

- 文章访问数: 5545

- PDF下载量: 125

- 被引次数: 0

下载:

下载: