-

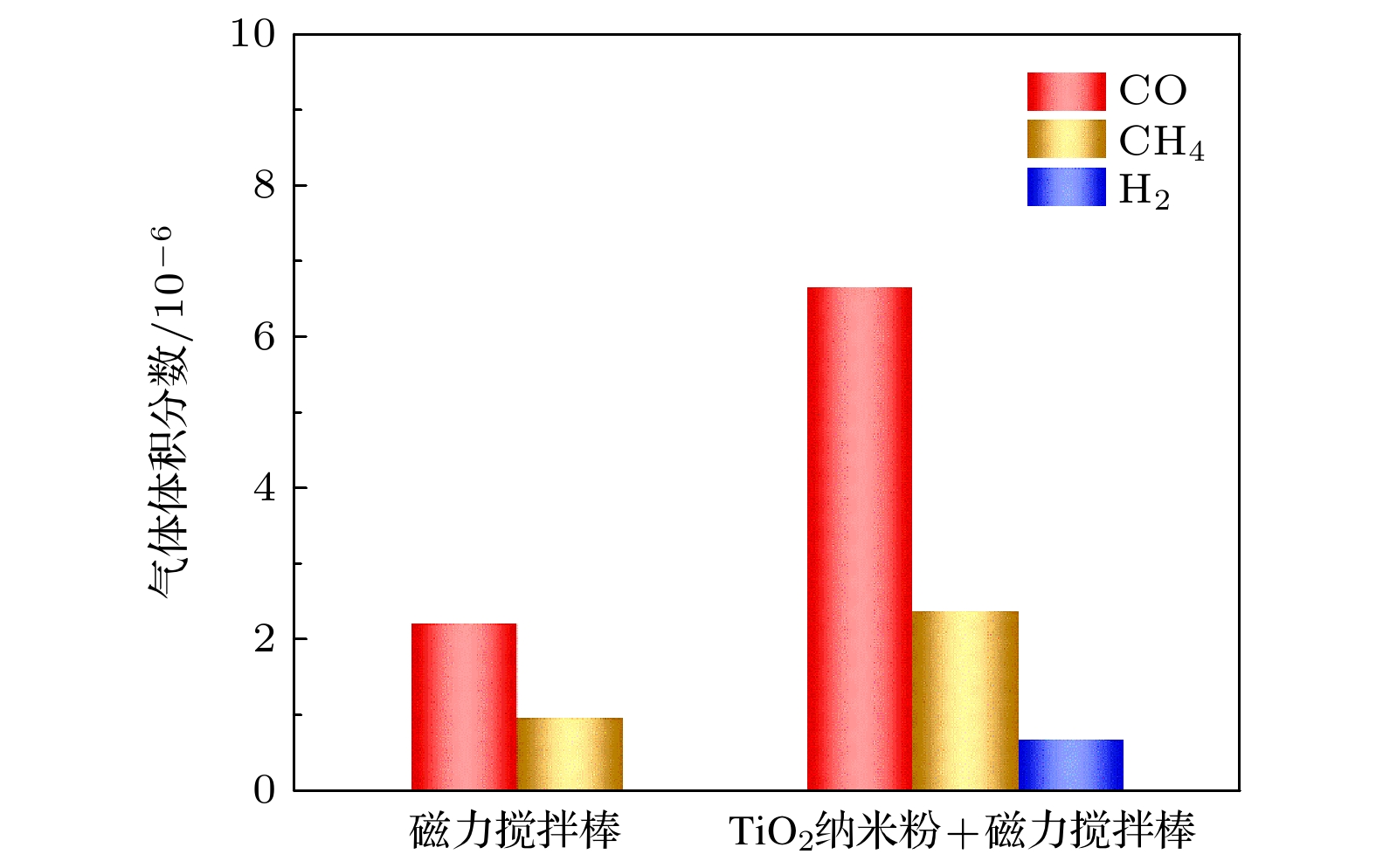

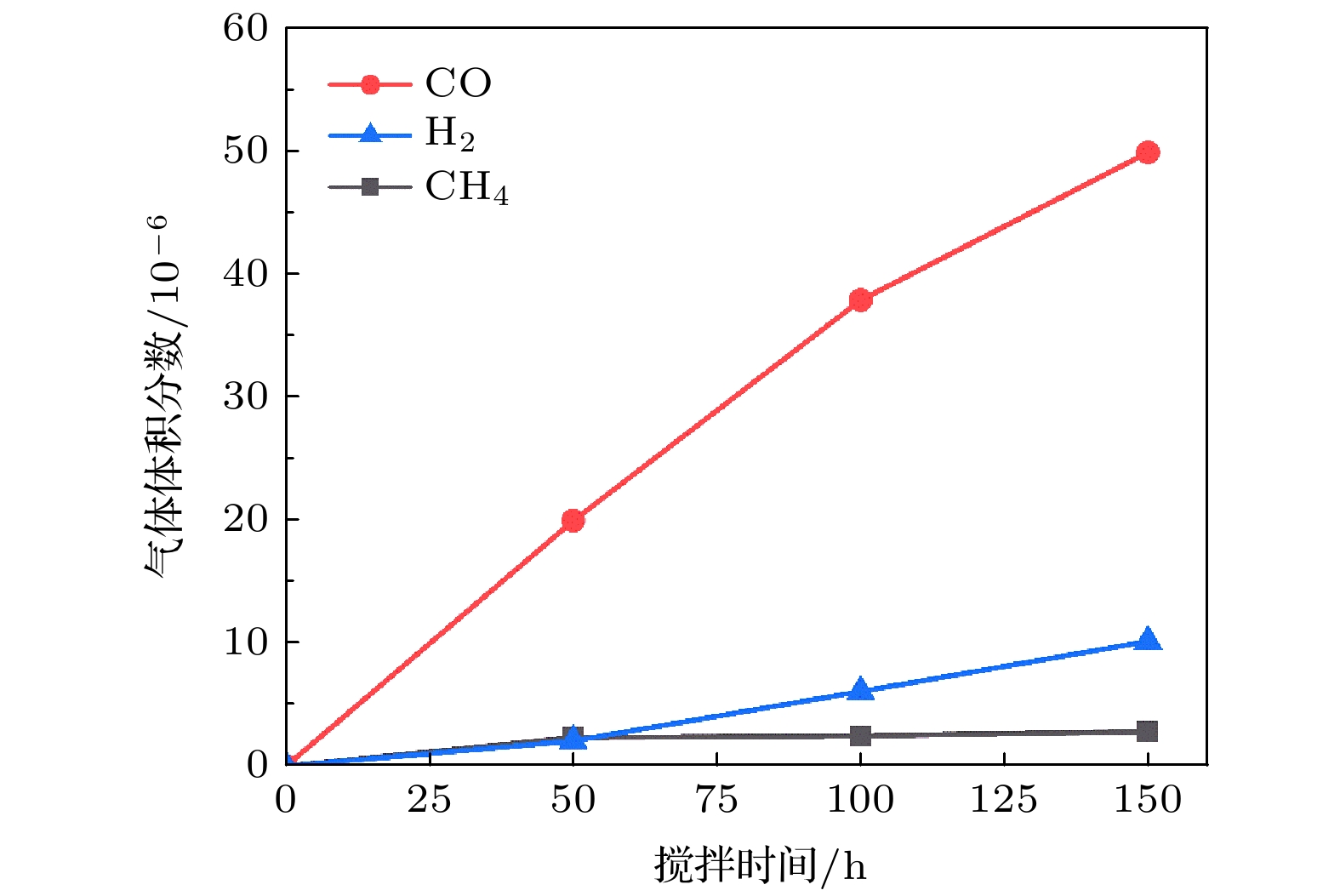

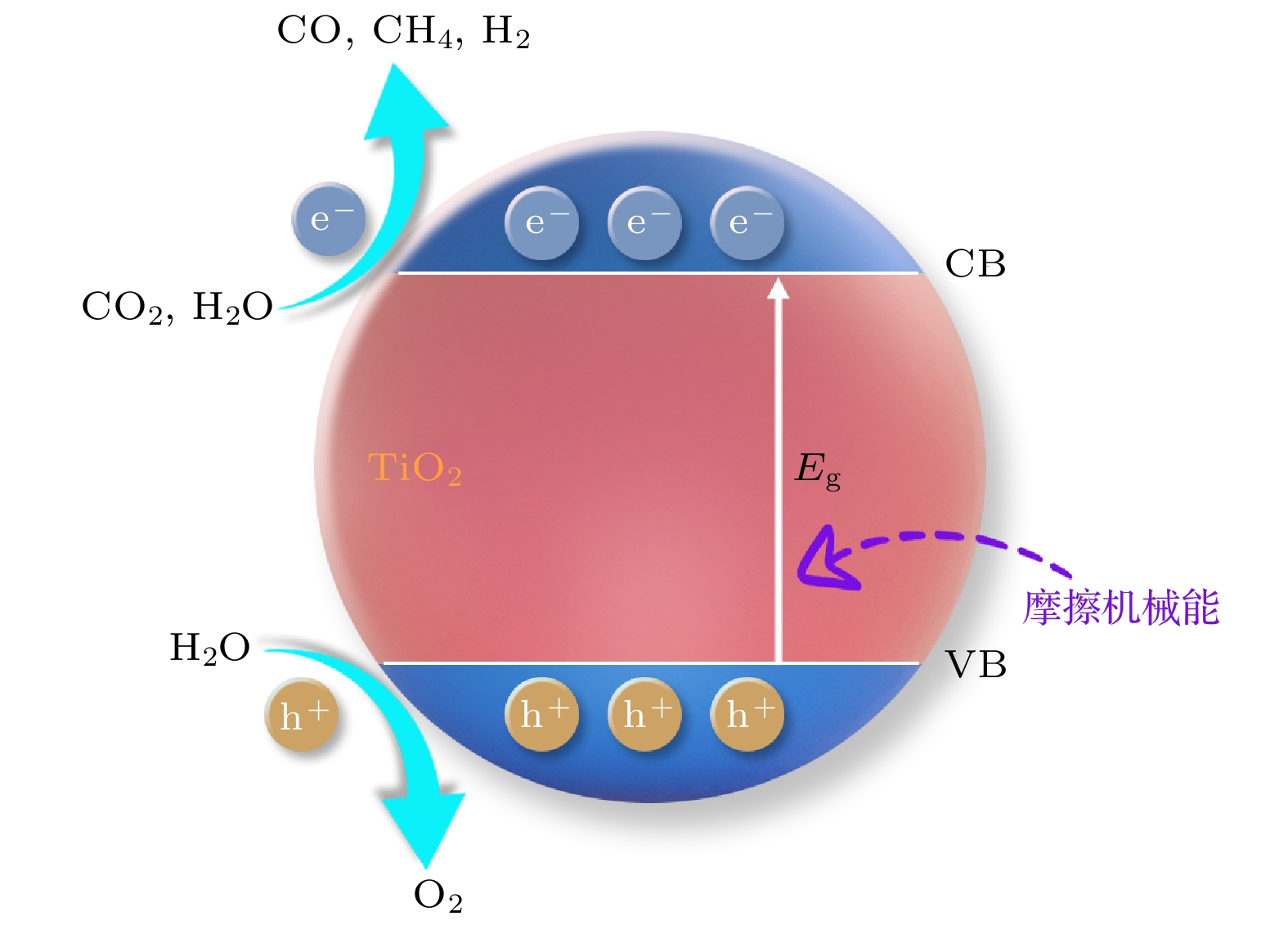

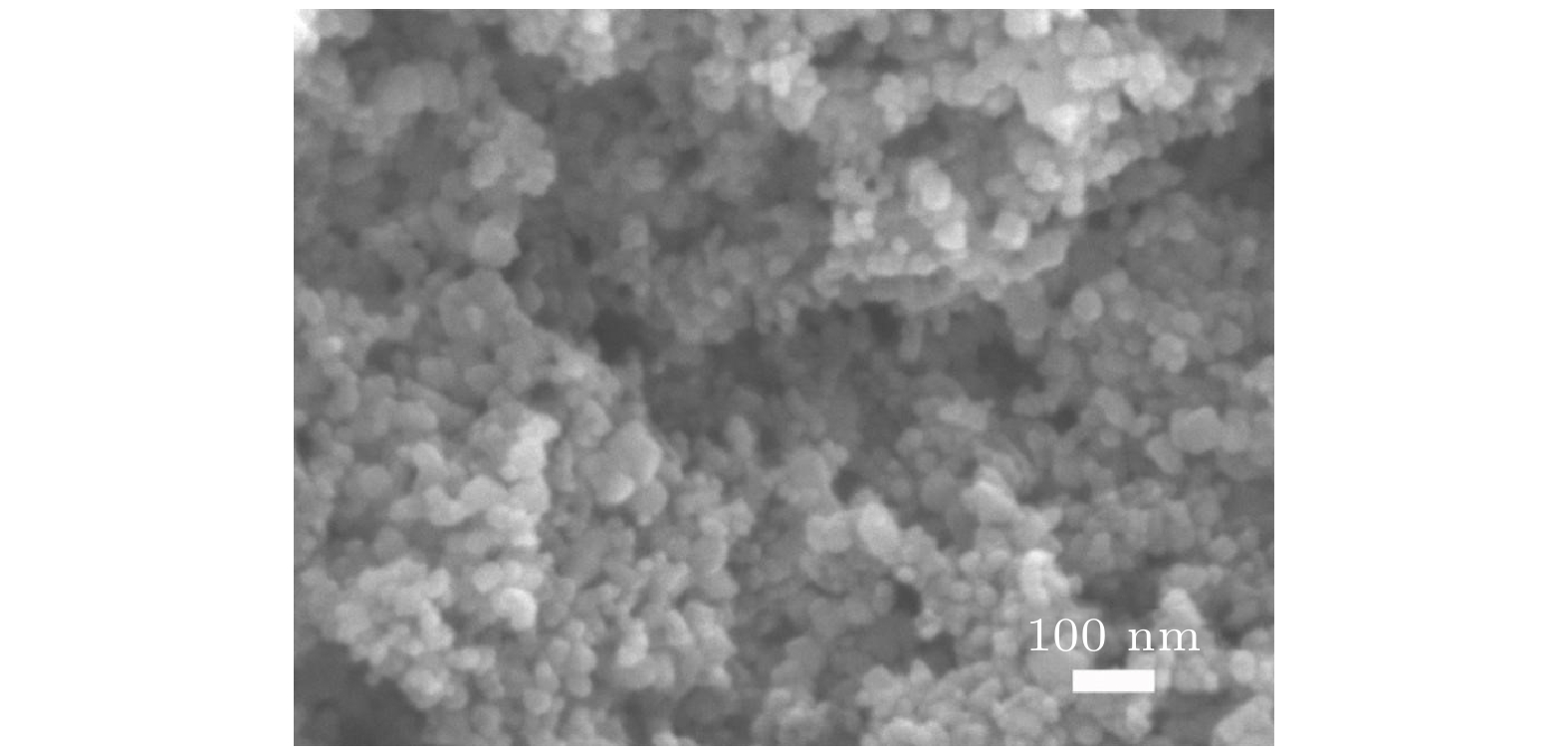

纳米材料与特氟龙磁力搅拌棒之间的摩擦被发现可导致磁力搅拌条件下的染料降解. 本文对磁力搅拌条件下TiO2纳米粉还原CO2进行了研究. 在充有CO2的100 mL石英反应器中, 在50 mL的水中分散1.00 g TiO2纳米粉, 经过50 h磁力搅拌可产生6.65 × 10–6 (体积分数, 下同) CO, 2.39 × 10–6 CH4和0.69 × 10–6 H2; 而如果没有TiO2纳米粉, 则只能产生2.22 × 10–6 CO和0.98 × 10–6 CH4. 对含有分散TiO2纳米粉的水同时采用4个磁力搅拌棒, 50 h磁力搅拌产生的气体进一步提高到19.94 × 10–6 CO, 2.33 × 10–6 CH4和2.06 × 10–6 H2. 基于TiO2纳米粉通过摩擦吸收机械能并被激发产生电子-空穴对, 建立了TiO2纳米粉对CO2和水还原的催化机理. 本发现表明, 纳米材料能够通过摩擦利用机械能进行CO2的还原, 从而为开发利用环境中的机械能提供了一个新的方向.The friction between some nanomaterials and teflon magnetic stirring rods has recently been found responsible for dye degradation by magnetic stirring in dark. In this work, a study is conducted on the reduction of CO2 by TiO2 nanoparticles under magnetic stirring in water. In a 100-mL reactor filled with 50-mL water, 1.00-g TiO2 nanoparticles and 1-atm CO2, 50-h magnetic stirring results in the formation of 6.65 × 10–6 (volume fraction) CO, 2.39 × 10–6 CH4 and 0.69 × 10–6 H2; while in a reactor without TiO2 nanoparticles, the same magnetic stirring leads only 2.22 × 10–6 CO and 0.98 × 10–6 CH4 to form. Four magnetic stirring rods are used simultaneously to further enhance the stirring, and 50-h magnetic stirring can form 19.94 × 10–6 CO, 2.33 × 10–6 CH4, and 2.06 × 10–6 H2. A mechanism for the catalytic role of TiO2 nanoparticles in the reduction of CO2 and H2O is established, which is based on the excitation of electron-hole pairs in TiO2 by mechanical energy absorbed through friction. This finding clearly demonstrates that nanostructured semiconductors are able to utilize mechanical energy obtained through friction to reduce CO2, thus providing a new direction for developing and utilizing the mechanical energy harvested from ambient environment.

-

Keywords:

- friction /

- magnetic stirring /

- CO2 reduction /

- TiO2

[1] 李冬冬, 王丽莉 2012 61 034212

Google Scholar

Google Scholar

Li D D, Wang L L 2012 Acta Phys. Sin. 61 034212

Google Scholar

Google Scholar

[2] 李平, 李海金, 涂文广, 周勇, 邹志刚 2015 64 094209

Google Scholar

Google Scholar

Li P, Li H J, Tu W G, Zhou Y, Zou Z G 2015 Acta Phys. Sin. 64 094209

Google Scholar

Google Scholar

[3] 吴化平, 令欢, 张征, 李研彪, 梁利华, 柴国钟 2017 66 167702

Google Scholar

Google Scholar

Wu H P, Ling H, Zhang Z, Li Y B, Liang L H, Chai G Z 2017 Acta Phys. Sin. 66 167702

Google Scholar

Google Scholar

[4] 赵娟, 胡慧芳, 曾亚萍, 程彩萍 2013 62 158104

Google Scholar

Google Scholar

Zhao J, Hu H F, Zeng Y P, Cheng C P 2013 Acta Phys. Sin. 62 158104

Google Scholar

Google Scholar

[5] 崔宗杨, 谢忠帅, 汪尧进, 袁国亮, 刘俊明 2020 69 127706

Google Scholar

Google Scholar

Cui Z Y, Xie Z S, Wang Y J, Yuan G L, Liu J M 2020 Acta Phys. Sin. 69 127706

Google Scholar

Google Scholar

[6] Ran J, Jaroniec M, Qiao S Z 2018 Adv. Mater. 30 1704649

Google Scholar

Google Scholar

[7] Kreft S, Wei D, Junge H, Beller M 2020 Energy Chem. 2 100044

Google Scholar

Google Scholar

[8] Wang X, Li Z, Yang X 2015 J. Mol. Sci. 31 190201

[9] 吴晔盛, 刘启, 曹杰, 李凯, 程广贵, 张忠强, 丁建宁, 蒋诗宇 2019 68 190201

Google Scholar

Google Scholar

Wu Y S, Liu Q, Cao J, Li K, Cheng G G, Zhang Z Q, Ding J N, Jiang S Y 2019 Acta Phys. Sin. 68 190201

Google Scholar

Google Scholar

[10] 韩杰敏, 王梅, 仝召民, 马一飞 2019 无机材料学报 34 839

Google Scholar

Google Scholar

Han J M, Wang M, Tong Z M, Ma Y F 2019 J. Inorg. Mater. 34 839

Google Scholar

Google Scholar

[11] 程广贵, 张伟, 方俊, 蒋诗宇, 丁建宁, Pesika N S, 张忠强, 郭立强, 王莹 2016 65 060201

Google Scholar

Google Scholar

Cheng G G, Zhang W, Fang J, Jiang S Y, Ding J N, Pesika N S, Zhang Z Q, Guo L Q, Wang Y 2016 Acta Phys. Sin. 65 060201

Google Scholar

Google Scholar

[12] 秦杰明, 田立飞, 赵东旭, 蒋大勇, 曹建明, 丁梦, 郭振 2011 60 107307

Google Scholar

Google Scholar

Qin J M, Tian L F, Zhao D X, Jiang D Y, Cao J M, Ding M, Guo Z 2011 Acta Phys. Sin. 60 107307

Google Scholar

Google Scholar

[13] Deng J N, Kuang X, Liu R Y, Ding W B, Wang A C, Lai Y C, Dong K, Wen Z, Wang Y X, Wang L L, Qi H J, Zhang T, Wang Z L 2018 Adv. Mater. 30 1705918

Google Scholar

Google Scholar

[14] Wu J M, Chang W E, Chang Y T, Chang C K 2016 Adv. Mater. 28 3718

Google Scholar

Google Scholar

[15] Liang Z, Yan C F, Rtimi S, Bandara J 2019 Appl. Catal. B-Environ 241 256

Google Scholar

Google Scholar

[16] 洪元婷, 马江平, 武峥, 应静诗, 尤慧琳, 贾艳敏 2018 67 107702

Google Scholar

Google Scholar

Hong Y T, Ma J P, Wu Z, Ying J S, You H L, Jia Y M 2018 Acta Phys. Sin. 67 107702

Google Scholar

Google Scholar

[17] 徐姝雅, 刘治宏, 张淮, 于金冉 2019 化学学报 77 427

Xu S Y, Liu Z H, Zhang H, Yu J R 2019 Acta Phys. Sin. 77 427

[18] Starr M B, Shi J, Wang X D 2012 Angew. Chem. Int. Ed. 51 5962

Google Scholar

Google Scholar

[19] You H, Wu Z, Zhang L, Ying Y, Liu Y, Fei L, Chen X, Jia Y, Wang Y, Wang F, Ju S, Qiao J, Lam C H, Huang H 2019 Angew. Chem. 58 11779

Google Scholar

Google Scholar

[20] Feng W, Yuan J, Zhang L, Hu W, Wu Z, Wang X, Huang X, Liu P, Zhang S 2020 Appl. Catal. B-Environ 277 119250

Google Scholar

Google Scholar

[21] Su R, Hsain H A, Wu M, Zhang D, Hu X, Wang Z, Wang X, Li F T, Chen X, Zhu L, Yang Y, Yang Y, Lou X, Pennycook S J 2019 Angew. Chem. 131 15220

Google Scholar

Google Scholar

[22] Yein W T, Wang Q, Liu Y, Li Y, Jian J H, Wu X H 2020 J. Environ. Chem. Eng. 8 103626

Google Scholar

Google Scholar

[23] Kang Z H, Qin N, Lin E Z, Wu J, Yuan B W, Bao D H 2020 J. Cleaner Prod. 261 121125

Google Scholar

Google Scholar

[24] Hao A, Ning X, Cao Y, Xie J, Jia D 2020 Mater. Chem. Front. 4 2096

Google Scholar

Google Scholar

[25] Wei Y, Zhang Y, Geng W, Su H, Long M 2019 Appl. Catal. B-Environ 259 118084

Google Scholar

Google Scholar

[26] Ismail M, Wu Z, Zhang L, Ma J, Jia Y, Hu Y, Wang Y 2019 Chemosphere 228 212

Google Scholar

Google Scholar

[27] Lin J H, Tsao Y H, Wu M H, Chou T M, Lin Z H, Wu J M 2017 Nano Energy 31 575

Google Scholar

Google Scholar

[28] Feng Y, Ling L, Wang Y, Xu Z, Cao F, Li H, Bian Z 2017 Nano Energy 40 481

Google Scholar

Google Scholar

[29] Zhu R, Xu Y, Bai Q, Wang Z, Guo X, Kimura H 2018 Chem. Phys. Lett. 702 26

Google Scholar

Google Scholar

[30] Nie Q, Xie Y, Ma J, Wang J, Zhang G 2020 J. Cleaner Prod. 242 118532

Google Scholar

Google Scholar

[31] Liu D, Song Y, Xin Z, Liu G, Jin C, Shan F 2019 Nano Energy 65 104024

Google Scholar

Google Scholar

[32] Li P, Wu J, Wu Z, Jia Y, Ma J, Chen W, Zhang L, Yang J, Liu Y 2019 Nano Energy 63 103832

Google Scholar

Google Scholar

[33] Lei H, Wu M, Mo F, Ji S, Dong X, Wu Z, Gao J, Yang Y, Jia Y 2020 Nano Energy 78 105290

Google Scholar

Google Scholar

[34] Zhao J, Chen L, Luo W, Li H, Wu Z, Xu Z, Zhang Y, Zhang H, Yuan G, Gao J, Jia Y 2020 Ceram. Int. 46 25293

Google Scholar

Google Scholar

[35] Yang B, Chen H, Guo X, Wang L, Xu T, Bian J, Yang Y, Liu Q, Du Y, Lou X 2020 J. Mater. Chem. C 8 14845

Google Scholar

Google Scholar

[36] Wu M, Lei H, Chen J, Dong X 2020 J. Colloid Interface Sci. 587 883

[37] Ishibashi K I, Fujishima A, Watanabe T, Hashimoto K 2000 Electrochem. Commun. 2 207

Google Scholar

Google Scholar

[38] Baytekin B, Baytekin H T, Grzybowski B A 2012 J. Am. Chem. Soc. 134 7223

Google Scholar

Google Scholar

[39] Heinicke G, Hennig H P, Linke E, Steinike U, Thiessen K P, Meyer K 1984 Cryst. Res. Technol. 19 1424

Google Scholar

Google Scholar

[40] Kajdas C, Hiratsuka K 2009 Proc. Inst. Mech. Eng., Part J 223 827

Google Scholar

Google Scholar

[41] Park J Y, Salmeron M 2014 Chem. Rev. 114 677

Google Scholar

Google Scholar

[42] Manini N, Mistura G, Paolicelli G, Tosatti E, Vanossi A 2017 Adv. Phys.: X 2 569

[43] Qi Y, Park J Y, Hendriksen B L M, Ogletree D F, Salmeron M 2008 Phys. Rev. B 77 184105

Google Scholar

Google Scholar

[44] Schneider J, Matsuoka M, Takeuchi M, Zhang J, Horiuchi Y, Anpo M, Bahnemann D W 2014 Chem. Rev. 114 9919

Google Scholar

Google Scholar

[45] Fujishima A, Zhang X, Tryk D 2008 Surf. Sci. Rep. 63 515

Google Scholar

Google Scholar

[46] Al-Mamoori A, Krishnamurthy A, Rownaghi A A, Rezaei F 2017 Energy Technol. 5 834

Google Scholar

Google Scholar

-

-

[1] 李冬冬, 王丽莉 2012 61 034212

Google Scholar

Google Scholar

Li D D, Wang L L 2012 Acta Phys. Sin. 61 034212

Google Scholar

Google Scholar

[2] 李平, 李海金, 涂文广, 周勇, 邹志刚 2015 64 094209

Google Scholar

Google Scholar

Li P, Li H J, Tu W G, Zhou Y, Zou Z G 2015 Acta Phys. Sin. 64 094209

Google Scholar

Google Scholar

[3] 吴化平, 令欢, 张征, 李研彪, 梁利华, 柴国钟 2017 66 167702

Google Scholar

Google Scholar

Wu H P, Ling H, Zhang Z, Li Y B, Liang L H, Chai G Z 2017 Acta Phys. Sin. 66 167702

Google Scholar

Google Scholar

[4] 赵娟, 胡慧芳, 曾亚萍, 程彩萍 2013 62 158104

Google Scholar

Google Scholar

Zhao J, Hu H F, Zeng Y P, Cheng C P 2013 Acta Phys. Sin. 62 158104

Google Scholar

Google Scholar

[5] 崔宗杨, 谢忠帅, 汪尧进, 袁国亮, 刘俊明 2020 69 127706

Google Scholar

Google Scholar

Cui Z Y, Xie Z S, Wang Y J, Yuan G L, Liu J M 2020 Acta Phys. Sin. 69 127706

Google Scholar

Google Scholar

[6] Ran J, Jaroniec M, Qiao S Z 2018 Adv. Mater. 30 1704649

Google Scholar

Google Scholar

[7] Kreft S, Wei D, Junge H, Beller M 2020 Energy Chem. 2 100044

Google Scholar

Google Scholar

[8] Wang X, Li Z, Yang X 2015 J. Mol. Sci. 31 190201

[9] 吴晔盛, 刘启, 曹杰, 李凯, 程广贵, 张忠强, 丁建宁, 蒋诗宇 2019 68 190201

Google Scholar

Google Scholar

Wu Y S, Liu Q, Cao J, Li K, Cheng G G, Zhang Z Q, Ding J N, Jiang S Y 2019 Acta Phys. Sin. 68 190201

Google Scholar

Google Scholar

[10] 韩杰敏, 王梅, 仝召民, 马一飞 2019 无机材料学报 34 839

Google Scholar

Google Scholar

Han J M, Wang M, Tong Z M, Ma Y F 2019 J. Inorg. Mater. 34 839

Google Scholar

Google Scholar

[11] 程广贵, 张伟, 方俊, 蒋诗宇, 丁建宁, Pesika N S, 张忠强, 郭立强, 王莹 2016 65 060201

Google Scholar

Google Scholar

Cheng G G, Zhang W, Fang J, Jiang S Y, Ding J N, Pesika N S, Zhang Z Q, Guo L Q, Wang Y 2016 Acta Phys. Sin. 65 060201

Google Scholar

Google Scholar

[12] 秦杰明, 田立飞, 赵东旭, 蒋大勇, 曹建明, 丁梦, 郭振 2011 60 107307

Google Scholar

Google Scholar

Qin J M, Tian L F, Zhao D X, Jiang D Y, Cao J M, Ding M, Guo Z 2011 Acta Phys. Sin. 60 107307

Google Scholar

Google Scholar

[13] Deng J N, Kuang X, Liu R Y, Ding W B, Wang A C, Lai Y C, Dong K, Wen Z, Wang Y X, Wang L L, Qi H J, Zhang T, Wang Z L 2018 Adv. Mater. 30 1705918

Google Scholar

Google Scholar

[14] Wu J M, Chang W E, Chang Y T, Chang C K 2016 Adv. Mater. 28 3718

Google Scholar

Google Scholar

[15] Liang Z, Yan C F, Rtimi S, Bandara J 2019 Appl. Catal. B-Environ 241 256

Google Scholar

Google Scholar

[16] 洪元婷, 马江平, 武峥, 应静诗, 尤慧琳, 贾艳敏 2018 67 107702

Google Scholar

Google Scholar

Hong Y T, Ma J P, Wu Z, Ying J S, You H L, Jia Y M 2018 Acta Phys. Sin. 67 107702

Google Scholar

Google Scholar

[17] 徐姝雅, 刘治宏, 张淮, 于金冉 2019 化学学报 77 427

Xu S Y, Liu Z H, Zhang H, Yu J R 2019 Acta Phys. Sin. 77 427

[18] Starr M B, Shi J, Wang X D 2012 Angew. Chem. Int. Ed. 51 5962

Google Scholar

Google Scholar

[19] You H, Wu Z, Zhang L, Ying Y, Liu Y, Fei L, Chen X, Jia Y, Wang Y, Wang F, Ju S, Qiao J, Lam C H, Huang H 2019 Angew. Chem. 58 11779

Google Scholar

Google Scholar

[20] Feng W, Yuan J, Zhang L, Hu W, Wu Z, Wang X, Huang X, Liu P, Zhang S 2020 Appl. Catal. B-Environ 277 119250

Google Scholar

Google Scholar

[21] Su R, Hsain H A, Wu M, Zhang D, Hu X, Wang Z, Wang X, Li F T, Chen X, Zhu L, Yang Y, Yang Y, Lou X, Pennycook S J 2019 Angew. Chem. 131 15220

Google Scholar

Google Scholar

[22] Yein W T, Wang Q, Liu Y, Li Y, Jian J H, Wu X H 2020 J. Environ. Chem. Eng. 8 103626

Google Scholar

Google Scholar

[23] Kang Z H, Qin N, Lin E Z, Wu J, Yuan B W, Bao D H 2020 J. Cleaner Prod. 261 121125

Google Scholar

Google Scholar

[24] Hao A, Ning X, Cao Y, Xie J, Jia D 2020 Mater. Chem. Front. 4 2096

Google Scholar

Google Scholar

[25] Wei Y, Zhang Y, Geng W, Su H, Long M 2019 Appl. Catal. B-Environ 259 118084

Google Scholar

Google Scholar

[26] Ismail M, Wu Z, Zhang L, Ma J, Jia Y, Hu Y, Wang Y 2019 Chemosphere 228 212

Google Scholar

Google Scholar

[27] Lin J H, Tsao Y H, Wu M H, Chou T M, Lin Z H, Wu J M 2017 Nano Energy 31 575

Google Scholar

Google Scholar

[28] Feng Y, Ling L, Wang Y, Xu Z, Cao F, Li H, Bian Z 2017 Nano Energy 40 481

Google Scholar

Google Scholar

[29] Zhu R, Xu Y, Bai Q, Wang Z, Guo X, Kimura H 2018 Chem. Phys. Lett. 702 26

Google Scholar

Google Scholar

[30] Nie Q, Xie Y, Ma J, Wang J, Zhang G 2020 J. Cleaner Prod. 242 118532

Google Scholar

Google Scholar

[31] Liu D, Song Y, Xin Z, Liu G, Jin C, Shan F 2019 Nano Energy 65 104024

Google Scholar

Google Scholar

[32] Li P, Wu J, Wu Z, Jia Y, Ma J, Chen W, Zhang L, Yang J, Liu Y 2019 Nano Energy 63 103832

Google Scholar

Google Scholar

[33] Lei H, Wu M, Mo F, Ji S, Dong X, Wu Z, Gao J, Yang Y, Jia Y 2020 Nano Energy 78 105290

Google Scholar

Google Scholar

[34] Zhao J, Chen L, Luo W, Li H, Wu Z, Xu Z, Zhang Y, Zhang H, Yuan G, Gao J, Jia Y 2020 Ceram. Int. 46 25293

Google Scholar

Google Scholar

[35] Yang B, Chen H, Guo X, Wang L, Xu T, Bian J, Yang Y, Liu Q, Du Y, Lou X 2020 J. Mater. Chem. C 8 14845

Google Scholar

Google Scholar

[36] Wu M, Lei H, Chen J, Dong X 2020 J. Colloid Interface Sci. 587 883

[37] Ishibashi K I, Fujishima A, Watanabe T, Hashimoto K 2000 Electrochem. Commun. 2 207

Google Scholar

Google Scholar

[38] Baytekin B, Baytekin H T, Grzybowski B A 2012 J. Am. Chem. Soc. 134 7223

Google Scholar

Google Scholar

[39] Heinicke G, Hennig H P, Linke E, Steinike U, Thiessen K P, Meyer K 1984 Cryst. Res. Technol. 19 1424

Google Scholar

Google Scholar

[40] Kajdas C, Hiratsuka K 2009 Proc. Inst. Mech. Eng., Part J 223 827

Google Scholar

Google Scholar

[41] Park J Y, Salmeron M 2014 Chem. Rev. 114 677

Google Scholar

Google Scholar

[42] Manini N, Mistura G, Paolicelli G, Tosatti E, Vanossi A 2017 Adv. Phys.: X 2 569

[43] Qi Y, Park J Y, Hendriksen B L M, Ogletree D F, Salmeron M 2008 Phys. Rev. B 77 184105

Google Scholar

Google Scholar

[44] Schneider J, Matsuoka M, Takeuchi M, Zhang J, Horiuchi Y, Anpo M, Bahnemann D W 2014 Chem. Rev. 114 9919

Google Scholar

Google Scholar

[45] Fujishima A, Zhang X, Tryk D 2008 Surf. Sci. Rep. 63 515

Google Scholar

Google Scholar

[46] Al-Mamoori A, Krishnamurthy A, Rownaghi A A, Rezaei F 2017 Energy Technol. 5 834

Google Scholar

Google Scholar

计量

- 文章访问数: 8123

- PDF下载量: 140

- 被引次数: 0

下载:

下载: