-

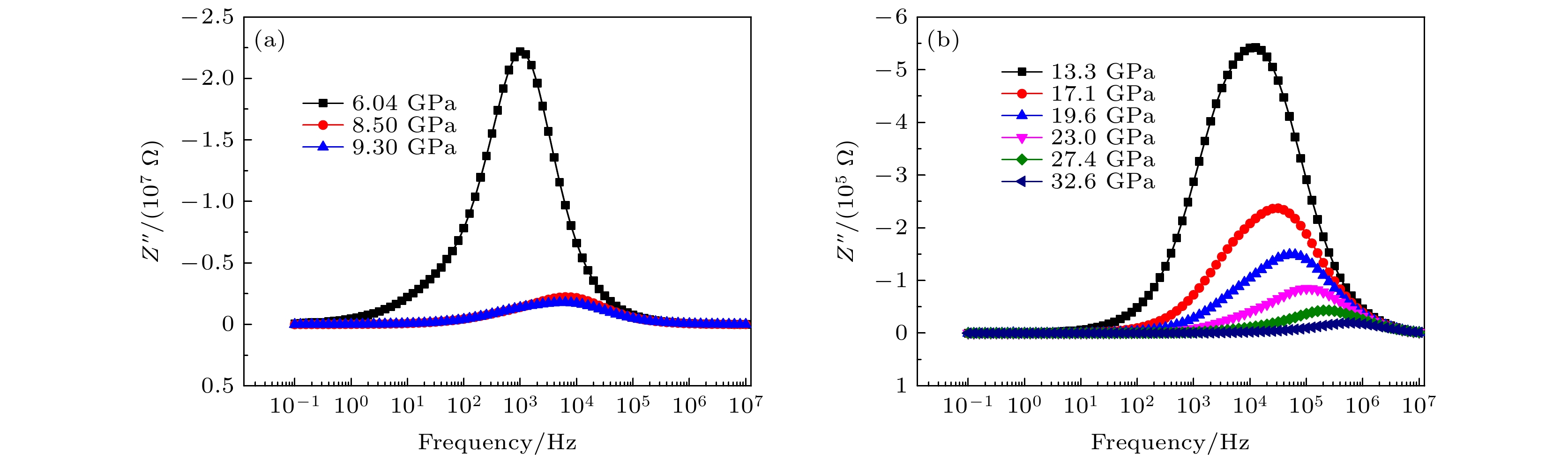

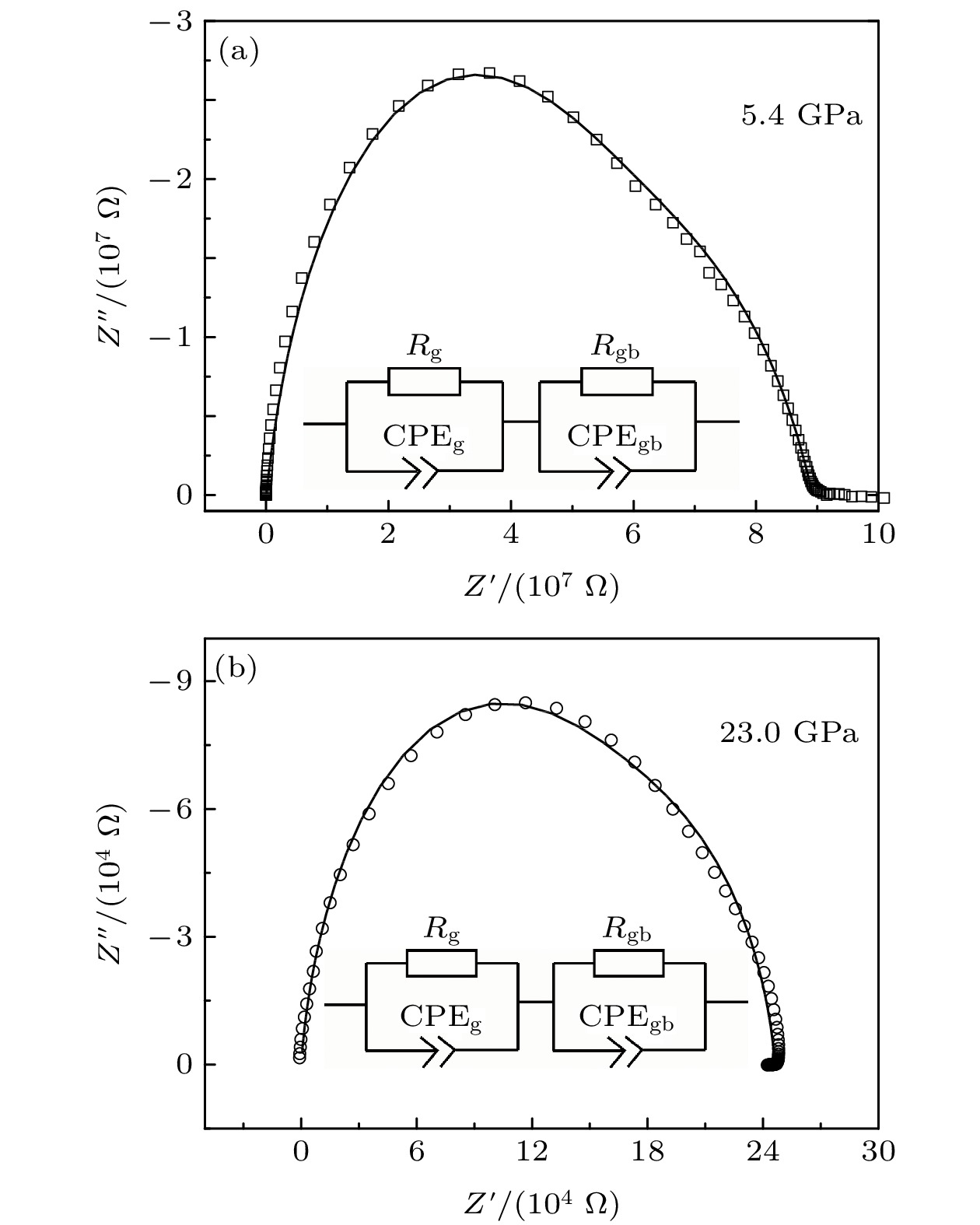

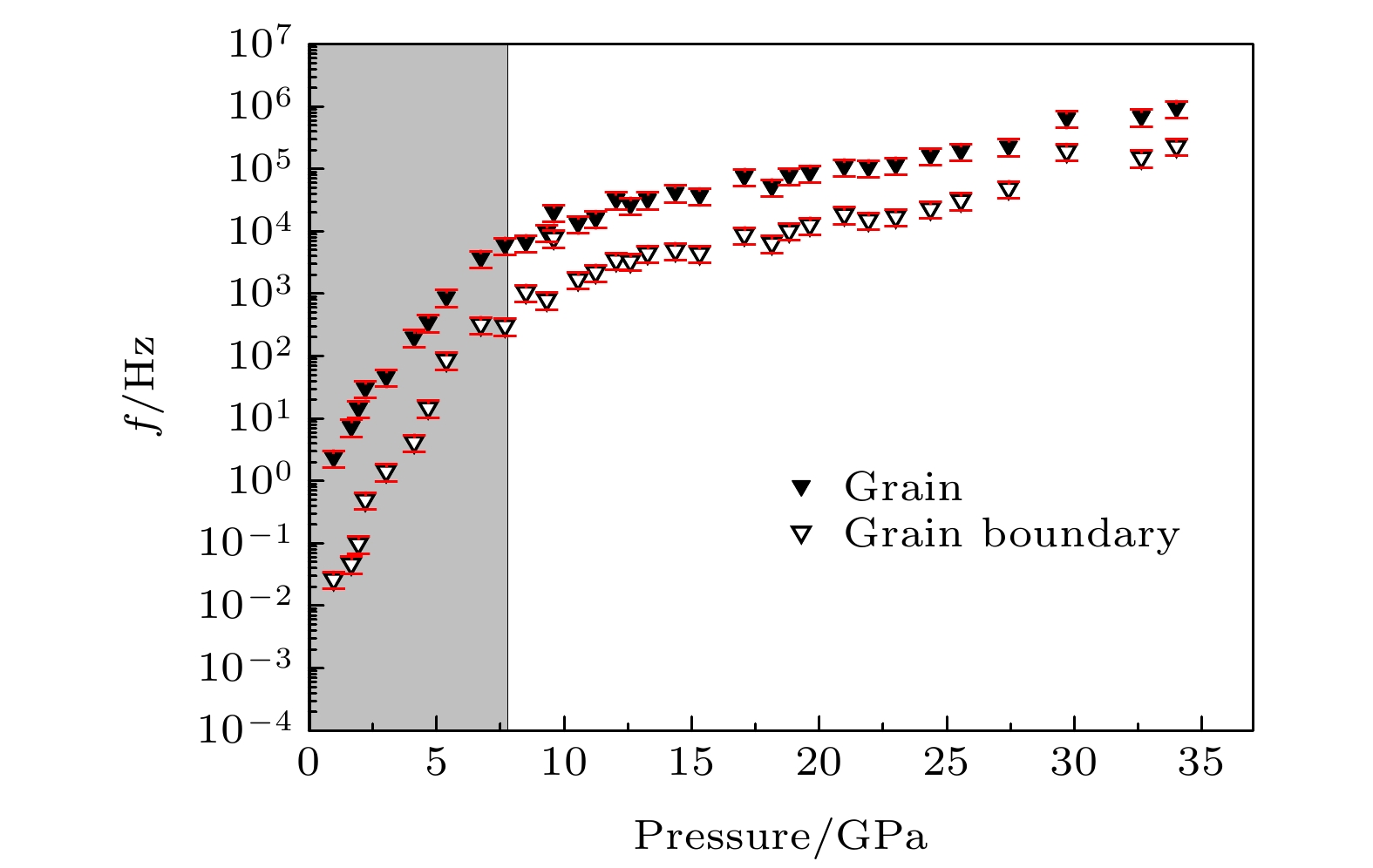

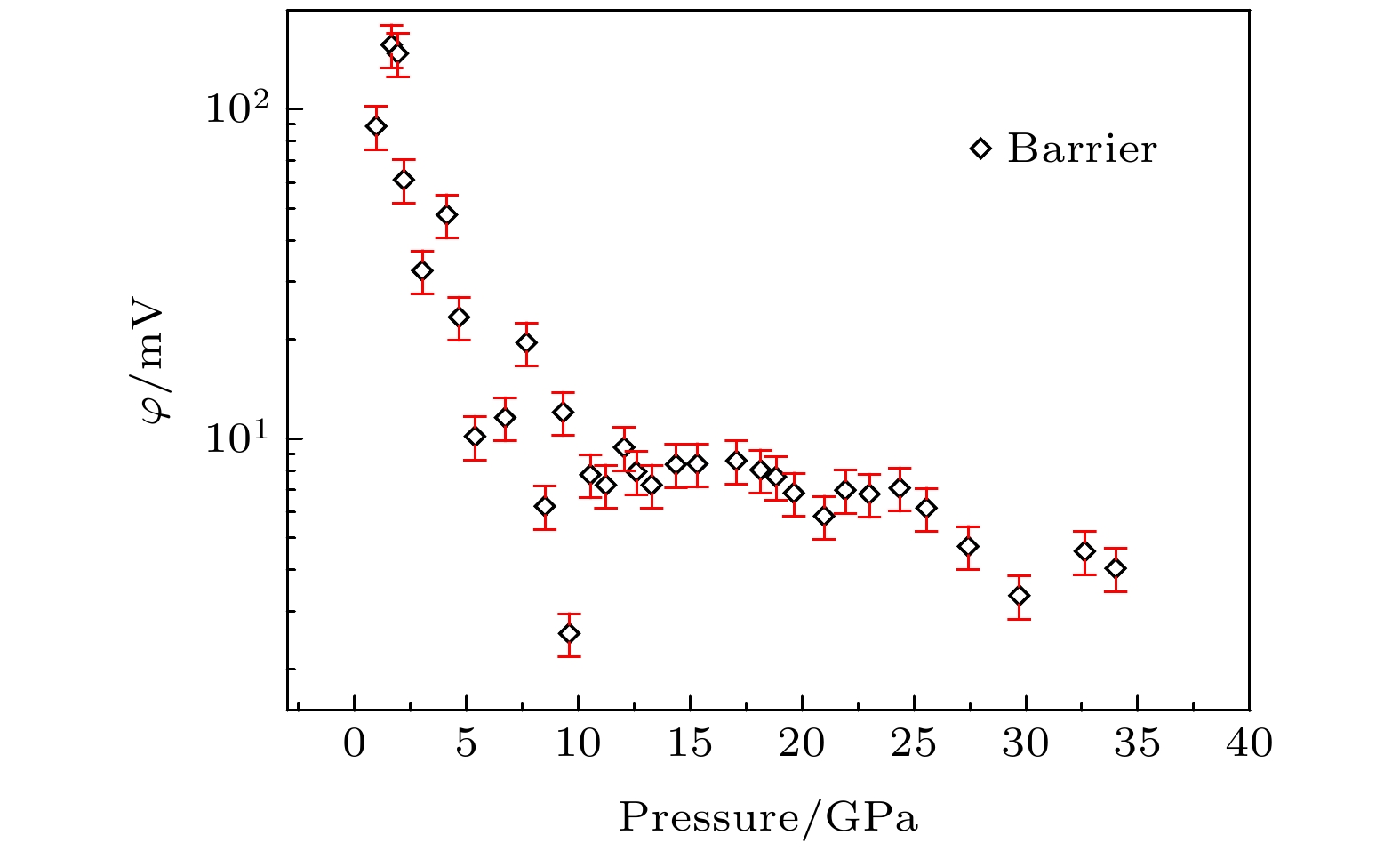

采用水热合成法制备了锐钛矿相TiO2纳米线, 并通过原位高压阻抗谱测量技术研究了TiO2纳米线晶粒和晶界性质及电输运行为随压力的变化关系. 研究结果表明: 在0—34.0 GPa压力区间, 锐钛矿TiO2纳米线的传导机制为电子电导. TiO2纳米线晶粒和晶界电阻以及弛豫频率在8.2—11.2 GPa压力区间均出现了不连续变化行为, 此压力区域对应着由锐钛矿相到斜锆石相的结构转变, 并且相变从晶粒表面逐渐延伸到晶粒内部. 晶粒激活能和晶界激活能均随压力的增加而减小, 说明压力对样品电导率的贡献为正. 在所测压力范围内, 空间电荷势始终为正值, 表明在空间电荷区阴离子缺陷更易形成, 氧缺陷是TiO2纳米线相变的主要诱因.In this work, anatase Titanium dioxide (TiO2) nanowires are synthesized by the hydrothermal method, and its grain and grain boundary behaviors and electrical properties are investigated by alternating current (AC) impedance method under high pressure (up to 34.0 GPa). The relationship between the frequency dependence of impedance Z'' and pressure indicate that the conduction mechanism of anatase phase TiO2 nanowires in the test pressure range is electronic conductivity. It should be noted that the characteristic peaks of Z'' move toward high frequency region with pressure increasing, demonstrating that the effect of grain interior on impedance becomes apparent. Additionally, the overall variation trends of grain and grain boundary resistance go downward with pressure increasing, and the descent rate of grain boundary is larger than those of grain before and after phase transition. However, in a range of phase transition (8.2–11.2 GPa, from anatase to baddeleyite phase), grain boundary resistance shows a discontinuously change (increases to 11.2 GPa and then decreases). Based on the different variation trends of grain and grain boundary resistance, it becomes obvious that the phase transition from anatase to baddeleyite phase first occurs at the surface of grain, and then extends to the interior of grain gradually. Also, as an intrinsic characteristic, the relaxation frequency is independent of the geometrical parameters. The pressure dependence of activation energy is obtained by fitting the pressure dependence of relaxation frequency. The activation energy of grain and grain boundary decrease with pressure increasing, implying that the contribution of pressure on the conductivity of sample is positive. Furthermore, the space charge potential for the whole test pressure range is positive, which is determined by the relationship between pressure and relaxation frequency. This fact illustrates that the anion defects are easily formed in the space charge region, and the oxygen defects are the main inducement for TiO2 phase transformation.

-

Keywords:

- high pressure /

- TiO2 nanowires /

- impedance spectrum /

- electronic conductivity

[1] Li Q J, Liu B B 2016 Chin. Phys. B 25 076107

Google Scholar

Google Scholar

[2] Dong Z H, Song Y 2015 Can. J. Chem. 93 165

Google Scholar

Google Scholar

[3] Swamy V, Kuznetsov A Y, Dubrovinsky L S, Kurnosov A, Prakapenka V B 2009 Phys. Rev. Lett. 103 075505

Google Scholar

Google Scholar

[4] Machon D, Daniel M, Pischedda V, Daniele S, Bouvier P, LeFloch S 2010 Phys. Rev. B 82 140102

Google Scholar

Google Scholar

[5] Machon D, Daniel M, Bouvier P, Daniele S, Floch S L, Melinon P, Pischedda V 2011 J. Phys. Chem. C 115 22286

Google Scholar

Google Scholar

[6] Li Q, Cheng B, Yang X, Liu R, Zou B 2013 J. Phys. Chem. C 117 8516

Google Scholar

Google Scholar

[7] Wang Z, Saxena S K 2001 Solid State Commun. 118 75

Google Scholar

Google Scholar

[8] Swamy V, Kuznetsov A, Dubrovinsky L S, Mcmillan P F, Prakapenka V B, Shen G, Muddle B C 2006 Phys. Rev. Lett. 96 135702

Google Scholar

Google Scholar

[9] Hearne G R, Zhao J, Dawe A M, Pischedda V, Comins J D 2004 Phys. Rev. B 70 134102

Google Scholar

Google Scholar

[10] Swamya V, Dubrovinsky L S, Dubrovinskaia N A, Simionovici A S, Drakopoulos M, Dmitriev V, Weber H P 2003 Solid State Commun. 125 111

Google Scholar

Google Scholar

[11] Swamy V, Dubrovinsky L S, Dubrovinskaia N A, Langenhorst F, Simionovici A, Drakopoulos M, Dmitriev V, Weber H P 2005 Solid State Commun. 134 541

Google Scholar

Google Scholar

[12] Arlt T, Bermejo M, Blanco M A, Gerward L, Jiang J Z, Olsen J S, Recio J M 2000 Phys. Rev. B 61 14414

Google Scholar

Google Scholar

[13] Haines J, Léger J M 1993 Physica B 192 233

Google Scholar

Google Scholar

[14] Lagarec K, Desgreniers S 1995 Solid State Commun. 94 519

Google Scholar

Google Scholar

[15] Li Q J, Liu B B, Wang L, Li D M, Liu R, Zou B, Cui T, Zou G T, Meng Y, Mao H K, Liu Z X, Liu J, Li J X 2010 J. Phys. Chem. Lett. 1 309

Google Scholar

Google Scholar

[16] Li Q J, Liu R, Cheng B Y, Wang L, Yao M G, Li D M 2012 Mater. Res. Bull. 47 1396

Google Scholar

Google Scholar

[17] Park S, Jang J, Cheon J, Lee H H, Lee D R, Lee Y 2008 J. Phys. Chem. C 112 9627

Google Scholar

Google Scholar

[18] Li Q, Cheng B, Tian B, Liu R, Liu B, Wang F, Chen Z, Zou B, Cui T, Liu B 2014 RSC Adv. 4 12873

Google Scholar

Google Scholar

[19] Dong Z, Xiao F, Zhao A, Liu L, Sham T K, Song Y 2016 RSC Adv. 6 76142

Google Scholar

Google Scholar

[20] Li Q, Ran L, Wang T, Ke X, Jing L 2015 AIP Adv. 5 097128

Google Scholar

Google Scholar

[21] Zhang Y, Wang Q, Zhang J, Wu X, Ma Y 2017 Nanotechnology 28 145705

Google Scholar

Google Scholar

[22] Liu B, Nakata K, Liu S, Sakai M, Ochia T, Murakami T, Takagi K, Fujishima A 2012 J. Phys. Chem. C 116 7471

Google Scholar

Google Scholar

[23] Tokudome H, Miyauchi M 2004 Chem. Commun. 8 958

Google Scholar

Google Scholar

[24] Wu J M, Shi H C, Wu W T 2006 Nanotechnology 17 105

Google Scholar

Google Scholar

[25] Rendón-Rivera A, Toledo-Antonio J A, Cortés-Jácome M A, Angeles-Chávez C 2011 Catal. Today 166 18

Google Scholar

Google Scholar

[26] Crossland E J W, Noel N, Sivaram V, Leijtens T, Alexander-Webber J A, Snaith H J 2013 Nature 495 215

Google Scholar

Google Scholar

[27] 韩迪仪, 顾阳, 胡涛政, 董雯, 倪亚贤 2021 70 038103

Google Scholar

Google Scholar

Han D Y, Gu Y, Hu T Z, Dong W, Ni Y X 2021 Acta Phys. Sin. 70 038103

Google Scholar

Google Scholar

[28] 王春杰, 王月, 高春晓 2020 69 147202

Google Scholar

Google Scholar

Wang C J, Wang Y, Gao C X 2020 Acta Phys. Sin. 69 147202

Google Scholar

Google Scholar

[29] 曹楚南, 张鉴清 2002 电化学阻抗谱导论 (典藏版 1) (北京: 科学出版社) 第21页

Cao C N, Zhang J Q 2002 Introduction to Electrochemical Impedance Spectroscopy (Vol. 1) (Beijing: Science Press) p21 (in Chinese)

[30] Watanabe T, Murakami T, Karashima S 1978 Scr. Metall. 12 361

Google Scholar

Google Scholar

[31] Dickey L E C 2004 Acta Mater. 52 809

Google Scholar

Google Scholar

[32] Zhang H, Zhang G, Wang J, Wang Q, Liu C 2021 J. Alloys Compd. 857 157482

Google Scholar

Google Scholar

[33] Wang Q, Wang X, Li J, Qin T, Sang D, Liu J, Ke F, Wang X, Li Y, Liu C 2021 J. Mater. Chem. C 9 4764

Google Scholar

Google Scholar

[34] Wang J, Zhang G, Liu H, Wang Q, Shen W, Yan Y, Liu C, Han Y, Gao C 2017 Appl. Phys. Lett. 111 031907

Google Scholar

Google Scholar

[35] Gerbig O, Merkle R, Maier J 2013 Adv. Mater. 25 3129

Google Scholar

Google Scholar

[36] Ali H, Karim S, Rafiq M A, Maaz K, Ahmad M 2014 J. Alloys Compd. 612 64

Google Scholar

Google Scholar

[37] Abouzari M, Berkemeier F, Schmitz G, Wilmer D 2009 Solid State Ionics 180 922

Google Scholar

Google Scholar

[38] Lü X, Yang W, Quan Z, Lin T, Bai L, Wang L, Huang F, Zhao Y 2014 J. Am. Chem. Soc. 136 419

Google Scholar

Google Scholar

[39] Wang Q, Li S, Peng F, Lei L, He D 2017 J. Appl. Phys. 121 215109

Google Scholar

Google Scholar

[40] Bai F, Bian K, Huang X, Wang Z, Fan H 2019 Chem. Rev. 119 7673

Google Scholar

Google Scholar

[41] Wang Q, He D, Peng F, Lei L, Xiong L, Wang P, Liu J 2014 High Pressure Res. 34 259

Google Scholar

Google Scholar

[42] Goncharov A F 1992 High Pressure Res. 8 607

Google Scholar

Google Scholar

[43] Popescu C, Sans J A, Errandonea D, Segura A, Sapia F 2014 Inorg. Chem. 53 11598

Google Scholar

Google Scholar

[44] Dutta A, Sinha T P, Shannigrahi S 2007 Phys. Rev. B 76 155113

Google Scholar

Google Scholar

[45] Buelbuel M M, Zeyrek S 2006 Microelectron. Eng. 83 2522

Google Scholar

Google Scholar

[46] Tolbert S H, Alivisatos A P 1995 J. Chem. Phys. 102 4642

Google Scholar

Google Scholar

[47] Brus L E, Harkless J A W, Stillinger F H 1996 J. Am. Chem. Soc. 118 4834

Google Scholar

Google Scholar

[48] Macdonald J R 1987 Impedance Spectrum (New York: Wiley) pp13–14, 205

[49] Fleig J 2002 Solid State Ionics 150 181

Google Scholar

Google Scholar

[50] Henisch H K 1984 Semiconductor Contacts (Oxford: Clarendon Press) p85

[51] Guo X 1995 Solid State Ionics 81 235

Google Scholar

Google Scholar

-

表 1 TiO2纳米线在不同压力区间的dHg/dP和dHgb/dP

Table 1. Fitting parameters from pressure dependence of active energy of grain and grain boundary of TiO2 nanowires.

Pressure region/GPa dH/dP/(meV·GPa–1) Grain Grain boundary 1.6—8.2 –0.578 –0.433 9.5—34.0 –0.084 –0.069 -

[1] Li Q J, Liu B B 2016 Chin. Phys. B 25 076107

Google Scholar

Google Scholar

[2] Dong Z H, Song Y 2015 Can. J. Chem. 93 165

Google Scholar

Google Scholar

[3] Swamy V, Kuznetsov A Y, Dubrovinsky L S, Kurnosov A, Prakapenka V B 2009 Phys. Rev. Lett. 103 075505

Google Scholar

Google Scholar

[4] Machon D, Daniel M, Pischedda V, Daniele S, Bouvier P, LeFloch S 2010 Phys. Rev. B 82 140102

Google Scholar

Google Scholar

[5] Machon D, Daniel M, Bouvier P, Daniele S, Floch S L, Melinon P, Pischedda V 2011 J. Phys. Chem. C 115 22286

Google Scholar

Google Scholar

[6] Li Q, Cheng B, Yang X, Liu R, Zou B 2013 J. Phys. Chem. C 117 8516

Google Scholar

Google Scholar

[7] Wang Z, Saxena S K 2001 Solid State Commun. 118 75

Google Scholar

Google Scholar

[8] Swamy V, Kuznetsov A, Dubrovinsky L S, Mcmillan P F, Prakapenka V B, Shen G, Muddle B C 2006 Phys. Rev. Lett. 96 135702

Google Scholar

Google Scholar

[9] Hearne G R, Zhao J, Dawe A M, Pischedda V, Comins J D 2004 Phys. Rev. B 70 134102

Google Scholar

Google Scholar

[10] Swamya V, Dubrovinsky L S, Dubrovinskaia N A, Simionovici A S, Drakopoulos M, Dmitriev V, Weber H P 2003 Solid State Commun. 125 111

Google Scholar

Google Scholar

[11] Swamy V, Dubrovinsky L S, Dubrovinskaia N A, Langenhorst F, Simionovici A, Drakopoulos M, Dmitriev V, Weber H P 2005 Solid State Commun. 134 541

Google Scholar

Google Scholar

[12] Arlt T, Bermejo M, Blanco M A, Gerward L, Jiang J Z, Olsen J S, Recio J M 2000 Phys. Rev. B 61 14414

Google Scholar

Google Scholar

[13] Haines J, Léger J M 1993 Physica B 192 233

Google Scholar

Google Scholar

[14] Lagarec K, Desgreniers S 1995 Solid State Commun. 94 519

Google Scholar

Google Scholar

[15] Li Q J, Liu B B, Wang L, Li D M, Liu R, Zou B, Cui T, Zou G T, Meng Y, Mao H K, Liu Z X, Liu J, Li J X 2010 J. Phys. Chem. Lett. 1 309

Google Scholar

Google Scholar

[16] Li Q J, Liu R, Cheng B Y, Wang L, Yao M G, Li D M 2012 Mater. Res. Bull. 47 1396

Google Scholar

Google Scholar

[17] Park S, Jang J, Cheon J, Lee H H, Lee D R, Lee Y 2008 J. Phys. Chem. C 112 9627

Google Scholar

Google Scholar

[18] Li Q, Cheng B, Tian B, Liu R, Liu B, Wang F, Chen Z, Zou B, Cui T, Liu B 2014 RSC Adv. 4 12873

Google Scholar

Google Scholar

[19] Dong Z, Xiao F, Zhao A, Liu L, Sham T K, Song Y 2016 RSC Adv. 6 76142

Google Scholar

Google Scholar

[20] Li Q, Ran L, Wang T, Ke X, Jing L 2015 AIP Adv. 5 097128

Google Scholar

Google Scholar

[21] Zhang Y, Wang Q, Zhang J, Wu X, Ma Y 2017 Nanotechnology 28 145705

Google Scholar

Google Scholar

[22] Liu B, Nakata K, Liu S, Sakai M, Ochia T, Murakami T, Takagi K, Fujishima A 2012 J. Phys. Chem. C 116 7471

Google Scholar

Google Scholar

[23] Tokudome H, Miyauchi M 2004 Chem. Commun. 8 958

Google Scholar

Google Scholar

[24] Wu J M, Shi H C, Wu W T 2006 Nanotechnology 17 105

Google Scholar

Google Scholar

[25] Rendón-Rivera A, Toledo-Antonio J A, Cortés-Jácome M A, Angeles-Chávez C 2011 Catal. Today 166 18

Google Scholar

Google Scholar

[26] Crossland E J W, Noel N, Sivaram V, Leijtens T, Alexander-Webber J A, Snaith H J 2013 Nature 495 215

Google Scholar

Google Scholar

[27] 韩迪仪, 顾阳, 胡涛政, 董雯, 倪亚贤 2021 70 038103

Google Scholar

Google Scholar

Han D Y, Gu Y, Hu T Z, Dong W, Ni Y X 2021 Acta Phys. Sin. 70 038103

Google Scholar

Google Scholar

[28] 王春杰, 王月, 高春晓 2020 69 147202

Google Scholar

Google Scholar

Wang C J, Wang Y, Gao C X 2020 Acta Phys. Sin. 69 147202

Google Scholar

Google Scholar

[29] 曹楚南, 张鉴清 2002 电化学阻抗谱导论 (典藏版 1) (北京: 科学出版社) 第21页

Cao C N, Zhang J Q 2002 Introduction to Electrochemical Impedance Spectroscopy (Vol. 1) (Beijing: Science Press) p21 (in Chinese)

[30] Watanabe T, Murakami T, Karashima S 1978 Scr. Metall. 12 361

Google Scholar

Google Scholar

[31] Dickey L E C 2004 Acta Mater. 52 809

Google Scholar

Google Scholar

[32] Zhang H, Zhang G, Wang J, Wang Q, Liu C 2021 J. Alloys Compd. 857 157482

Google Scholar

Google Scholar

[33] Wang Q, Wang X, Li J, Qin T, Sang D, Liu J, Ke F, Wang X, Li Y, Liu C 2021 J. Mater. Chem. C 9 4764

Google Scholar

Google Scholar

[34] Wang J, Zhang G, Liu H, Wang Q, Shen W, Yan Y, Liu C, Han Y, Gao C 2017 Appl. Phys. Lett. 111 031907

Google Scholar

Google Scholar

[35] Gerbig O, Merkle R, Maier J 2013 Adv. Mater. 25 3129

Google Scholar

Google Scholar

[36] Ali H, Karim S, Rafiq M A, Maaz K, Ahmad M 2014 J. Alloys Compd. 612 64

Google Scholar

Google Scholar

[37] Abouzari M, Berkemeier F, Schmitz G, Wilmer D 2009 Solid State Ionics 180 922

Google Scholar

Google Scholar

[38] Lü X, Yang W, Quan Z, Lin T, Bai L, Wang L, Huang F, Zhao Y 2014 J. Am. Chem. Soc. 136 419

Google Scholar

Google Scholar

[39] Wang Q, Li S, Peng F, Lei L, He D 2017 J. Appl. Phys. 121 215109

Google Scholar

Google Scholar

[40] Bai F, Bian K, Huang X, Wang Z, Fan H 2019 Chem. Rev. 119 7673

Google Scholar

Google Scholar

[41] Wang Q, He D, Peng F, Lei L, Xiong L, Wang P, Liu J 2014 High Pressure Res. 34 259

Google Scholar

Google Scholar

[42] Goncharov A F 1992 High Pressure Res. 8 607

Google Scholar

Google Scholar

[43] Popescu C, Sans J A, Errandonea D, Segura A, Sapia F 2014 Inorg. Chem. 53 11598

Google Scholar

Google Scholar

[44] Dutta A, Sinha T P, Shannigrahi S 2007 Phys. Rev. B 76 155113

Google Scholar

Google Scholar

[45] Buelbuel M M, Zeyrek S 2006 Microelectron. Eng. 83 2522

Google Scholar

Google Scholar

[46] Tolbert S H, Alivisatos A P 1995 J. Chem. Phys. 102 4642

Google Scholar

Google Scholar

[47] Brus L E, Harkless J A W, Stillinger F H 1996 J. Am. Chem. Soc. 118 4834

Google Scholar

Google Scholar

[48] Macdonald J R 1987 Impedance Spectrum (New York: Wiley) pp13–14, 205

[49] Fleig J 2002 Solid State Ionics 150 181

Google Scholar

Google Scholar

[50] Henisch H K 1984 Semiconductor Contacts (Oxford: Clarendon Press) p85

[51] Guo X 1995 Solid State Ionics 81 235

Google Scholar

Google Scholar

计量

- 文章访问数: 5569

- PDF下载量: 87

- 被引次数: 0

下载:

下载: