-

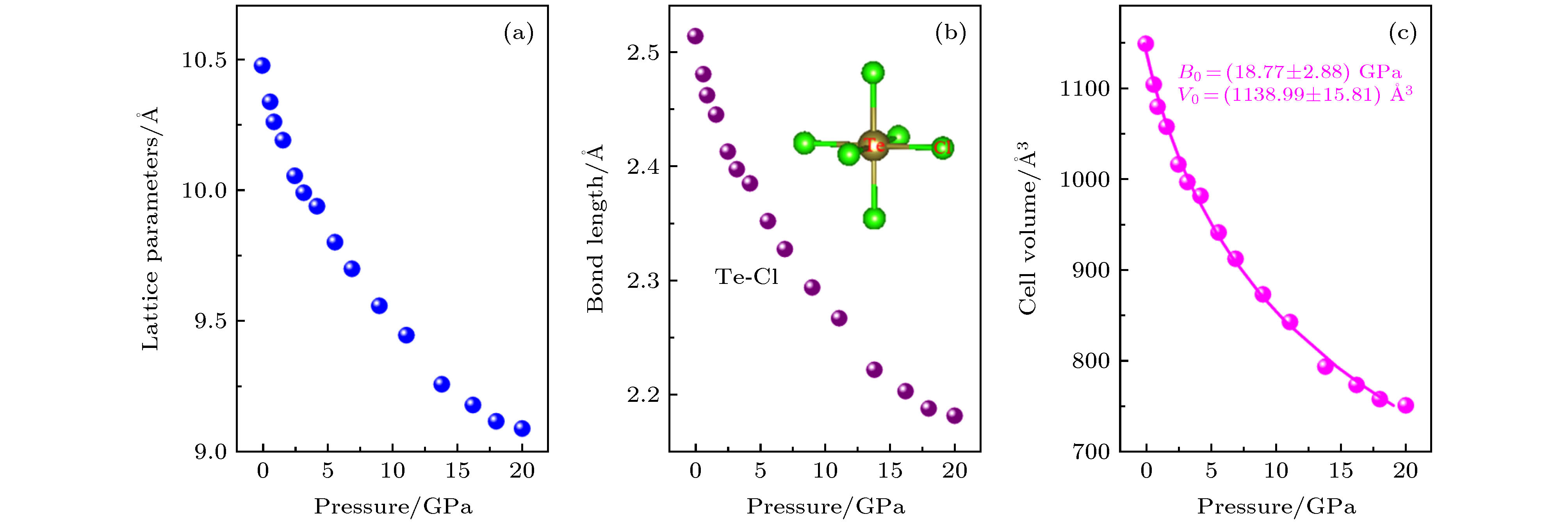

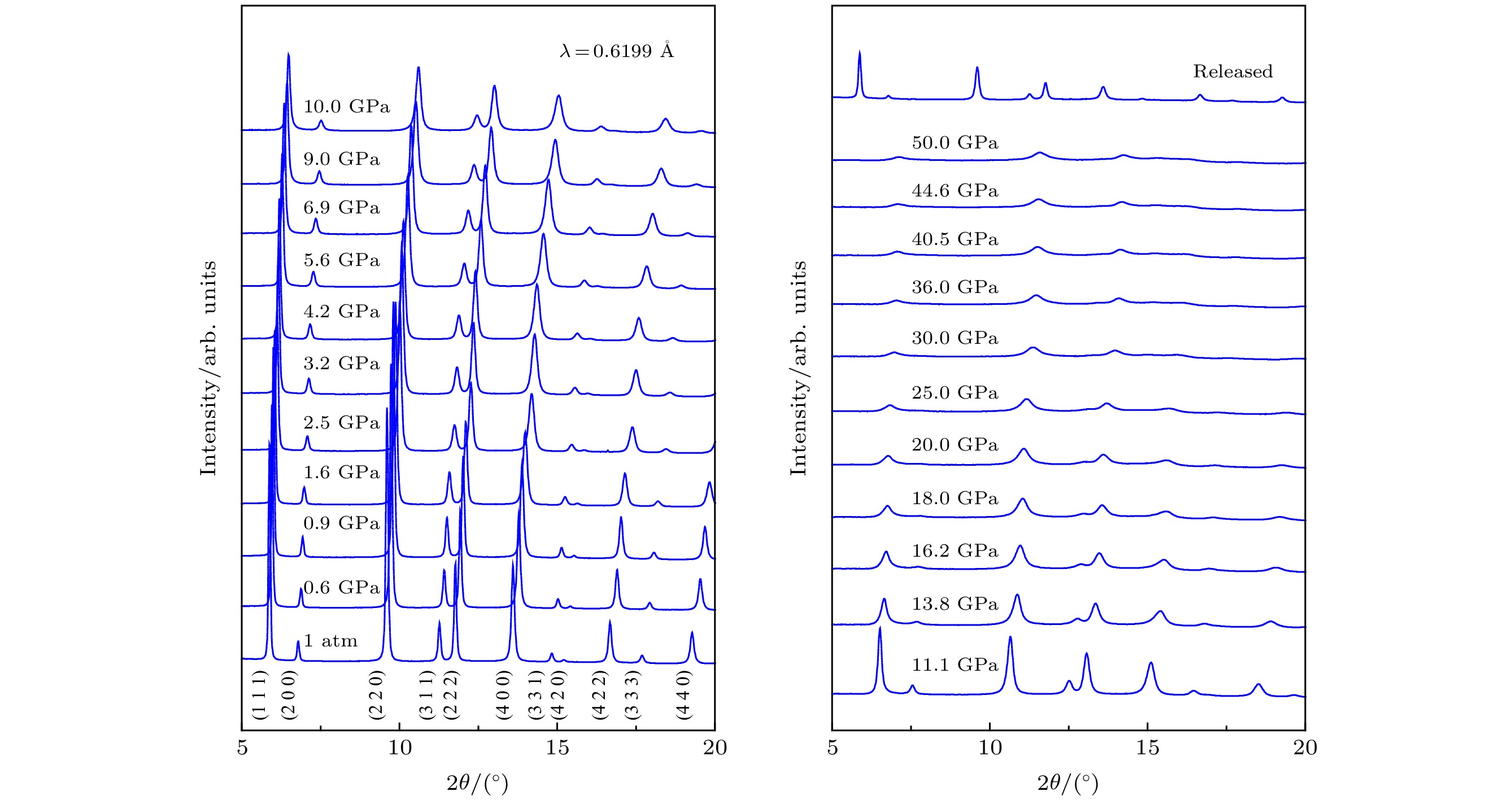

无毒环保且稳定的非铅双钙钛矿材料因具有和铅基钙钛矿相似的三维结构, 被认为是铅基钙钛矿材料最有前景的替代品之一. 本文采用溶液法制备了一种新型非铅双钙钛矿材料Cs2TeCl6, 利用金刚石对顶砧高压装置和高压原位同步辐射X射线衍射、紫外-可见吸收光谱技术, 对其在高压下的晶体结构、光学带隙和电子结构演化进行了深入研究. 研究表明, 在实验压力范围(0—50.0 GPa)内Cs2TeCl6晶体结构并未发生改变, 始终保持Fm-3m的结构对称性, 表明该样品具有良好的稳定性; Cs2TeCl6的体积随压力的增加曲线变化比较平滑, 通过三阶Birch-Mumaghan状态方程得到了体弹模量B0 = (18.77 ± 2.88) GPa; Cs2TeCl6为间接带隙半导体, 在0—20.0 GPa范围内其光学带隙随着压力的增大逐渐减小, 这与高压下八面体[TeCl6]2–的收缩相关. 完全卸压后, Cs2TeCl6恢复到加压前的初始状态. 研究结果为深入理解此类材料的晶体结构和光学性质提供科学依据, 并为调控其晶格结构、光学带隙及电子结构提供思路.In recent years, organic-inorganic hybrid perovskite materials have been widely used in solar cells, photodetectors, and light-emitting diodes due to their advantages such as high light absorption coefficient, good carrier mobility, and long carrier diffusion length. However, the high toxicity of lead and poor stability still restrict the application and promotion of such materials. The lead-free double perovskite material derived from the concept of “heterovalent substitution”, while maintaining the high symmetrical structure of perovskite, avoids using the toxic lead elements, which has the advantages of environmental friendly, stable structure, and suitable band gap. At present, the limited research on lead-free double perovskite materials still leaves a big room to researchers, and such a limited research seriously restricts the development and promotion of such materials. Therefore, the relationship between the structure and performance of lead-free double perovskite materials needs further exploring in order to provide theoretical basis for the practical application of such materials. Here in this work, the lead-free double perovskite material Cs2TeCl6 is prepared by the solution method. The crystal structure and optical properties of the lead-free double perovskite Cs2TeCl6 under high pressure are investigated by using diamond anvil cell combined with in-situ high-pressure angle-dispersive X-ray diffraction and ultraviolet-visible absorption technology. The results show that the crystal structure of Cs2TeCl6 is not changed within the experimental pressure range of 0-50.0 GPa, and the structural symmetry of Fm-3m is still maintained, indicating the sample has good stability. The lattice constant and volume of Cs2TeCl6 gradually decrease within the pressure range of 0-50.0 GPa. The volume and pressure of Cs2TeCl6 are fitted using the third-order Birch-Mumaghan equation of state, the bulk elastic modulus is obtained to be B0 = (18.77 ± 2.88) GPa. The smaller bulk elastic modulus indicates that the lead-free double perovskite material Cs2TeCl6 has higher compressibility. The optical band gap of Cs2TeCl6 is 2.68(3) eV at 1 atm and its optical band gap gradually decreases with the increase of pressure, which is related to the shrinkage of octahedral [TeCl6]2– under high pressure. The calculation results show that the Cs2TeCl6 possesses an indirect band gap, the valence band maximum is mainly composed of Cl 3p orbits, and the conduction band minimum is mainly composed of Te 5p and Cl 3p orbits. After the pressure is completely relieved, Cs2TeCl6 returns to the initial state. The above conclusions further deepen the understanding of the crystal structure and optical properties of lead-free double perovskite Cs2TeCl6, and provide a theoretical basis for designing and optimizing the lead-free double perovskite materials.

-

Keywords:

- lead-free double perovskite /

- diamond anvil cell /

- high pressure /

- band gap

[1] Dursun I, Shen C, Parida M R, Pan J, Sarmah S P, Priante D, Alyami N, Liu J, Saidaminov M I, Alias M S, Abdelhady A L, Ng T K, Mohammed O F, Ooi B S, Bakr O M 2016 ACS Photonics 3 1150

Google Scholar

Google Scholar

[2] Chen J, Zhao X, Kim S G, Park N G 2019 Adv. Mater. 31 e1902902

Google Scholar

Google Scholar

[3] Liu M, Johnston M B, Snaith H J 2013 Nature 501 395

Google Scholar

Google Scholar

[4] Xu Y, Chen Q, Zhang C, Wang R, Wu H, Zhang X, Xing G, Yu W W, Wang X, Zhang Y, Xiao M 2016 J. Am. Chem. Soc. 138 3761

Google Scholar

Google Scholar

[5] Wang J, Zhang C, Liu H, McLaughlin R, Zhai Y, Vardeny S R, Liu X, McGill S, Semenov D, Guo H, Tsuchikawa R, Deshpande V V, Sun D, Vardeny Z V 2019 Nat. Commun. 10 129

Google Scholar

Google Scholar

[6] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[7] Li Y, Shi Z F, Li X J, Shan C X 2019 Chin. Phys. B 28 017803

Google Scholar

Google Scholar

[8] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[9] Best Research-Cell Efficiency Chart https://www.nrel.gov/pv/cell-efficiency.html [2020-06-26]

[10] Wang Z, Shi Z, Li T, Chen Y, Huang W 2017 Angew. Chem. Int. Ed. 56 1190

Google Scholar

Google Scholar

[11] Zhang Q, Hao F, Li J, Zhou Y, Wei Y, Lin H 2018 Sci. Technol. Adv. Mater. 19 425

Google Scholar

Google Scholar

[12] Abate A 2017 Joule 1 659

Google Scholar

Google Scholar

[13] Qin X, Zhao Z, Wang Y, Wu J, Jiang Q, You J 2017 J. Semicond. 38 011002

Google Scholar

Google Scholar

[14] Zhang Y Y, Chen S Y, Xu P, Xiang H J, Gong X G, Walsh A, Wei S H 2018 Chin. Phys. Lett. 35 036104

Google Scholar

Google Scholar

[15] Zhao X G, Yang D, Ren J C, Sun Y, Xiao Z, Zhang L 2018 Joule 2 1662

Google Scholar

Google Scholar

[16] Zhao X G, Yang J H, Fu Y, Yang D, Xu Q, Yu L, Wei S H, Zhang L 2017 J. Am. Chem. Soc. 139 2630

Google Scholar

Google Scholar

[17] Ju M G, Chen M, Zhou Y, Garces H F, Dai J, Ma L, Padture N P, Zeng X C 2018 ACS Energy Lett. 3 297

Google Scholar

Google Scholar

[18] Chen M, Ju M G, Carl A D, Zong Y, Grimm R L, Gu J, Zeng X C, Zhou Y, Padture N P 2018 Joule 2 558

Google Scholar

Google Scholar

[19] Greul E, Petrus M L, Binek A, Docampo P, Bein T 2017 J. Mater. Chem. A 5 19972

Google Scholar

Google Scholar

[20] 程金光 2017 66 037401

Google Scholar

Google Scholar

Cheng J G 2017 Acta Phys. Sin. 66 037401

Google Scholar

Google Scholar

[21] 董家君, 姚明光, 刘世杰, 刘冰冰 2017 66 039101

Google Scholar

Google Scholar

Dong J J, Yao M G, Liu S J, Liu B B, 2017 Acta Phys. Sin. 66 039101

Google Scholar

Google Scholar

[22] 段德芳, 马艳斌, 邵子霁, 谢慧, 黄晓丽, 刘冰冰, 崔田 2017 66 036102

Google Scholar

Google Scholar

Duan D F, Ma Y B, Shao Z J, Xie H, Huang X L, Liu B B, Cui T 2017 Acta Phys. Sin. 66 036102

Google Scholar

Google Scholar

[23] 时旭含, 李海燕, 姚震, 刘冰冰 2020 69 067101

Google Scholar

Google Scholar

Shi X H, Li H Y, Yao Z, Liu B B 2020 Acta Phys. Sin. 69 067101

Google Scholar

Google Scholar

[24] 王春杰, 王月, 高春晓 2020 69 147202

Google Scholar

Google Scholar

Wang C J, Wang Y, Gao C X 2020 Acta Phys. Sin. 69 147202

Google Scholar

Google Scholar

[25] Wang L, Wang K, Zou B 2016 J. Phys. Chem. Lett. 7 2556

Google Scholar

Google Scholar

[26] Xiao G, Cao Y, Qi G, Wang L, Liu C, Ma Z, Yang X, Sui Y, Zheng W, Zou B 2017 J. Am. Chem. Soc. 139 10087

Google Scholar

Google Scholar

[27] Zhang L, Zeng Q, Wang K 2017 J. Phys. Chem. Lett. 8 3752

Google Scholar

Google Scholar

[28] Zhang L, Liu C, Wang L, Liu C, Wang K, Zou B 2018 Angew. Chem. Int. Ed. 57 11213

Google Scholar

Google Scholar

[29] 郭宏伟, 刘然, 王玲瑞, 崔金星, 宋波, 王凯, 刘冰冰, 邹勃 2017 66 030701

Google Scholar

Google Scholar

Guo H W, Liu R, Wang L R, Cui J X, Song B, Wang K, Liu B B, Zou B 2017 Acta Phys. Sin. 66 030701

Google Scholar

Google Scholar

[30] Li Q, Wang Y, Pan W, Yang W, Zou B, Tang J, Quan Z 2017 Angew. Chem. Int. Ed. 56 15969

Google Scholar

Google Scholar

[31] Wang L, Yao P, Wang F, Li S, Chen Y, Xia T, Guo E, Wang K, Zou B, Guo H 2020 Adv. Sci. 7 1902900

Google Scholar

Google Scholar

[32] Maughan A E, Ganose A M, Bordelon M M, Miller E M, Scanlon D O, Neilson J R 2016 J. Am. Chem. Soc. 138 8453

Google Scholar

Google Scholar

[33] Birch F 1978 J. Geophys. Res. 83 1257

Google Scholar

Google Scholar

[34] Lee Y, Mitzi D B, Barnes P W, Vogt T 2003 Phys. Rev. B 68 020103

Google Scholar

Google Scholar

[35] Lü X, Wang Y, Stoumpos C C, Hu Q, Guo X, Chen H, Yang L, Smith J S, Yang W, Zhao Y, Xu H, Kanatzidis M G, Jia Q 2016 Adv. Mater. 28 8663

Google Scholar

Google Scholar

[36] Tauc J, Grigorovici R, Vancu A 1966 Phys. Status Solidi 15 627

Google Scholar

Google Scholar

[37] Sa R, Wei Y, Zha W, Liu D 2020 Chem. Phys. Lett. 754 137538

Google Scholar

Google Scholar

[38] Wang L, Ou T, Wang K, Xiao G, Gao C, Zou B 2017 Appl. Phys. Lett. 111 233901

Google Scholar

Google Scholar

[39] Kong L, Liu G, Gong J, Hu Q, Schaller R D, Dera P, Zhang D, Liu Z, Yang W, Zhu K, Tang Y, Wang C, Wei S H, Xu T, Mao H K 2016 Proc. Natl. Acad. Sci. 113 8910

Google Scholar

Google Scholar

-

-

[1] Dursun I, Shen C, Parida M R, Pan J, Sarmah S P, Priante D, Alyami N, Liu J, Saidaminov M I, Alias M S, Abdelhady A L, Ng T K, Mohammed O F, Ooi B S, Bakr O M 2016 ACS Photonics 3 1150

Google Scholar

Google Scholar

[2] Chen J, Zhao X, Kim S G, Park N G 2019 Adv. Mater. 31 e1902902

Google Scholar

Google Scholar

[3] Liu M, Johnston M B, Snaith H J 2013 Nature 501 395

Google Scholar

Google Scholar

[4] Xu Y, Chen Q, Zhang C, Wang R, Wu H, Zhang X, Xing G, Yu W W, Wang X, Zhang Y, Xiao M 2016 J. Am. Chem. Soc. 138 3761

Google Scholar

Google Scholar

[5] Wang J, Zhang C, Liu H, McLaughlin R, Zhai Y, Vardeny S R, Liu X, McGill S, Semenov D, Guo H, Tsuchikawa R, Deshpande V V, Sun D, Vardeny Z V 2019 Nat. Commun. 10 129

Google Scholar

Google Scholar

[6] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[7] Li Y, Shi Z F, Li X J, Shan C X 2019 Chin. Phys. B 28 017803

Google Scholar

Google Scholar

[8] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[9] Best Research-Cell Efficiency Chart https://www.nrel.gov/pv/cell-efficiency.html [2020-06-26]

[10] Wang Z, Shi Z, Li T, Chen Y, Huang W 2017 Angew. Chem. Int. Ed. 56 1190

Google Scholar

Google Scholar

[11] Zhang Q, Hao F, Li J, Zhou Y, Wei Y, Lin H 2018 Sci. Technol. Adv. Mater. 19 425

Google Scholar

Google Scholar

[12] Abate A 2017 Joule 1 659

Google Scholar

Google Scholar

[13] Qin X, Zhao Z, Wang Y, Wu J, Jiang Q, You J 2017 J. Semicond. 38 011002

Google Scholar

Google Scholar

[14] Zhang Y Y, Chen S Y, Xu P, Xiang H J, Gong X G, Walsh A, Wei S H 2018 Chin. Phys. Lett. 35 036104

Google Scholar

Google Scholar

[15] Zhao X G, Yang D, Ren J C, Sun Y, Xiao Z, Zhang L 2018 Joule 2 1662

Google Scholar

Google Scholar

[16] Zhao X G, Yang J H, Fu Y, Yang D, Xu Q, Yu L, Wei S H, Zhang L 2017 J. Am. Chem. Soc. 139 2630

Google Scholar

Google Scholar

[17] Ju M G, Chen M, Zhou Y, Garces H F, Dai J, Ma L, Padture N P, Zeng X C 2018 ACS Energy Lett. 3 297

Google Scholar

Google Scholar

[18] Chen M, Ju M G, Carl A D, Zong Y, Grimm R L, Gu J, Zeng X C, Zhou Y, Padture N P 2018 Joule 2 558

Google Scholar

Google Scholar

[19] Greul E, Petrus M L, Binek A, Docampo P, Bein T 2017 J. Mater. Chem. A 5 19972

Google Scholar

Google Scholar

[20] 程金光 2017 66 037401

Google Scholar

Google Scholar

Cheng J G 2017 Acta Phys. Sin. 66 037401

Google Scholar

Google Scholar

[21] 董家君, 姚明光, 刘世杰, 刘冰冰 2017 66 039101

Google Scholar

Google Scholar

Dong J J, Yao M G, Liu S J, Liu B B, 2017 Acta Phys. Sin. 66 039101

Google Scholar

Google Scholar

[22] 段德芳, 马艳斌, 邵子霁, 谢慧, 黄晓丽, 刘冰冰, 崔田 2017 66 036102

Google Scholar

Google Scholar

Duan D F, Ma Y B, Shao Z J, Xie H, Huang X L, Liu B B, Cui T 2017 Acta Phys. Sin. 66 036102

Google Scholar

Google Scholar

[23] 时旭含, 李海燕, 姚震, 刘冰冰 2020 69 067101

Google Scholar

Google Scholar

Shi X H, Li H Y, Yao Z, Liu B B 2020 Acta Phys. Sin. 69 067101

Google Scholar

Google Scholar

[24] 王春杰, 王月, 高春晓 2020 69 147202

Google Scholar

Google Scholar

Wang C J, Wang Y, Gao C X 2020 Acta Phys. Sin. 69 147202

Google Scholar

Google Scholar

[25] Wang L, Wang K, Zou B 2016 J. Phys. Chem. Lett. 7 2556

Google Scholar

Google Scholar

[26] Xiao G, Cao Y, Qi G, Wang L, Liu C, Ma Z, Yang X, Sui Y, Zheng W, Zou B 2017 J. Am. Chem. Soc. 139 10087

Google Scholar

Google Scholar

[27] Zhang L, Zeng Q, Wang K 2017 J. Phys. Chem. Lett. 8 3752

Google Scholar

Google Scholar

[28] Zhang L, Liu C, Wang L, Liu C, Wang K, Zou B 2018 Angew. Chem. Int. Ed. 57 11213

Google Scholar

Google Scholar

[29] 郭宏伟, 刘然, 王玲瑞, 崔金星, 宋波, 王凯, 刘冰冰, 邹勃 2017 66 030701

Google Scholar

Google Scholar

Guo H W, Liu R, Wang L R, Cui J X, Song B, Wang K, Liu B B, Zou B 2017 Acta Phys. Sin. 66 030701

Google Scholar

Google Scholar

[30] Li Q, Wang Y, Pan W, Yang W, Zou B, Tang J, Quan Z 2017 Angew. Chem. Int. Ed. 56 15969

Google Scholar

Google Scholar

[31] Wang L, Yao P, Wang F, Li S, Chen Y, Xia T, Guo E, Wang K, Zou B, Guo H 2020 Adv. Sci. 7 1902900

Google Scholar

Google Scholar

[32] Maughan A E, Ganose A M, Bordelon M M, Miller E M, Scanlon D O, Neilson J R 2016 J. Am. Chem. Soc. 138 8453

Google Scholar

Google Scholar

[33] Birch F 1978 J. Geophys. Res. 83 1257

Google Scholar

Google Scholar

[34] Lee Y, Mitzi D B, Barnes P W, Vogt T 2003 Phys. Rev. B 68 020103

Google Scholar

Google Scholar

[35] Lü X, Wang Y, Stoumpos C C, Hu Q, Guo X, Chen H, Yang L, Smith J S, Yang W, Zhao Y, Xu H, Kanatzidis M G, Jia Q 2016 Adv. Mater. 28 8663

Google Scholar

Google Scholar

[36] Tauc J, Grigorovici R, Vancu A 1966 Phys. Status Solidi 15 627

Google Scholar

Google Scholar

[37] Sa R, Wei Y, Zha W, Liu D 2020 Chem. Phys. Lett. 754 137538

Google Scholar

Google Scholar

[38] Wang L, Ou T, Wang K, Xiao G, Gao C, Zou B 2017 Appl. Phys. Lett. 111 233901

Google Scholar

Google Scholar

[39] Kong L, Liu G, Gong J, Hu Q, Schaller R D, Dera P, Zhang D, Liu Z, Yang W, Zhu K, Tang Y, Wang C, Wei S H, Xu T, Mao H K 2016 Proc. Natl. Acad. Sci. 113 8910

Google Scholar

Google Scholar

计量

- 文章访问数: 12404

- PDF下载量: 351

- 被引次数: 0

下载:

下载: